A hydrogen flow regulating device for vertical melting and sintering of tungsten alloy materials

A flow regulating device and tungsten alloy technology, applied in the field of vertical melting sintering, can solve the problems of increasing the production cost of enterprises, high labor intensity, and manually adjusting the hydrogen flow, and achieve the effect of saving cost and saving hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

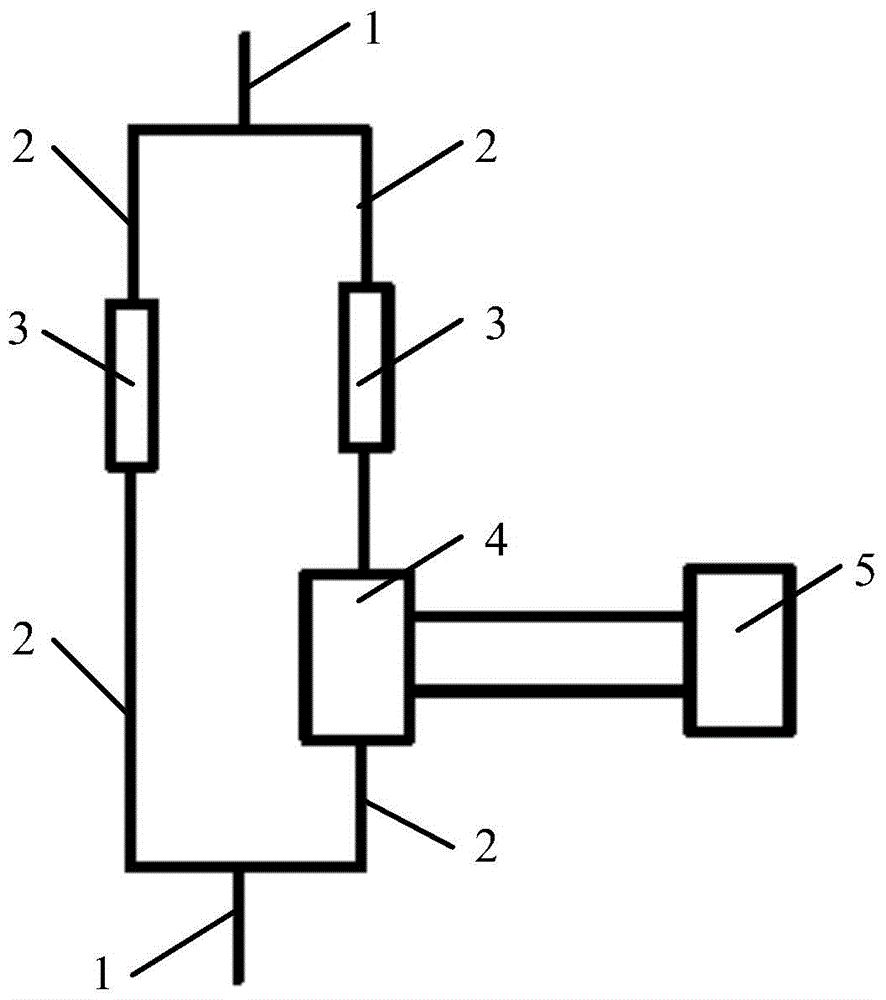

[0025] like figure 1 As shown, the hydrogen flow regulating device provided by the embodiment of the present invention is used on a vertical melting sintering equipment, and the vertical melting sintering equipment is used to carry out vertical melting sintering of 1 kg / piece of thoriated tungsten 20. The specific implementation process is as follows:

[0026] (1) Connect the hydrogen flow regulating device provided by the embodiment of the present invention to the vertical melting and sintering equipment in the prior art according to the above technical solution.

[0027] (2) Adjust the hydrogen flow meters 3 on the two hydrogen supply branches 2 so that the hydrogen flow rate of the small flow hydrogen supply branch is 0.5m 3 / hour, the hydrogen flow rate of the large flow hydrogen supply branch is 2.5m 3 / Hour.

[0028] (3) Input the heating process parameters on the vertical melting control system of the vertical melting sintering equipment: the heating time is 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com