Patents

Literature

46results about How to "Improve propylene yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

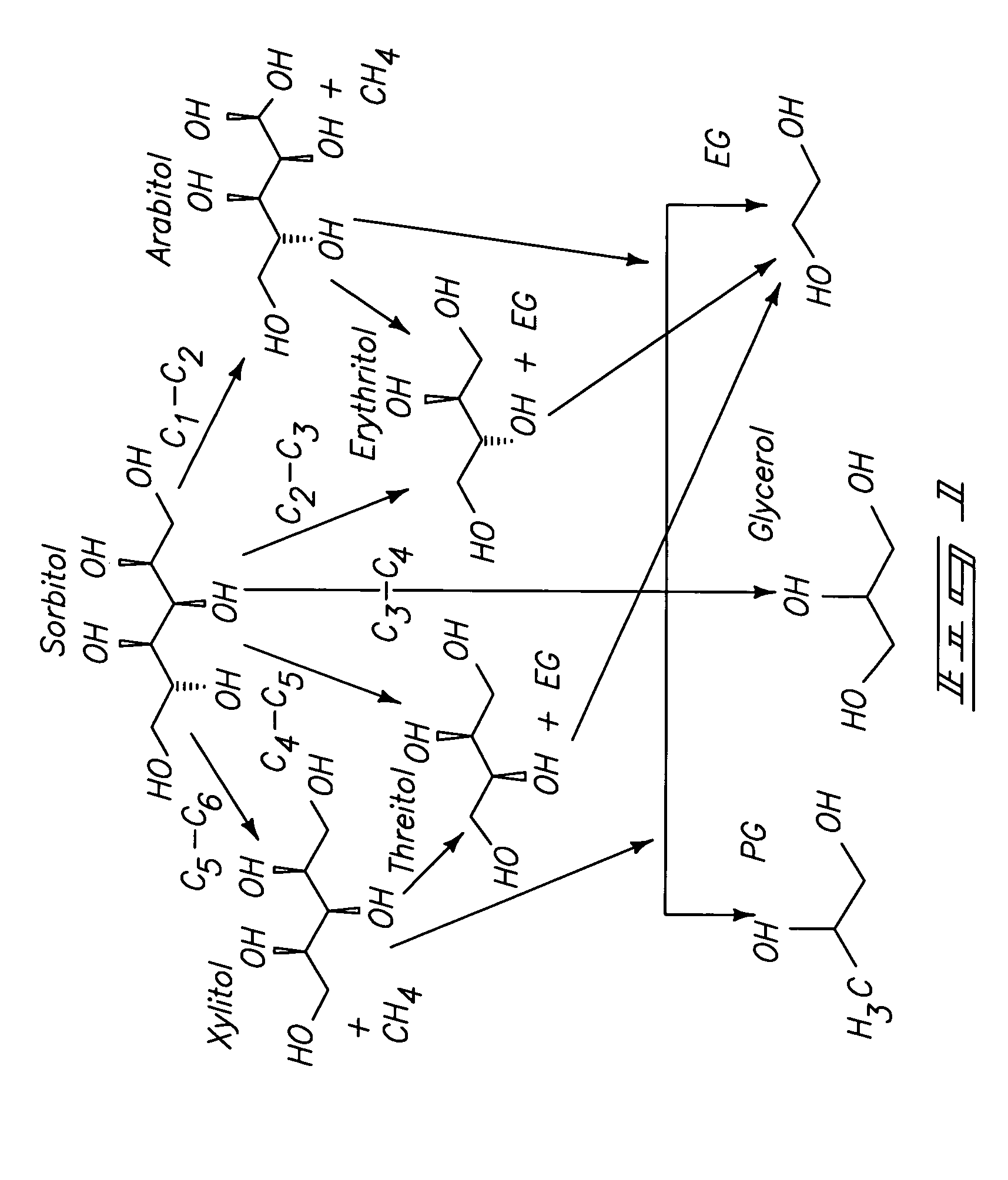

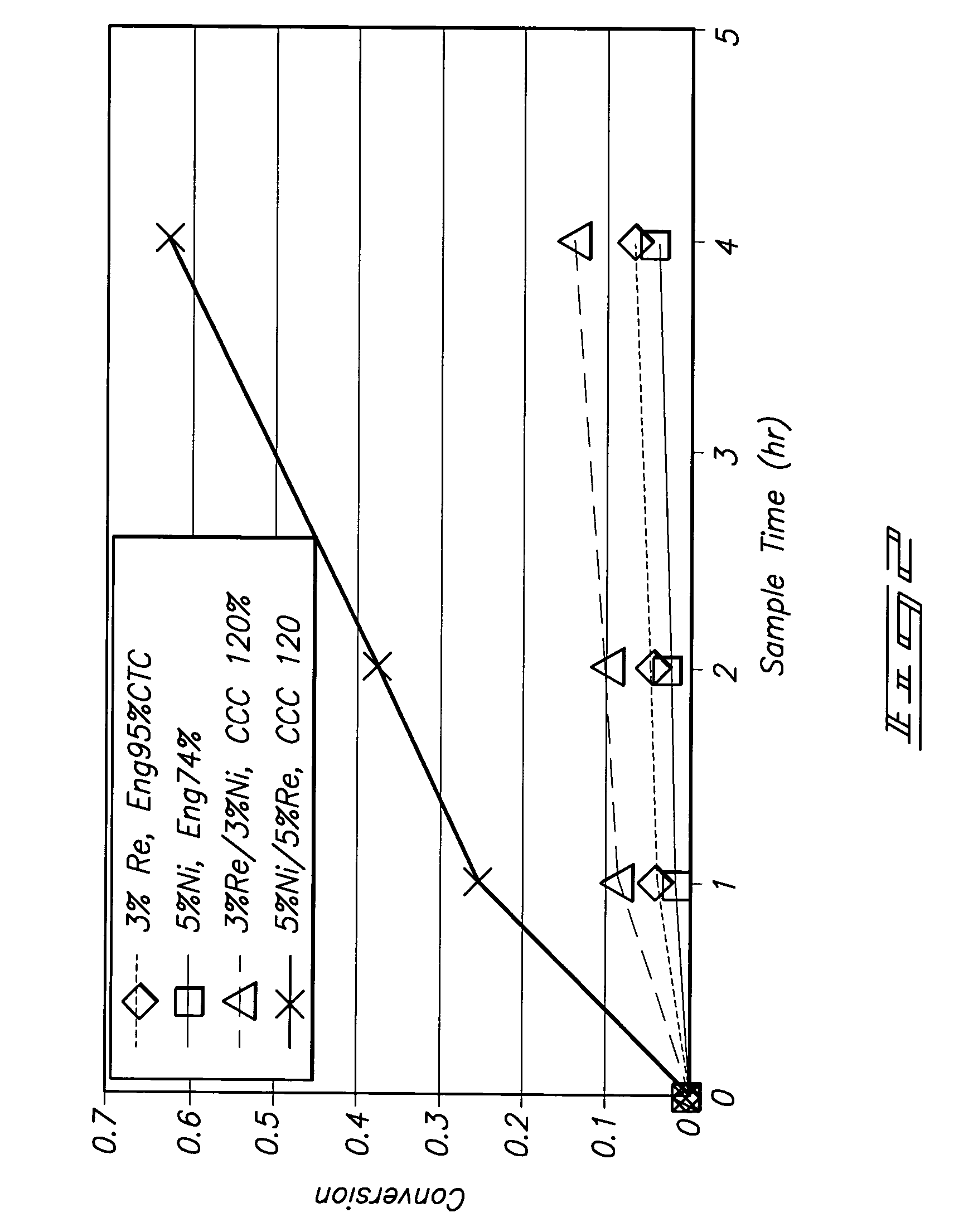

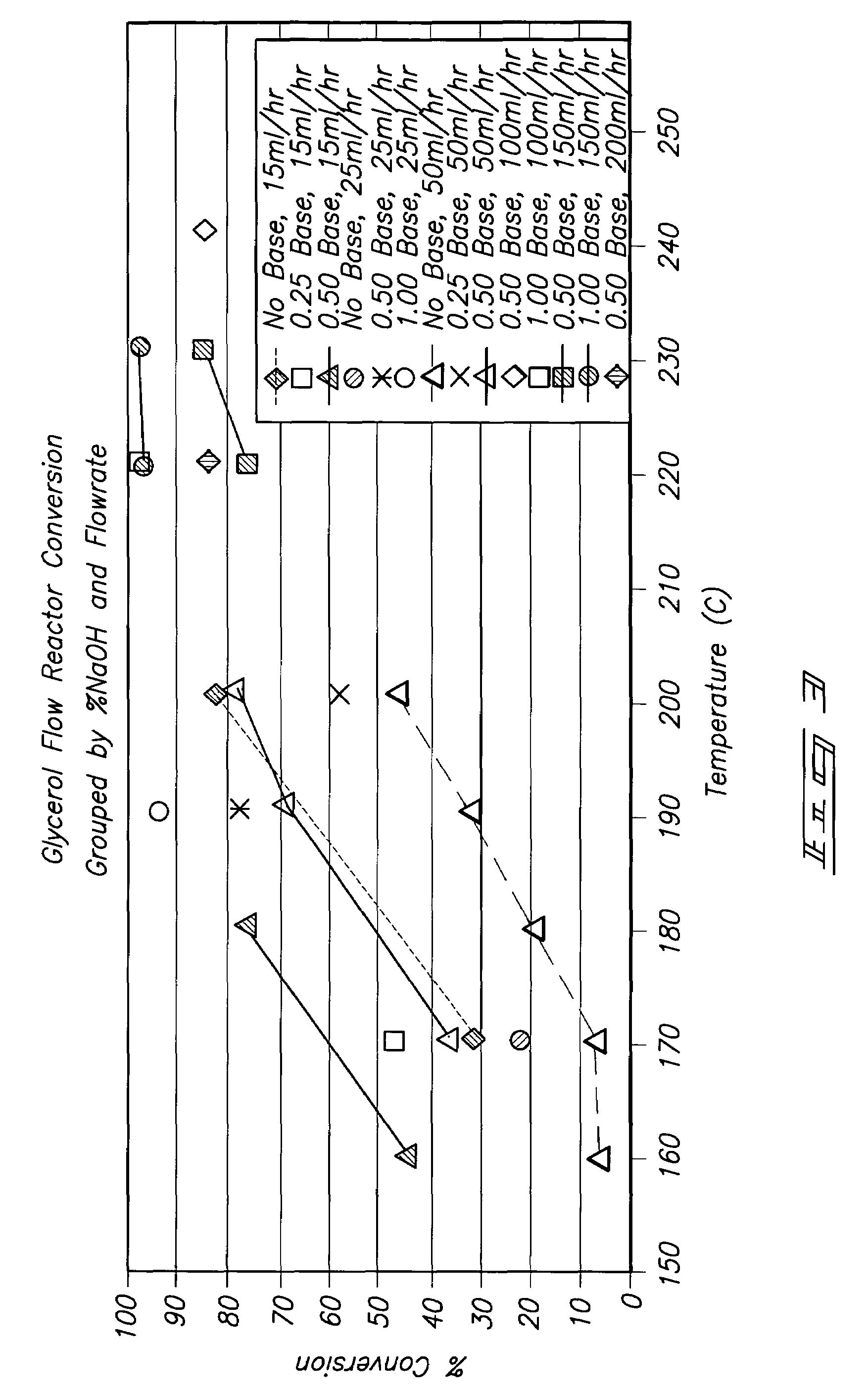

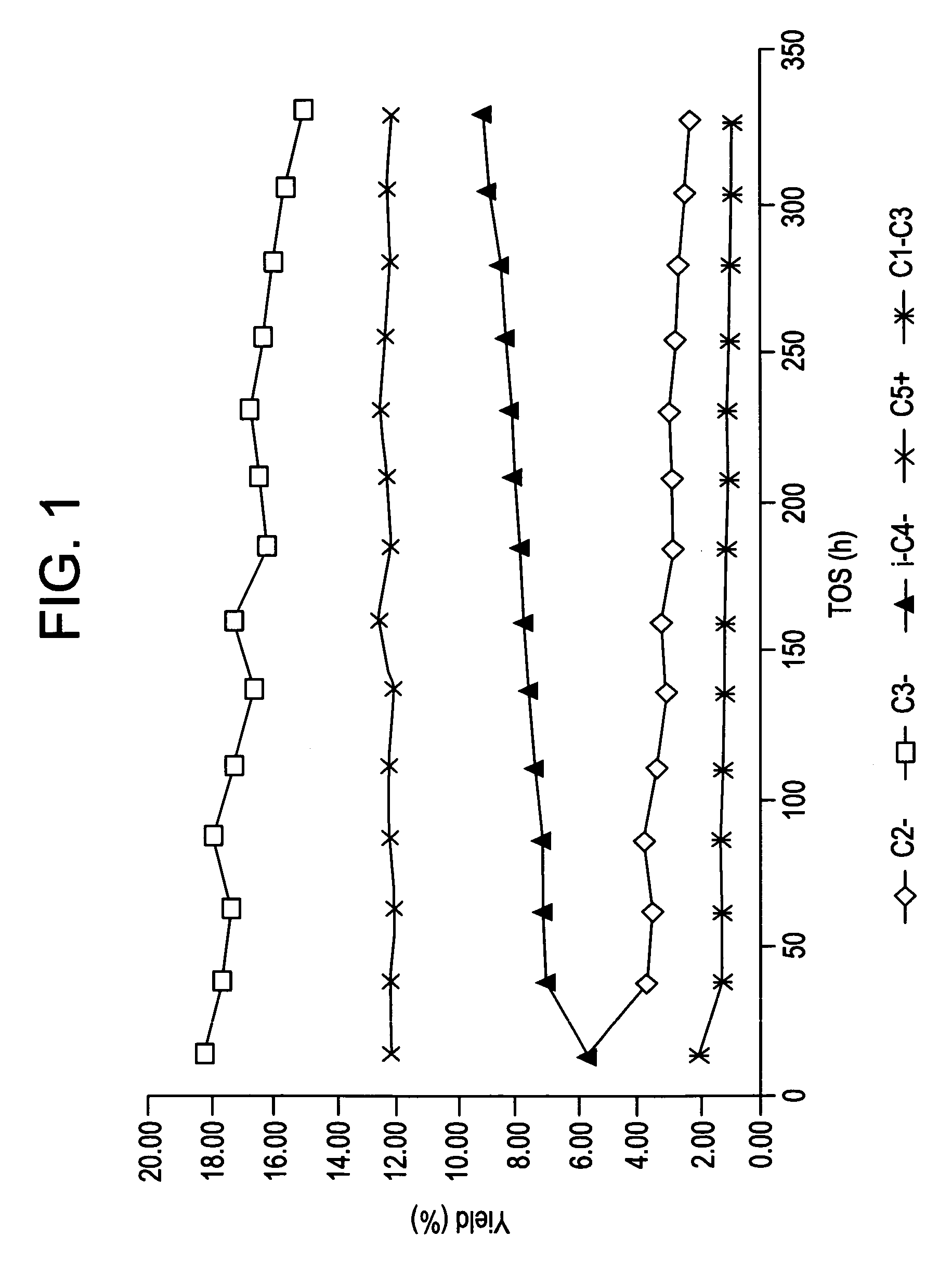

Hydrogenolysis of 5-carbon sugars, sugar alcohols, and methods of making propylene glycol

InactiveUS7038094B2High selectivityHigh activityOrganic compound preparationOxygen compounds preparation by reductionIsopropylene glycolPropylene glycol

Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 5-carbon sugar, sugar alcohol, or lactic acid are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol. A process for the synthesis of PG from lactate or lactic acid is also described.

Owner:BATTELLE MEMORIAL INST

Production of propylene

InactiveUS6977321B1Improve propylene yieldHigh purityCatalytic crackingMolecular sieve catalystsAlkeneSilicon

