Patents

Literature

33results about How to "Increased weight yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic cracking method

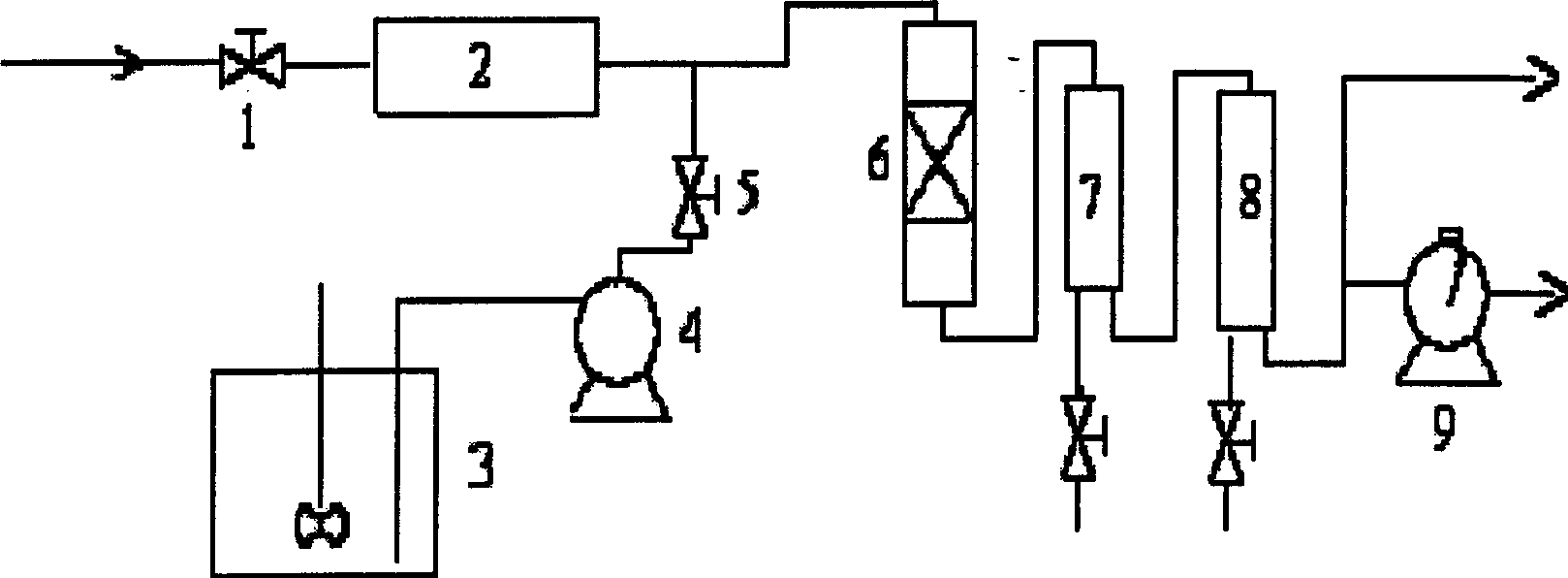

This invention describes a process for catalytic pyrolysis, comprising the steps of: (1) introducing the reactants into a pre-heater, wherein the reactants are vaporized into gases; (2) introducing the mixed solutions containing ultrafine or nanoscale catalyst into the pipeline between the pre-heater and the reactor, or directly into the reactor, wherein the said ultrafine or nanoscale catalyst is uniformly mixed with the process (1) wherein said gaseous reactants; (3) pyrolysis of the said uniform mixture in the reactor. The average diameter of the said ultrafine or nanoscale catalyst is in the range of 1nm-100ª–m. This invention resolves such problems existing in the present fixed-bed reaction process as easy carbonization of the catalyst, a short service periodic and frequent need for recovery. The process of this invention is easy to operate, and suitable for a wide variety of catalytic pyrolysis reactions. Compared with the present pyrolytic process, the process of this invention can increase the weight yield rate of ethylene+propylene+butadiene by at least 5%, while the equipment remains the same with only a feeding pipeline added.

