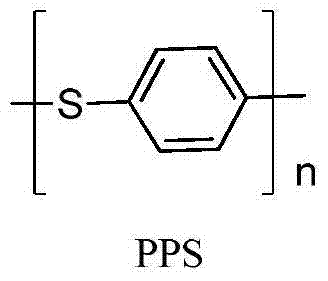

Improved synthesis method of polyphenylene sulfide

A polyphenylene sulfide and synthesis method technology, applied in the field of engineering plastics, can solve problems such as difficulties in actual production and application, slow polymerization reaction speed, high content of low polymer chains, etc., to achieve favorable mechanical properties, improve performance, and increase weight-average molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

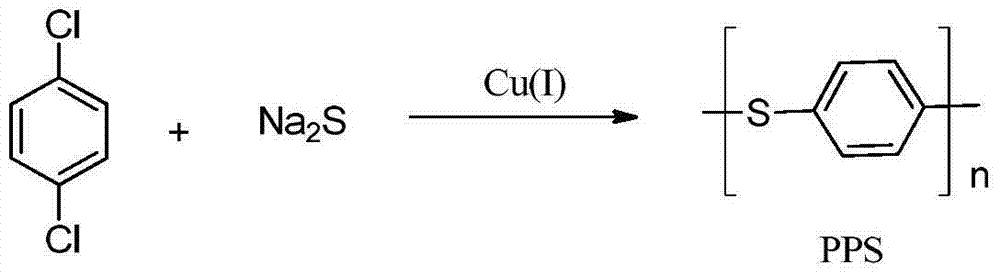

Method used

Image

Examples

Embodiment 1

[0016]

[0017] At room temperature, add 14.6g (0.1mol) of p-dichlorobenzene, sodium sulfide hydrate (0.1mol), CuCl (99mg, 1mmol), and NMP (120ml) into the autoclave, and heat it to about 150°C to 160°C. The reaction is initiated, and the internal temperature can reach up to 220°C (reaction exotherm), keep at 180°C for 2 hours, heat up to 260-280°C for 2 hours, cool to room temperature, filter, wash the filter cake with NMP (20ml×2), water Washing until the conductivity remains unchanged, drying, the weight yield is 94.2%, the product has a molecular weight of 80,000-100,000 accounting for 78.5% (weight ratio, the same below), and the weight average molecular weight is 89,300.

[0018] Using the same method, using CuBr, CuI, and CuOAc as raw materials, the yield and molecular weight distribution obtained are shown in Table 1.

[0019] Table 1 Effect of different copper salts on the reaction results

[0020]

[0021] The experimental results show that: a variety of coppe...

Embodiment 2

[0023] Adopt the mode of embodiment 1, change the sodium sulfide (number of moles constant) with different water content, the results are shown in Table 2.

[0024] Table 2 Effect of water content in sodium sulfide on reaction results

[0025]

[0026] The research results show that: sodium sulfide with different water content can get more ideal results.

Embodiment 3

[0028] At room temperature, add CuCl (99 mg, 1 mol), cis-cyclohexanediamine (125.4 mg, 1.1 mmol), and NMP (5 mL) into a round bottom flask and heat to 80 ° C. After 30 min of incubation, the solution is transferred to the reaction kettle 14.6g (0.1mol) of p-dichlorobenzene, 7.8g (0.1mol) of sodium sulfide, and NMP (115ml) were added to the kettle, and the reaction was initiated by heating to about 150°C to 160°C. 220°C (exothermic reaction), keep warm at 180°C for 2 hours, heat up to 260-280°C and keep warm for 2 hours, cool to room temperature, filter, wash the filter cake with NMP (20ml×2), wash with water until the conductivity remains unchanged, and dry Drying, the yield is 94.3%, the part with molecular weight of 80,000-100,000 in the product accounts for 84.1%, and the weight average molecular weight is 93,700.

[0029] Using the same method, tetramethylethylenediamine, N,N'-dimethylethylenediamine, trans-cyclohexanediamine, triphenylphosphine, 2,2'-bis(diphenylphosphine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com