A kind of preparation method of cefotetan acid

A technology for cefotetan acid and cefotetan, which is applied in the field of preparation of cefotetan acid, can solve problems such as low weight yield, and achieve the effects of high product purity, good application prospect and good color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

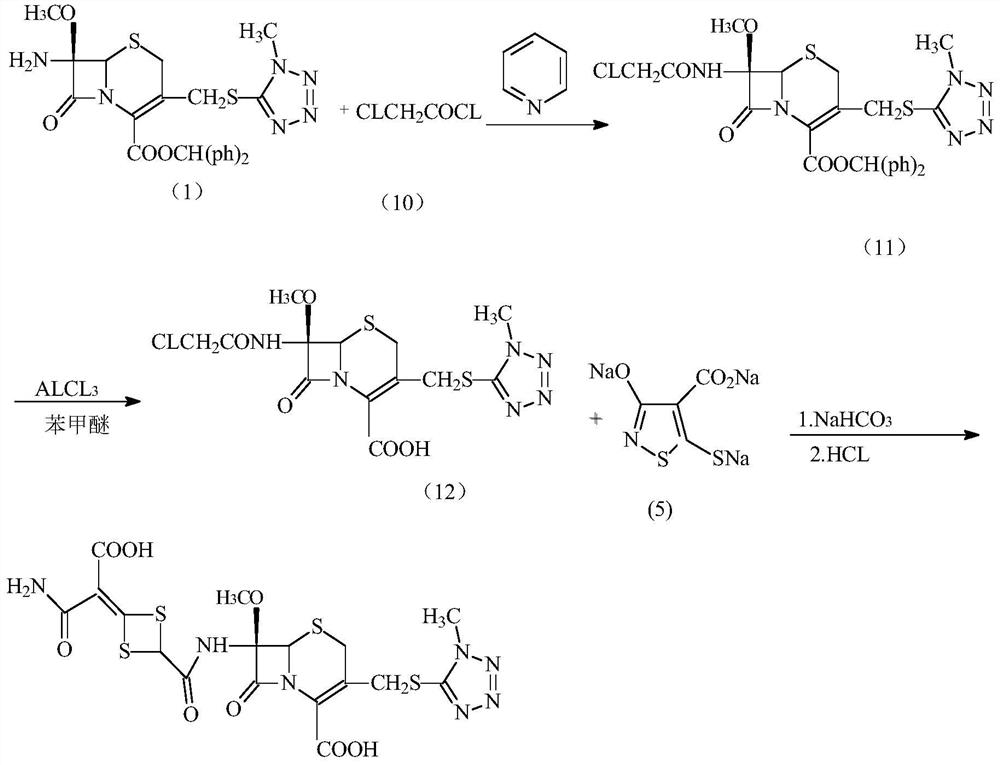

Method used

Image

Examples

preparation example Construction

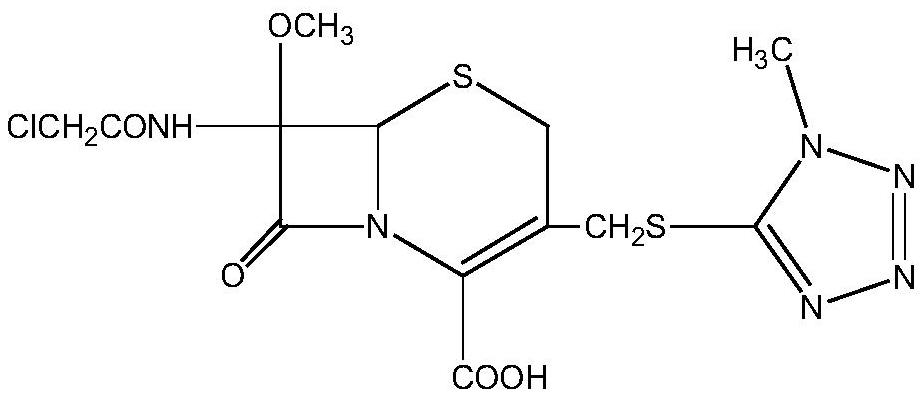

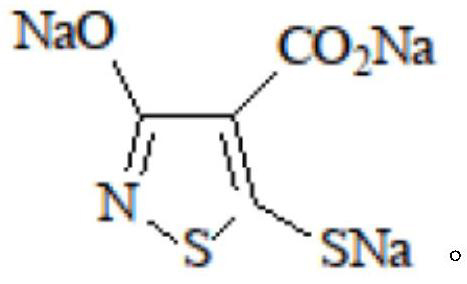

[0025] A preparation method of cefotetan acid, comprising the following steps:

[0026] 1) Add water into the reaction tank, cool down to 0-6°C, start stirring, then add 7-MCTT (structural formula 12), sodium bicarbonate, cefotetan side chain (trisodium isothiazole), stir to dissolve;

[0027] 2) Control the temperature of the reaction liquid in the reaction tank to be 0-6°C, and react for 88-90 hours at a pH value of 7.5-8.0, wherein, when the reaction time reaches 48-56 hours, add the previous batch of secondary crystallized cephalosporins Titan salt dry powder;

[0028] 3) After the reaction, transfer the reaction solution to the extraction tank, adjust the pH value of the reaction solution to 4.0-5.0 with hydrochloric acid, add medicinal charcoal to the extraction tank, stir the carbon for 30-40 minutes, then filter and collect the filtrate;

[0029] 4) Add butanone to the filtrate, adjust the pH value of the feed solution to 1.5-2.0 with hydrochloric acid, stir for 15-25...

Embodiment 1

[0036] A preparation method of cefotetan acid:

[0037] 1) Add 250ml of water to the reaction tank, cool down to 3°C, start stirring, add 30g of 7-MCTT, 12g of sodium bicarbonate, 18.5g of cefotetan side chain, and stir to dissolve;

[0038] 2) Control the temperature of the reaction liquid in the tank to 3°C, and react at a pH value of 7.8 for 88 hours (after 52 hours of reaction time, add 4.5 g of the dry powder of cefotetan salt from the previous batch of secondary crystallization);

[0039] 3) After the reaction is finished, transfer the reaction solution to an extraction tank, and adjust the pH value of the reaction solution to 4.5 with hydrochloric acid. After the pH adjustment is completed, add 0.3 g of medicinal charcoal to the tank, stir for 35 minutes to remove the charcoal, and then filter;

[0040] 4) After the filtration, add 600 ml of methyl ethyl ketone to the filtrate, adjust the pH of the feed liquid to 1.8 with hydrochloric acid, stir for 20 minutes, then let...

Embodiment 2

[0046] A preparation method of cefotetan acid:

[0047] 1) Add 250ml of water into the reaction tank, cool down to 0°C, start stirring, add 30g of 7-MCTT, 12g of sodium bicarbonate, 18.5g of cefotetan side chain, and stir to dissolve;

[0048] 2) Control the temperature of the reaction solution in the tank to 0°C, and react at a pH value of 7.5 for 90 hours (after 48 hours of reaction time, add 5.5 g of the dry powder of cefotetan salt of the previous batch of secondary crystallization);

[0049] 3) After the reaction is finished, transfer the reaction solution to an extraction tank, and adjust the pH value of the reaction solution to 4.0 with hydrochloric acid. After the pH adjustment is completed, add 0.3 g of medicinal charcoal to the tank, stir for 30 minutes to remove the charcoal, and then filter;

[0050]4) After the filtration, add 600ml of methyl ethyl ketone to the filtrate, adjust the pH of the feed solution to 1.5 with hydrochloric acid, stir for 15 minutes, then l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com