Owner:CHINA PETROLEUM & CHEM CORP +1

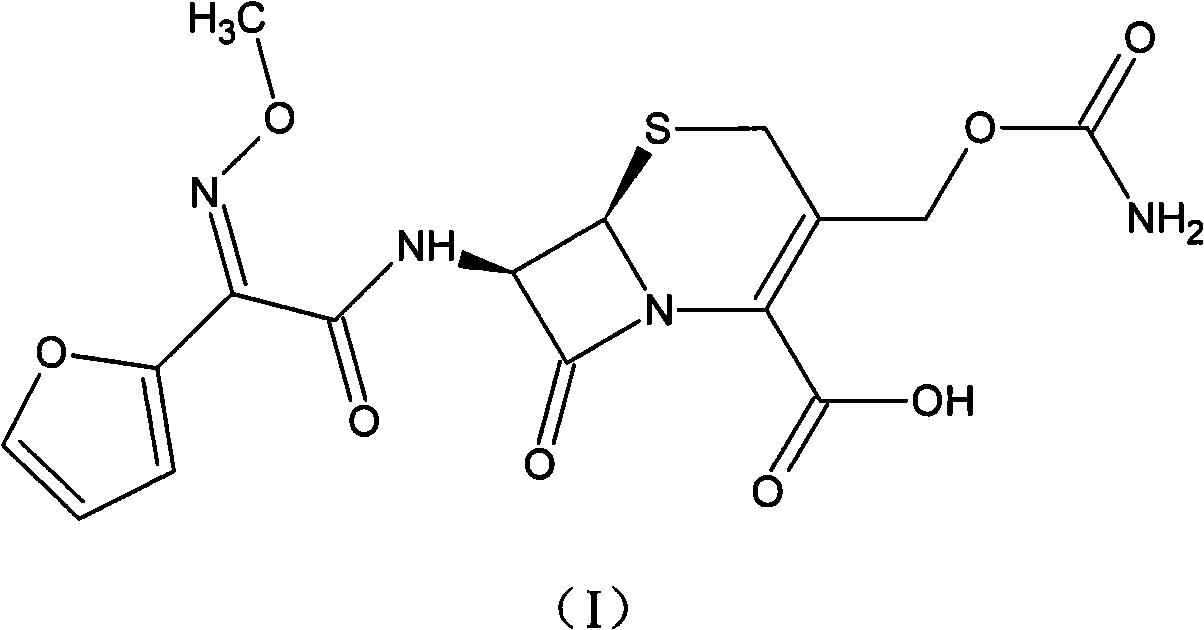

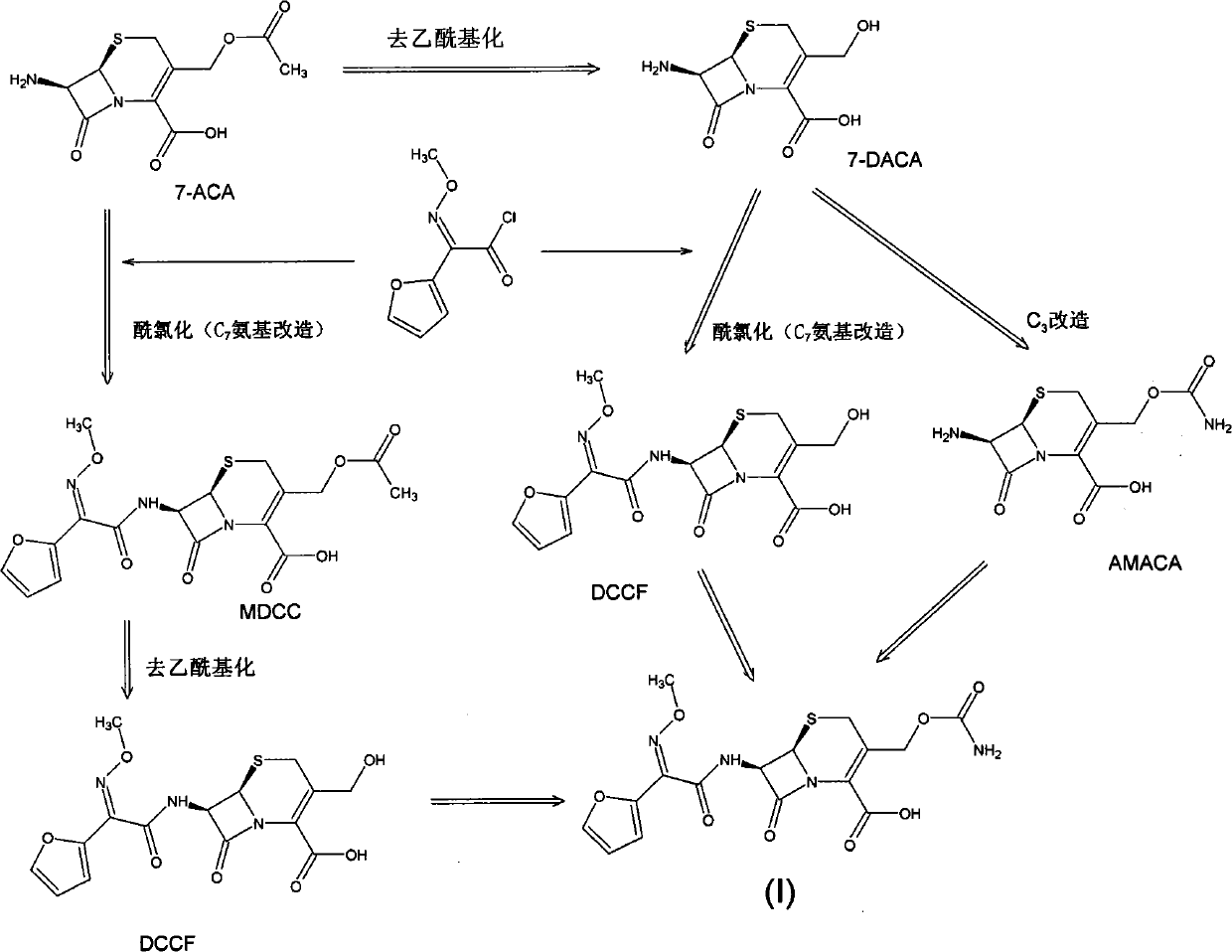

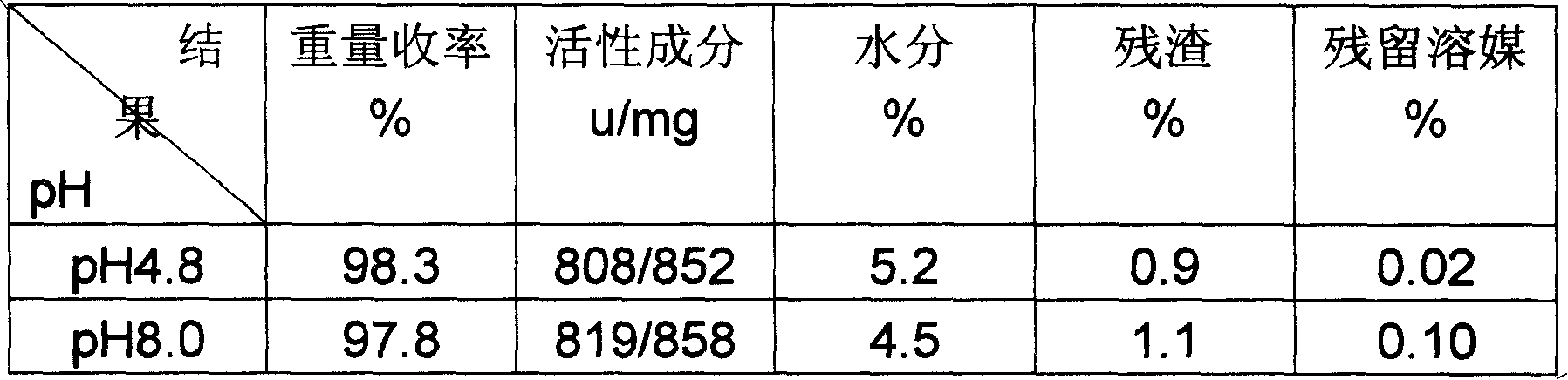

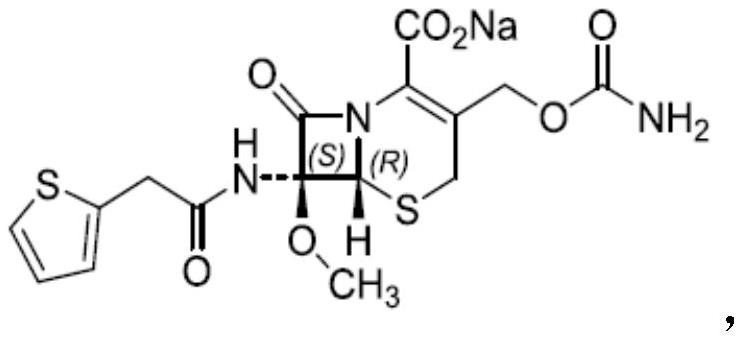

Method for preparing cefuroxime acid

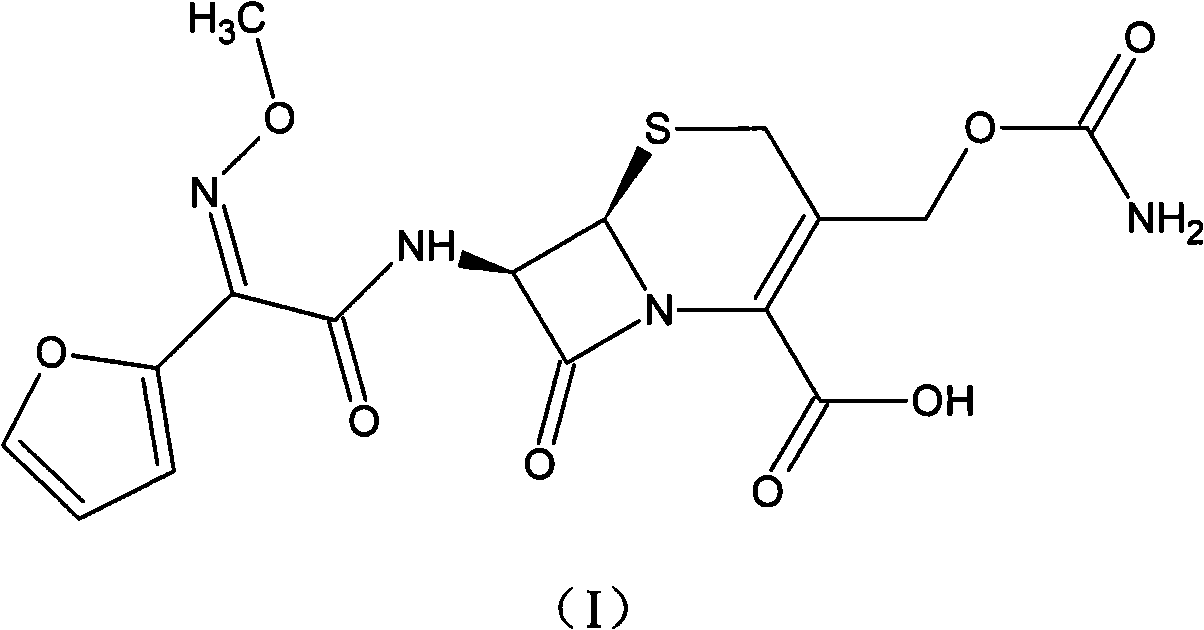

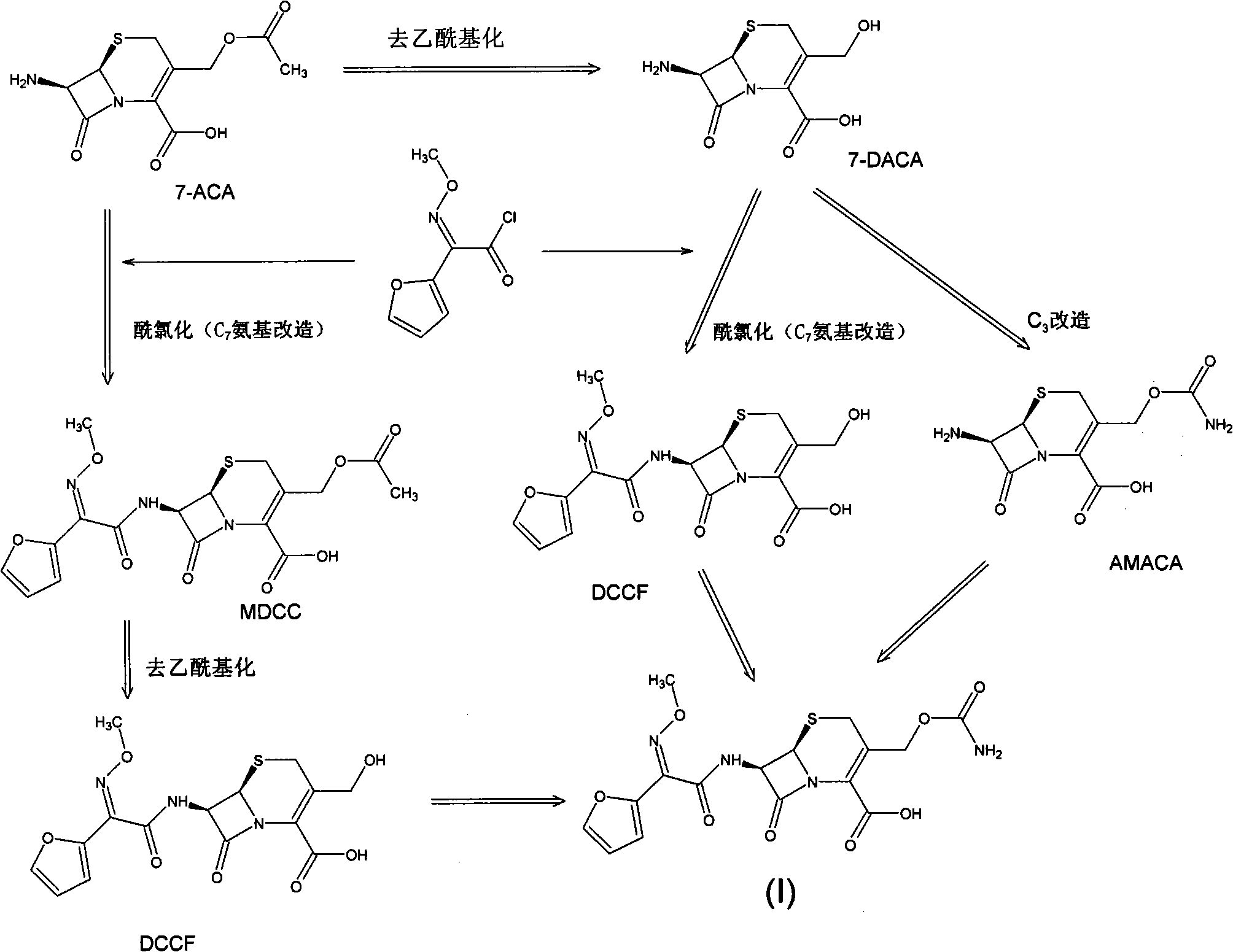

The invention discloses a method for preparing cefuroxime acid. The method comprises the following steps of: performing a chloride acylation reaction on 7-aminocephalosporanic acid (7-ACA) and methoxyiminofuran acetate serving as raw materials; performing deacetylation to synthesize DCCF; performing nucleophilic addition on the DCCF and chlorosulfonyl isocyanate (CSI) serving as a strong carbamoyl reagent to obtain chlorosulfonyl cefuroxime; and hydrolyzing the chlorosulfonyl cefuroxime to obtain cefuroxime acid. In the preparation method, the preparation process is simple, and the cefuroximeacid is crystallized by adopting aqueous solution, so that the loss of organic solvents is reduced; simultaneously, aids are added selectively in the reaction process to improve the quality of products, so that finished products with high purity and yield and good colors are obtained. The purity of the cefuroxime acid prepared by the method is more than 98.5 percent, and the weight yield is approximately 100 percent.

Owner:国药集团致君(苏州)制药有限公司

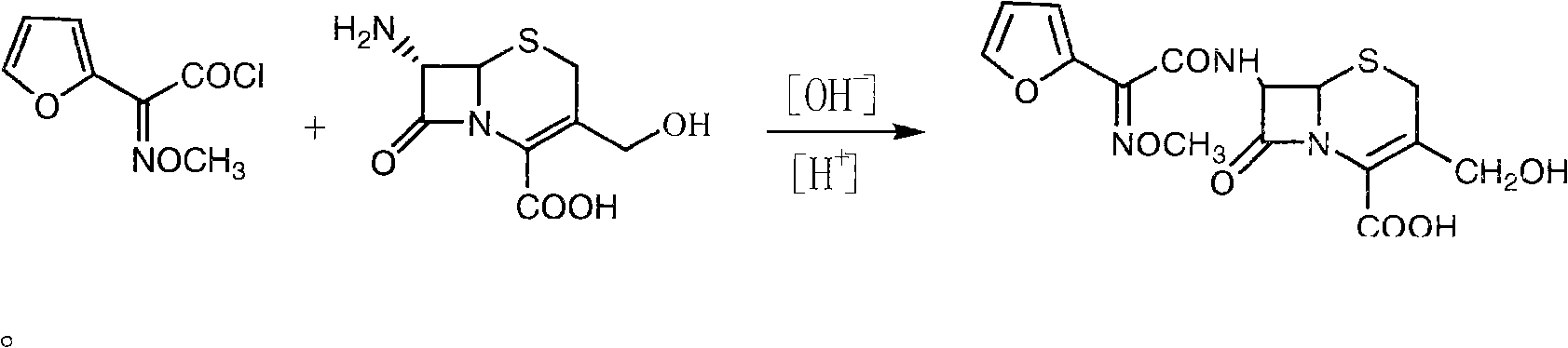

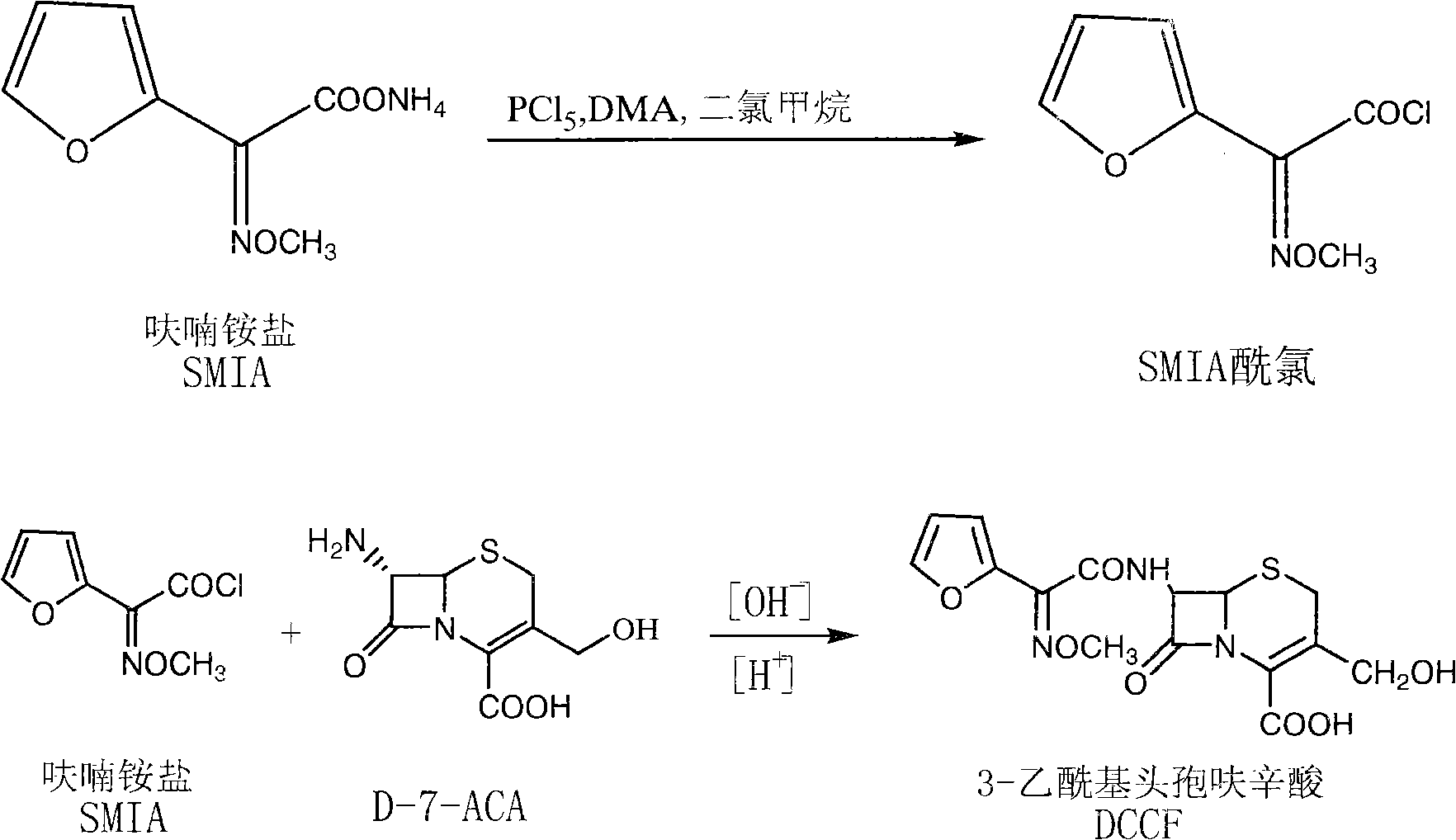

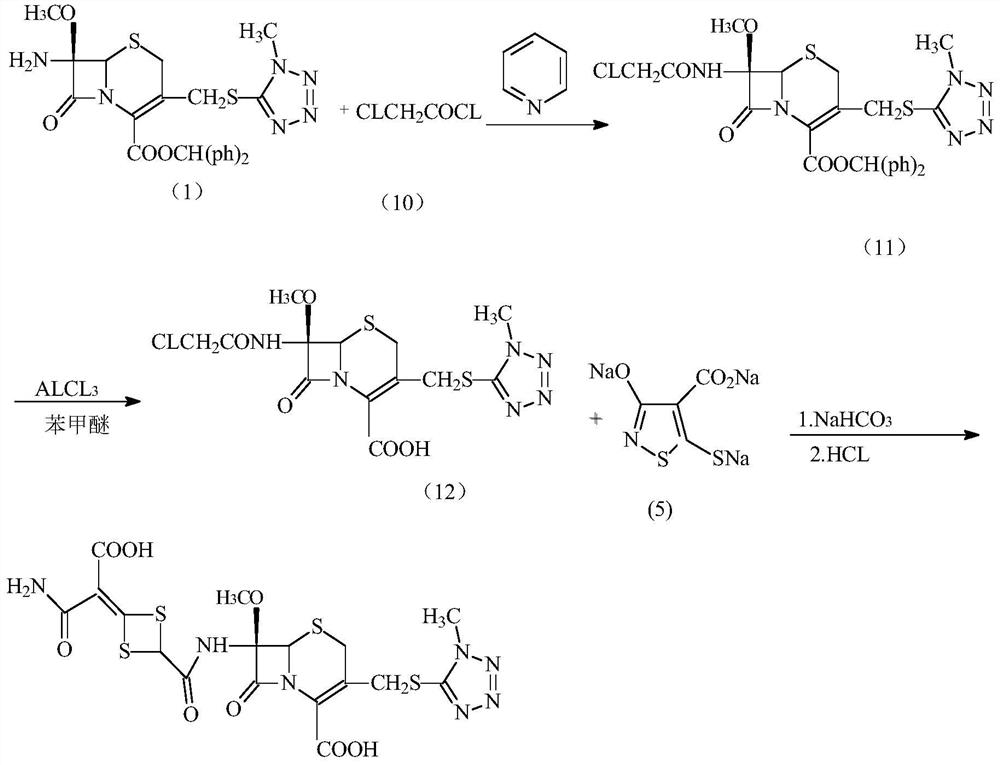

Novel process for synthesizing 3-deacetyl cefuroxime sodium (DCCF)

InactiveCN101289457AReduce typesEasy to recycleAntibacterial agentsOrganic chemistry7-ACAChemical reaction

The invention relates to a synthesis art of a chemical product, in particular to a new synthesis art for 3-deacetyl cefuroxime acid (DCCF). The art of the invention uses SMIA acyl chloride and 3-deacetyl cephalosporin acid (D-7-ACA) as the main synthesis ingredients to replace the SMIA acyl chloride and the 7-ACA, which reduces the chemical reaction process needed in the synthesis, shortens the production cycle, reduces the using solvent species, facilitates the solvent recovery and improves the product synthesis rate.

