Process for providing high-purity hydrogen

A hydrogen and hydrogen-rich technology, applied in container discharge methods, chemical instruments and methods, hydrogen, etc., can solve the problems of low purity and inability to use directly, and achieve the effect of reducing reaction temperature, reducing operating costs, and improving reaction selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

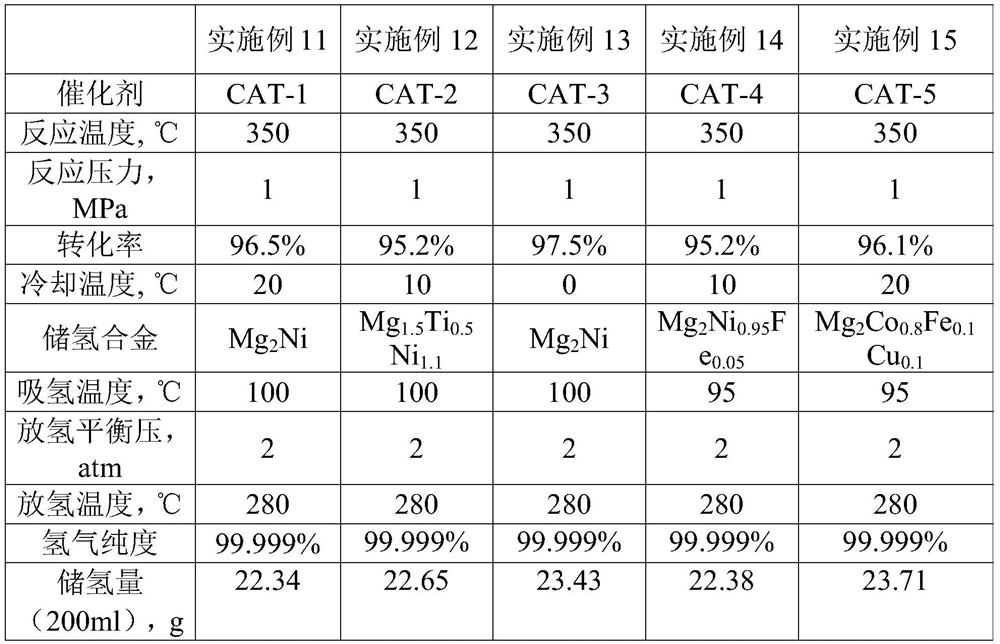

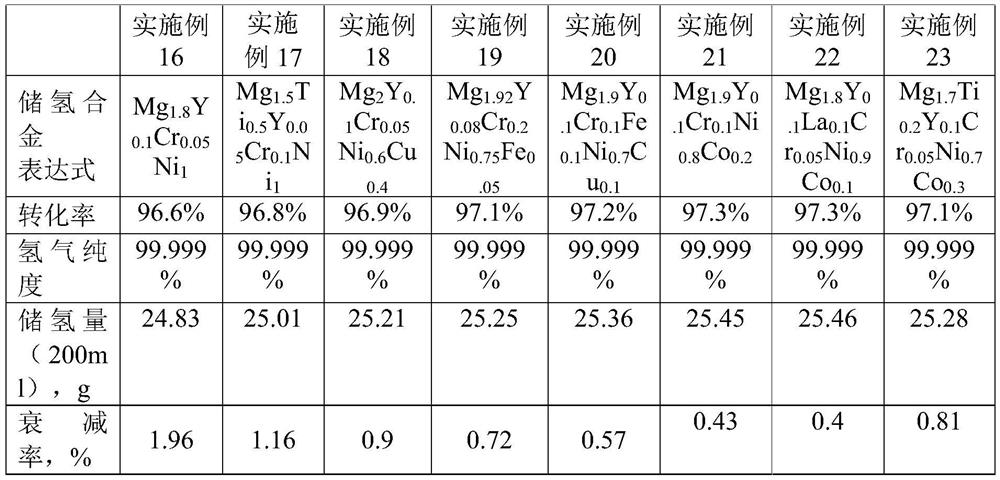

Examples

preparation example Construction

[0029] The present invention has no limitation on the preparation method of the dehydrogenation catalyst, as long as the active metal can be loaded on the carrier; preferably, the metal precursor is dissolved in deionized water to obtain a metal precursor solution; the metal precursor solution It is introduced onto the support by means of co-impregnation or step-by-step impregnation, and the impregnation can be saturated impregnation or supersaturated impregnation. When the catalyst contains two or more active metals, the co-impregnation means that two or more metal elements can be dissolved together in deionized water, and then the impregnating solution is impregnated on the carrier, followed by drying and roasting. The step-by-step impregnation is to dissolve two or more active metal elements in deionized water respectively, and impregnate the metal impregnating solution on the carrier respectively, and the carrier obtained after each impregnation needs to be dried and roaste...

Embodiment 1

[0073] Calcining SB powder at 500℃ for 5h to obtain γ-Al 2 o 3 , named M-1.

Embodiment 2

[0075]The P25 vector was used and named M-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com