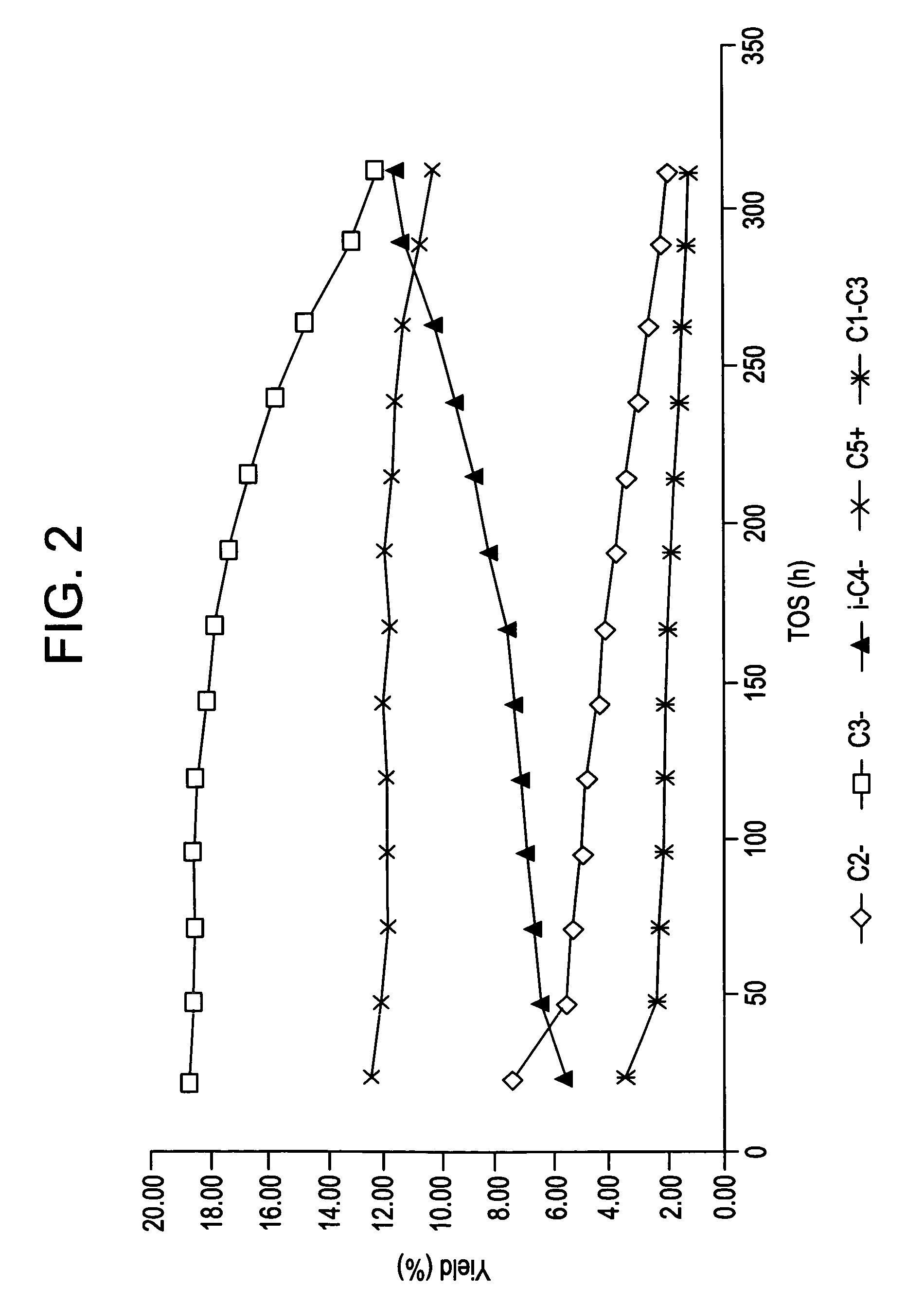

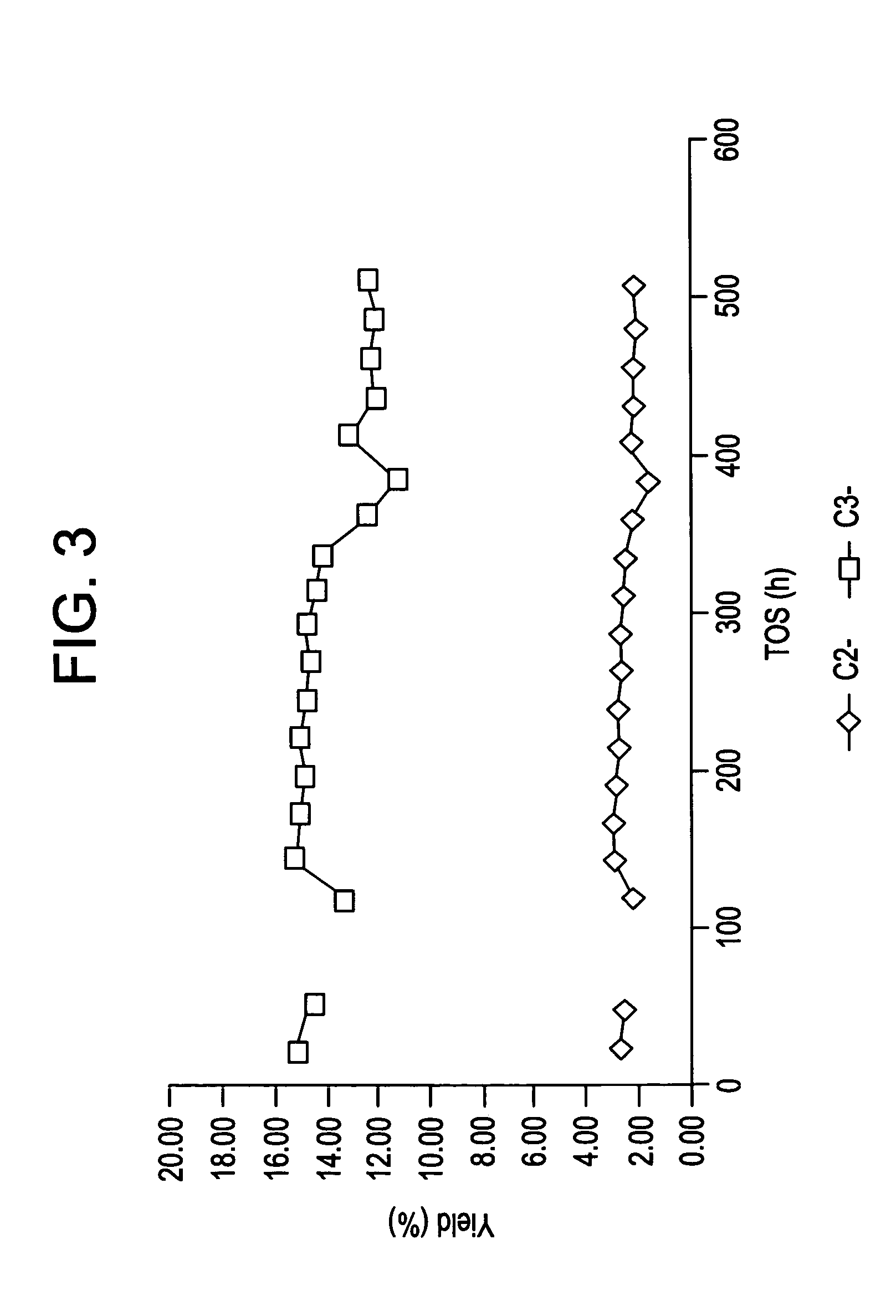

A process for the production of propylene from an olefinic feedstock containing at least one olefin of C4 or greater, the process comprising contacting the olefinic feedstock with a catalyst of the MFI-type having a silicon / aluminum atomic ratio of at least about 180 to produce an effluent containing propylene, the propylene yield on an olefin basis being from 30 to 50k based on the olefinic content of the feedstock.

Owner:FINA RES SA

Method of Producing Propylene Containing Biomass-Origin Carbon

InactiveUS20080312485A1Quality improvementSwitch-over frequencyMolecular sieve catalystsBiofuelsButeneDecomposition

Ethanol obtained from ordinary biomass resources contains many impurities other than water and these impurities themselves or their decomposition products contaminate ethylene when the ethylene is produced by a dehydration reaction, whereby the activity of metathesis catalyst is adversely affected. A method for producing propylene of the present invention is characterized in that the ethanol obtained from biomass is converted to ethylene by a dehydration reaction, the ethylene is separated from the generated water, the separated ethylene is purified by adsorption in an adsorption tower filled with an adsorbent, and then a metathesis reaction is carried out along with a raw material containing n-butene. With the present invention, propylene having biomass-derived carbon and reduced-environmental burden can be efficiently produced without lowering the catalysis activity.

Owner:MITSUI CHEM INC

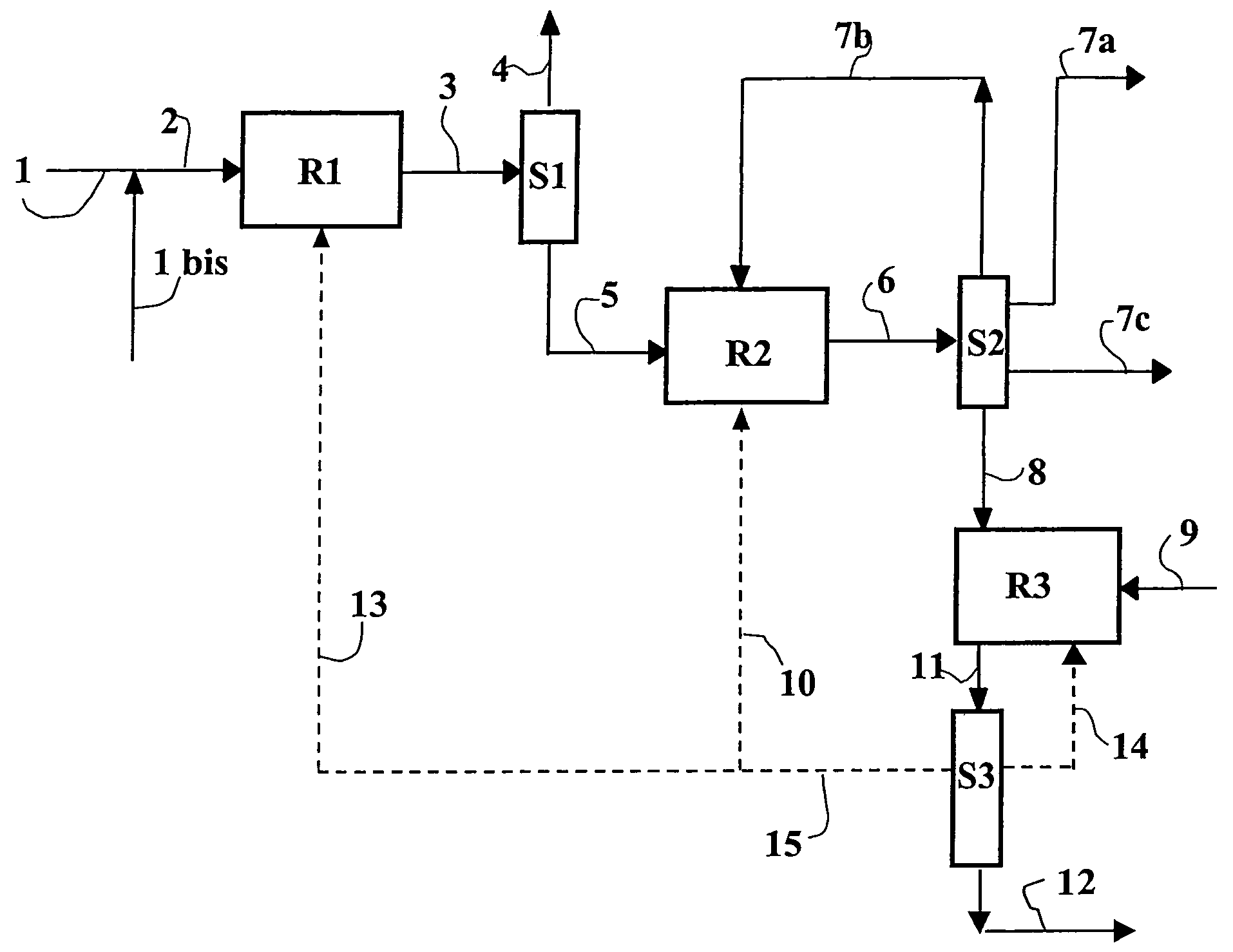

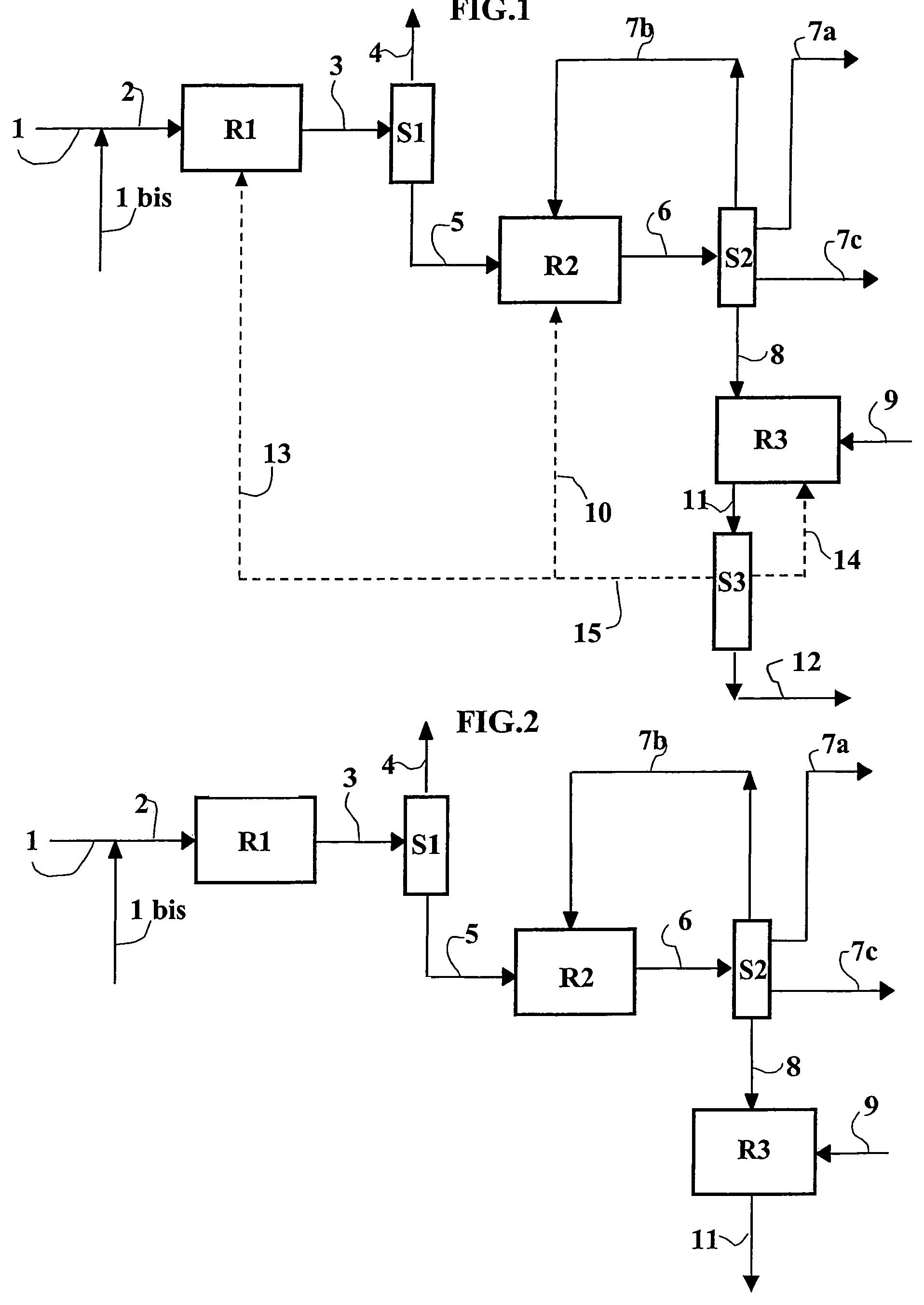

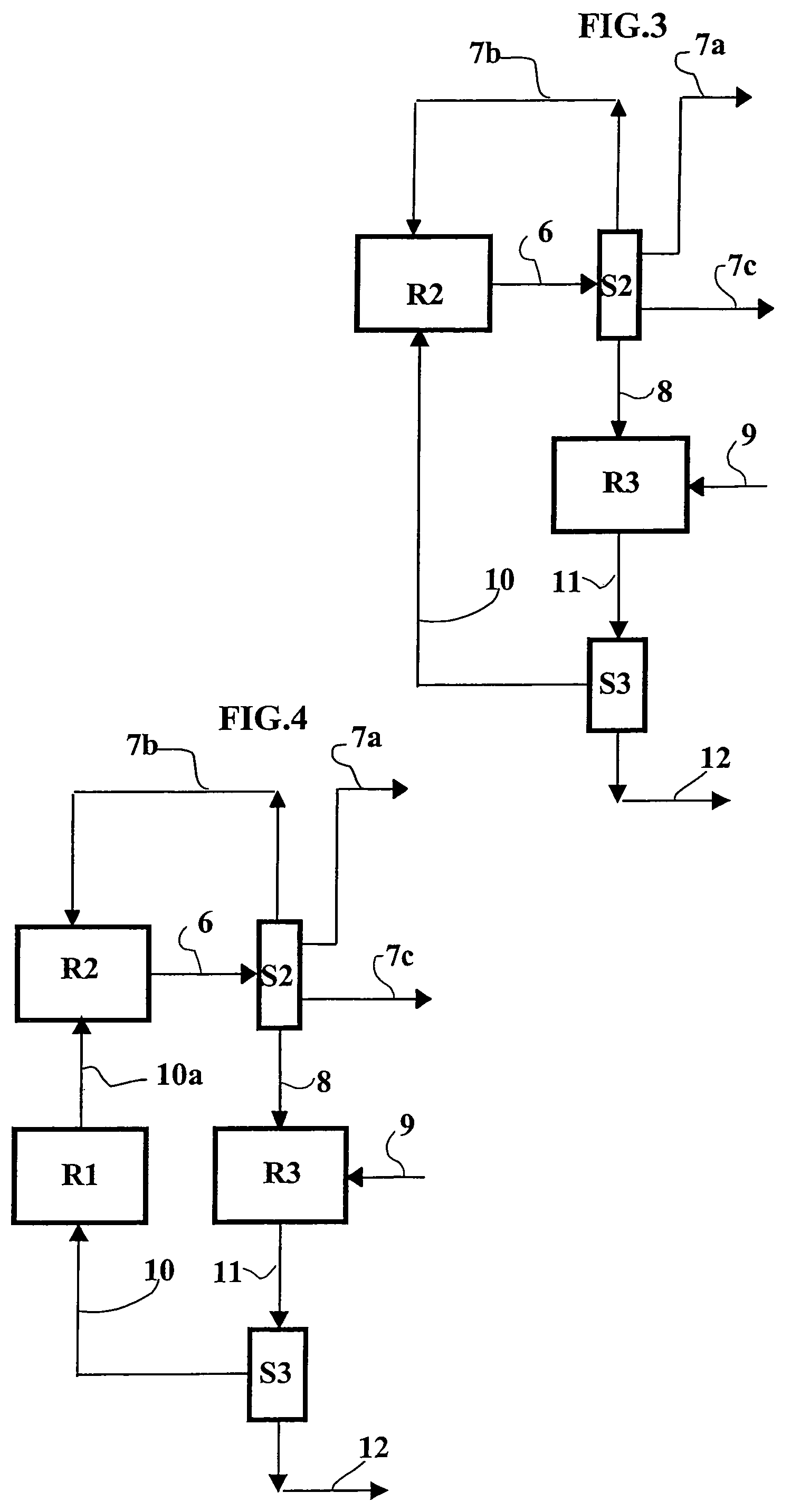

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS20050121361A1Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerBoiling point

