Preparation method of atorvastatin calcium intermediate

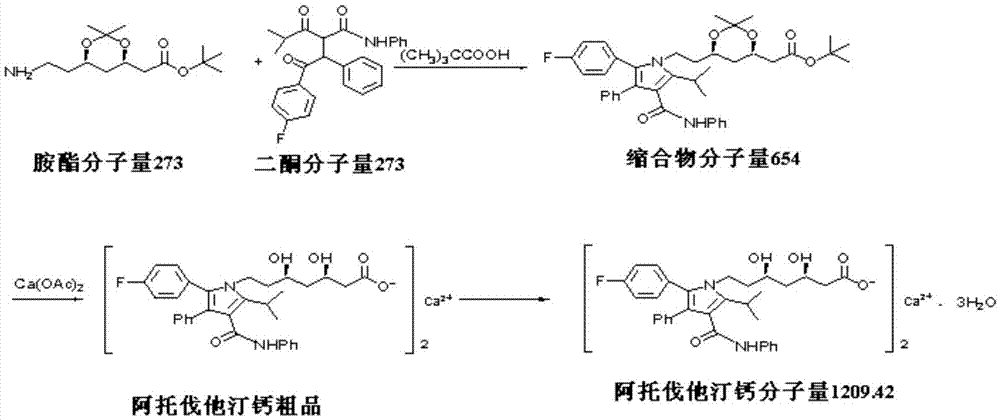

A technology of atorvastatin calcium and intermediates, which is applied in the field of preparation of atorvastatin, can solve the problems of complicated steps in the intermediate condensate treatment process, large consumption of organic solvents, production safety and the like, and achieves clean production, dangerous The effect of reducing and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

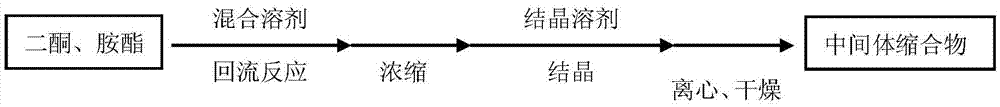

Method used

Image

Examples

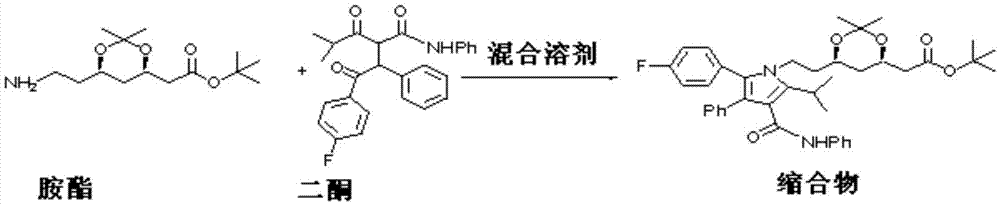

Embodiment 1

[0022] Add 16 g of amine ester and 20 g of diketone into a 250 ml reaction flask and dissolve them in a mixed solvent consisting of 34 ml of n-heptane and 68 ml of tetrahydrofuran. The reaction is heated and refluxed for 40 hours. After the reaction is completed, the reaction solution is concentrated to remove the mixed solvent to obtain atorvastatin For the crude calcium intermediate, add 110ml of ethanol to dissolve and clarify the crude intermediate, add 64ml of purified water, cool to 50°C to precipitate the material, and centrifuge to obtain 25.1g of the intermediate. The weight yield relative to the diketone is 125.5%. The HPLC purity is 99.0%.

Embodiment 2

[0024] Add 16g of amine ester and 20g of diketone to a 250ml reaction flask and dissolve them in a mixed solvent consisting of 34ml of n-heptane and 85ml of tetrahydrofuran. The reaction is heated and refluxed for 36 hours. After the reaction is completed, the reaction solution is concentrated to remove the mixed solvent to obtain atorvastatin For the crude calcium intermediate, add 64ml of ethanol to dissolve and clarify the crude intermediate, add 48ml of purified water, cool to 75°C to precipitate the material, and centrifuge to obtain 25.3g of the intermediate condensate, with a weight yield of 126.5% relative to the diketone. , HPLC purity is 99.0%.

Embodiment 3

[0026] Add 16 g of amine ester and 24 g of diketone into a 250 ml reaction flask and dissolve them in a mixed solvent consisting of 34 ml of n-heptane and 85 ml of tetrahydrofuran. The reaction is heated and refluxed for 50 hours. After the reaction is completed, the reaction solution is concentrated to remove the mixed solvent to obtain atorvastatin For the crude calcium intermediate, add 80ml ethanol to make the crude intermediate dissolve and clarify, add 32ml purified water, cool to 70°C to precipitate the material, centrifuge and filter to obtain 25.2g intermediate condensate, relative to the weight yield of diketone 126.0% , HPLC purity is 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com