Owner:河源市制药工程技术研究开发中心

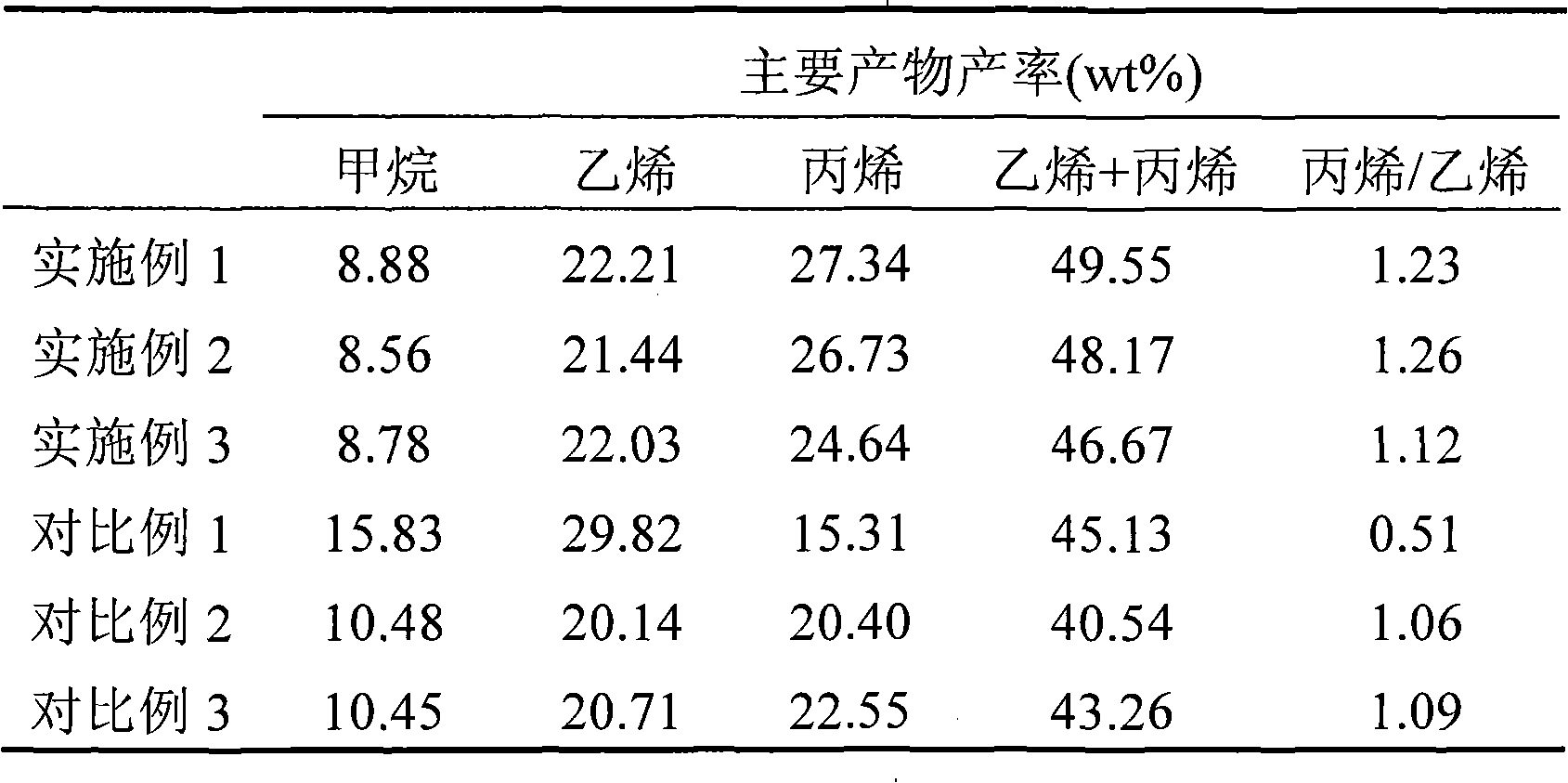

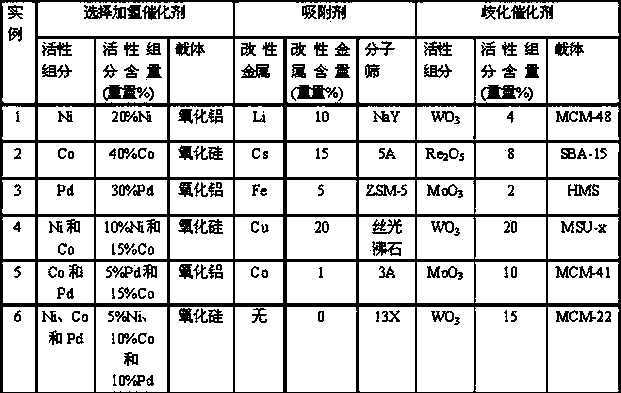

Catalyst for producing low-carbon olefins through catalytic cracking by fixed bed

ActiveCN101683621AHigh yieldRaise the ratioMolecular sieve catalystsBulk chemical productionMolecular sieveAlkaline earth metal

The invention discloses a molecular sieve-containing catalyst for producing low-carbon olefins through catalytic cracking by a fixed bed. To solve the problem that the prior catalyst has high acid content and is easy to coke, the catalyst provided by the invention contains a molecular sieve with the aperture between 5 and 6.5, a modified component thereof and an adhesive. The modified component contains alkaline earth metal oxides, phosphorous oxides and group VIII metal oxides. When the catalyst is used for catalytic cracking, under the condition that a temperature is 200 DEG or more lower than the conventional pyrolysis temperature, compared with the pyrolysis process, the total weight yield of ethylene and propylene is improved, the yield of methane is reduced by about 6 percent, and the ratio of the propylene to the ethylene is improved by more than 1 time.

Owner:CHINA PETROLEUM & CHEM CORP +1

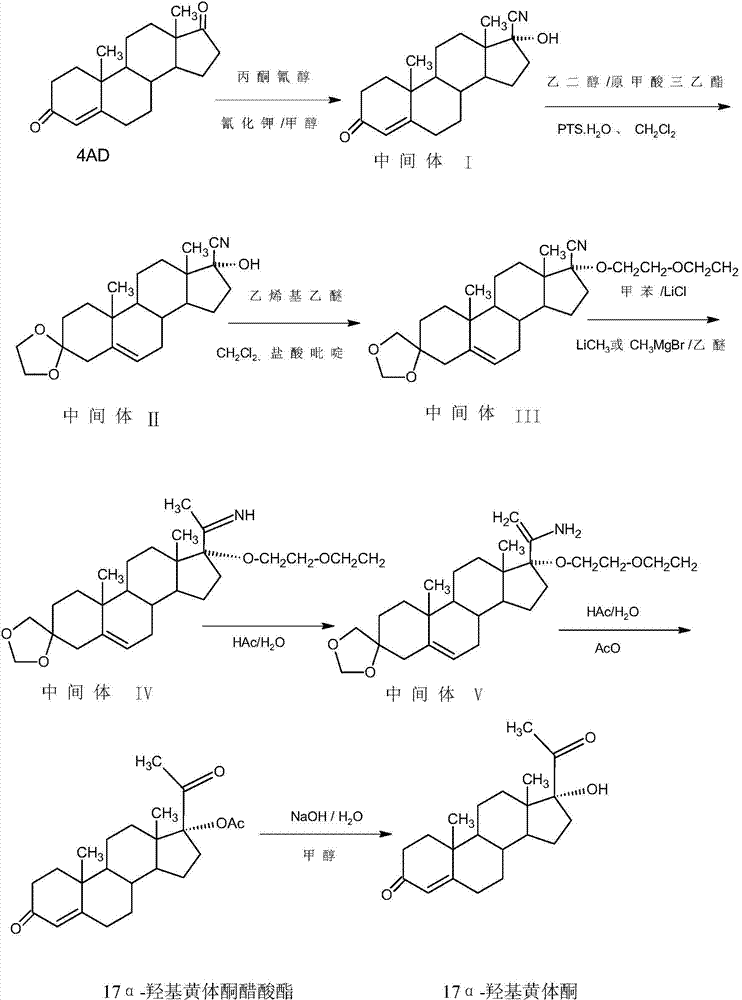

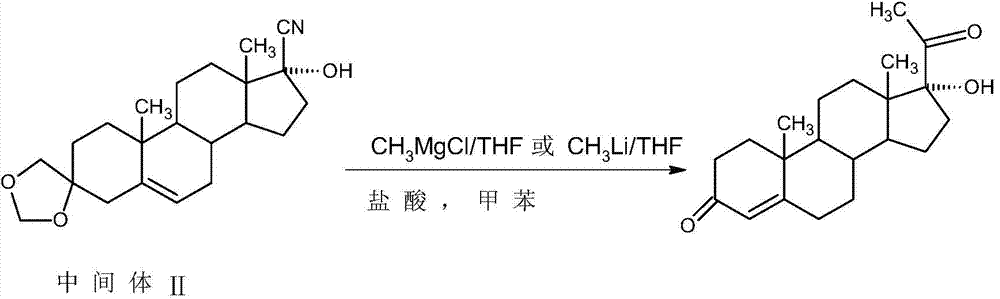

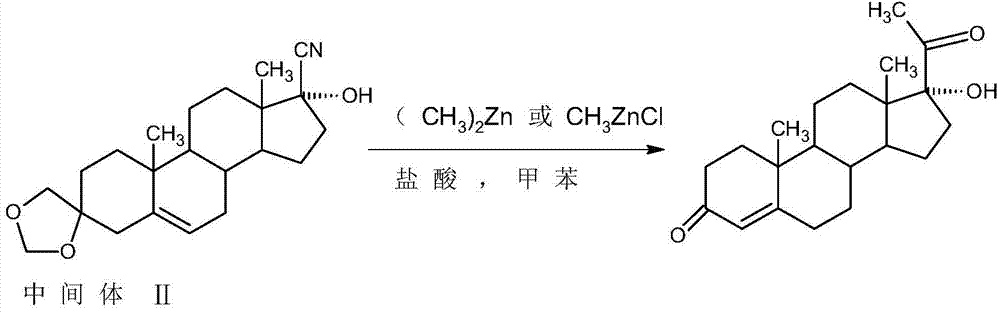

Method for preparing 17alpha-hydroxyprogesteron

The invention relates to a method for preparing 17alpha-hydroxyprogesterone. The17alpha-hydroxyprogesterone is prepared by taking 17beta- cyano-5-androstene-17-ol-3,3-diethylene ketal (referred as an intermediate II) as a raw material and dimethylzinc or methylzinc chloride as a reagent; the content of the 17alpha-hydroxyprogesterone by HPLC is above 99.5% and the weight yield is 83-87%. The method comprises the following steps of dissolving the intermediate II in an organic solvent, adding lithium chloride as a catalyst, stirring, raising the temperature to 40-80 DEG C, dropwise adding a toluene solution of dimethylzinc or methylzinc chloride of which the concentration is 2M, and continuing to complete the reaction; and then adding an ammonium chloride solution of which the concentration is 25% to destruct an organic zinc reagent, separating the aqueous layer out and extracting, merging the organic layer and the extract and concentrating the solvent to near dryness, and then adding lower alcohol, stirring, raising the temperature to 40-60 DEG C, adding the acid of which the concentration is 2M, hydrolyzing, adjusting the pH value with a weak base after the reaction is completed, evaporating 90% of the solvent out, adding tap water, cooling and crystallizing to obtain a crude 17alpha-hydroxyprogesterone product; and then carrying out reflux decolorizing on the crude product with activated carbon by virtue of alcohol, and refining to obtain the commercial grade 17alpha-hydroxyprogesterone. The 17alpha-hydroxyprogesterone produced by the method disclosed by the invention has the advantages of good purity and high yield and is economic and environment-friendly, and the solvent can be recycled.