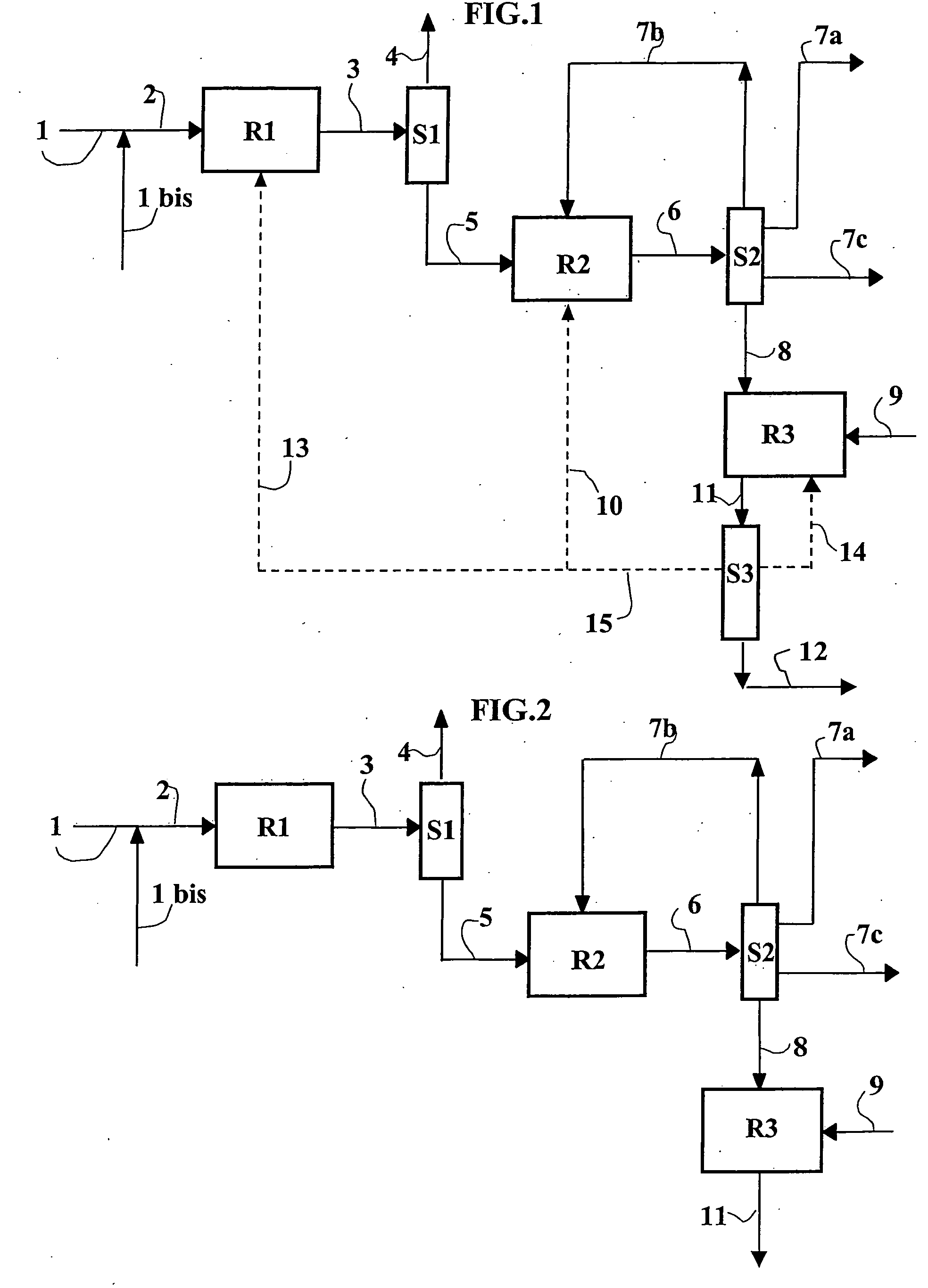

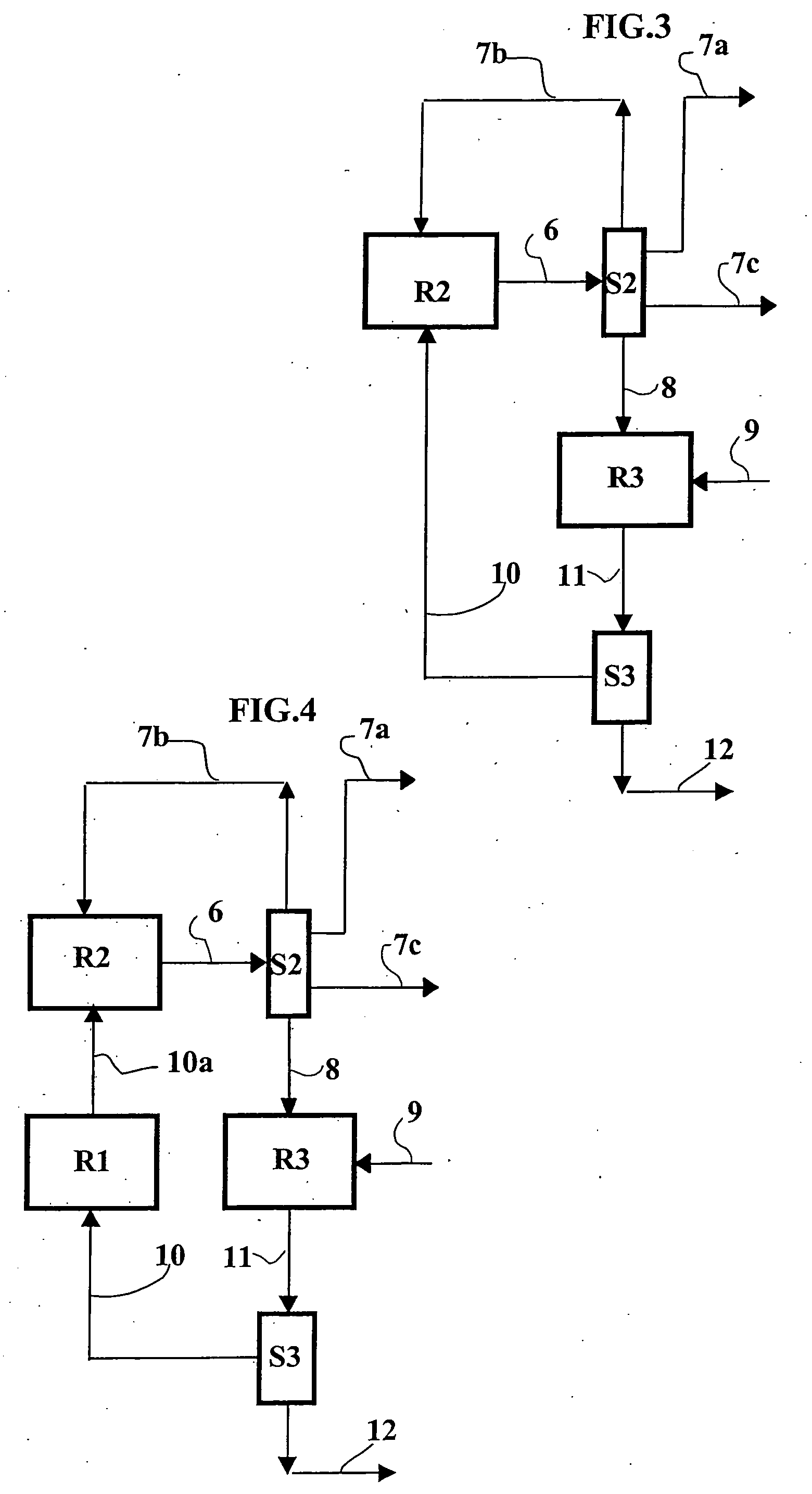

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein, the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst, the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS7374662B2Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerFluidized bed

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein,the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst,the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

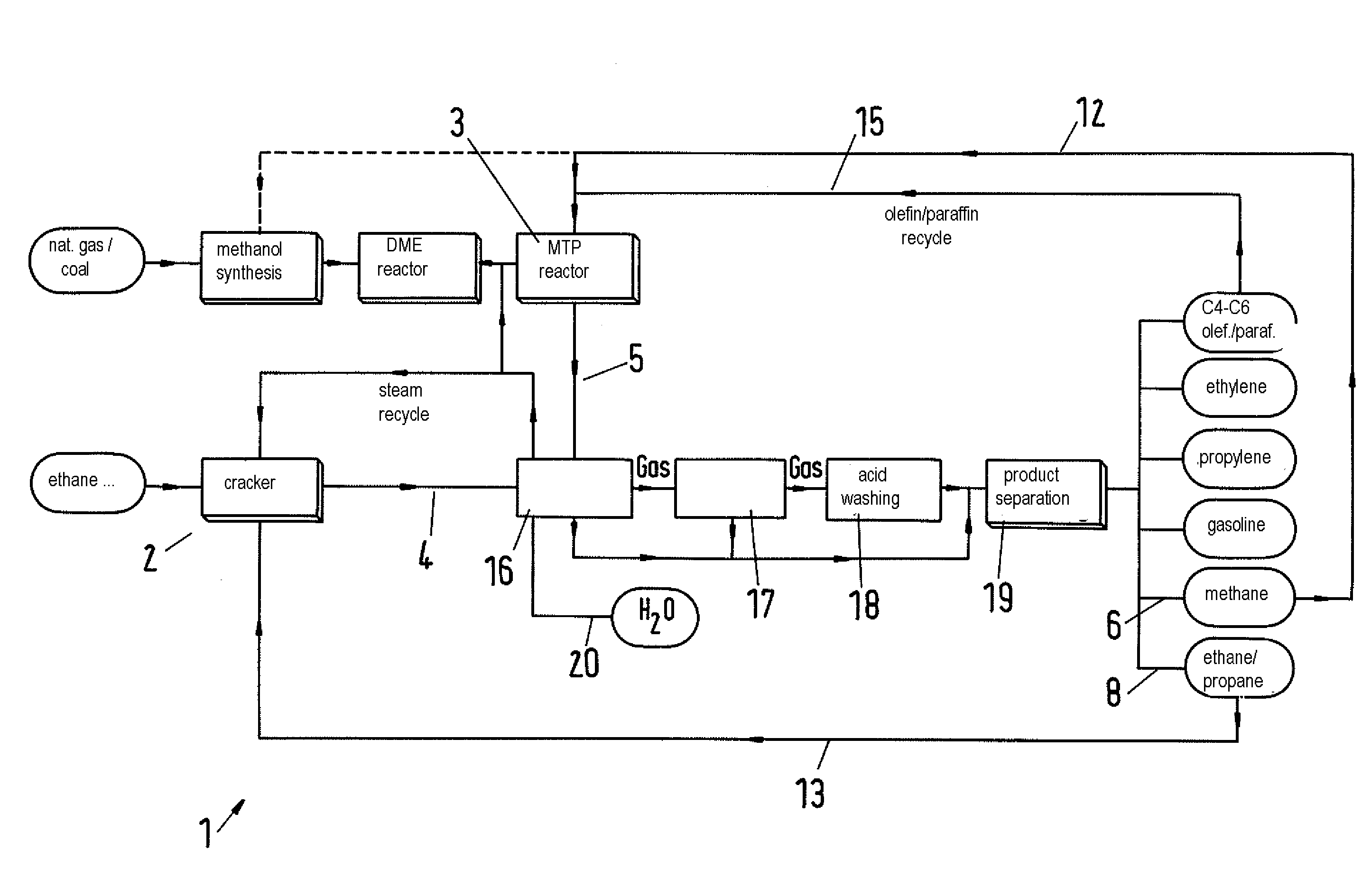

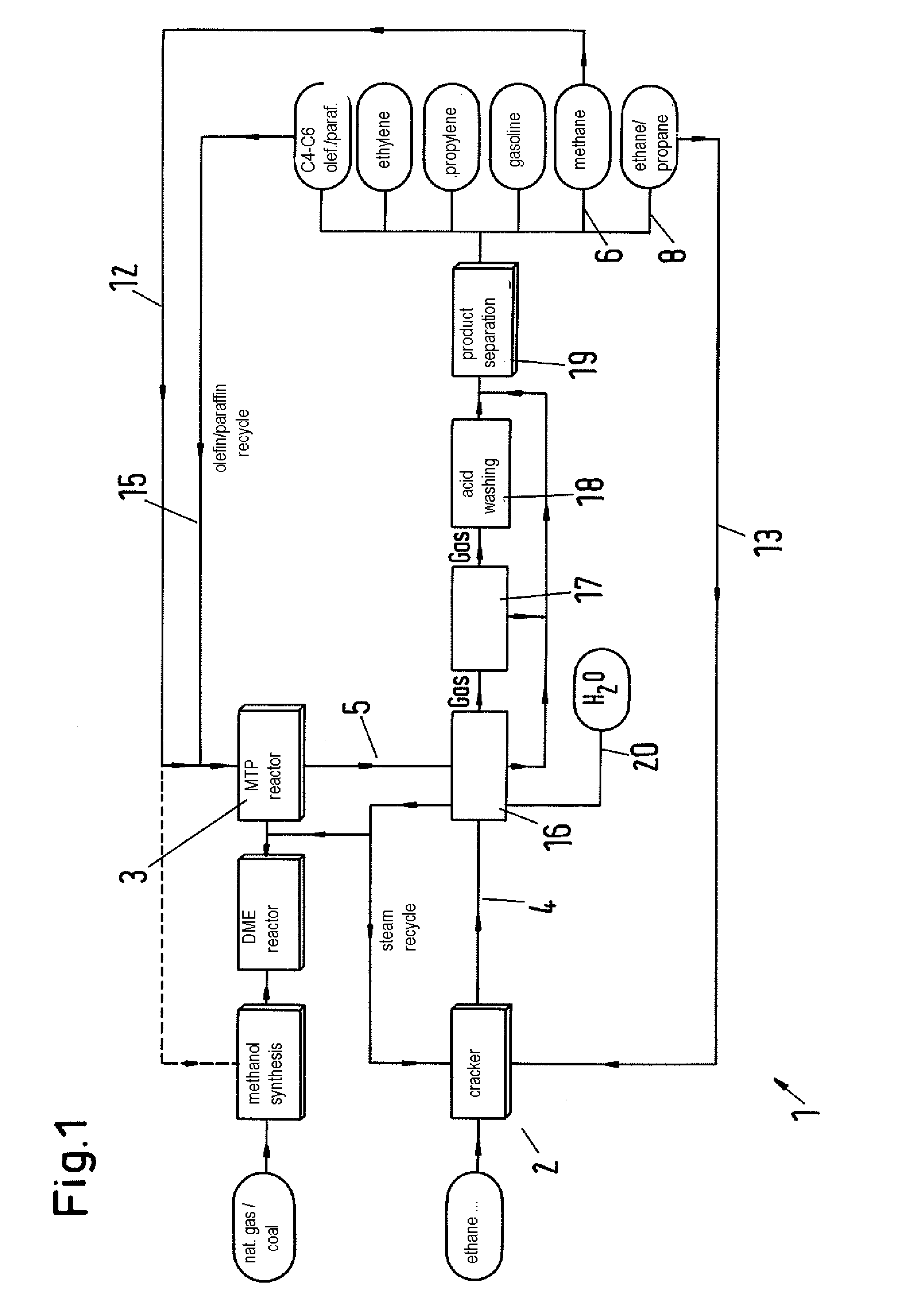

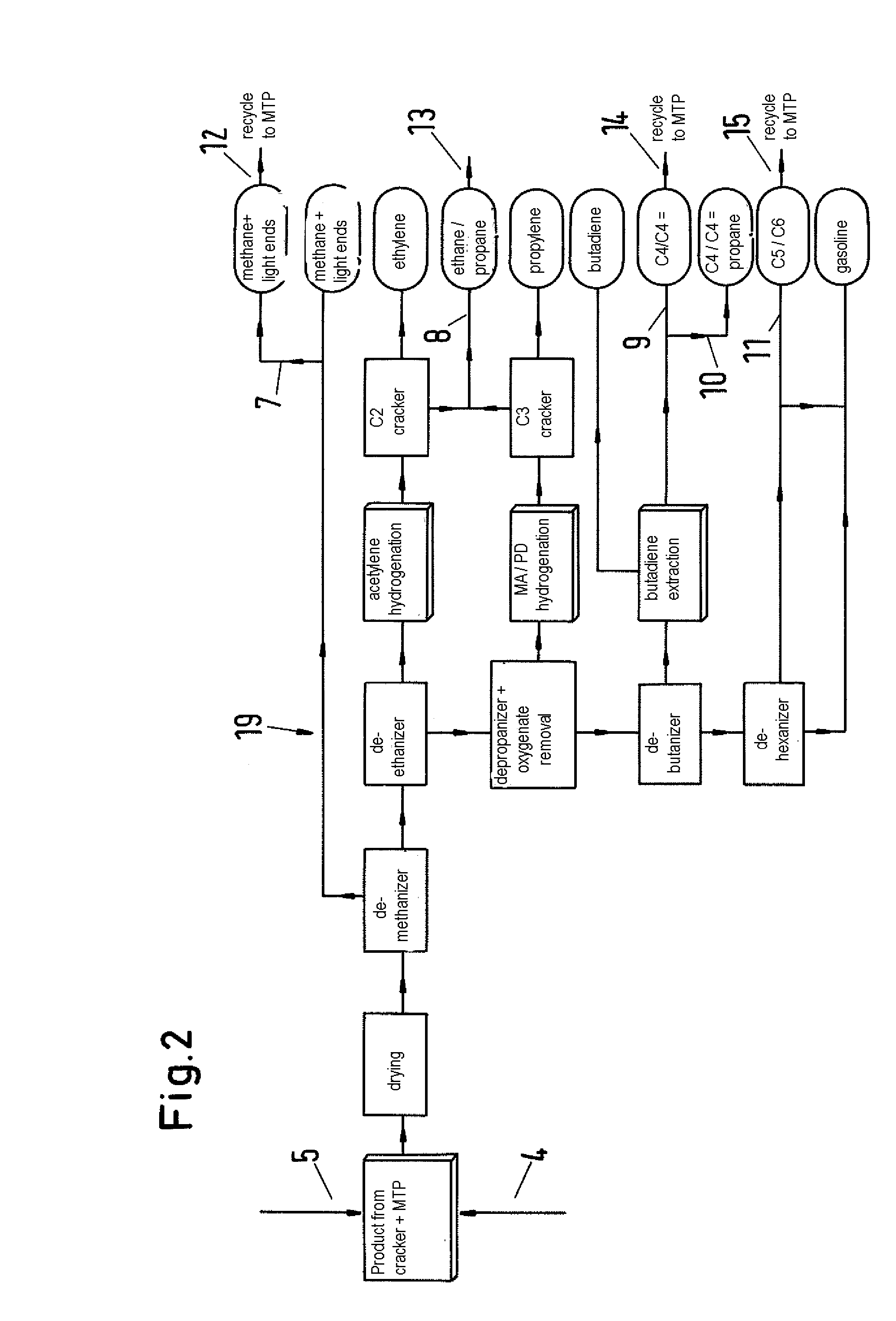

Process and plant for producing hydrocarbons

InactiveUS20100206771A1Increase productionSave energyMolecular sieve catalystTreatment with plural serial stages onlyHydrocotyle bowlesioidesCompound (substance)

For the production of hydrocarbons, in particular C2-C4 olefins, using a combined plant with a steam cracker and at least one reactor for converting an educt mixture which includes steam and at least one oxygenate, the respective intermediate product streams of the steam cracker and of the reactor are at least partly combined. To increase the yield of valuable products, a shape-selective zeolite material is used as catalyst in the reactor for oxygenate conversion and at least a part of the product streams obtained downstream of the combined plant is recirculated to the steam cracker and / or the reactor.

