Coal tar hydrogenation process and catalyst therefor

A catalyst, coal tar technology, applied in the field of coal chemical industry, can solve the problems of dust pollution, air pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

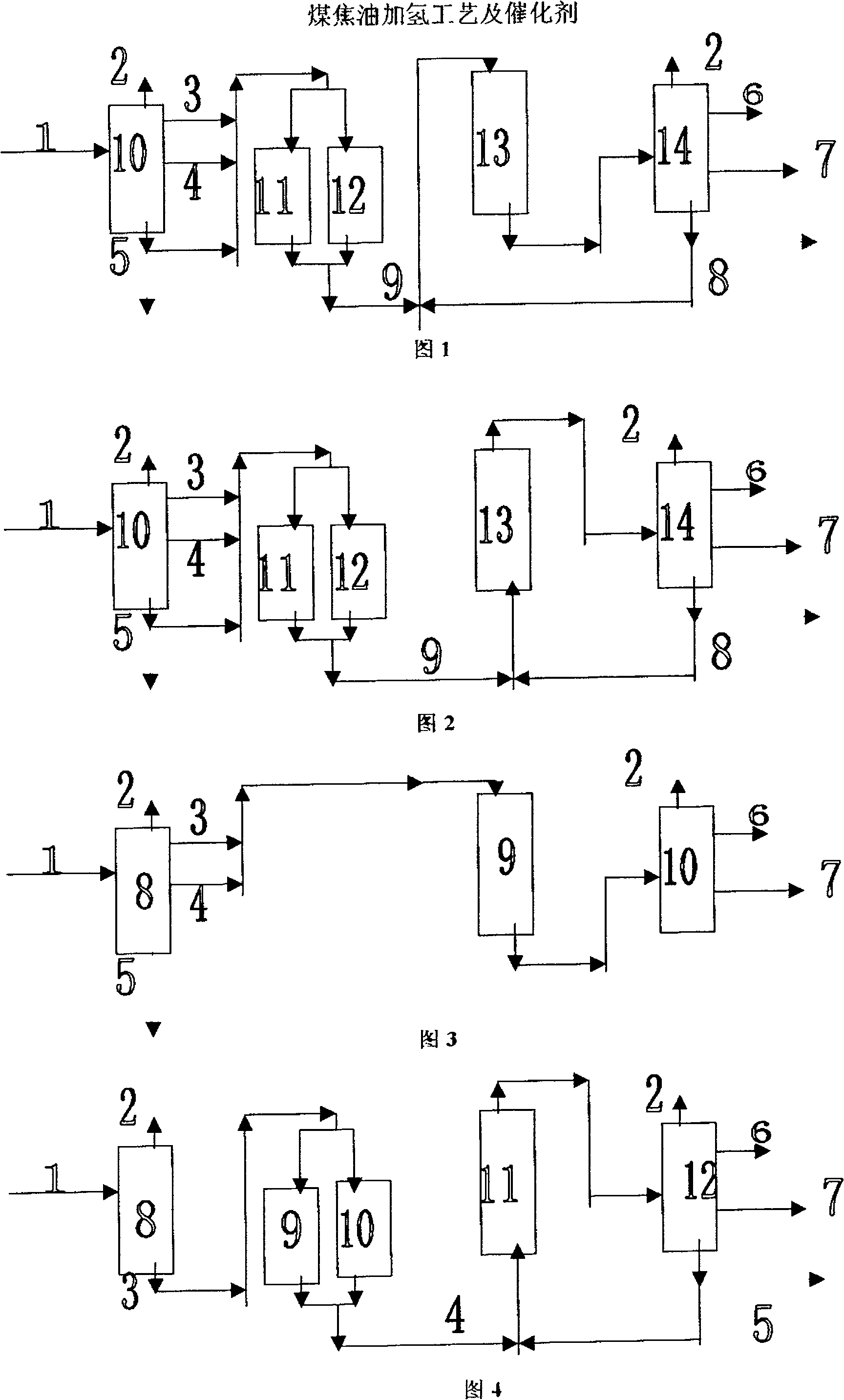

[0023] The main properties of by-product coal tar in a gasification plant are shown in Table 3. The fixed bed hydrogenation process and special catalyst are adopted. The main properties of the catalyst are shown in Table 4. The feedstock for hydrogenation is the light fraction of coal tar less than 350°C. The target products are high-quality naphtha and high-quality diesel blending components.

[0024] The distillate above 350°C is used as bitumen to exit the hydrogenation unit. There is no switching protection reactor. Its technological process is shown in Figure 3. The main process parameters of hydrogenation are shown in Table 5. The main properties of the product are shown in Table 6.

[0025] Table 3 Properties of coal tar

[0026] Fraction range

whole distillate

Less than 350℃ coal tar light

distillate

Density (20℃), g / m 3

0.98

0.93

Carbon residue, m%

4.0

2.5

...

Embodiment 2

[0034] The main properties of by-product coal tar in a gasification plant are shown in Table 3. Ebullated bed technology and special catalyst are adopted. The main properties of the catalyst are shown in Table 7. The feedstock for hydrogenation is full-fraction coal tar, and the target products are high-quality naphtha and high-quality diesel oil. The fraction of unconverted oil above 350°C is sent out of the hydrogenation unit as needle coke raw material or recycled into the hydrogenation reactor. Set up a switching protection reactor. Its technological process is shown in Figure 4. The main process parameters of hydrogenation are shown in Table 8. The main properties of the product are shown in Table 9.

[0035] Table 7 Main Properties of Catalysts

[0036] name

Coal tar hydrogenation pre-refining catalyst

Coal tar hydrogenation upgrading catalyst

Chemical composition, % (mass)

MoO 3

5.0-9.0

10.0-11.0

WO 3

/ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com