Owner:HUNAN KEREY BIOTECH

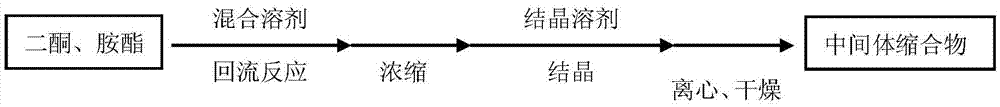

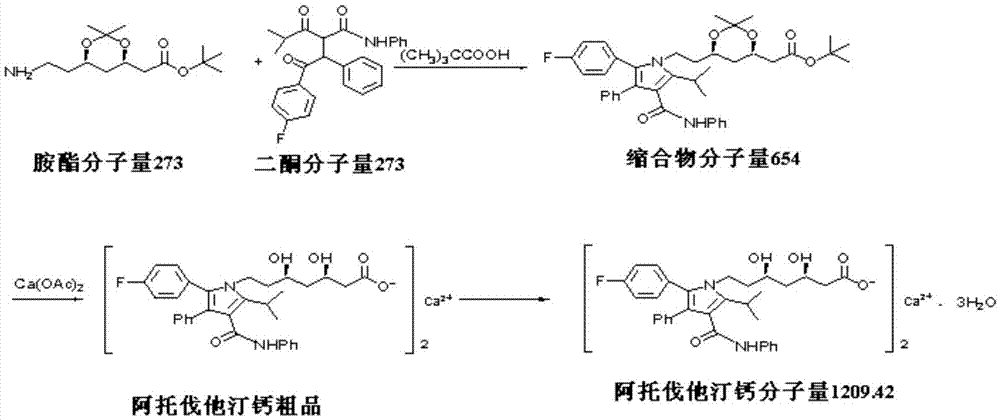

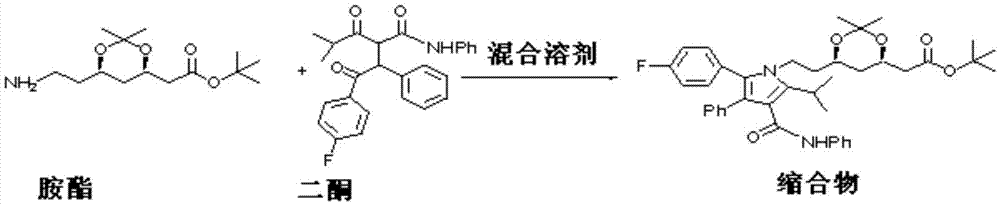

Preparation method of atorvastatin calcium intermediate

The invention relates to a preparation method of an atorvastatin calcium intermediate. The preparation method of the atorvastatin calcium intermediate has the advantages of increase of the yield of the atorvastatin calcium intermediate, simple post-treatment process, simplified operating flow, production period shortening, reduction of the consumption of an organic solvent, reduction of the production cost, and reduction of the danger during the production operation. The method comprises the following steps: 1, carrying out a reaction on amine ester and dione used as initial raw materials in a mixed solvent, wherein the mixed solvent comprises n-heptane and tetrahydrofuran according to a volume ratio of 1:(1-3), and 5-8 ml of the mixed solvent is added to every gram of the amine ester; 2, concentrating a reaction solution obtained in step 1 to remove the mixed solvent to obtain a crude atorvastatin calcium intermediate; and 3, adding a crystallization solvent 1 ethanol to the product obtained in step 2, dissolving the product to clarify the obtained solution, adding a crystallization solvent 2 purified water, cooling obtained crystals, and centrifuging and drying the obtained solution to obtain the atorvastatin calcium intermediate.

Owner:TOPFOND PHARMA CO LTD

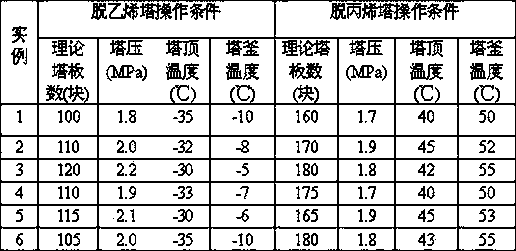

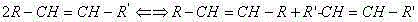

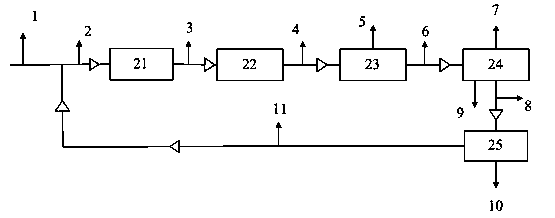

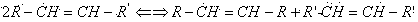

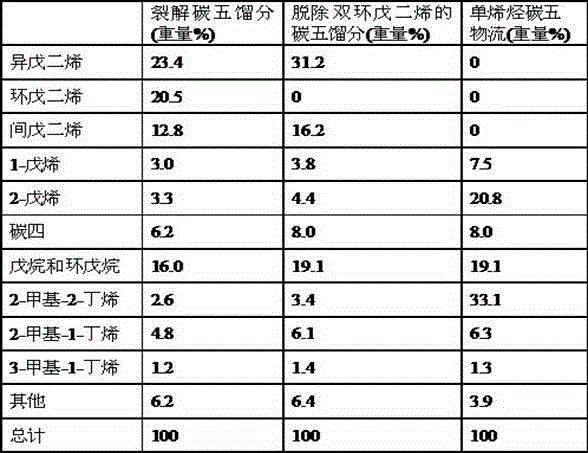

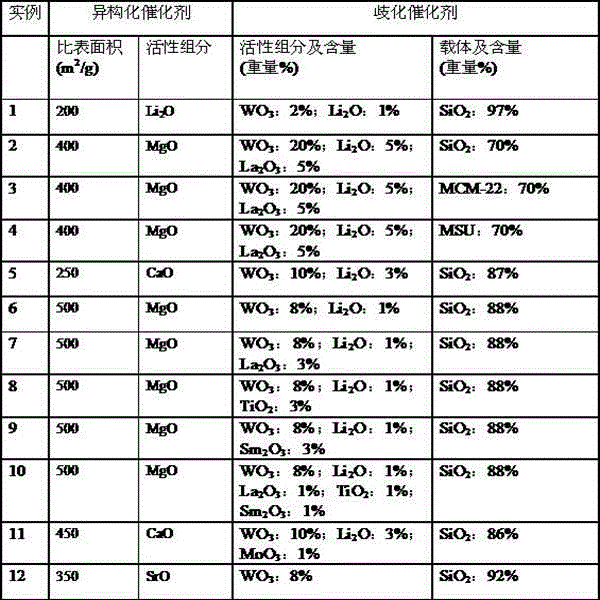

Method for preparing propylene by using cracking C5 fraction

ActiveCN104109071AOptimize the marketSave hydrogenHydrocarbon by metathesis reactionHydrocarbonsDisproportionationEthylene

The invention relates to a method for preparing propylene by using a cracking C5 fraction. The problem of low mass yield of propylene in the prior art is mainly solved. The method for preparing propylene by using cracking C5 fraction, adopting the cracking C5 fraction and ethylene as raw materials, comprises the following steps: sending the cracking C5 fraction to a cyclopentadiene removal unit, reacting, separating to obtain a cyclopentadiene removed C5 flow, sending the cyclopentadiene removed C5 flow to a selective hydrogenation reactor, selectively hydrogenating diolefin in the presence of a hydrogenation catalyst and hydrogen to obtain monoolefin, mixing the obtained monoolefin C5 material with ethylene, processing by an adsorbent, allowing the obtained adsorption flow to contact and react with a disproportionation catalyst to obtain a flow containing a product propylene, unreacted ethylene and C5, and separating to obtain propylene. The method well solves the problem, and can be used in the industrial production for preparing propylene by using the cracking C5 fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

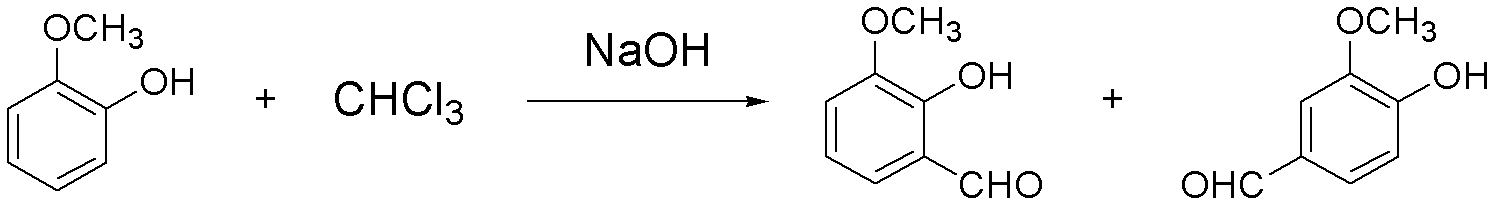

Method for preparing mixture of ortho vanillin and vanillin

InactiveCN102516045AIncreased weight yieldRaise the ratioOrganic compound preparationCarbonyl compound preparationChemistryOrtho-Vanillin

The invention relates to a method for preparing a mixture of ortho vanillin and vanillin, which is applied to the field of medicine synthesis. The method comprises the following steps of: taking guaiacol and chloroform as raw materials; taking carbinol as a medium; reacting under the condition that sodium hydroxide aqueous solution is added; and utilizing acid to adjust the pH value of the obtained products to be at acid level, thereby obtaining the mixture of ortho vanillin and vanillin, wherein the weight ratio of guaiacol to chloroform to carbinol to sodium hydroxide is (40-60): (200-280): (20-45): (50-80); the concentration of the sodium hydroxide aqueous solution is 40-50%; the reaction temperature in the preparing method is 55 DEG C; the holding time is 4 hours; and the pH value is 5-6. The method further comprises the step of steaming carbinol from the mixture and distilling and removing dregs; the process of steaming carbinol comprises the following steps of: pumping and filtering the mixture, carrying out distilling under reduced pressure by a water pump at 40 DEG C and drying the carbinol, thereby obtaining an oily matter; and the oily matter is subjected to distilling under reduced pressure for 30 minutes at 60 DEG C, thereby obtaining oily liquid. According to the method provided by the invention, the yield of total weight is high and the proportion of the ortho vanillin is increased.

Owner:NORTHEAST PHARMA GRP

Preparation process of viscose-based carbon fiber composite material graphite felt and prepared graphite felt

PendingCN113774604AReduce volatilityExtend the production cycleCarbon fibresHeating/cooling textile fabricsViscoseGraphite

The invention discloses a preparation process of a viscose-based carbon fiber composite material graphite felt, and relates to the technical field of graphite felts. The preparation process comprises the following steps of 1, pre-oxidizing a viscose-based white felt to prepare a carbon fiber pre-oxidized felt, soaking the carbon fiber pre-oxidized felt in a 1% diammonium hydrogen phosphate solution, then performing drying, and performing heating treatment in a pre-oxidation furnace to obtain a pre-oxidized felt; 2, treating the pre-oxidized felt by a continuous pre-treatment furnace at the treatment temperature of 630-650 DEG C to obtain a viscose-based carbon fiber pre-treated felt; and 3, treating the pre-treated felt by a continuous carbonization and graphitization furnace to prepare the viscose-based carbon fiber graphite felt, wherein the treatment temperature is 1900-2400 DEG C. The process has the beneficial effects that the raw materials which are treated by the pretreatment process and then integrally produced by the continuous carbonization and graphitization furnace can obtain higher yield and higher width, and the production efficiency is improved.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

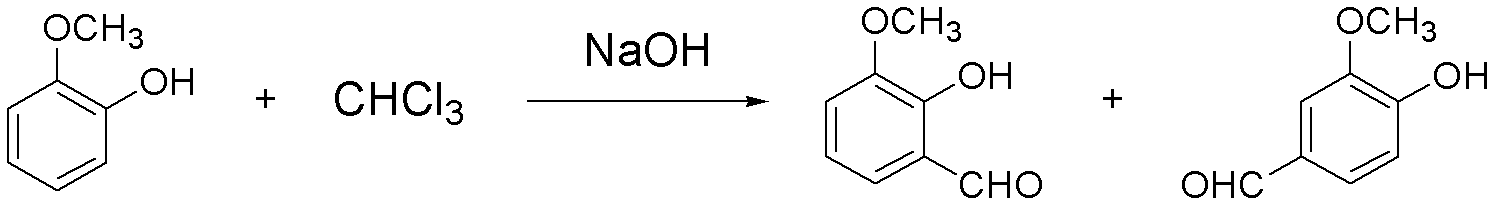

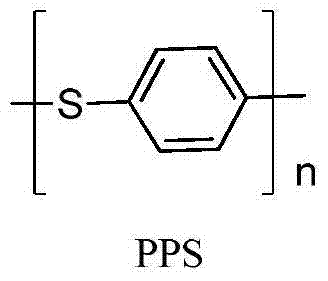

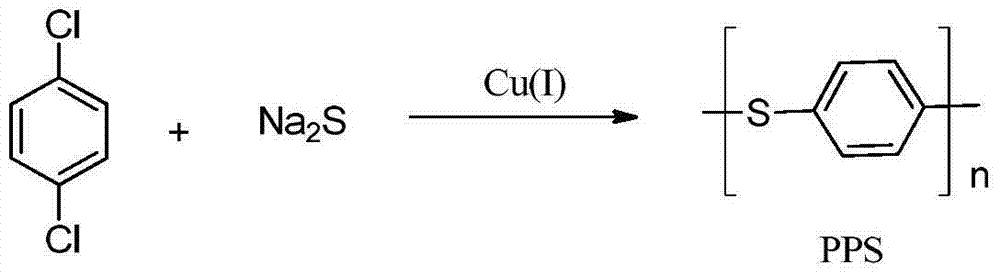

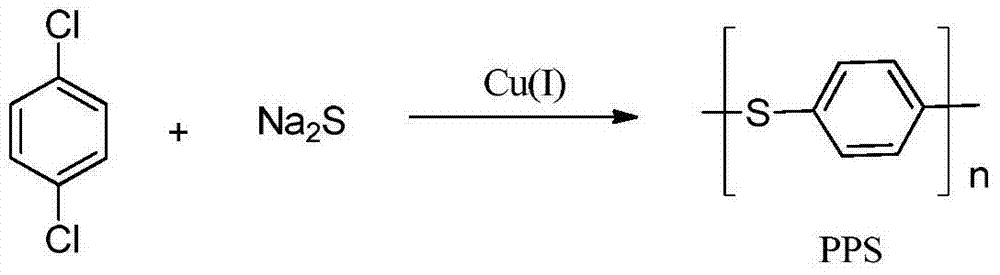

Improved synthesis method of polyphenylene sulfide

InactiveCN104744699AImprove mechanical propertiesIncrease reaction ratePolymer scienceSynthesis methods

The invention discloses an improved synthesis method of polyphenylene sulfide, and belongs to the field of engineering plastics. The improved synthesis method comprises the following step: with p-dichlorobenzene and sodium sulfide as raw materials, preparing polyphenylene sulfide with high molecular weight and narrow molecular weight distribution under the catalysis of univalent copper ions or complexes of the univalent copper ions. The polymerization product disclosed by the invention is high in yield and few in low polymers, and has good industrialized application prospect.