Owner:LURGI

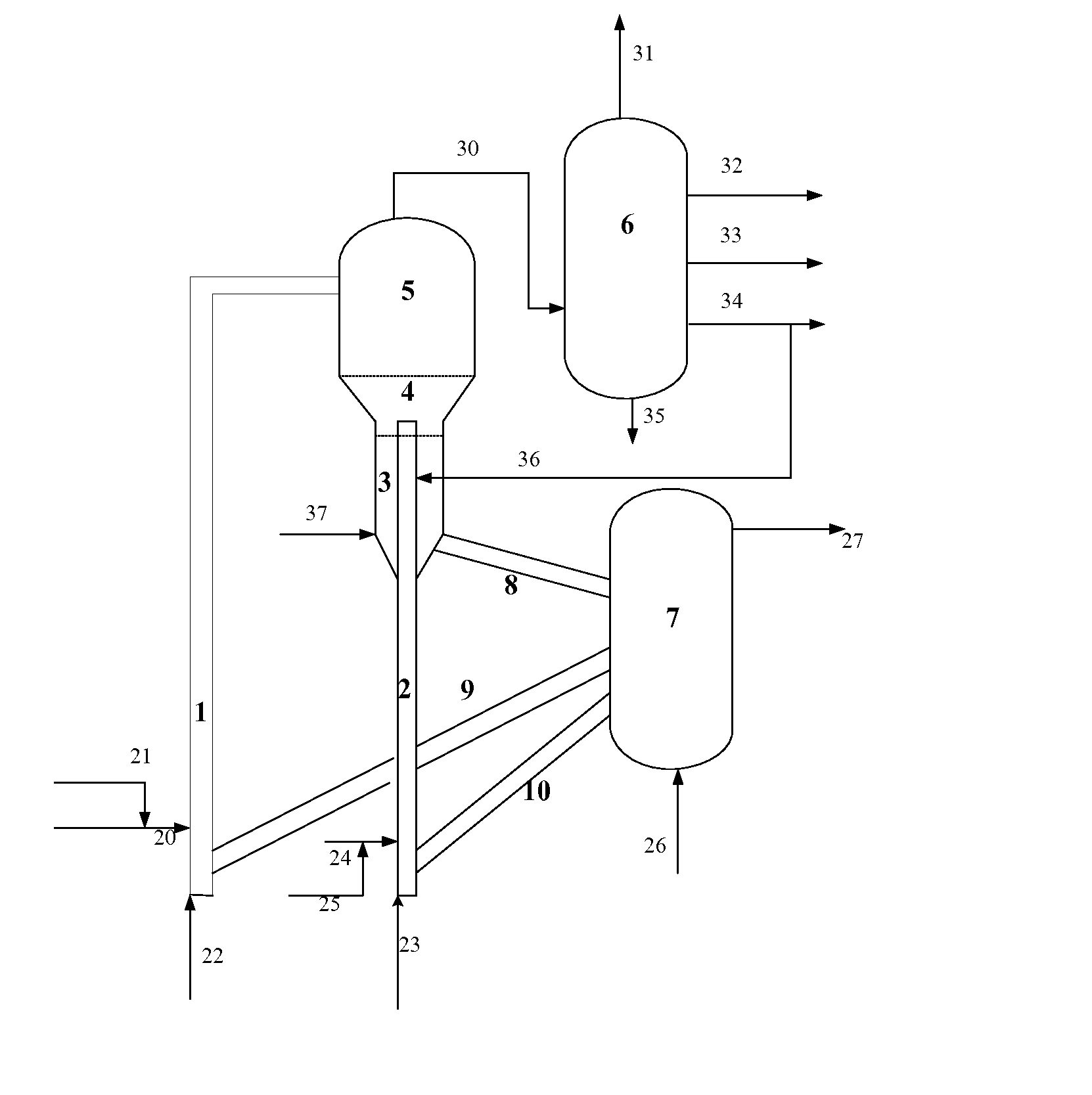

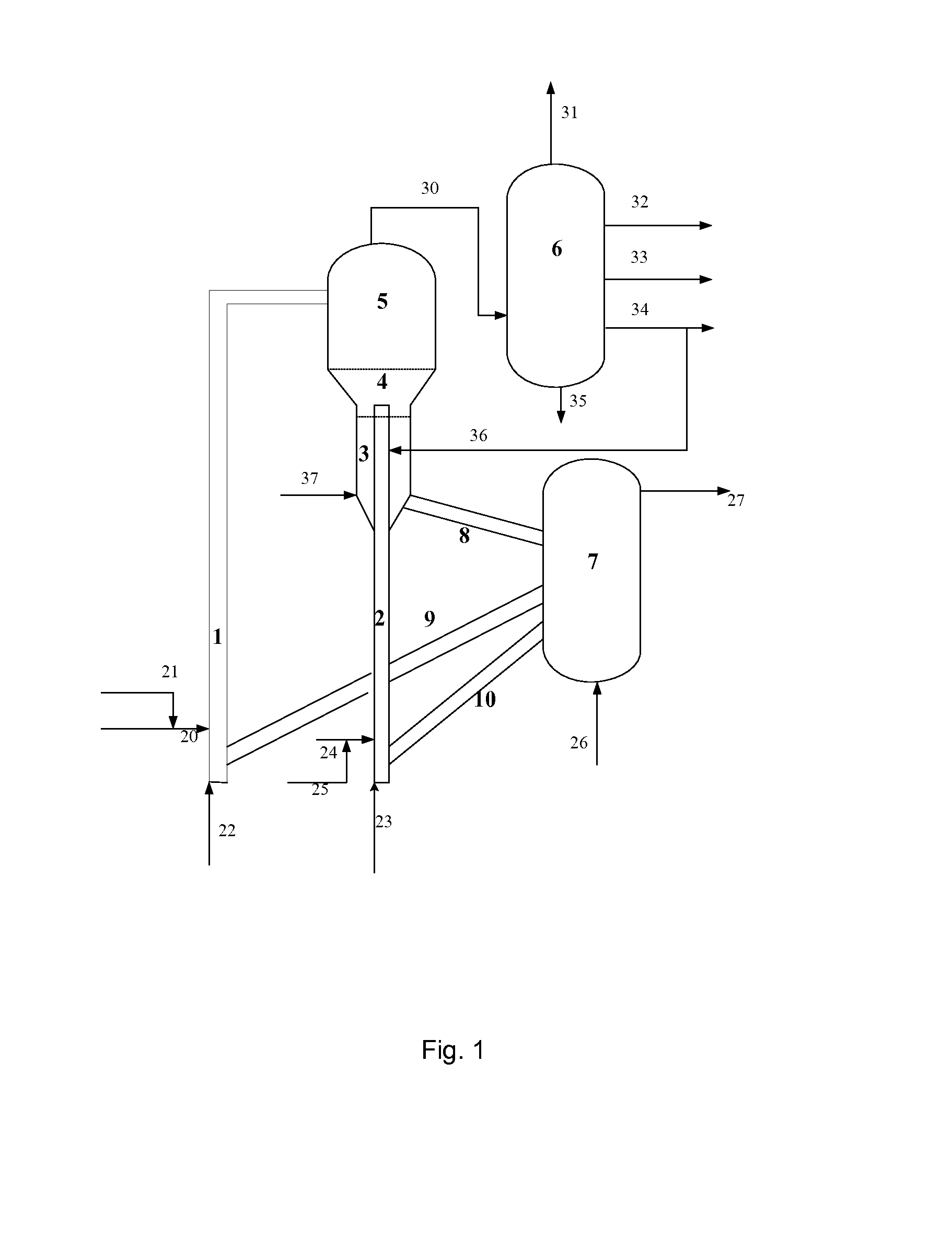

Process for converting inferior feedstock to high quality fuel oil

ActiveUS20110000818A1Improve propylene yieldQuality improvementCatalytic crackingTreatment with plural serial stages onlyAlkaneFuel oil

A catalytic conversion process can convert inferior feedstock to high quality fuel oil and propylene. A inferior feedstock is introduced into first and second reactor zone, wherein the feedstock carry out first step and second step reactions by contacting with catalytic conversion catalyst. Product vapors separate from spent catalyst by gas-solid separation. The spent catalyst is stripped, regenerated by burning off coke and then returns to reactor. The product vapors are introduced into separation system to obtain propylene, gasoline, diesel, fluid catalytic cracking gas oil (FGO) and other products. The FGO is introduced into hydrotreating unit and / or extraction unit to obtain hydrotreated FGO and / or extracted FGO. Said hyrotreated FGO and / or extracted FGO return to the first reactor zone and / or another catalytic cracking unit to obtain propylene and gasoline. The extracted oil of said FGO is rich in double ring aromatics which are good chemical materials. The raffinate of said FGO is rich in chain alkane and cycloalkane which are suitable for catalytic cracking. More particularly, the invention relates to a process to utilize petroleum oil resources efficiently for decreasing the yield of dry gas and coke significantly.

Owner:CHINA PETROCHEMICAL CORP +1

Process for Obtaining a Catalyst Composite

ActiveUS20110118518A1Improve propylene yieldLow selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkaline earth metal

A process for obtaining a catalyst composite comprising the following steps:a). selecting a molecular sieve having pores of 10-or more-membered ringsb). contacting the molecular sieve with a metal silicate different from said molecular sieve comprising at least one alkaline earth metal and one or more of the following metals: Ga, Al, Ce, In, Cs, Sc, Sn, Li, Zn, Co, Mo, Mn, Ni, Fe, Cu, Cr, Ti and V, such that the composite comprises at least 0.1 wt % of silicate.

