Inert gas protector

A technology of inert gas and safety devices, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of unable to maintain pressure, unable to ensure maintenance safety, quality, waste of time, etc., to save hydrogen, eliminate Major vicious accidents and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

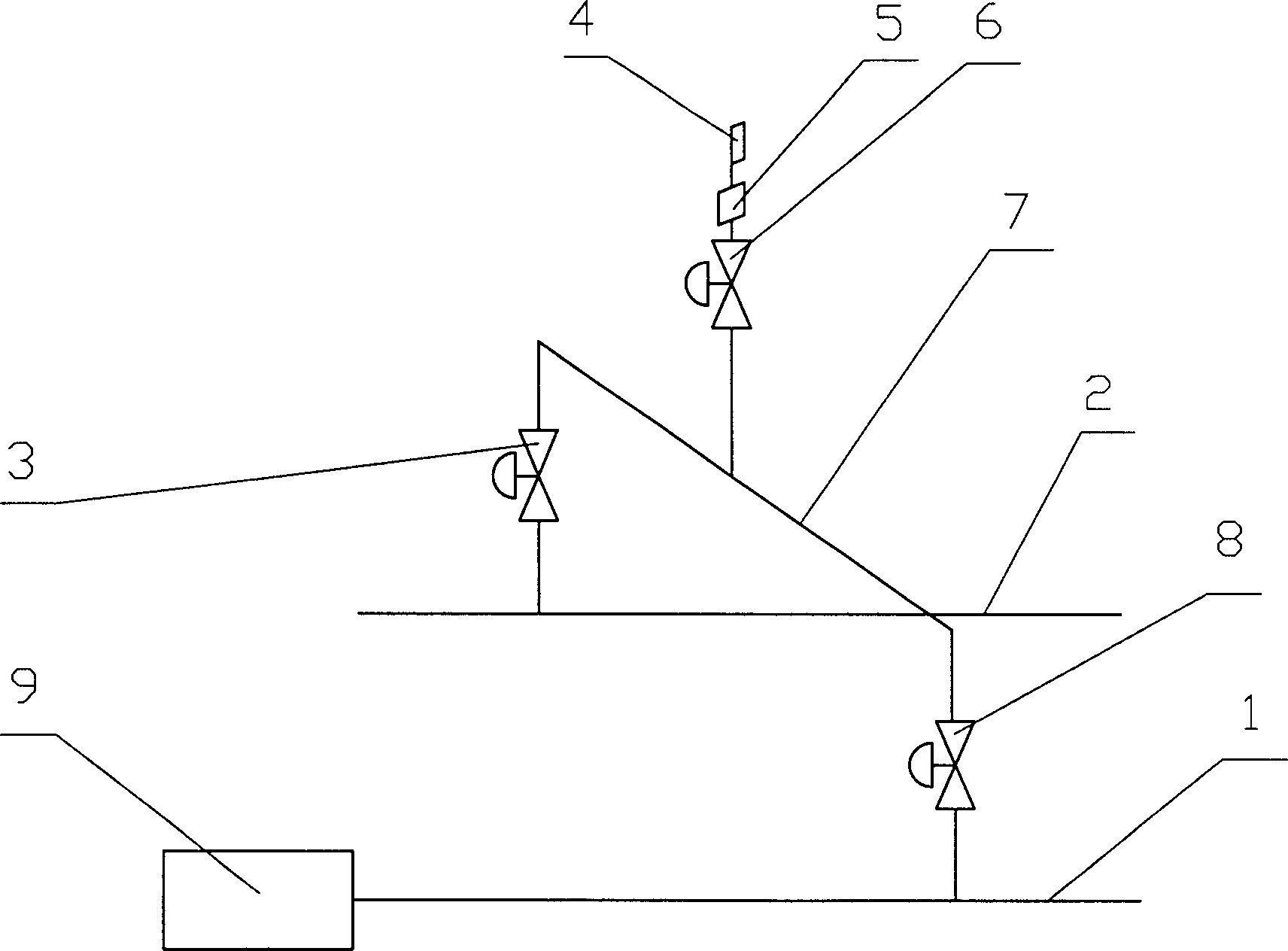

[0016] Such as figure 1 As shown, the inert gas safety device includes an inert gas container 9, a gas delivery pipe 1 connected to the inert gas container 9, and the three ports of the three-way connection pipe 7 are respectively provided with an inert gas control valve 8, a combustible gas control valve 3, and a vent valve. Control valve 6, the other end of the above-mentioned valve is respectively connected with the gas delivery pipe 1, the combustible gas pipe 2 and the vent pipe 4, and the flame arrester 5 is set on the passage where the vent pipe 4 communicates with the vent control valve 6, and the valves 3, 6 , 8 is a pneumatic film regulating valve.