Owner:CHANGZHOU UNIV

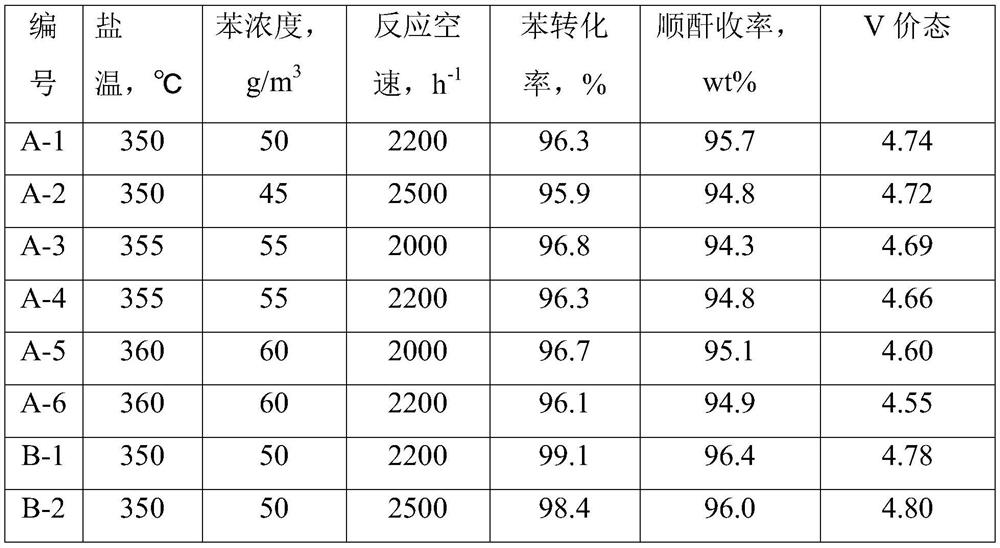

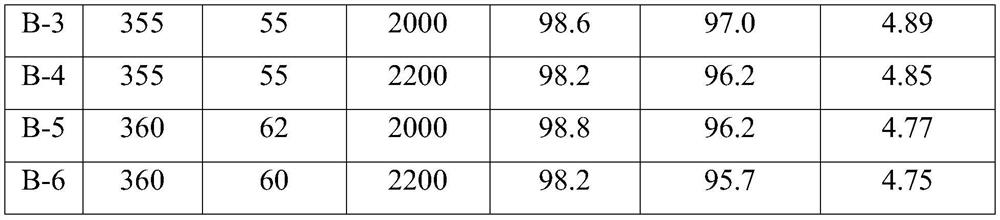

Oxidation catalyst as well as preparation method and application thereof

ActiveCN113842934AImprove conversion rateIncreased weight yieldOrganic chemistryHeterogenous catalyst chemical elementsBenzenePtru catalyst

The invention discloses an oxidation catalyst and a preparation method and application thereof, wherein the oxidation catalyst comprises a first vanadium-molybdenum catalyst and / or a second vanadium-molybdenum catalyst, the first vanadium-molybdenum catalyst and / or the second vanadium-molybdenum catalyst independently contain vanadium, molybdenum, nickel and an auxiliary agent, and wherein, the average oxidation state of vanadium in the first vanadium-molybdenum catalyst is lower than the average oxidation state of vanadium in the second vanadium-molybdenum catalyst. In the process of preparing the catalytic active substance precursor, the oxidation state of the main metal vanadium in the active substance precursor is modulated by using an oxidation-reduction reaction, and the main metal vanadium is coupled with different types of metal additives. When the catalyst is applied to a reaction for oxidative synthesis of maleic anhydride, under the condition that the benzene concentration is 40-65 g / Nm3, the benzene conversion rate reaches more than 98%, and the weight yield of maleic anhydride reaches 94-99%. Under the same operation conditions, the conversion rate of benzene can be increased by 3.6% at most, and the weight yield of maleic anhydride can be increased by 4.4% at most.

Owner:CHINA PETROLEUM & CHEM CORP +1

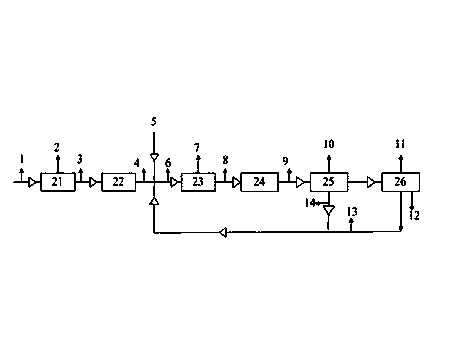

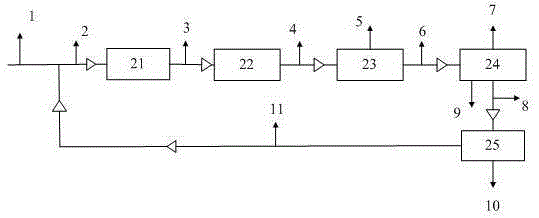

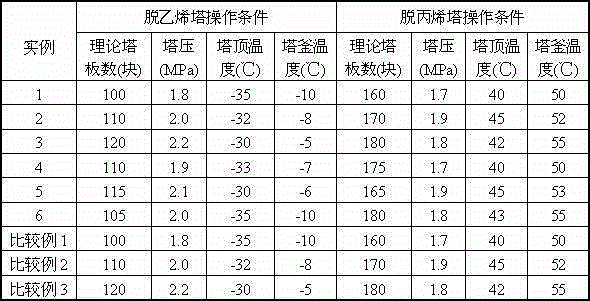

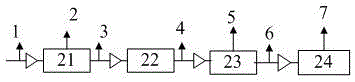

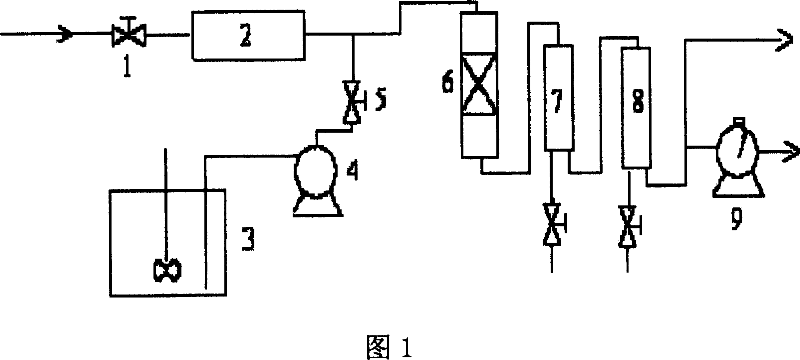

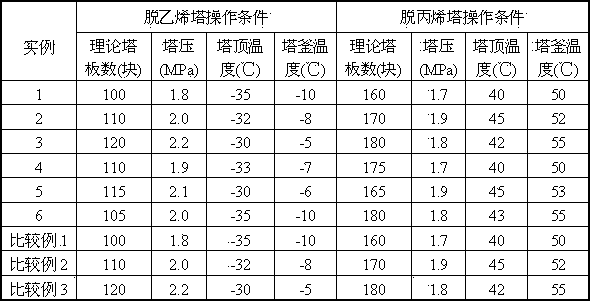

Propylene production method

ActiveCN103420759AIncrease profitIncreased weight yieldHydrocarbon by metathesis reactionButene2-Butene

The present invention relates to a propylene production method, wherein the problem of ethylene consumption in the prior art is mainly solved with the present invention. The technical scheme comprises that: a material containing 1-butene, 2-butene, isobutane and n-butane is adopted as a C4 raw material, the C4 raw material is respectively subjected to an extraction separation process to obtain a butene stream containing 1-butene and 2-butene, and the butene stream passes through a disproportionation reactor, an ethylene removing tower and a propylene removing tower to obtain the product propylene. The propylene production method can be used for industrial production of preparation of propylene from C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