Owner:TOTAL RES & TECH FELUY

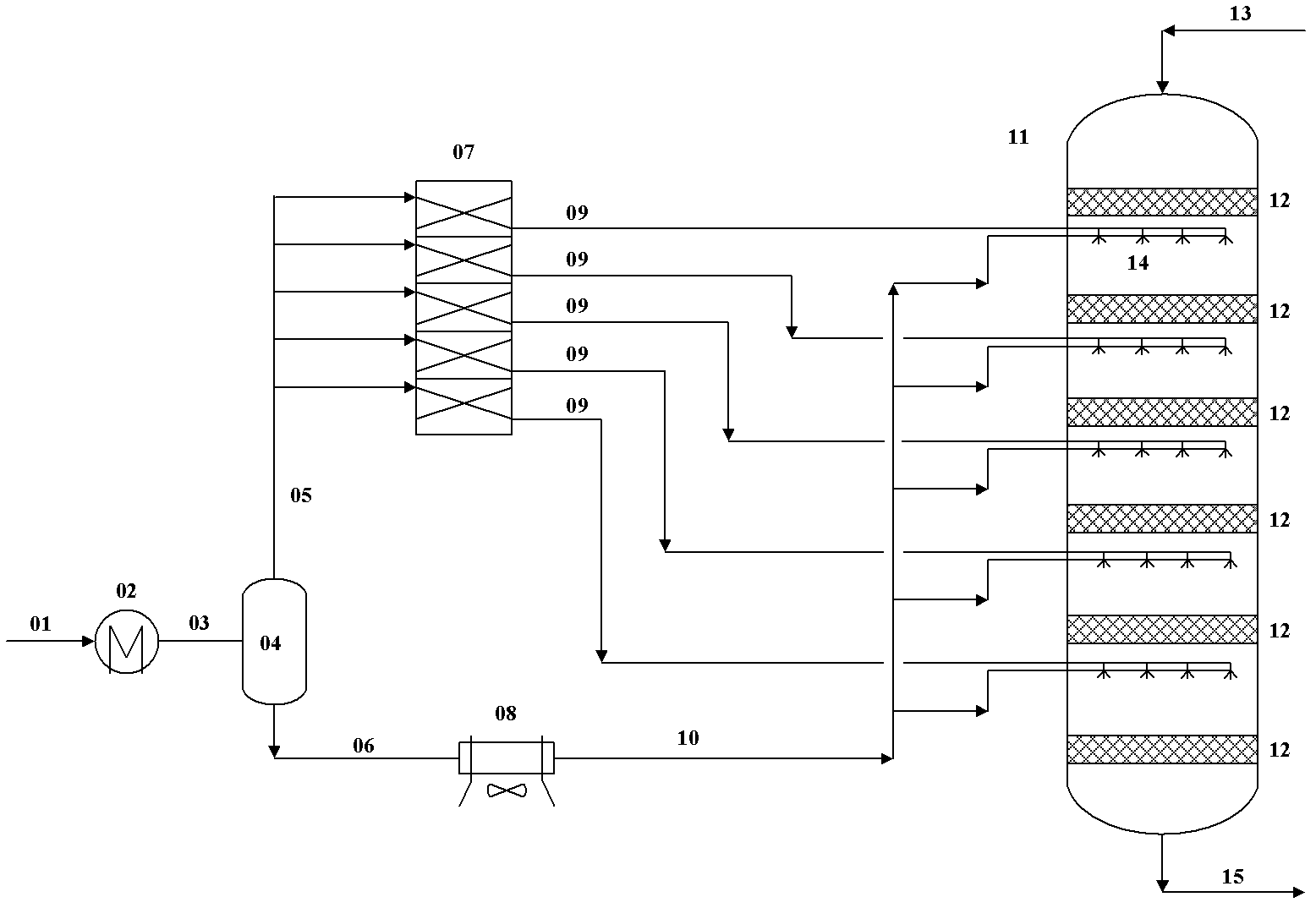

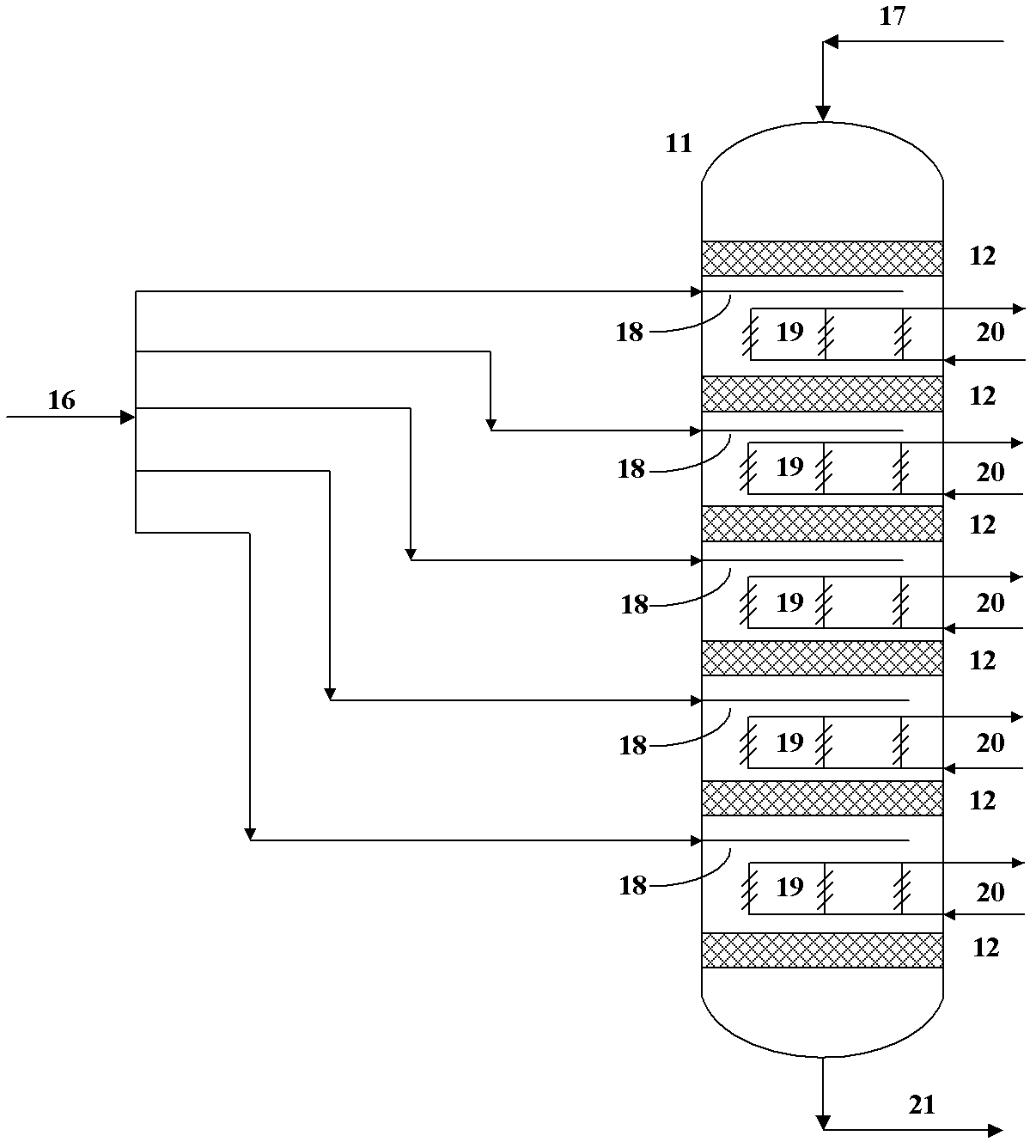

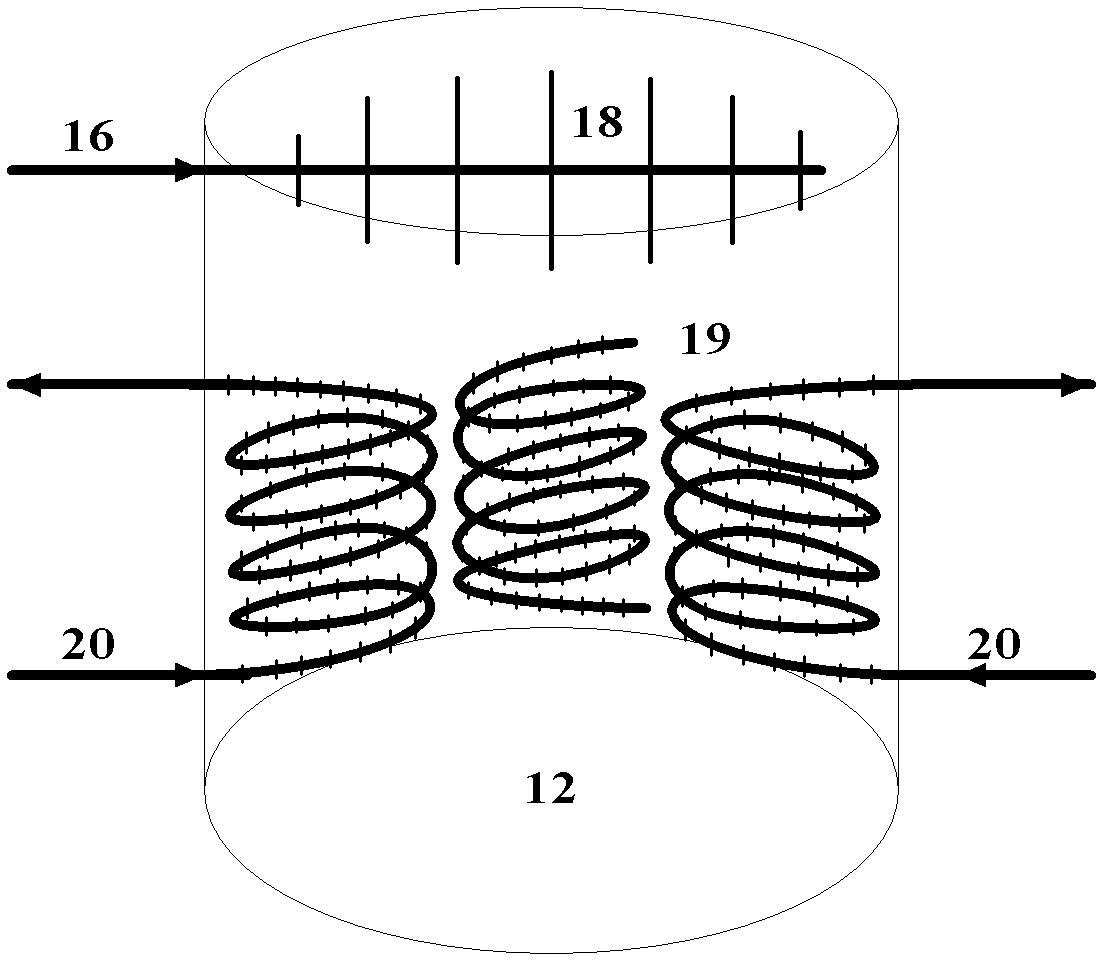

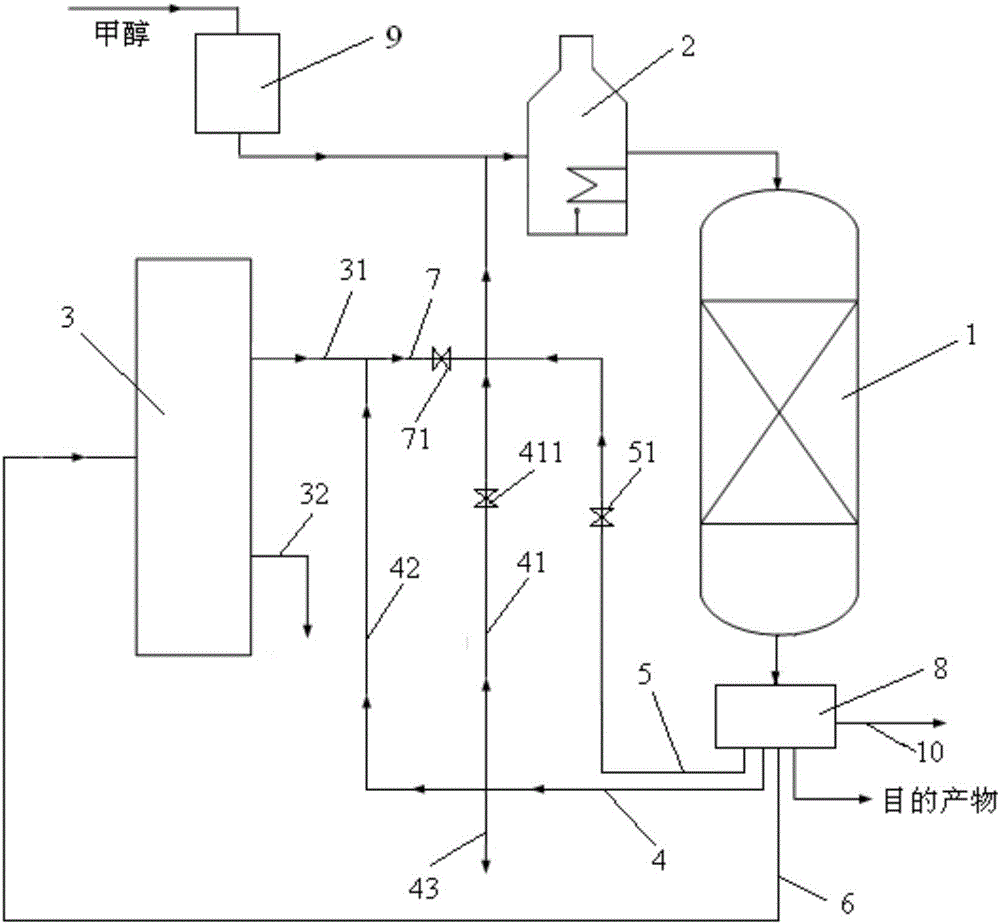

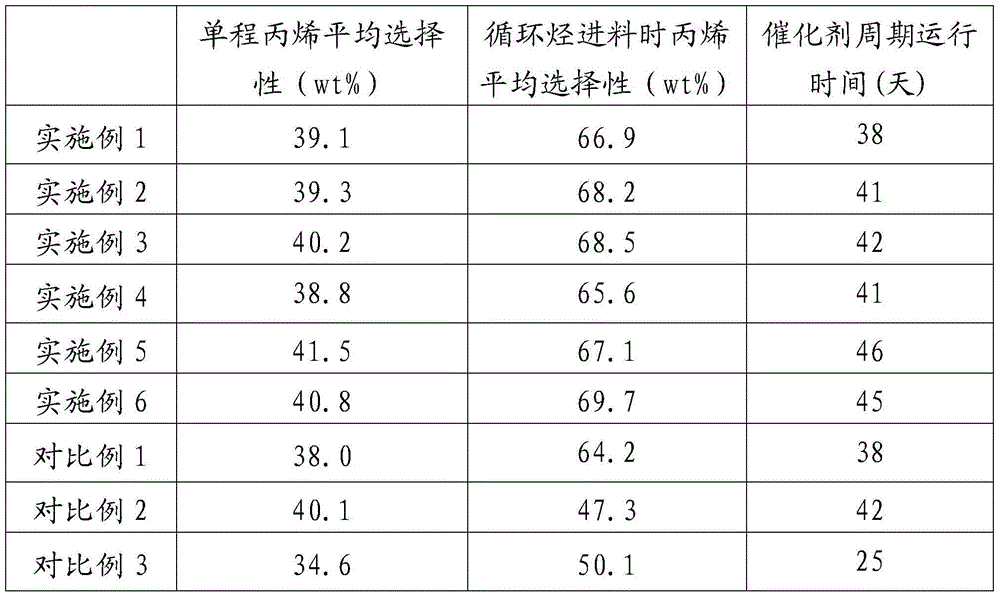

MTP (methanol to propylene) method

ActiveCN103030505AImprove propylene yieldReduce oxygenate contentHydrocarbon from oxygen organic compoundsMethanolMaterial flow

The invention relates to an MTP (methanol to propylene) method, which mainly solves the problems that the reaction condition of the existing MTP multi-section fixed bed technology cannot be easily controlled, the propylene yield is unstable, and the content of oxygen-containing compounds in the product cannot be ensured. According to the method, raw materials containing methanol are adopted as feeding and chilling materials, the feeding materials enter a reactor from the top of the multi-section fixed bed reactor to be in contact with catalysts filled in the reactor, and material flows containing propylene are generated through reaction, wherein chilling material distributors and inner heat taking devices are arranged between all catalyst bed layers and sections of the multi-section fixed bed reactor, and the chilling material flows enter positions among all catalyst bed layers and sections through the chilling material distributor. Through the technical scheme, the problems are perfectly solved, and the MTP method can be applied into the industrial production of the MTP.

