Production method of propylene

A production method and propylene technology, applied in the field of propylene production, can solve the problems of ethylene consumption and the like, and achieve the effects of improving utilization rate, improving economic benefits, and improving technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

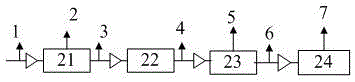

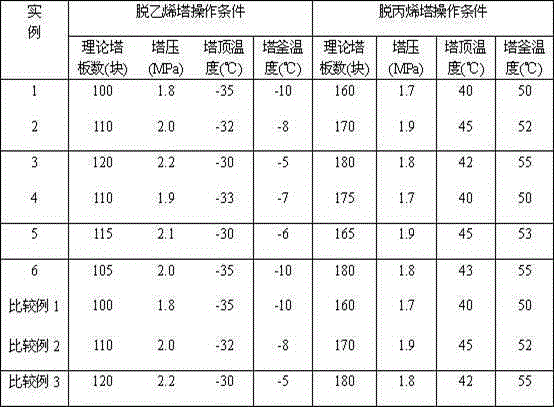

[0020] according to figure 1 In the process flow shown, the extractant is a mixed solvent of nitrogen-formylmorpholine and methyl ethyl ketone, and the weight ratio is 1:1; the disproportionation catalyst in the disproportionation reactor is 8% WO 3 / SiO 2 , the operating conditions are: reaction temperature 300°C, reaction pressure 3MPa in absolute pressure, mass space velocity of C4 2h -1 . The operating conditions of the extraction process are shown in Table 1, the operating conditions of the deethylene tower and the depropylene tower are shown in Table 2, and the reaction results are shown in Table 3.

Embodiment 2~6

[0022] React by each condition and step of embodiment 1, just change different operating parameters, the operating condition of extraction process is as shown in table 1, the operating condition of deethylene tower and depropylene tower is as shown in table 2, its reaction conditions and The reaction results are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com