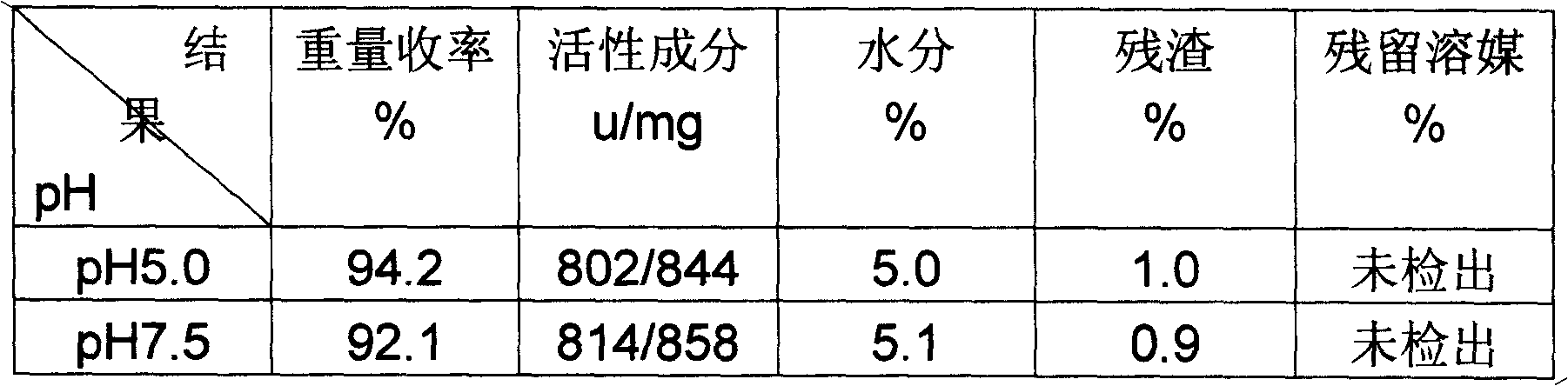

Method for preparing cefuroxime acid

Owner:国药集团致君(苏州)制药有限公司

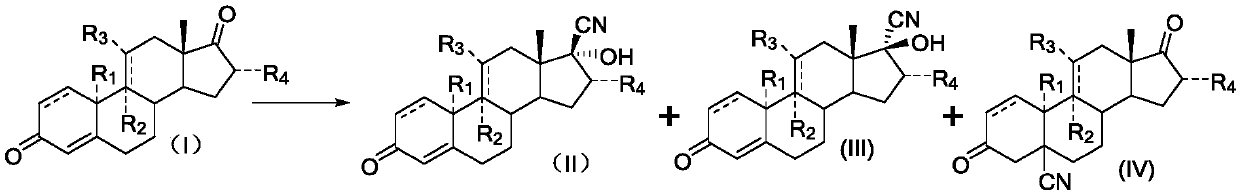

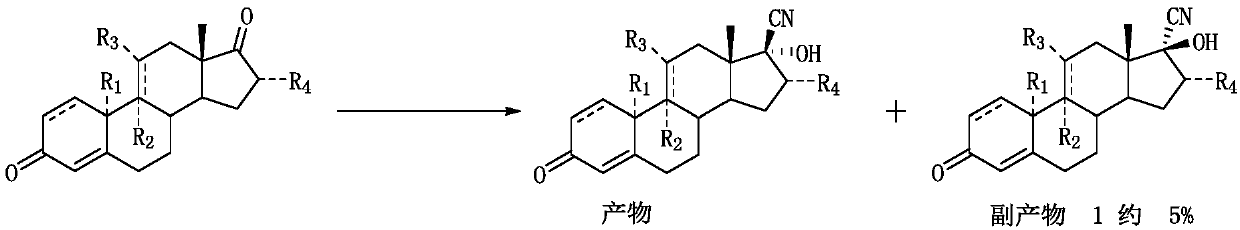

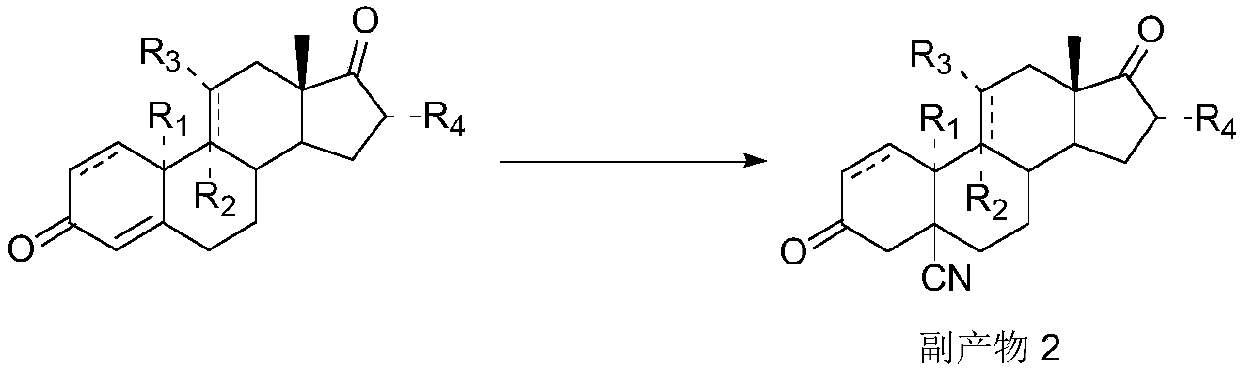

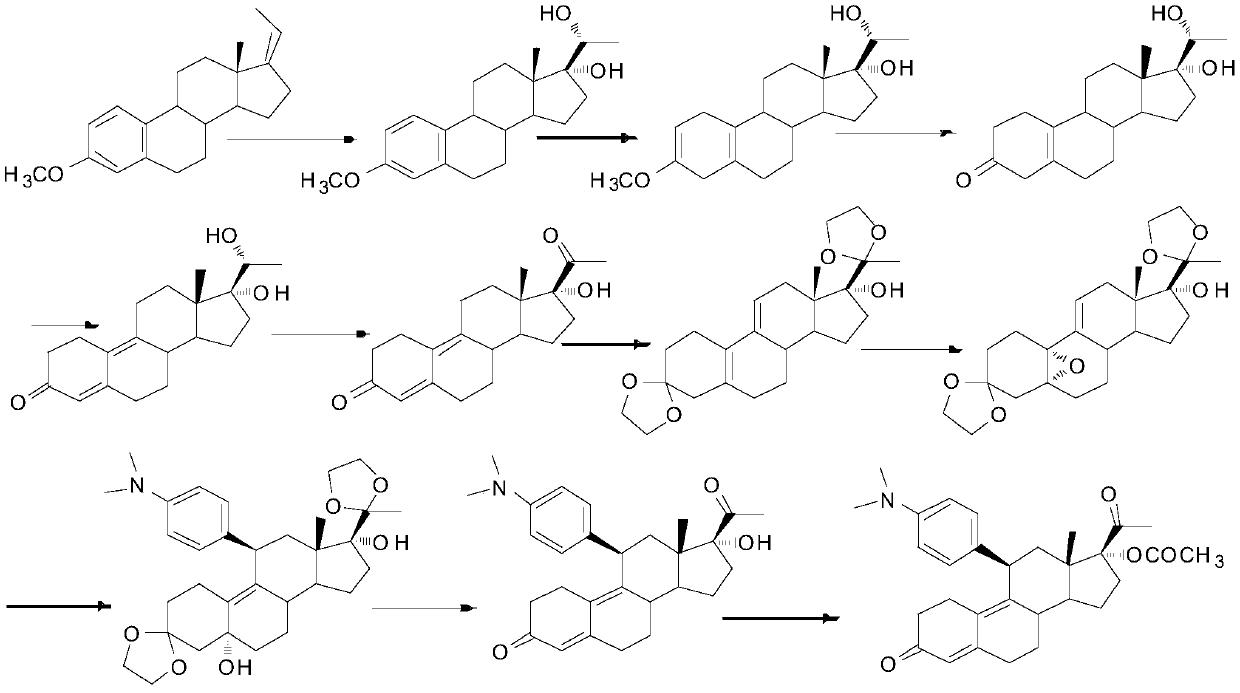

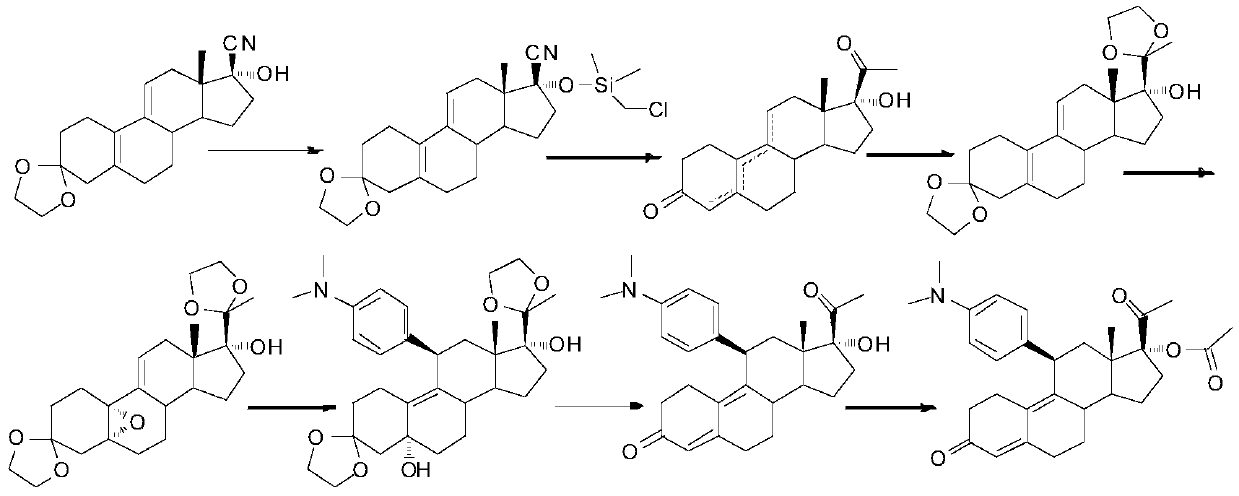

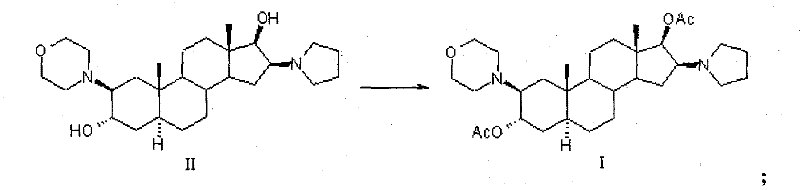

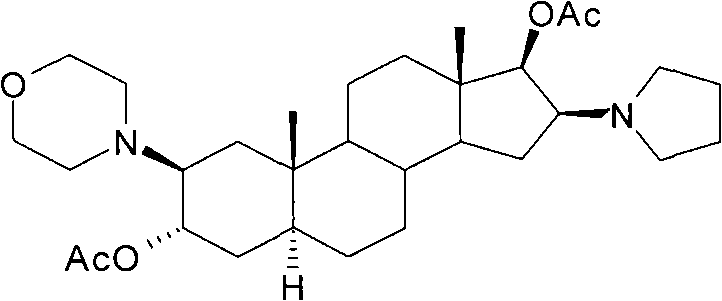

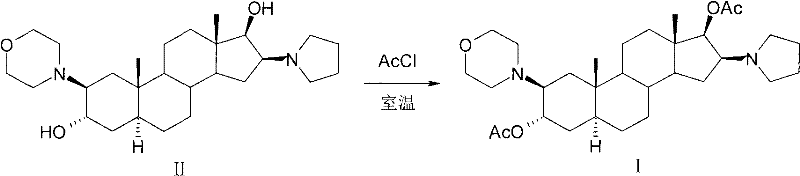

A synthetic method of 17alpha-hydroxy-17beta-cyano-steroid compounds

A synthetic method of 17alpha-hydroxy-17beta-cyano-steroid compounds is disclosed. The method includes a) dispersing a compound of a formula (I) into methanol, heating the mixture to 30-32 DEG C, adding 3-buten-2-one into the mixture, then adding acetone cyanohydrin into the mixture, fully stirring the mixture, then adding dropwise a prepared aqueous potassium carbonate solution, and maintaining the temperature until the reaction is completed; and 2) cooling the reaction solution to 0-5 DEG C after the reaction is finished, then stirring the reaction solution until a product is completely precipitated, performing suction filtration, washing filter cake with a small amount of water until neutrality, and drying the product to obtain a compound of a formula (II), and a small amount of a compound of a formula (III) and a compound of a formula (IV) which are adopted as byproducts. The weight ratio of the compound of the formula (I), the methanol, the 3-buten-2-one and the acetone cyanohydrin is 100:90-110:0.9-1.1:80-90. The weight-to-volume ratio of the compound of the formula (I) to the potassium carbonate solution is 100:90-110. The weight percentage of the potassium carbonate solution is 2.5-3.5%.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD

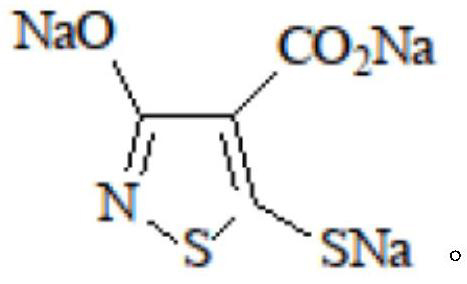

A kind of preparation method of cefotetan acid

A cefotetan acid preparation method is disclosed. A filtrate after filtration of cefotetan acid crystals is subjected to secondary crystallization, and the cefotetan salt obtained by the secondary crystallization is added into a reaction solution when the cyclization reaction time between 7-MCTT and a cefotetan side chain compound is 48-56 h so that the weight yield of cefotetan acid prepared fromthe 7-MCTT is increased to 90% or above and a product is high in purity and good in color. The method is suitable for industrial production and has a good application prospect.

Owner:FUJIAN FUKANG PHARMA

Production process of chlorcyclizine hydrochloride

InactiveCN111793043AIncreased weight yieldHigh purityOrganic chemistryBulk chemical productionChlorcyclizineRaw material

The invention belongs to the technical field of medicine synthesis and especially relates to a production process of chlorcyclizine hydrochloride. The production process comprises the following steps:a bromination reaction; a condensation reaction; distillation; acid and alkali adjustment; crystallization; refining and purifying; and packaging. The production process has the advantages of simpleprocess, few synthesis steps, cheap and easily available raw materials, mild reaction conditions, strong operability, capacity of realizing continuous production, high total yield and suitability forlarge-scale industrial production. Three recrystallization operations are carried out in the process of refining and purifying, so an impurity content is reduced, the purity of chlorcyclizine hydrochloride reaches relevant weight standards prescribed in Pharmacopeia, and the purity of chlorcyclizine hydrochloride is remarkably improved; and meanwhile, refining yield is improved, and production efficiency can be remarkably improved.

Owner:JIAOZUO FURUITANG PHARMA

Method for preparing phosphate eritrocina using eritrocina

ActiveCN100434435CNot easy to precipitateIncreased weight yieldSugar derivativesSugar derivatives preparationOrganic solventPhosphate

The invention relates to a Method for preparation of erythrocin salt, especially a method on using erythrocin to prepare phosphoric acid erythrocin. The characters are: dissolving erythrocin in organic solventn or water of c2-c6 containing hydroxyl group and carbonyl group, agitating, controlling the reaction temperature of forming salt, carrying through synthesize reaction by dripping phosphoric acid solution to regulate the solution's pH value and control reflecting terminal, finally, getting phosphoric acid erythrocin finished product after separation and desiccation. Its technology is advanced, the hazardness for people and circumstance is small, the productivity is high, the cost is low.

Owner:XIAN LIJUN PHARMA CO LTD

Production method of propylene

ActiveCN103539613BIncrease profitIncreased weight yieldHydrocarbon by metathesis reaction2-ButeneDisproportionation

The invention relates to a production method of propylene, which mainly solves the problem that ethylene is to be consumed in the prior art. Due to the adoption of the technical scheme of obtaining a product propylene by a carbon 4 raw material comprising 1-butene, 2-butene, iso-butane and n-butane through a disproportionation reactor, an ethylene removing tower, a propylene removing tower and an extraction flow, the production method of the propylene can be used for industrialized production of preparing the propylene by carbon 4.

Owner:CHINA PETROLEUM & CHEM CORP +1

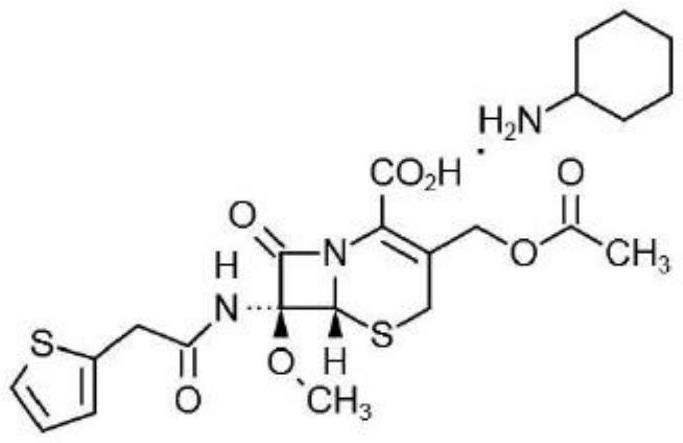

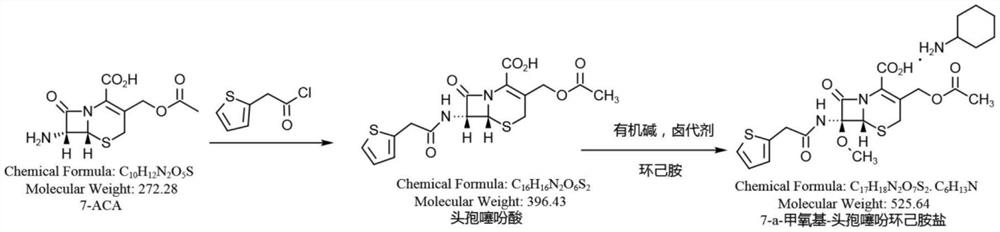

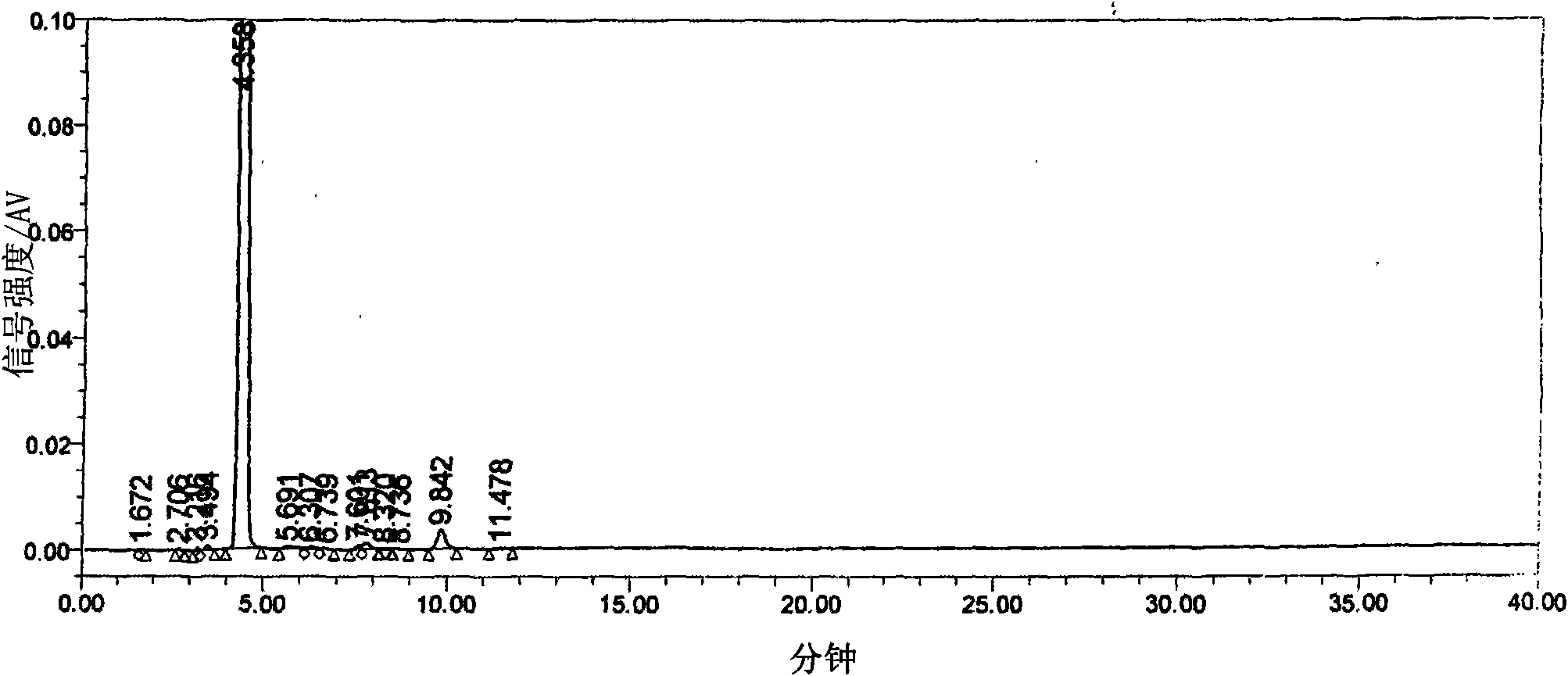

Synthesis method of cefoxitin sodium key intermediate

PendingCN113583024AReduce anhydrous requirementsFix stability issuesAmino preparation from aminesAcetic acidCyclohexylamines