Owner:CHINA PETROLEUM & CHEM CORP +1

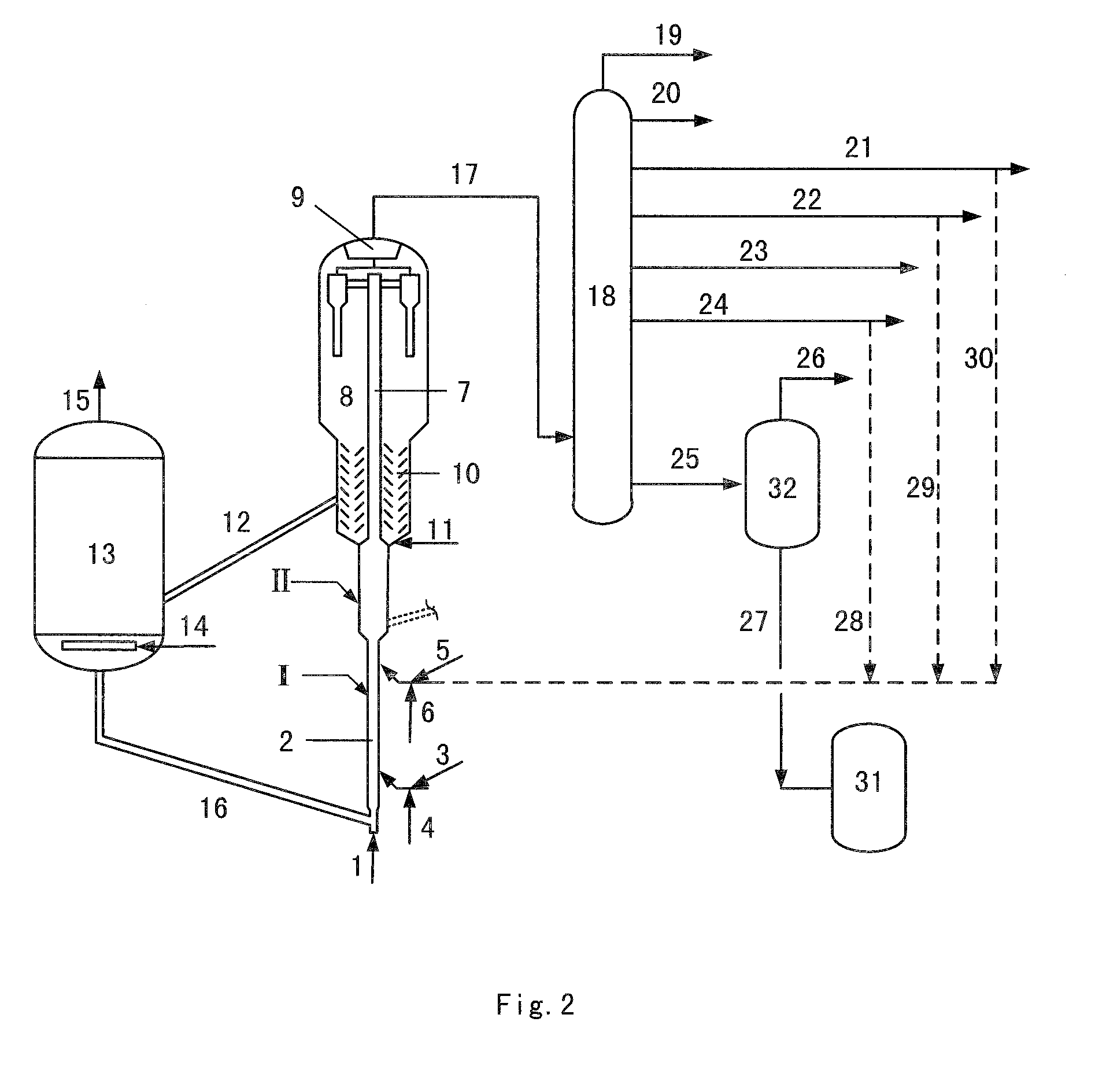

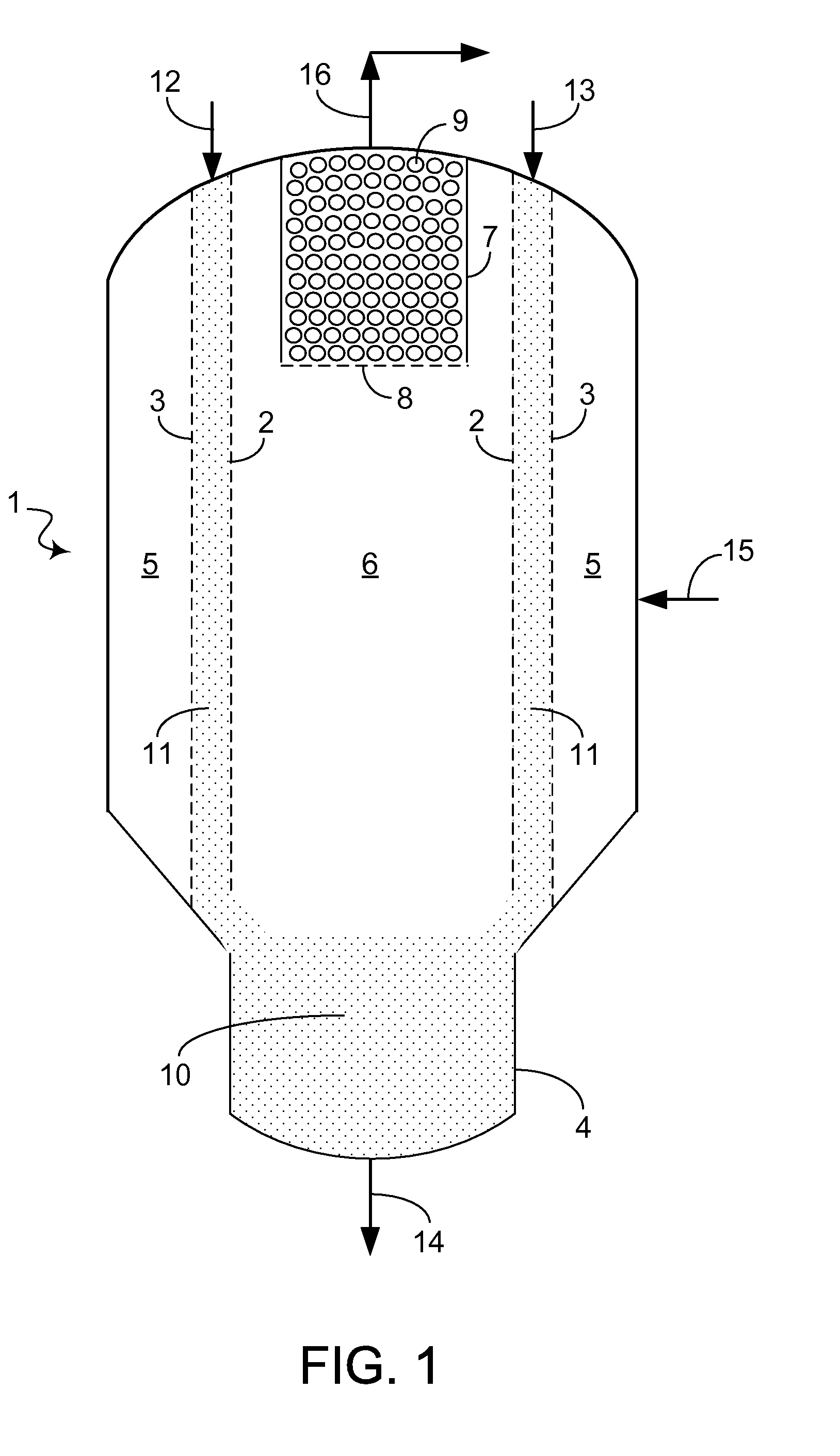

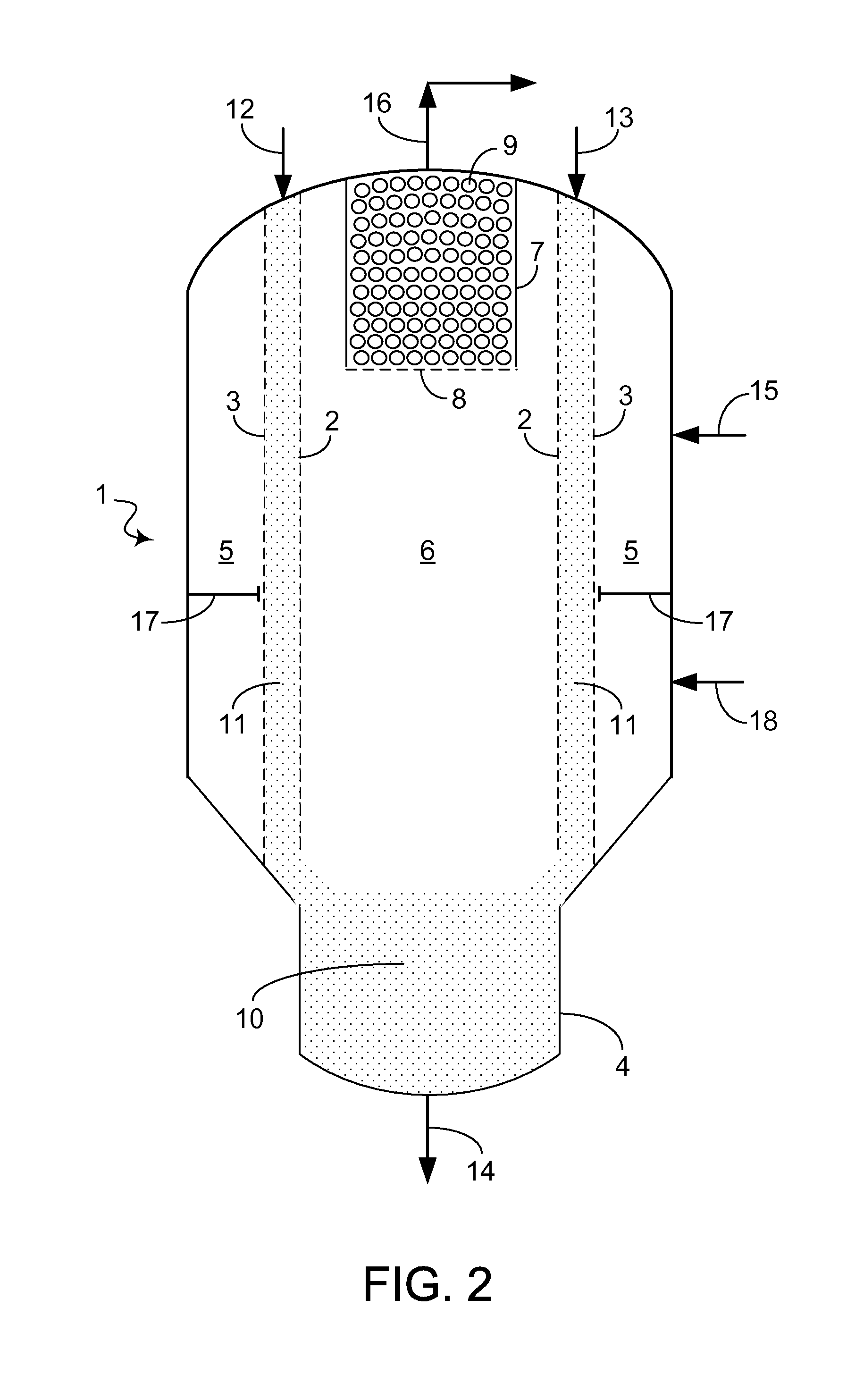

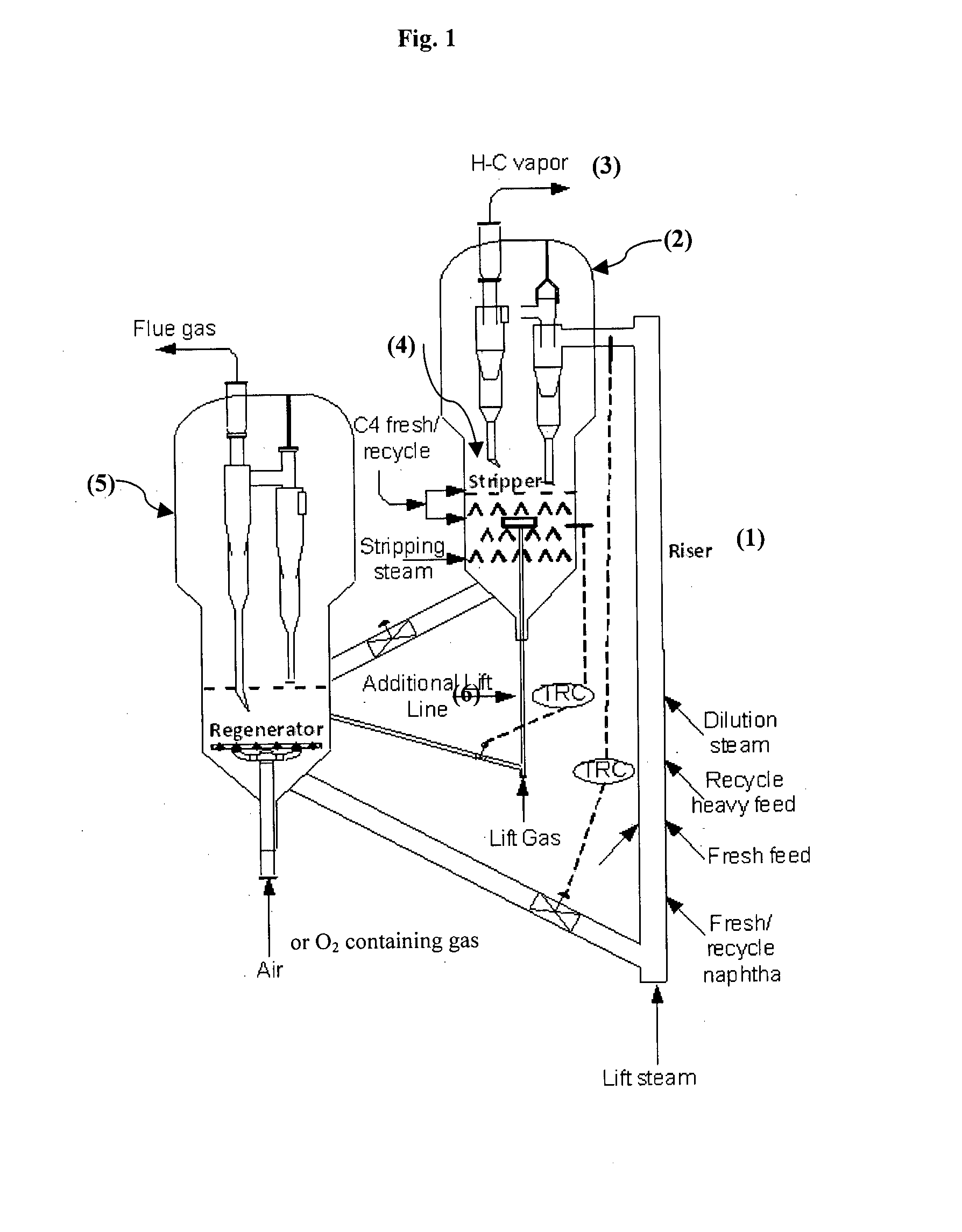

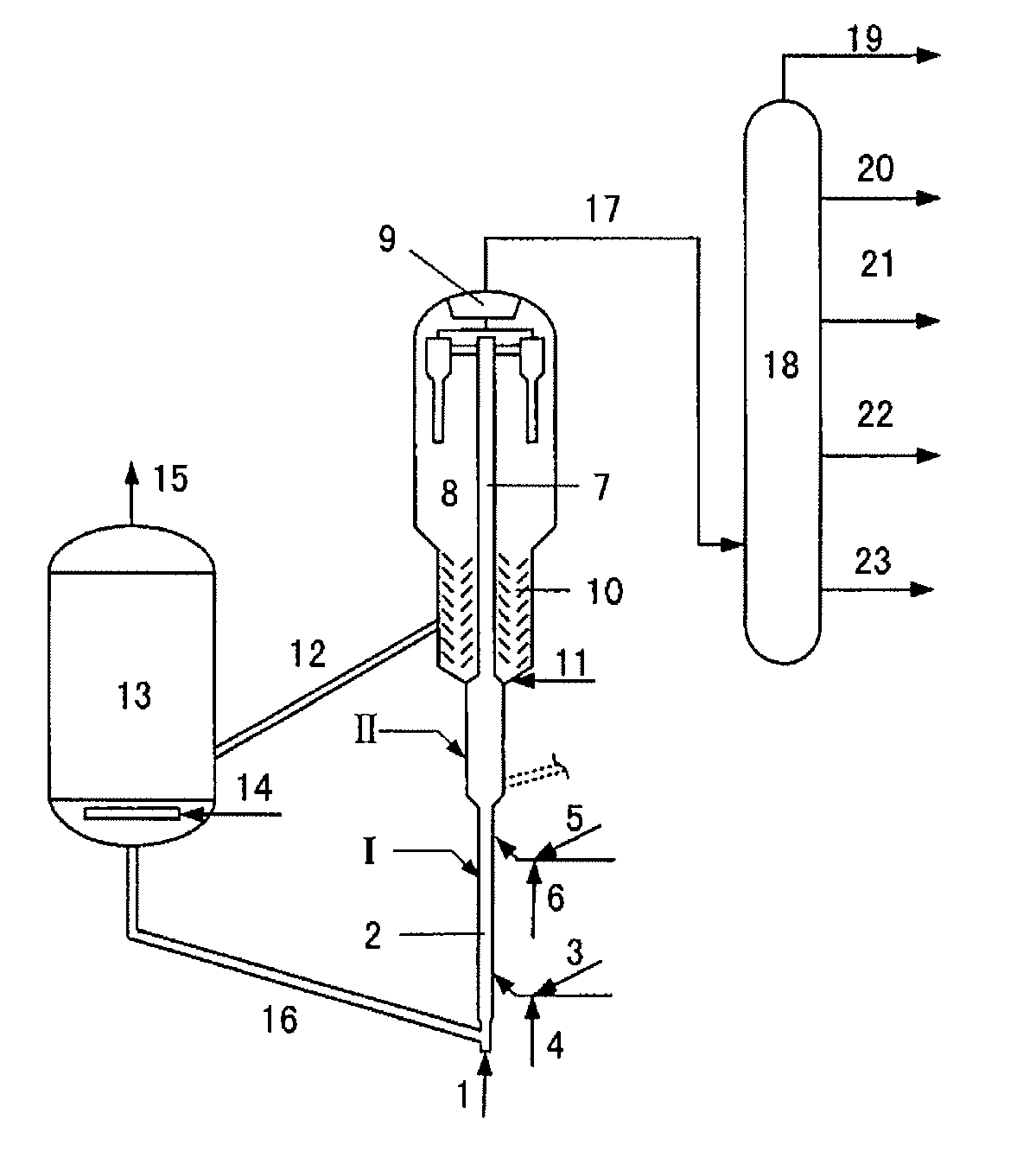

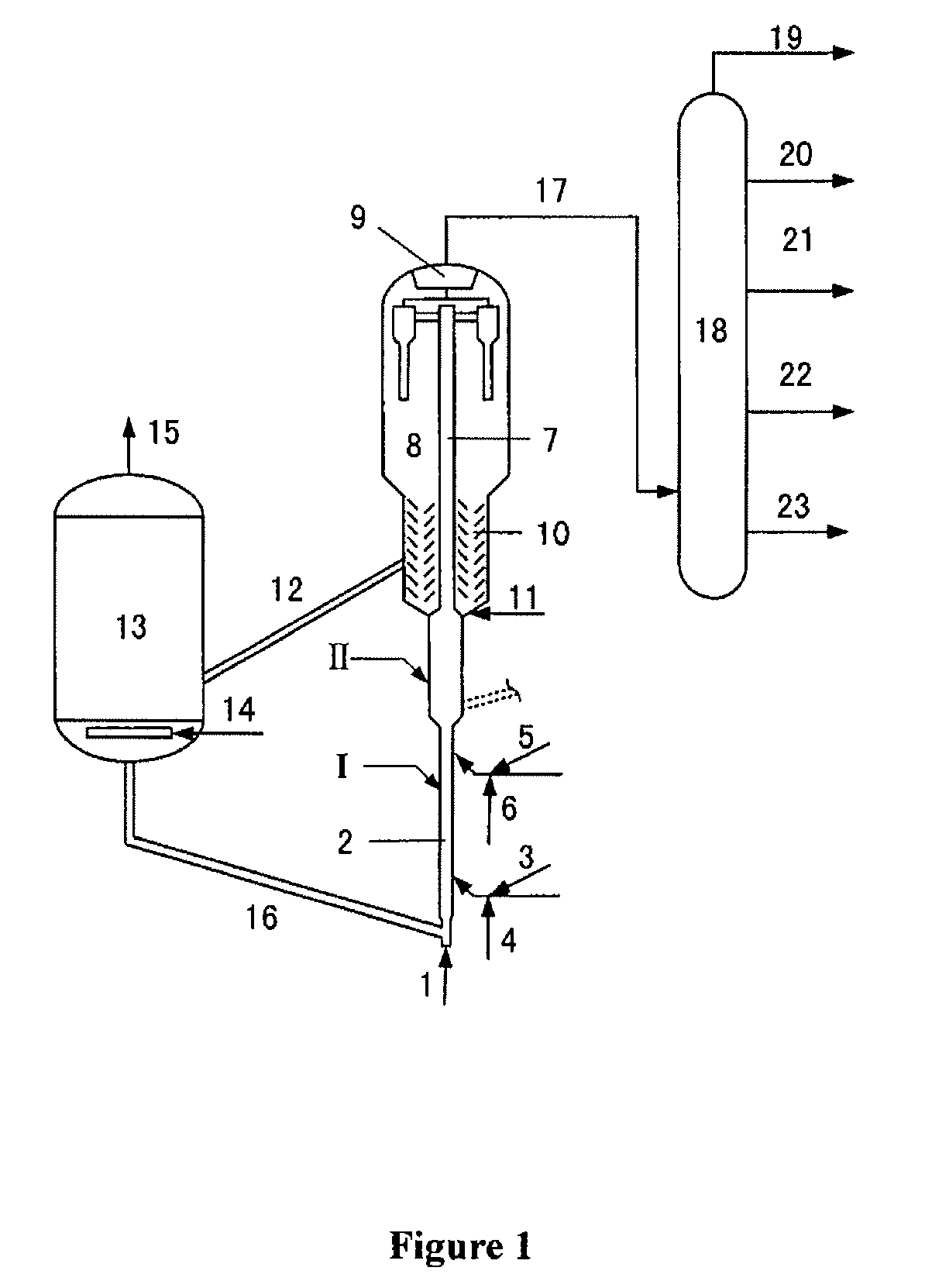

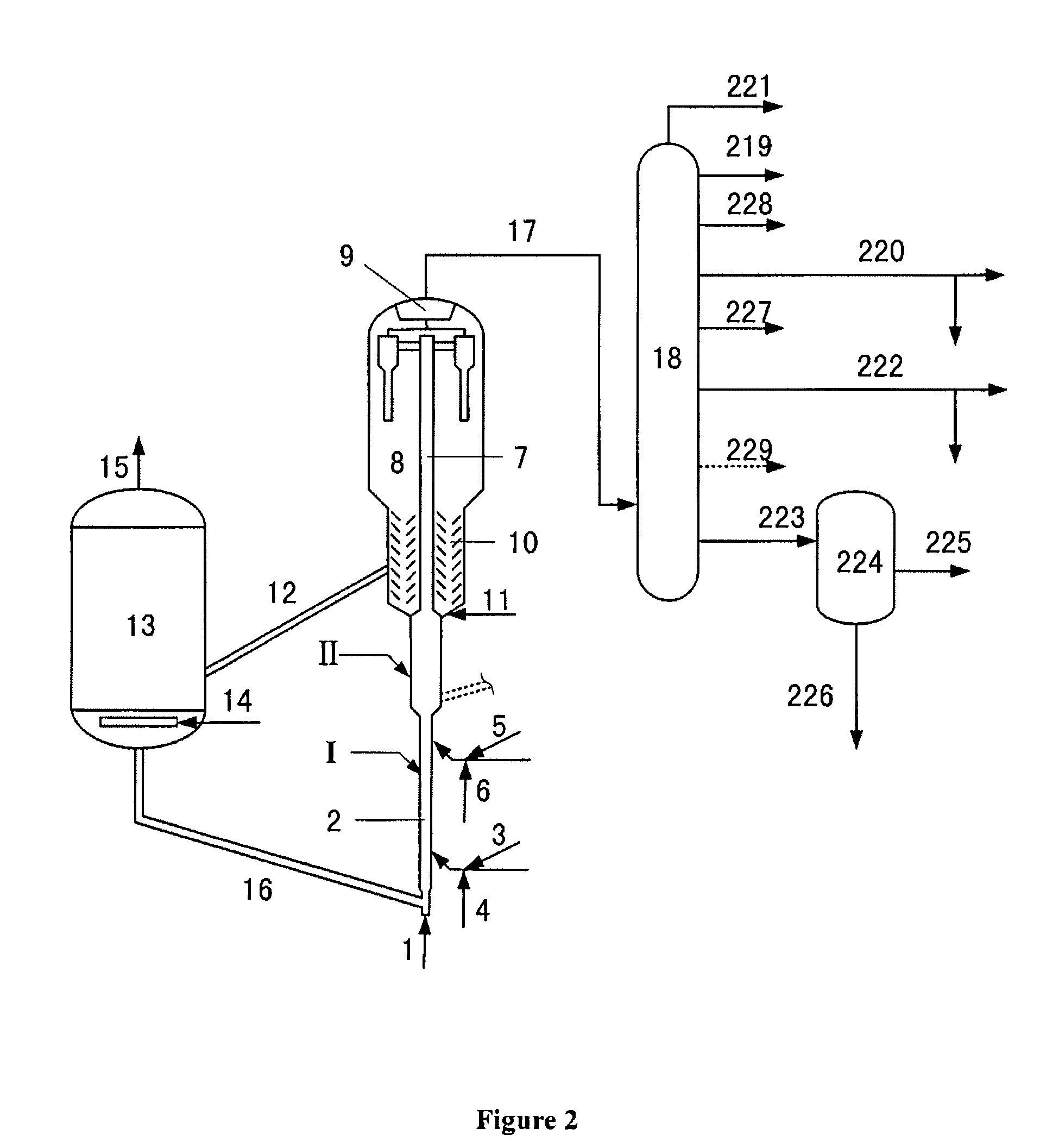

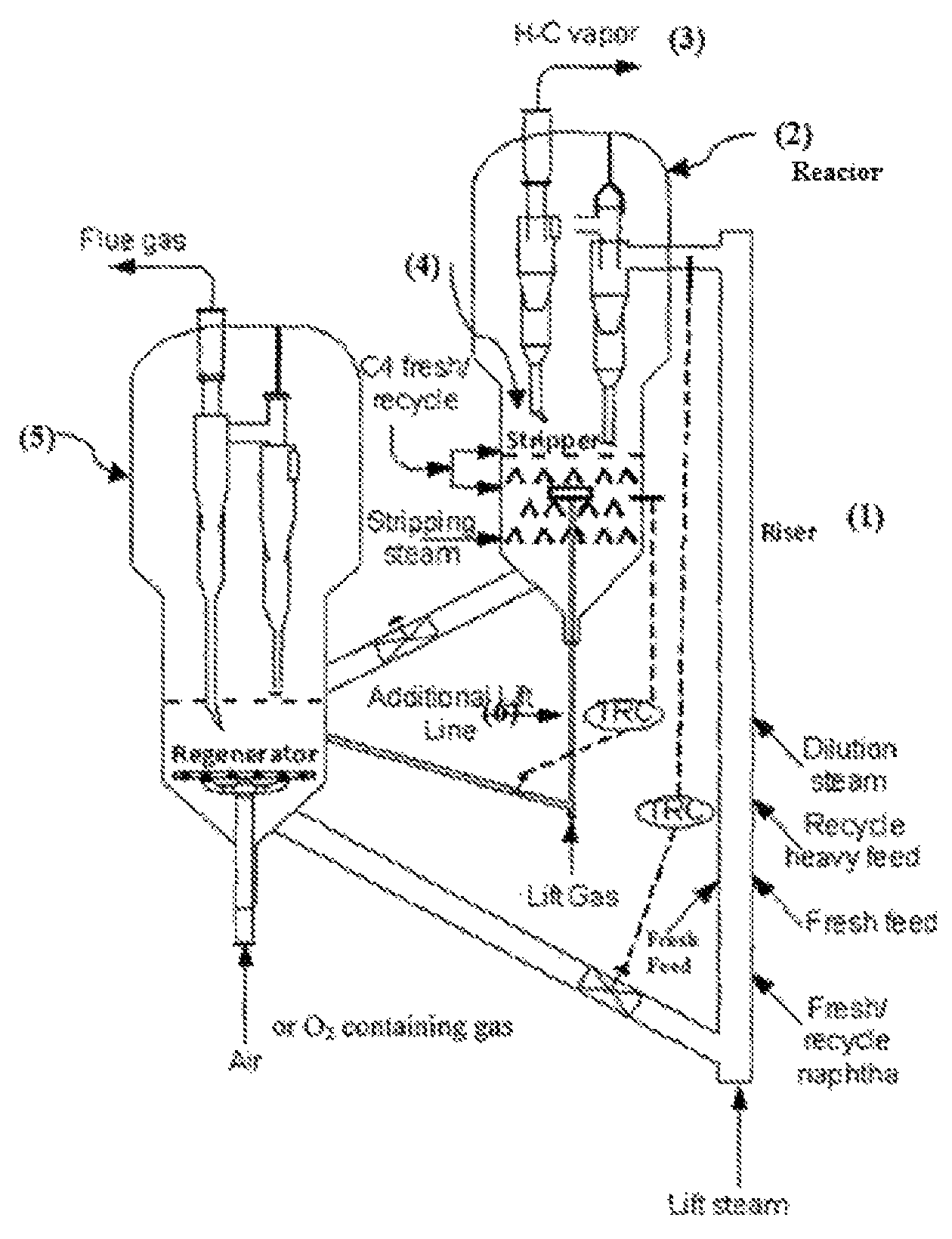

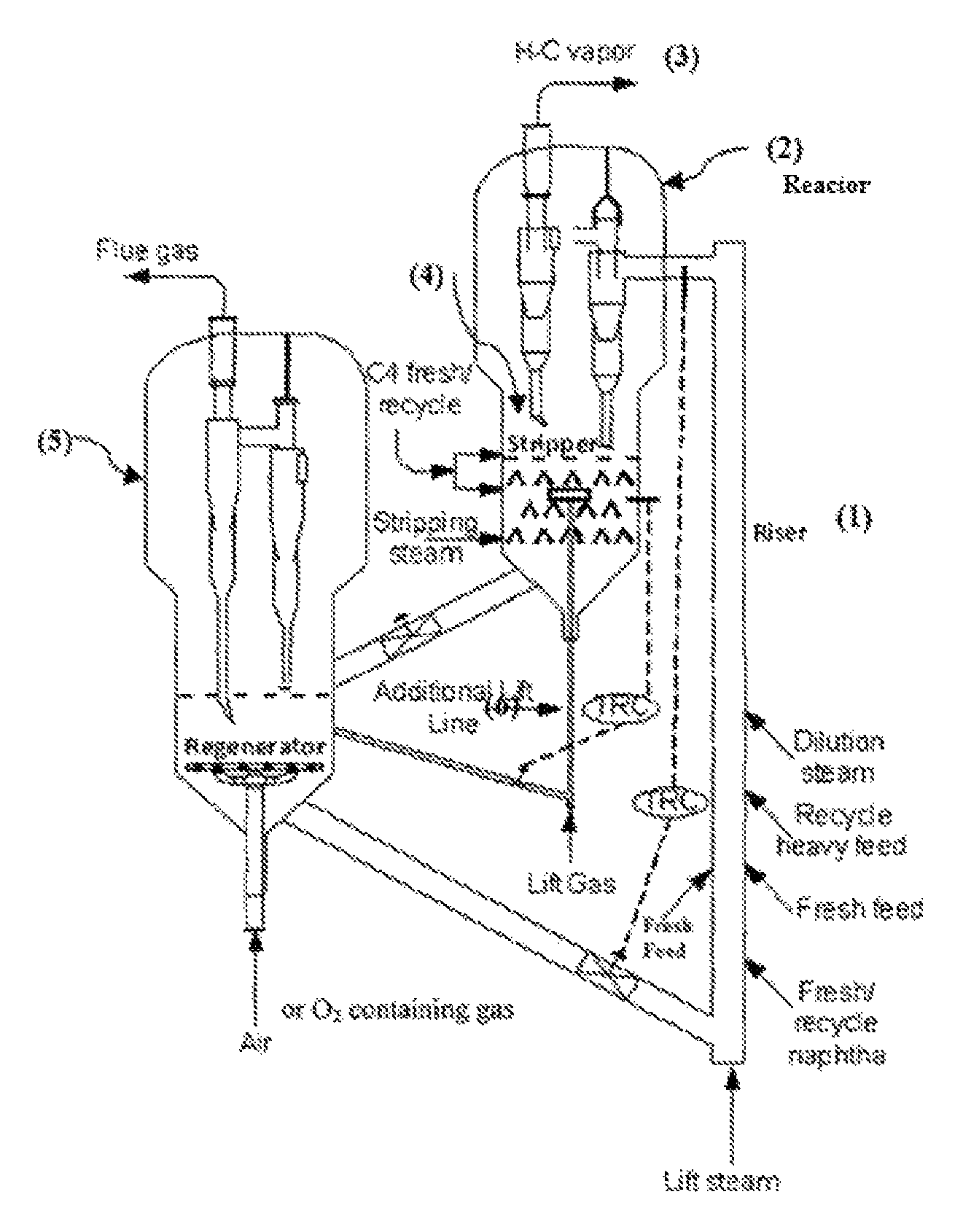

Catalytic cracking apparatus and process

ActiveUS20130006028A1Increase productionConversion of heavyCatalytic crackingTreatment with plural parallel cracking stages onlyFuel oilChemistry

