High-purity hydrogen providing system, movable hydrogen supply system and distributed hydrogen supply device

A high-purity, supply device technology, applied in the field of hydrogen energy, can solve the problems of difficult storage and transportation of hydrogen, high construction costs, and high costs, and achieve the effects of promoting the dehydrogenation reaction of organic liquids, reducing reaction temperature, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

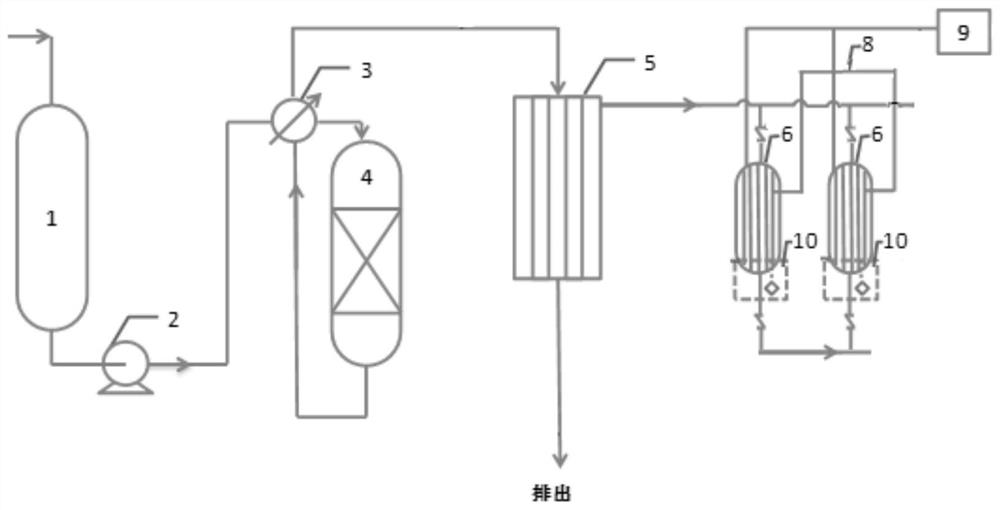

Method used

Image

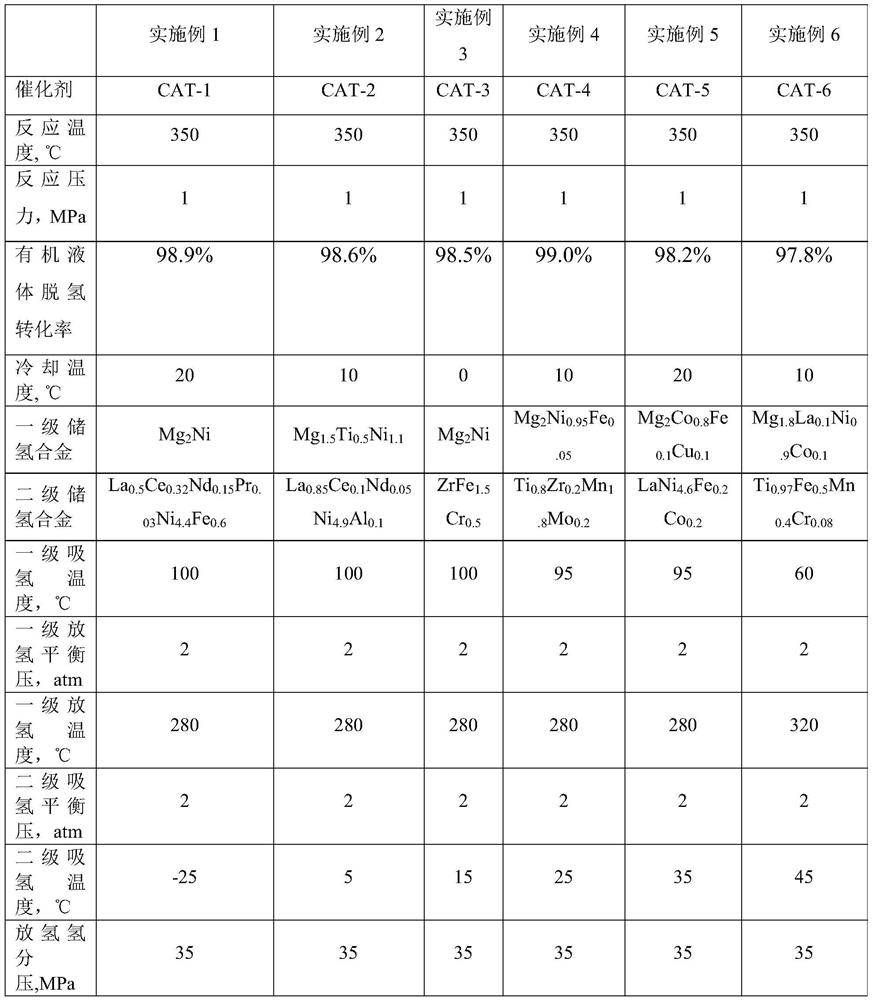

Examples

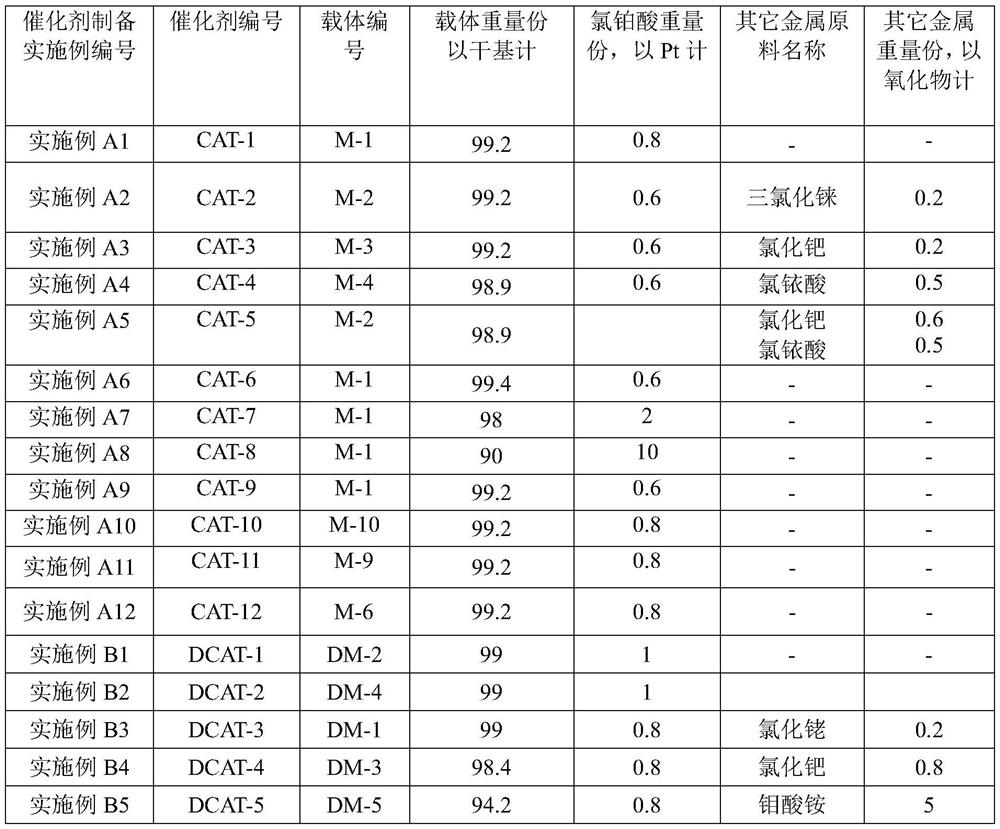

preparation example Construction

[0051] The preparation method of the hydrogen storage alloy is not particularly limited in the present invention, and it can be prepared by any existing method in the art. Preferably, the preparation method of the hydrogen storage alloy comprises the following steps:

[0052] 1) Weighing each raw material of the hydrogen storage alloy in a manner to achieve the composition of the hydrogen storage alloy and mixing;

[0053] 2) melting the material obtained by mixing in step 1), and then annealing.

[0054] The present invention has a wide range of options for the smelting methods and conditions, and various existing smelting methods and conditions are within the protection scope of the present invention. The smelting includes but not limited to electric furnace smelting and induction smelting. The electric furnace smelting and induction smelting have conventional illustrations in the field, and the present invention will not repeat them here.

[0055] The smelting and anneali...

Embodiment approach