The invention provides a synthesis method of a cefoxitin sodium key intermediate, and belongs to the technical field of heterocyclic compounds. The method comprises the following steps: by taking a cephalotin solution as a treatment object, adding organic alkali, adding a halogenating agent, carrying out halogenating methoxyl reaction, adding acetic acid and saline water, regulating acid and layering, drying an organic layer, concentrating, adding cyclohexylamine to form salt, filtering and drying to obtain a key intermediate 7-alpha methoxyl cephalothin cyclohexylamine salt According to the method, one-step synthesis of the 7-alpha methoxyl cephalothin cyclohexylamine salt is realized, subsequent main impurities of cefoxitin sodium are effectively reduced from the source, the quality and purity of the product are improved, the competitiveness of the cefoxitin product is improved, the product is stable and reliable, the yield is high, the synthesis process is greatly simplified, and the method has an industrial prospect.

Owner:ZHEJIANG GUOBANG PHARMA +1

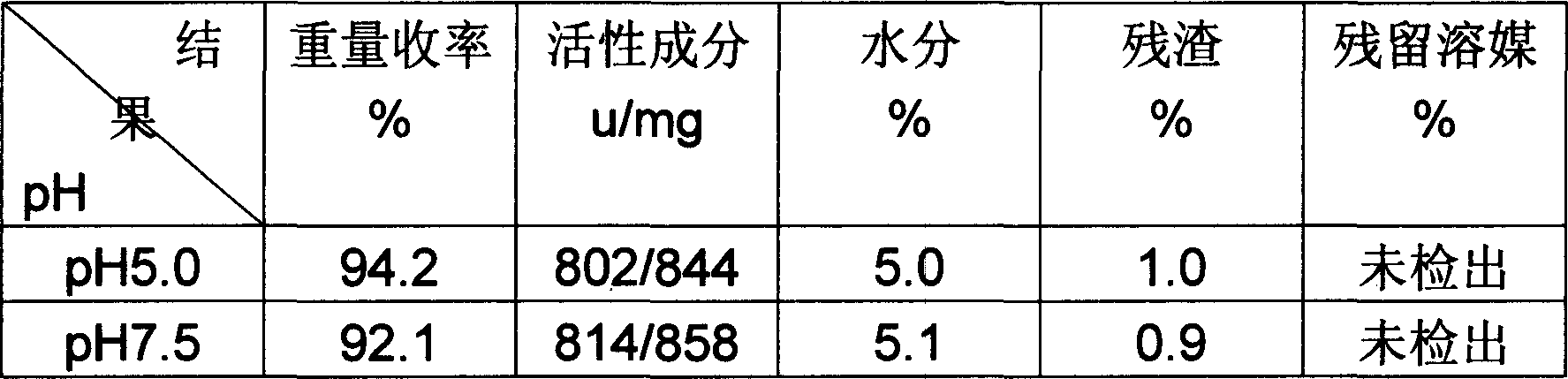

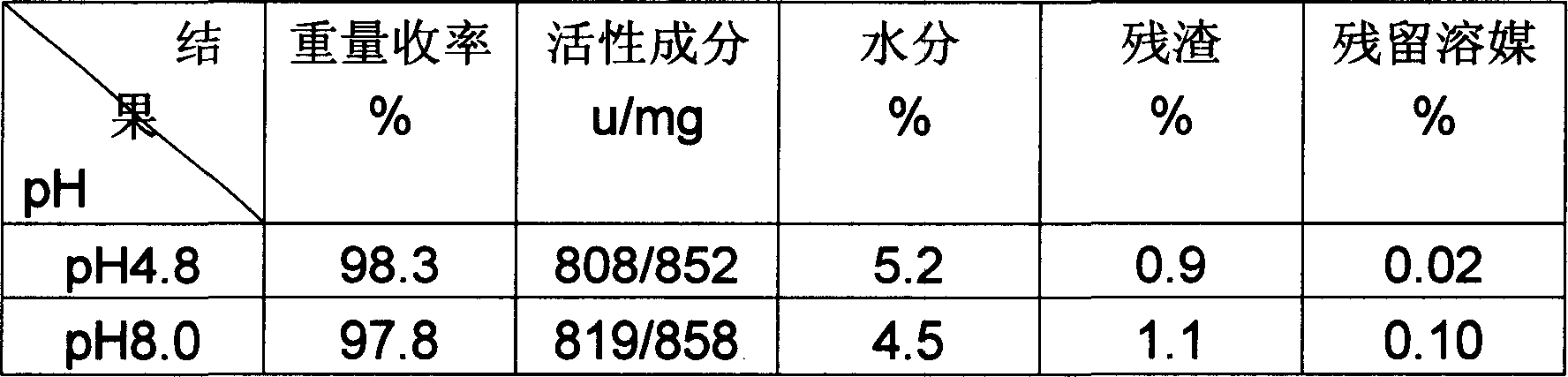

A kind of catalysis method of cephalosporin nucleolysis reaction

ActiveCN105506050BEnzymolysis temperature is lowMaximum Unknown Simplex ReductionFermentationCatalytic methodPolyethylene glycol

The invention belongs to the field related to cephalosporin drug intermediate synthesis, and provides a cephalosporin parent nucleus enzymolysis reaction catalysis method which comprises the following steps: (1) by using p-methoxybenzyl 7-phenylacetylamino-3-vinyl-4-cephalosporanate as an initial raw material, adding into phenol, and heating to react; after the reaction finishes, extracting the intermediate product to a water phase, and adding penicillin acylase and polyethyleneglycol accounting for 5+ / -2 wt% of the penicillin acylase as an enzymolysis catalyst; and (2) while controlling the temperature at 20-25 DEG C, dropwisely adding a 5-10 wt% sodium carbonate solution, and controlling the pH value of the system at 7.0-7.5 to perform enzymolysis. According to the method, the enzymolysis speed and enzymolysis conditions are changed. On the premise of not increasing the 7-AVNA raw material cost, the enzymolysis reaction speed is enhanced, the operation time is shortened, and the enzymolysis process is performed under the conditions of low pH value and low temperature. The method has the advantages of high product purity, fewer impurities and high yield, and is very suitable for large-scale industrial production.

Owner:湖北凌晟药业股份有限公司

Preparation method of 5'-deoxidization-2',3'-diacetyl-5-fluoro-cytidine

ActiveCN101525362BIncreased weight yieldHigh synthetic yieldSugar derivativesSugar derivatives preparationSolventPromotion effect

Owner:ZHEJIANG CHENGYI PAHRMACEUTICAL

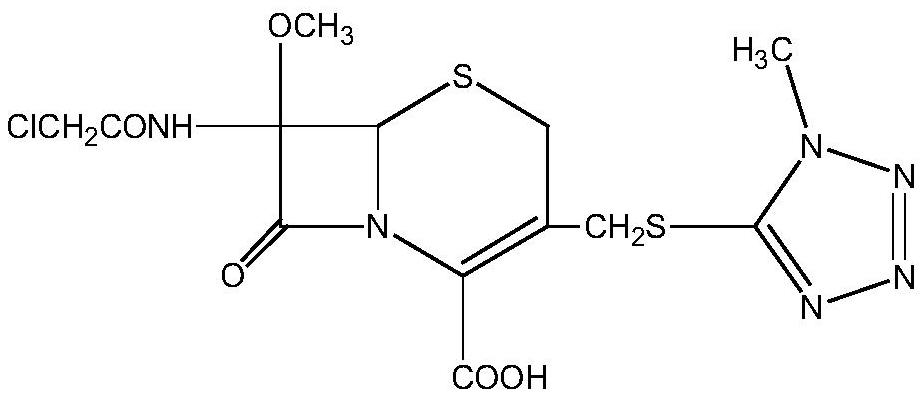

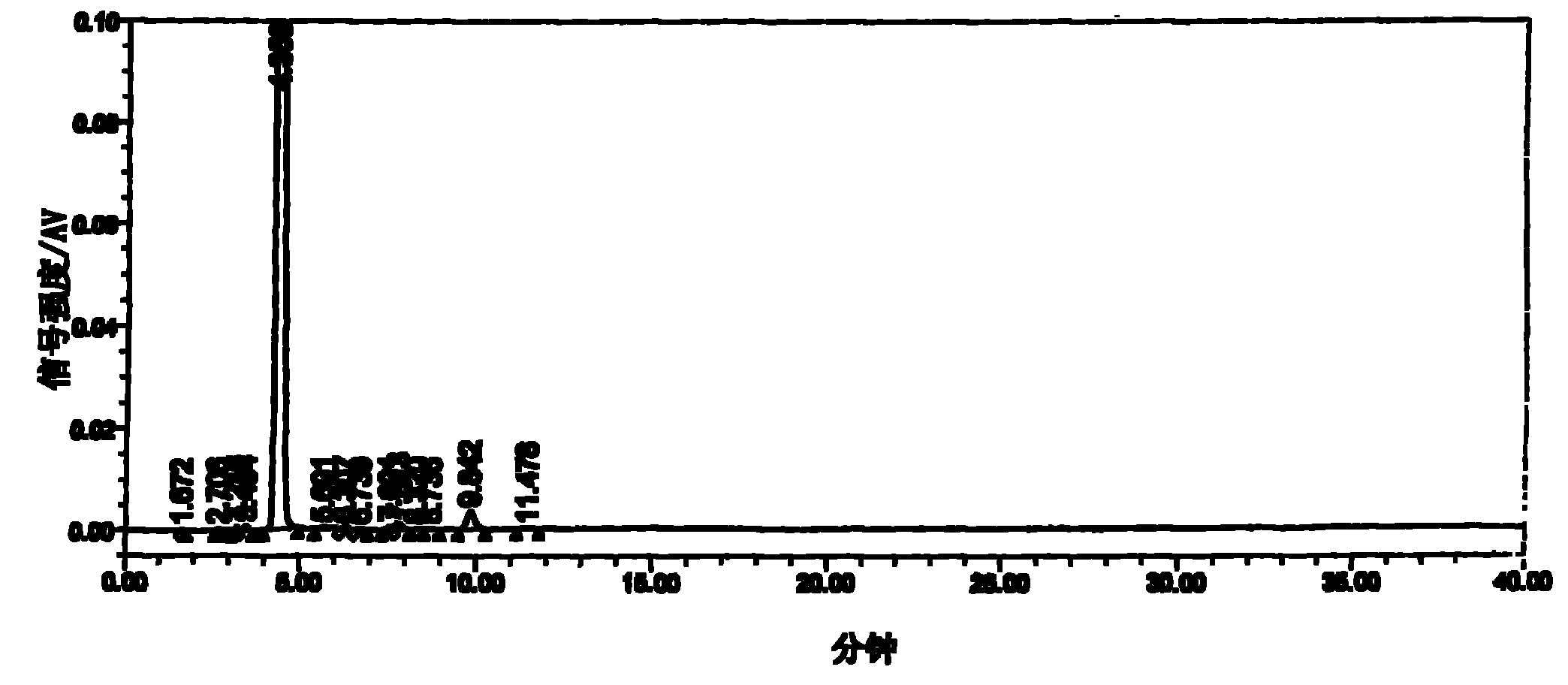

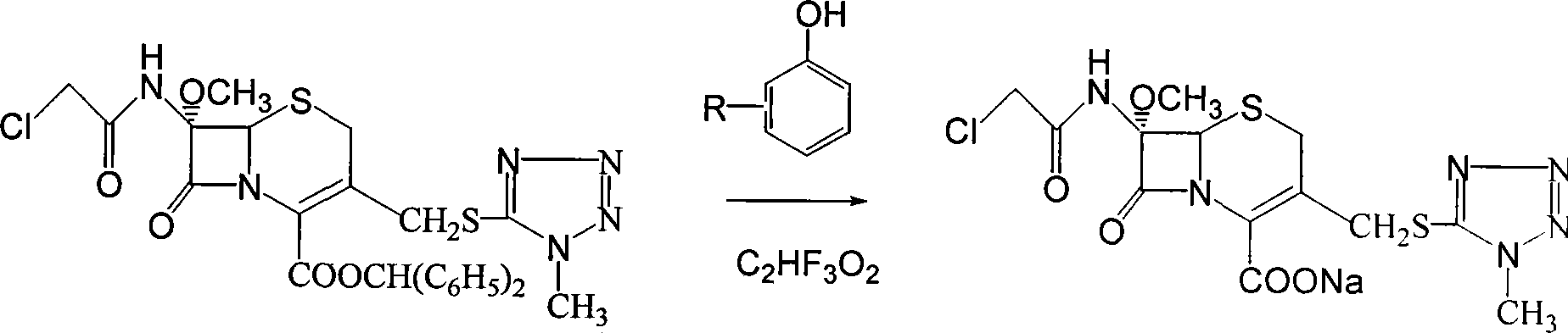

Method for preparing sodium 7-methoxy-7-chloracetylamino-3-methyltetrazole sulfidomethyl cephalosporanic acid

