Method for producing propylene

A technology of propylene and ethylene, which is applied in the production of bulk chemicals, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve the problems of low propylene weight yield, achieve hydrogen saving, increase weight yield, and good activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

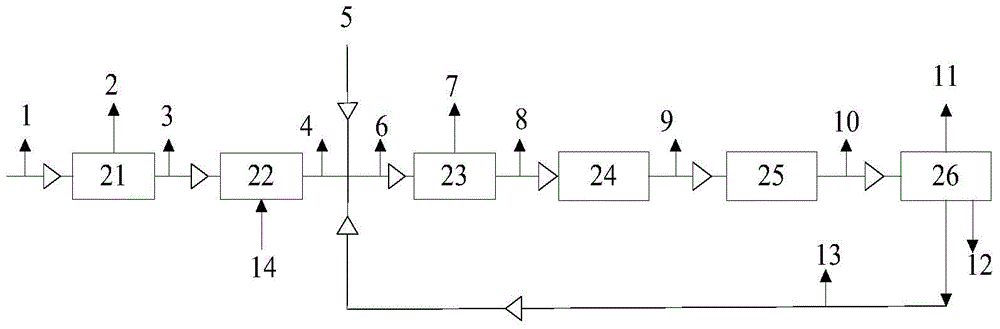

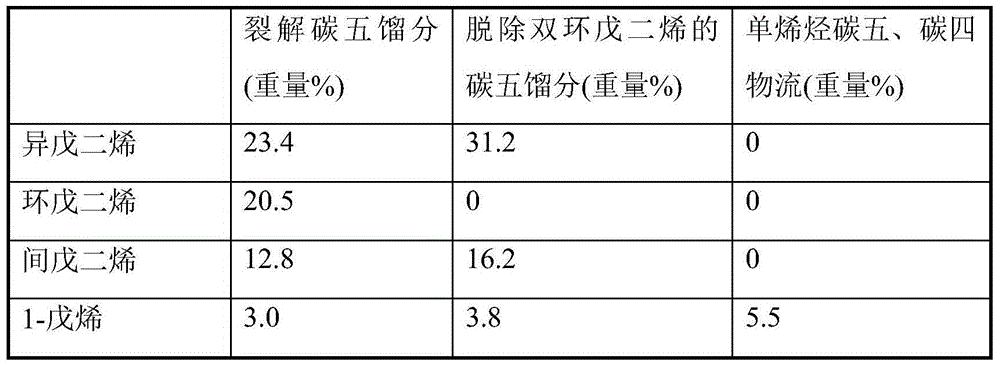

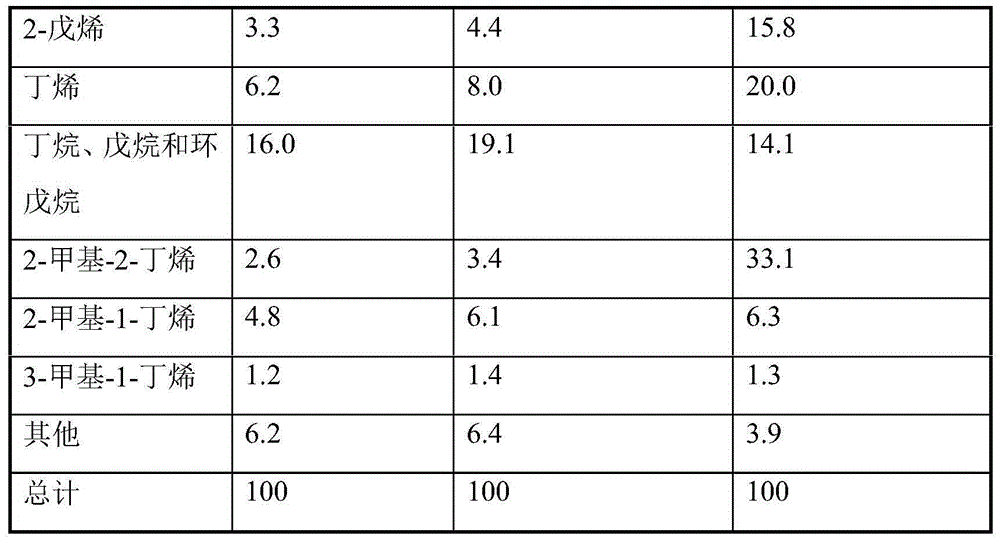

[0049] according to figure 1 Shown technological process, the component of cracking C5 fraction is as shown in table 1, obtains the C5 fraction not containing cyclopentadiene after decyclopentadiene unit removes the cyclopentadiene in raw material, removes The carbon five distillate components of dicyclopentadiene are as shown in table 1, and then enter the selective hydrogenation catalyst contact reaction with the carbon four raw material to obtain the monoolefin carbon four and carbon five streams, and its components are as shown in table 1, and the monoolefin carbon 5. The C4 stream is mixed with fresh ethylene outside the boundary area to form a mixed raw material. The mixed raw material is treated by an adsorbent in an adsorption tower to remove impurities in the raw material. The treated material is passed through an isomerization reactor and a disproportionation reactor. The reaction produces the target product propylene, unreacted ethylene, C5 and C4 olefins, and the r...

Embodiment 2~12

[0055] React by each condition and step of embodiment 1, just change different operating parameters, select the component of hydrogenation catalyst, adsorbent as shown in table 2, the component of isomerization catalyst and disproportionation catalyst as shown in table 3 , the operating conditions of the decyclopentadiene unit are shown in Table 4, the operating conditions of the selected hydrogenation reactor and the adsorption tower are shown in Table 5, and the operating conditions of the isomerization reactor and the disproportionation reactor are shown in Table 6 , and the reaction results are shown in Table 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com