[0017] Under normal conditions, the gas in the inert gas container 9 should be sufficient, and its outlet valve is normally open; the inert gas control valve 8 and the combustible gas control valve 3 on the gas safety device are closed, and the vent control valve 6 is opened to prevent the inert gas control valve from 8...

Embodiment 2

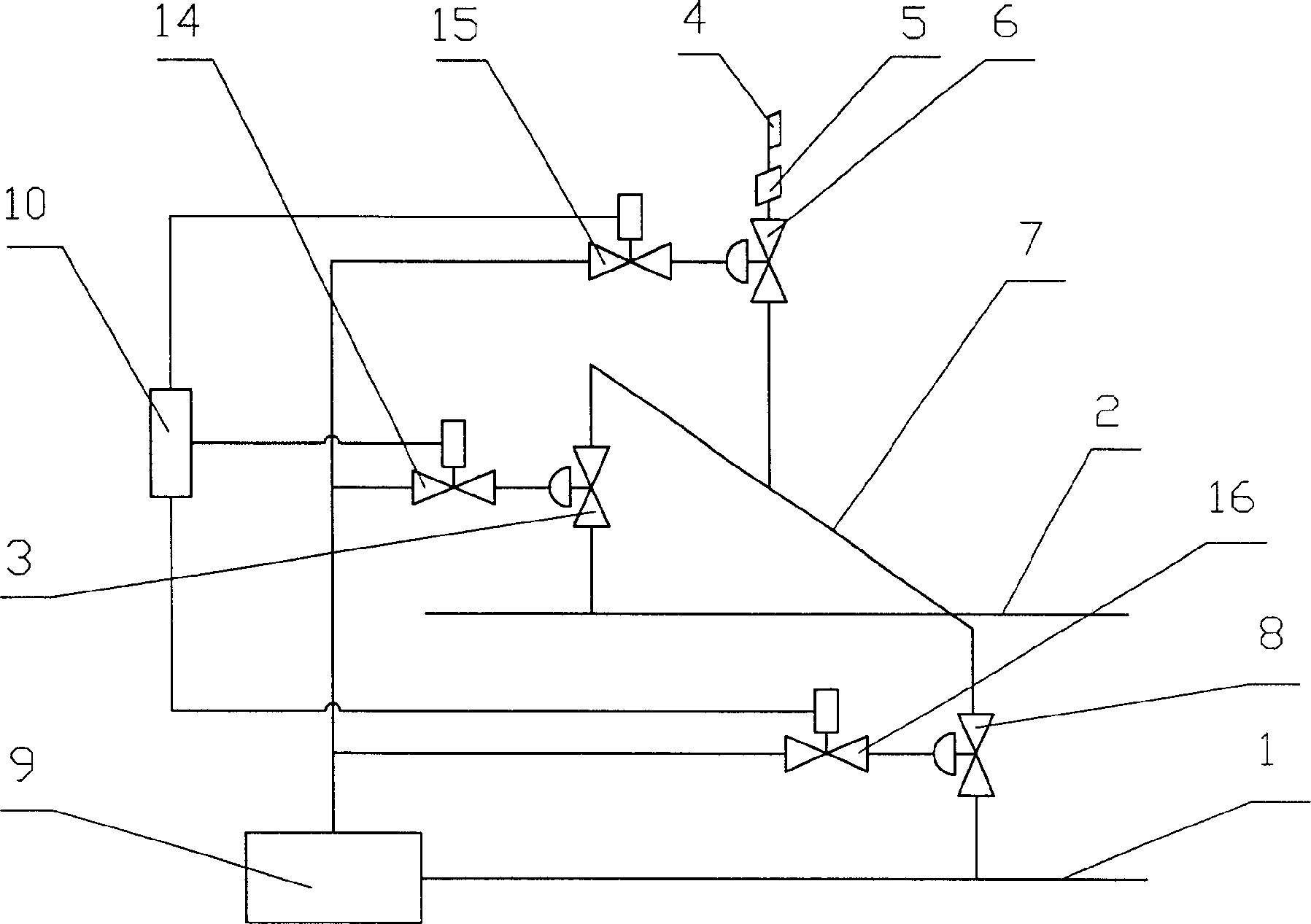

[0020] Such as figure 2 As shown, the control ends of the combustible gas control valve 3, the venting control valve 6, and the inert gas control valve 8 are respectively connected with the inert gas container 9, and the inert gas container 9 provides a pneumatic film regulating valve type combustible gas control valve. 3. For the gas required for air-opening or air-closing of the venting control valve 6 and the inert gas control valve 8, electromagnetic valves 14, 15, 16 are respectively inserted in the passages where the control ends of the three valves communicate with the inert gas container 9, The control ends of the solenoid valves 14, 15, 16 are connected with the control switches in the valve control box 10, and the solenoid valves 14, 15, 16 are controlled by the valve control box 10, and then the three valves 3, 6, 8 are air-opened or air-closed. The required gas is controlled, thereby realizing the control of the combustible gas control valve 3 , the venting contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com