InactiveCN101423523BCompletely precipitatedMild reaction conditionsOrganic chemistrySolventEthyl Chloride

The invention discloses a preparation method for 7-methoxy-7-chloracetyl amido-3-methyl tetrazole s-methyl sodium cephalosporanic acid. The method comprises the following steps: adding 7-methoxy-7-chloracetyl amido-3-methyl tetrazole s-methyl cephalosporanic acid benzyl ester and trifluoroacetic acid in turn into the phenolic compound solvent for reaction; adding ethyl acetate into the reaction liquor when the reaction residue is less than 1 percent; adjusting the pH value of the reaction liquor to form an organic phase and a water phase; taking the water phase and adding ethyl acetate into the water phase; after even mixing, regulating the pH value, splitting phases through standing, collecting the organic phase after extraction, and then carrying out concentration and drying; adding theorganic phase into ethanol isopropyl alcohol mixed liquor; stirring to dissolve the organic phase, adding sodium iso-octoate and isopropyl alcohol mixed liquor into the mixed solution for reaction; cooling, filtrating and drying the product after the reaction to obtain the finished product. The method saves the preparation process of adopting an alchlor catalyst; and simultaneously trifluoroacetic acid is added into the solvent of o-cresol, m-cresol or p-cresol for benzyl ester removing hydrolysis, thereby not only shortening the technical flow and simplifying the operation, but also improving the yield to 75 to 80 percent.

Owner:河北九派制药股份有限公司

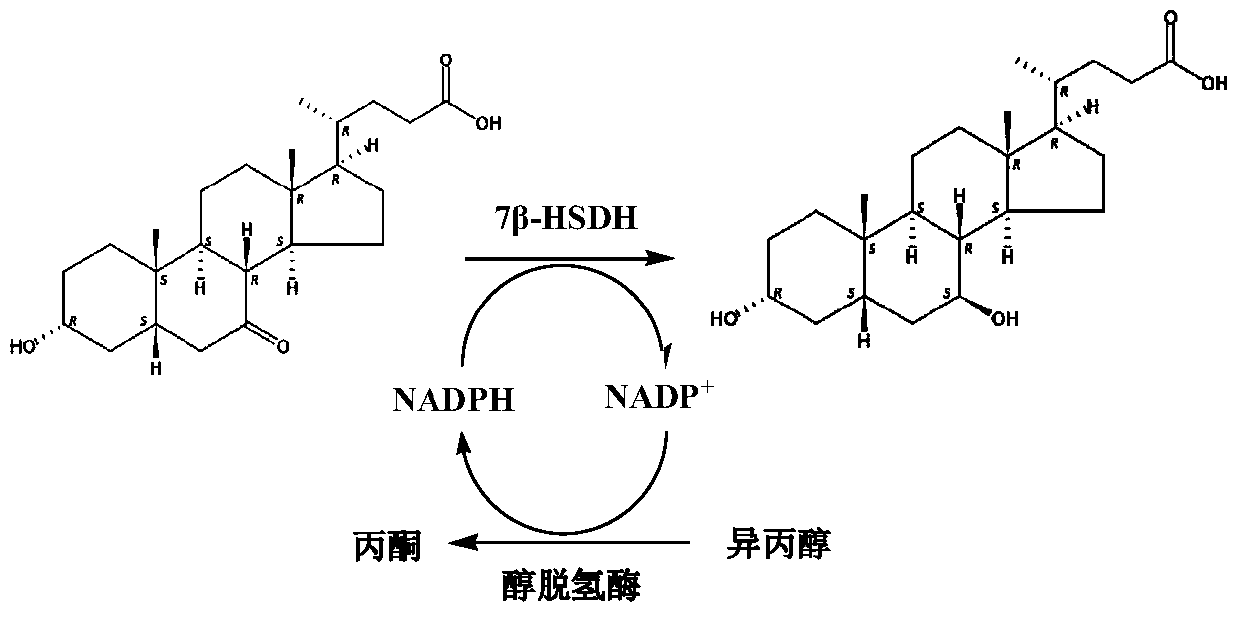

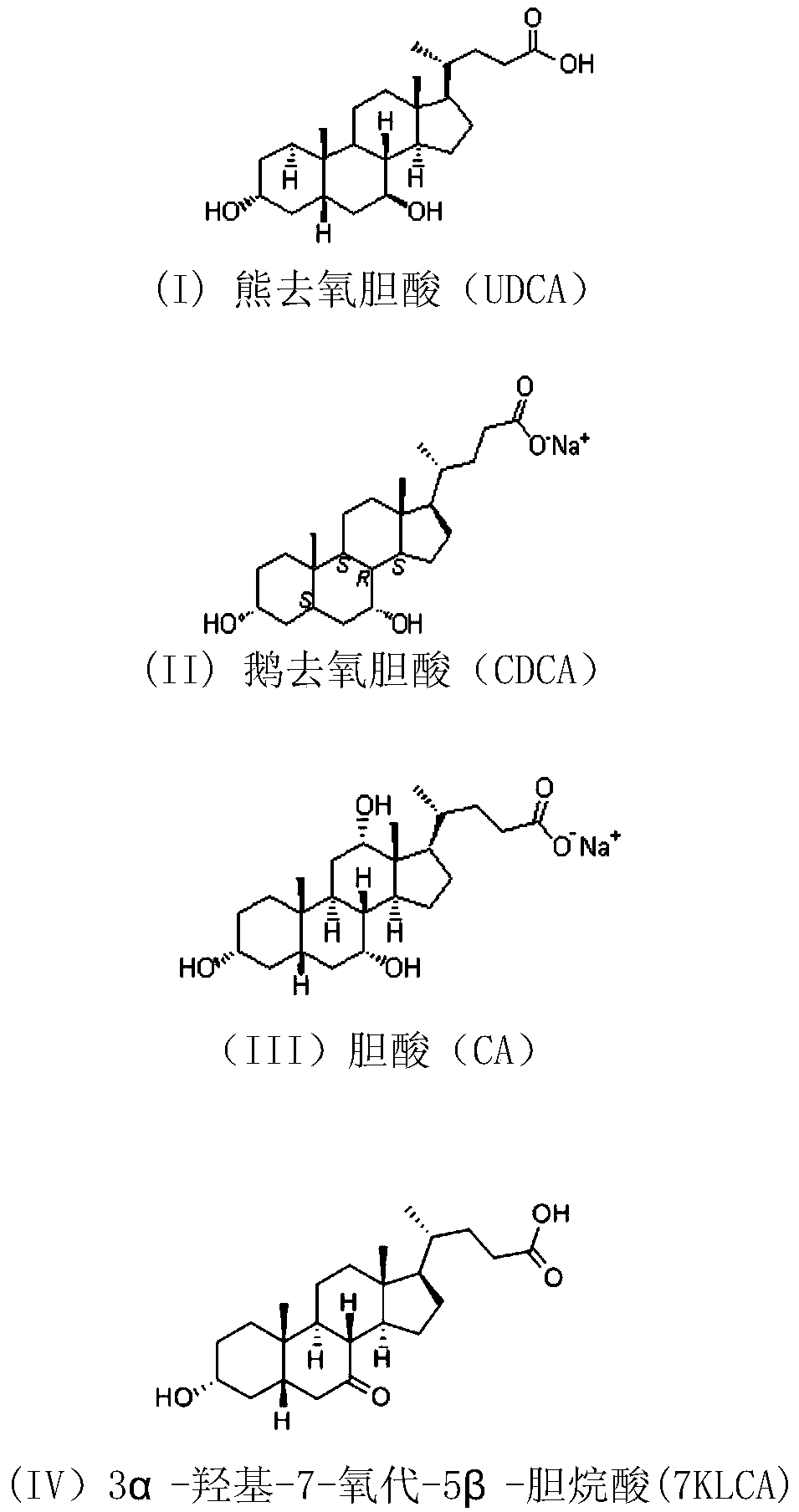

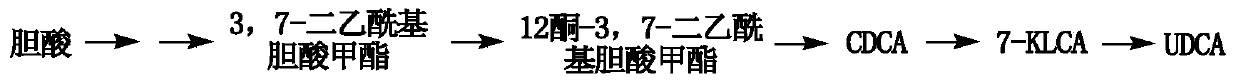

7β-hydroxysteroid dehydrogenase mutant, its application and synthesis method

ActiveCN105274070BIncreased weight yieldSuitable for industrial productionOxidoreductasesFermentationCholic acidChemical synthesis

Owner:苏州天绿生物制药有限公司

Production method of propylene

ActiveCN103420759BIncrease profitIncreased weight yieldHydrocarbon by metathesis reactionButeneButane

Owner:CHINA PETROLEUM & CHEM CORP +1

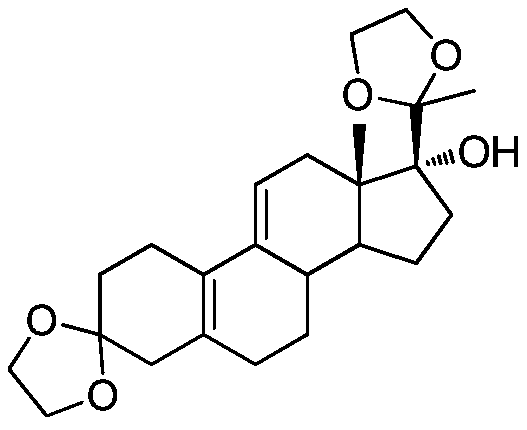

The method for preparing uliplast acetate bisketal

Owner:台州仙琚药业有限公司

Method for preparing phosphate eritrocina using eritrocina

ActiveCN1807443ANot easy to precipitateIncreased weight yieldSugar derivativesSugar derivatives preparationOrganic solventPhosphate

The invention relates to a Method for preparation of erythrocin salt, especially a method on using erythrocin to prepare phosphoric acid erythrocin. The characters are: dissolving erythrocin in organic solventn or water of c2-c6 containing hydroxyl group and carbonyl group, agitating, controlling the reaction temperature of forming salt, carrying through synthesize reaction by dripping phosphoric acid solution to regulate the solution's pH value and control reflecting terminal, finally, getting phosphoric acid erythrocin finished product after separation and desiccation. Its technology is advanced, the hazardness for people and circumstance is small, the productivity is high, the cost is low.

Owner:XIAN LIJUN PHARMA CO LTD

Catalytic cracking method

This invention describes a process for catalytic pyrolysis, comprising the steps of: (1) introducing the reactants into a pre-heater, wherein the reactants are vaporized into gases; (2) introducing the mixed solutions containing ultrafine or nanoscale catalyst into the pipeline between the pre-heater and the reactor, or directly into the reactor, wherein the said ultrafine or nanoscale catalyst is uniformly mixed with the process (1) wherein said gaseous reactants; (3) pyrolysis of the said uniform mixture in the reactor. The average diameter of the said ultrafine or nanoscale catalyst is in the range of 1nm-100mum. This invention resolves such problems existing in the present fixed-bed reaction process as easy carbonization of the catalyst, a short service periodic and frequent need for recovery. The process of this invention is easy to operate, and suitable for a wide variety of catalytic pyrolysis reactions. Compared with the present pyrolytic process, the process of this invention can increase the weight yield rate of ethylene+propylene+butadiene by at least 5%, while the equipment remains the same with only a feeding pipeline added.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of propylene

ActiveCN103539613AIncrease profitIncreased weight yieldHydrocarbon by metathesis reactionDisproportionationButane

The invention relates to a production method of propylene, which mainly solves the problem that ethylene is to be consumed in the prior art. Due to the adoption of the technical scheme of obtaining a product propylene by a carbon 4 raw material comprising 1-butene, 2-butene, iso-butane and n-butane through a disproportionation reactor, an ethylene removing tower, a propylene removing tower and an extraction flow, the production method of the propylene can be used for industrialized production of preparing the propylene by carbon 4.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing rocuronium bromide midbody compound crystal

Owner:ZHEJIANG XIANJU PHARMA

Method for producing propylene from C5

ActiveCN104557398AOptimize the marketSave hydrogenHydrocarbon by isomerisationHydrocarbon by metathesis reactionHydrogenIsomerization

The invention relates to a method for producing propylene from C5 and mainly aims at solving the problem of low yield of propylene by weight in the prior art. The problem is well solved by use of the following technical scheme: the method for producing propylene from C5 is adopted and cracked C5 and ethylene are taken as raw materials; the method comprises the following steps: feeding the cracked C5 fraction into a cyclopentadiene removal unit, feeding a C5 material flow removed from the cyclopentadiene and obtained after reaction separation into a selective hydrogenation reactor, performing selective hydrogenation on a diolefin to obtain monoolefines in the presence of a hydrogenation catalyst and hydrogen, mixing the obtained monoolefine C5 material with the ethylene, next, treating by use of an adsorbent, performing a contact reaction on the obtained adsorbed material flow in the presence of an isomerization catalyst and a disproportionation catalyst to obtain a material flow containing the product propylene and the non-reacted ethylene and C5, and separating to obtain the propylene; and the method is applicable to the industrial production of producing propylene from C5.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com