[0067] According to a preferred embodiment of the present invention, the carrier is a carrier composition, the carrier composition includes alumina and a modified metal oxide, and the modified metal oxide is titanium oxide and / or zirconium oxide ; The η of the modified metal oxide in the carrier composition2 In terms of zirconium oxide as ZrO 2 count.

[0068] According to the dehydrogenation catalyst described in any of the above technical solutions, preferably, based on 100 parts by weight of the total mass of alumina and modified metal oxides, the parts by weight of alumina are 80-98.5 parts by weight, preferably 83-97.5 parts by weight The parts by weight of the modified metal oxide are 1.5-20 parts by weight, preferably 2.5-17 parts by weight.

[0069] According to the dehydrogenation catalyst described in any of the above technical solutions, preferably, the modified metal oxide includes titanium oxide; based on 100 parts by weight of the total mass of alumina and the m...

preparation example A1

[0119] Calcining SB powder at 500℃ for 4h to obtain γ-Al 2 o 3 , the γ-Al 2 o 3 The specific surface area is 176m 2 / g, the pore volume is 0.48ml / g.

[0120] Take the above γ-Al 2 o 3 500g is placed in a fluidized reactor, titanium tetrachloride is placed in a constant temperature bath at 20°C, nitrogen is passed through titanium tetrachloride at a flow rate of 10L / min and then enters the fluidized reactor from the bottom of the fluidized reactor, and fluidized for 1h Finally, stop passing nitrogen through the titanium tetrachloride bath; pass nitrogen at a flow rate of 10L / min through deionized water placed in a 50°C constant temperature bath, and then enter the fluidized reactor from the bottom of the reactor, fluidize for 4h, and obtain the hydrolyzed Carrier. The hydrolyzed carrier was calcined at 550° C. for 4 hours in an air atmosphere to obtain a carrier composition, which was named GM-1. The properties of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com