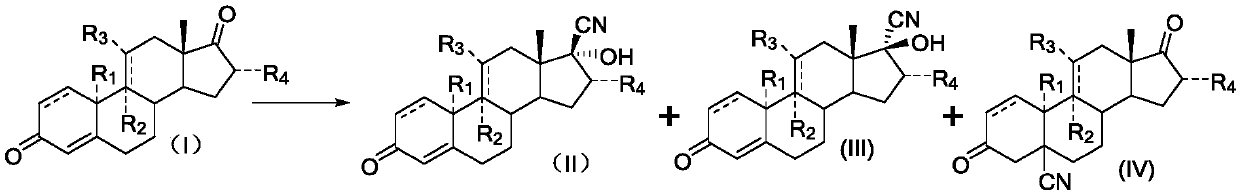

A synthetic method of 17alpha-hydroxy-17beta-cyano-steroid compounds

A technology of steroidal compounds and synthetic methods, which is applied in the field of synthesis of 17αhydroxyl-17βnitrile-steroidal compounds, can solve problems such as incomplete reaction and long reaction time, and achieve product quality improvement, quality and yield improvement, The effect of solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]

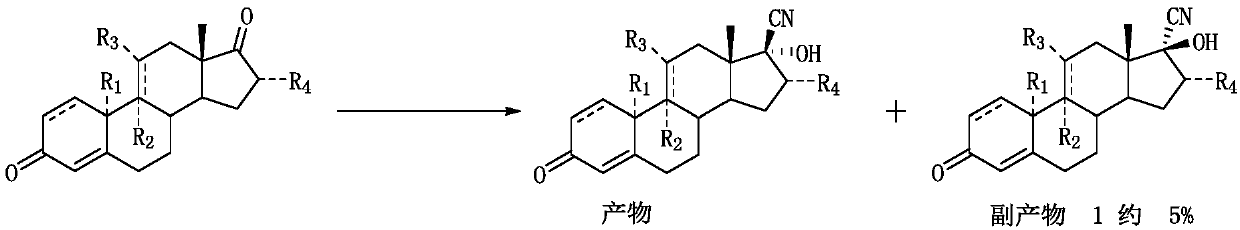

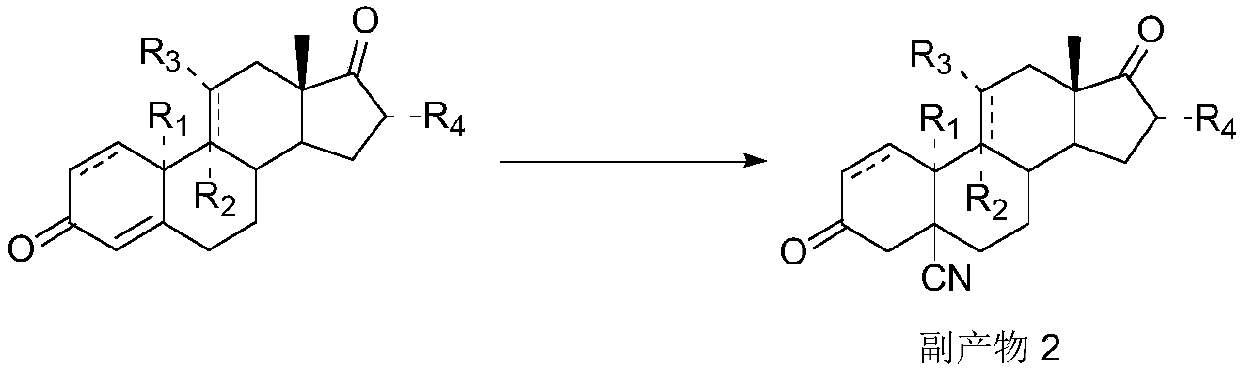

[0023] Take a three-necked reaction flask, add 100g of compound (I-1), add 90g of methanol, heat up to 30-32°C, add 1g of 3-butene-2-ketone, then add 80g of acetone cyanohydrin and stir for 3min, add the prepared 3 % potassium carbonate aqueous solution 200ml. Insulated for 30 hours, the raw materials were basically completely reacted by sampling. After cooling down to 0-5°C, stir for 30 minutes. Suction filtration, wash the filter cake with a small amount of water until neutral, and dry to obtain 104.9 g of the product, with a mass yield of 104.9%. HPLC content: compound (II-1) 98.2%, compound (III-1) 0.8%, compound (IV-1) 0.5%.

Embodiment 2

[0025]

[0026] Take a three-necked reaction flask, add 100g of compound (I-2), add 100g of methanol, heat up to 29-31°C, add 1g of 3-butene-2 ketone, then add 80g of acetone cyanohydrin and stir for 3min, add dropwise 3% 200ml of sodium carbonate aqueous solution. Insulated for 32 hours, the raw materials were basically completely reacted by sampling. After cooling down to 0-5°C, stir for 30 minutes. Suction filtration, wash the filter cake with a small amount of water until neutral, and dry to obtain 105.1 g of the product, with a mass yield of 105.1%. HPLC content: compound (II-2) 98.4%, compound (III-1) 0.6%, compound (IV-1) 0.5%.

Embodiment 3

[0028]

[0029] Take a three-necked reaction flask, add 100g of compound (I-3), add 110g of methanol, heat up to 32-33°C, add 1g of 3-buten-2-ketone, then add 90g of acetone cyanohydrin and stir for 3min, add the prepared 3% 200ml of sodium carbonate aqueous solution. Insulated for 31 hours, the raw materials were basically completely reacted by sampling. After cooling down to 0-5°C, stir for 30 minutes. Suction filtration, wash the filter cake with a small amount of water until neutral, and dry to obtain 105.3 g of the product, with a mass yield of 105.3%. HPLC content: compound (II-3) 98.3%, compound (III-3): 0.7%, compound (IV-3) 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com