Owner:CHINA PETROCHEMICAL CORP

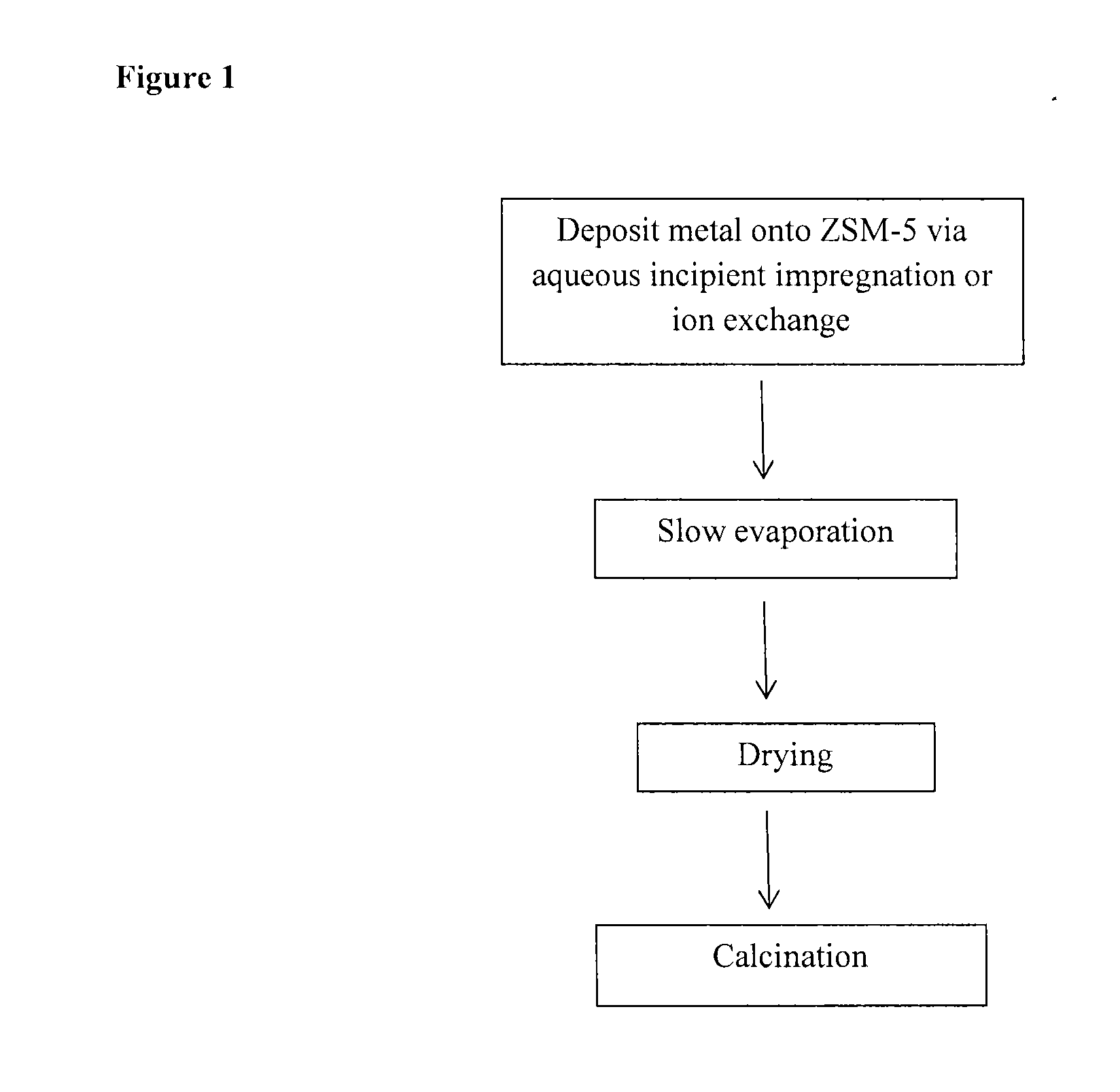

Metal-modified zeolite for catalytic cracking of heavy oils and process for producing light olefins

InactiveUS20150165427A1Improve propylene yieldLess expenseMolecular sieve catalystsHydrocarbonsIon exchangeModified zeolite

The present invention relates to a fluid catalytic cracking (FCC) catalyst containing a metal-modified ZSM-5 zeolite catalyst additive for catalytically cracking heavy oils. The metal-modified ZSM-5 zeolite may be obtained by first preparing a mixture in which the metal is introduced to the zeolite via an impregnation method or an ion exchange method, stirring and drying the mixture, and then calcining to form the final metal-modified ZSM-5 zeolite. The metal-modified ZSM-5 zeolite is used with a FCC base catalyst at different ratios to increase the production of light olefins, particularly propylene, from the catalytic cracking of heavy oils.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Moving Bed Catalyst Regeneration Apparatus with Integral CO Oxidation Zone and Method of Use to Accelerate Coke Burning

InactiveUS20100034718A1Effectively and selectively useReduce dependenceGas treatmentOther chemical processesCombustionFlue gas

A combination of moving bed regeneration technology and CO oxidation technology is used in a novel moving bed regeneration apparatus containing an integral CO oxidation zone to solve the problem of regenerating a coke-containing catalyst that does not contain a CO oxidation promoter without generating an effluent flue gas stream containing hazardous and undesired amounts of CO. The CO oxidation zone is located in the flue gas collection zone within the moving bed regeneration apparatus and functions autogenously to eliminate the CO hazard by oxidizing CO to CO2 with a portion of the unreacted oxygen withdrawn from the coke combustion zone of the moving bed regeneration apparatus.

Owner:UOP LLC

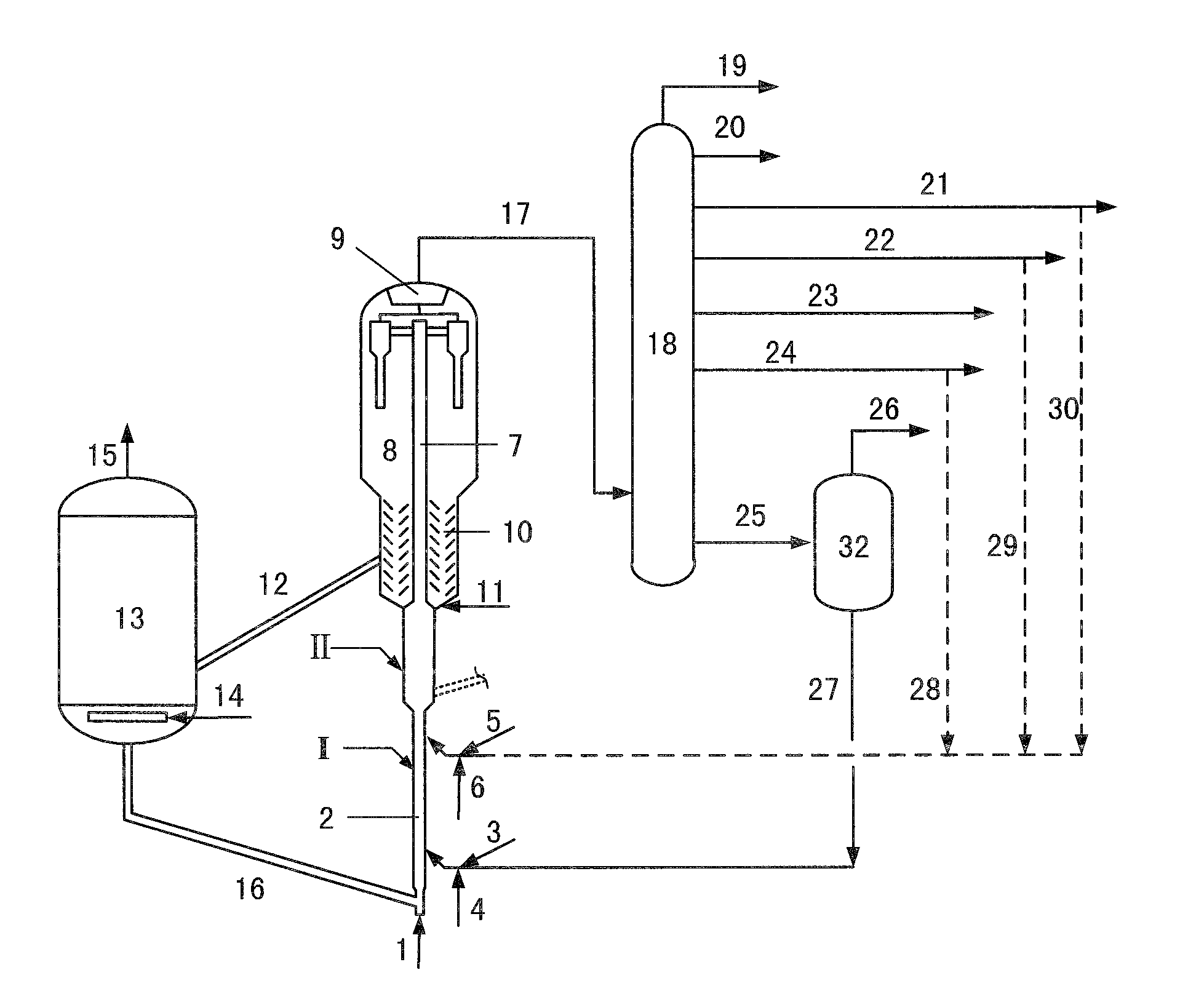

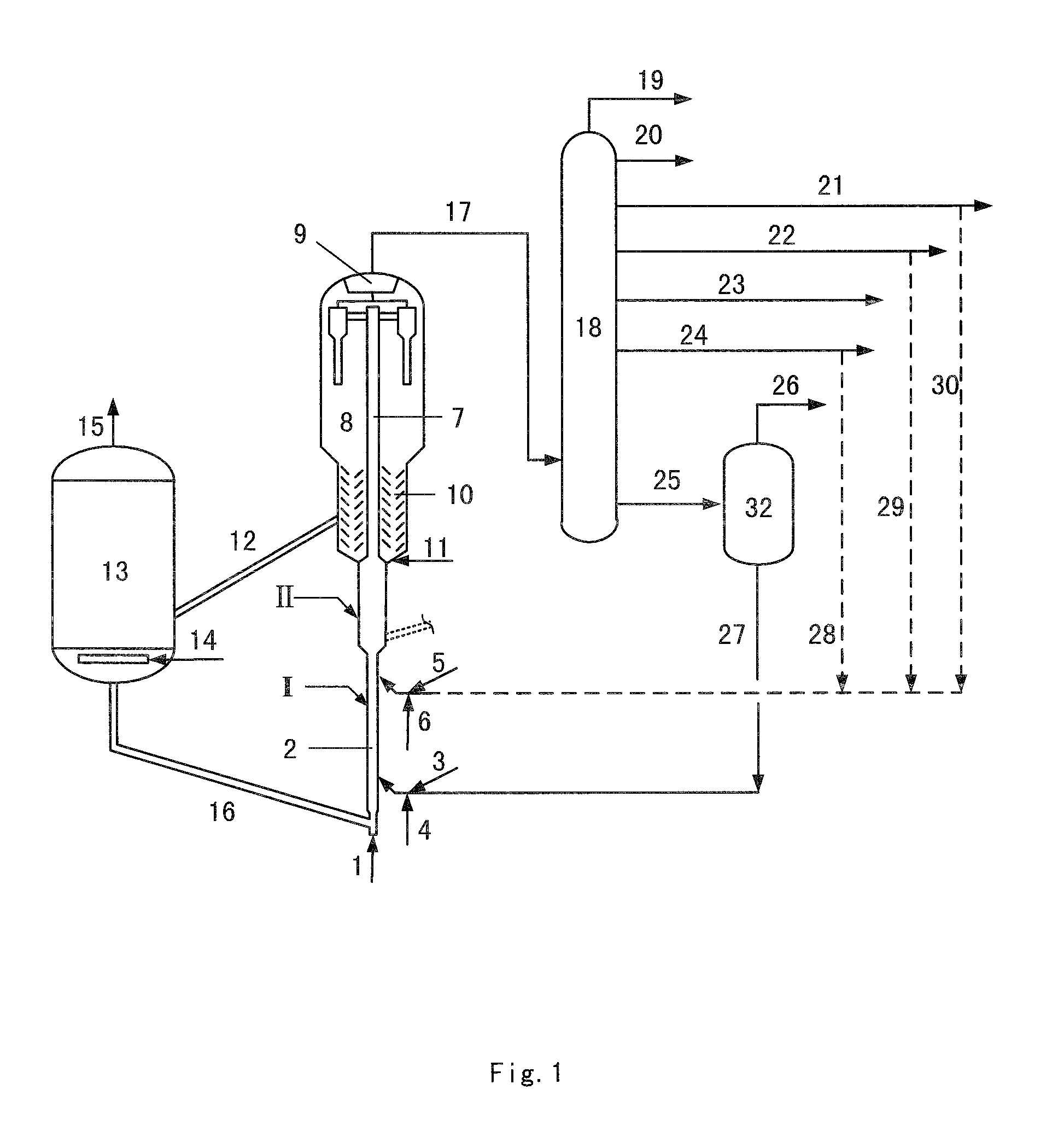

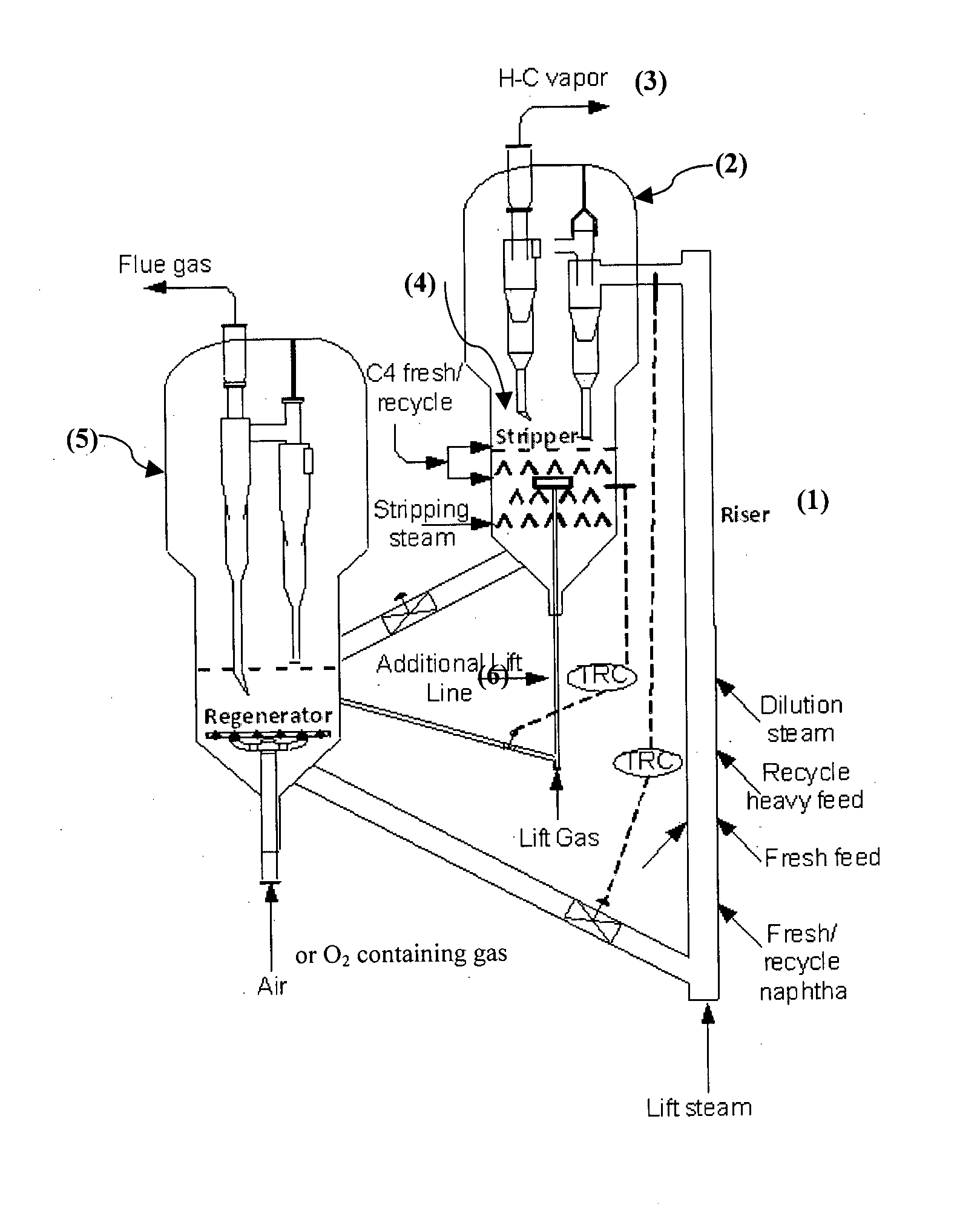

PROCESS FOR PRODUCTION OF C3 OLEFIN IN A FLUID CATALYTIC CRACKING UNIT

ActiveUS20140257006A1High yieldImprove propylene yieldCatalytic crackingHydrocarbonsFluidized bedReaction zone

A process for increasing the yield of C3 olefin in fluidized bed catalytic cracking of hydrocarbon feedstocks is disclosed. C4 fraction produced from the cracking of hydrocarbon feedstock in the primary reaction zone (riser), optionally with external source of C4 stream is fed into the stripper which acts as a secondary reaction zone at an elevated temperature and at an optimum WHSV. The elevated temperature is achieved by injecting a part of the regenerated catalyst from regenerator, which is at a higher temperature, directly into the stripper through a dedicated additional lift line. This raises the activity of catalyst inside the stripper. The direct injection of regenerated catalyst into the stripper, besides producing higher yields of propylene, improves the stripping efficiency leading to enhanced recovery of strippable hydrocarbons.

Owner:INDIAN OIL CORPORATION

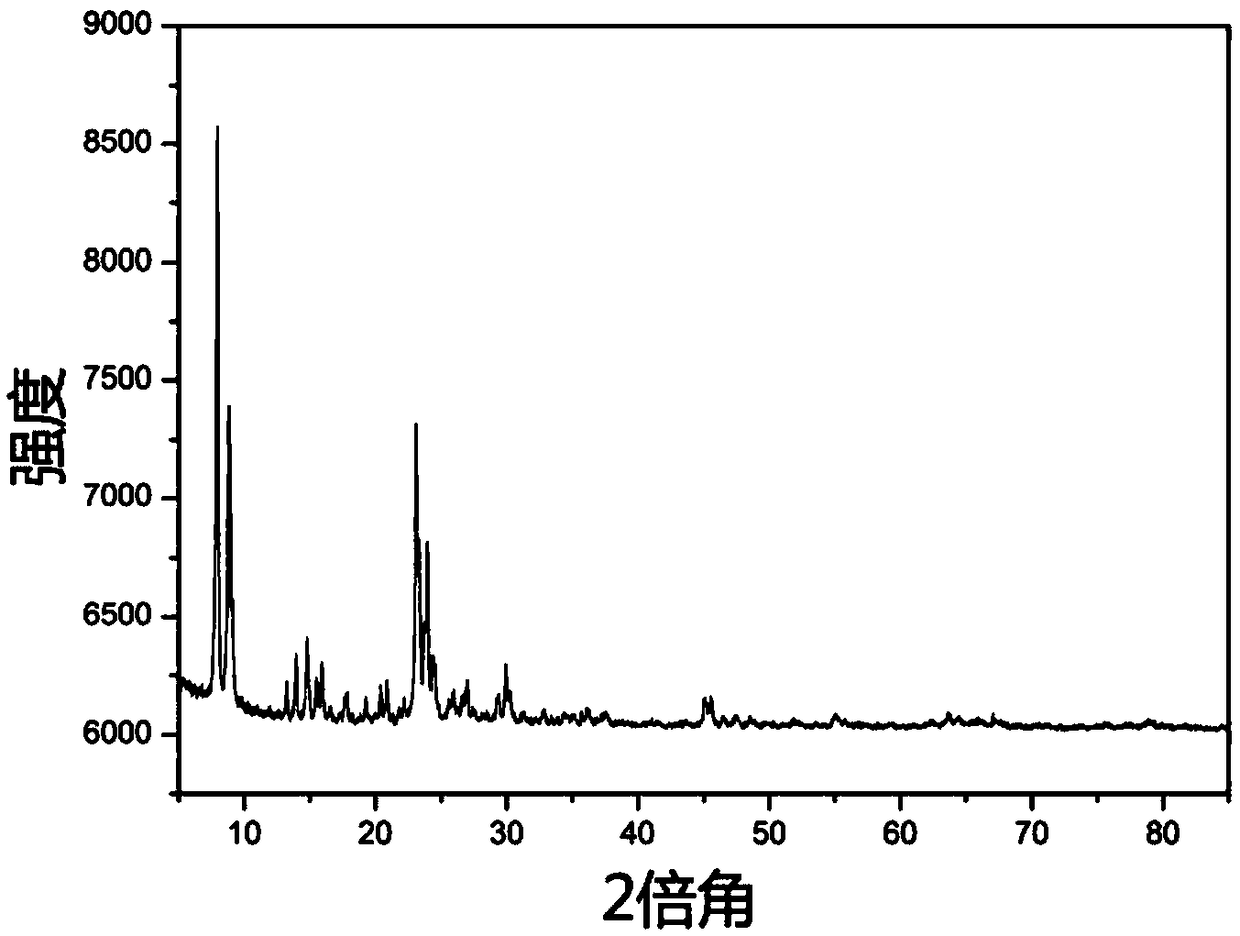

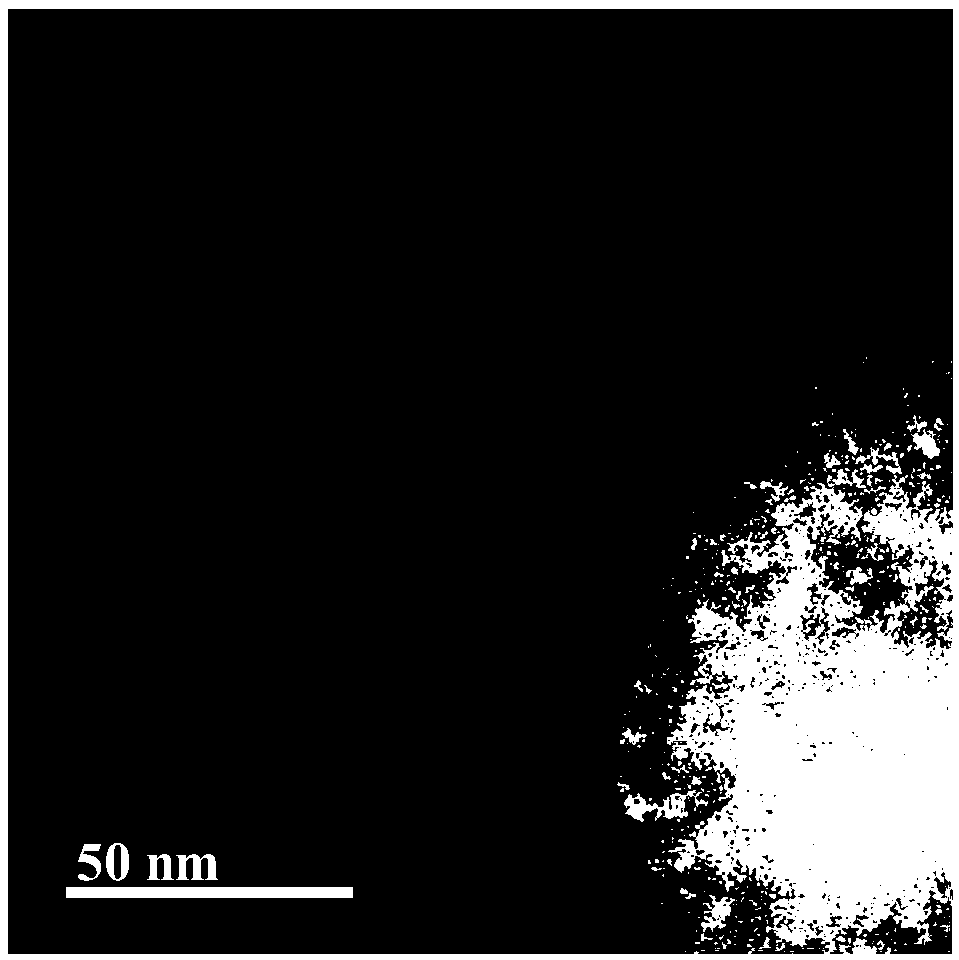

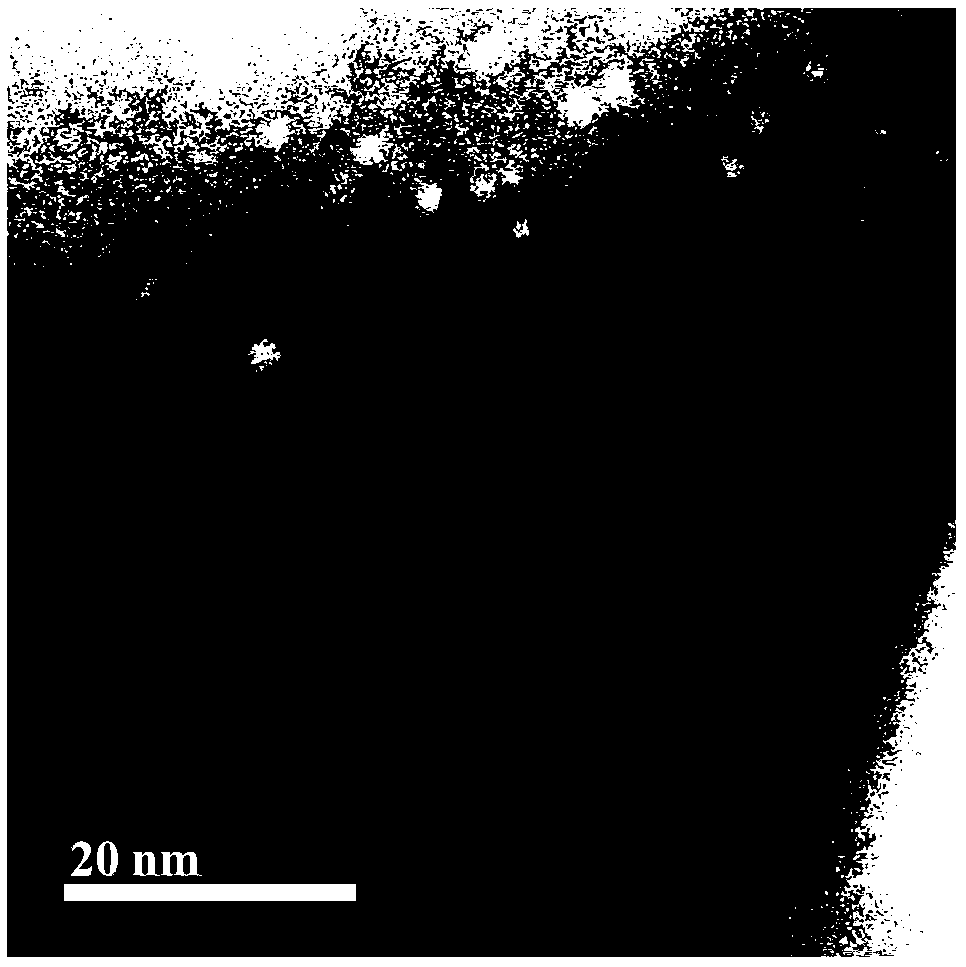

Highly dispersed ZnO-based catalyst as well as preparation method and propane anaerobic dehydrogenation method thereof

ActiveCN108727148AImprove stabilityImprove propylene yieldMolecular sieve catalystsMolecular sieve catalystSolventCompound s

The invention provides a highly dispersed ZnO-based catalyst as well as a preparation method and a propane anaerobic dehydrogenation method thereof. The preparation method of the catalyst comprises the following steps: dispersing Silicalite-1 into a solvent so as to obtain a suspension I; putting a zinc source into the suspension I, and stirring so as to obtain a suspension II; putting 2-methylimidazole into the suspension II, and stirring so as to obtain a ZIF-8 / Silicalite-1 compound; and centrifuging the ZIF-8 / Silicalite-1 compound, washing, drying, and carrying out pyrolysis in a nitrogen atmosphere, thereby obtaining a ZnO@ / NC / Silialite-1 catalyst, namely the highly dispersed ZnO-based catalyst. Due to acid pickling, the stability of the catalyst can be also improved. The invention further provides a catalyst prepared by using the method and a propane anaerobic dehydrogenation method using the catalyst. The catalyst provided by the invention has no harsh requirement on a propane anaerobic dehydrogenation process, is capable of achieving efficient conversion of propane, and meanwhile has high catalyst stability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

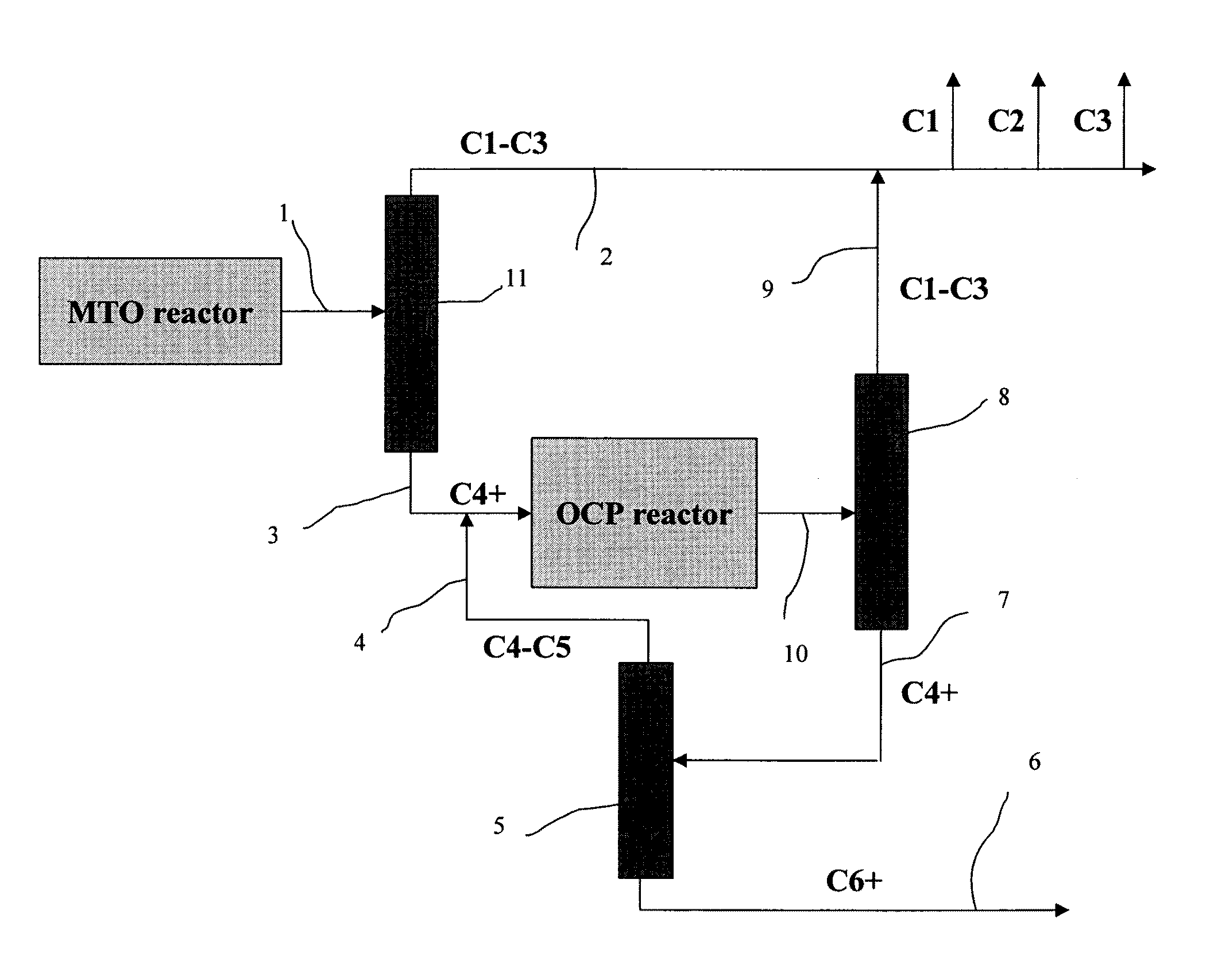

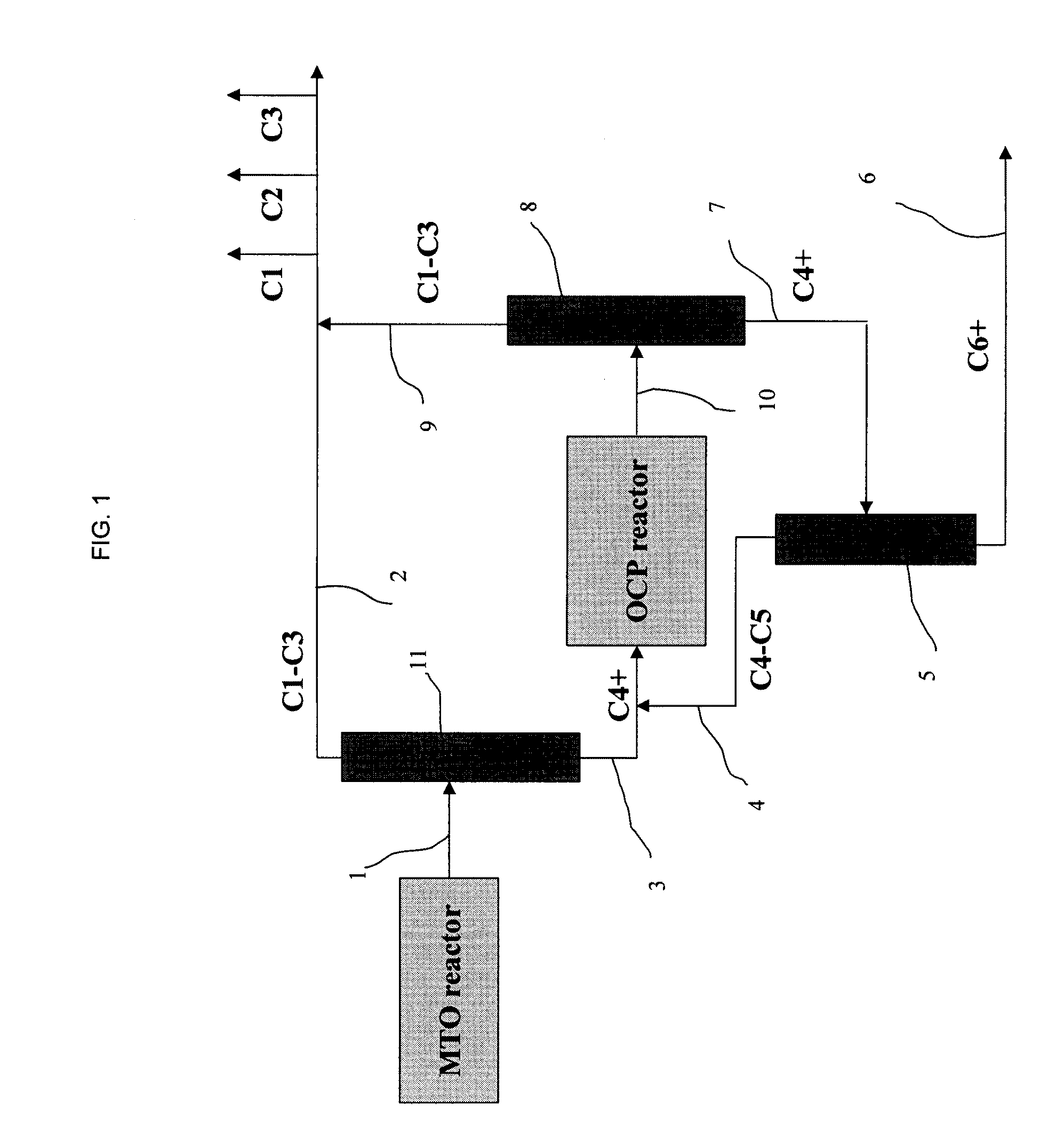

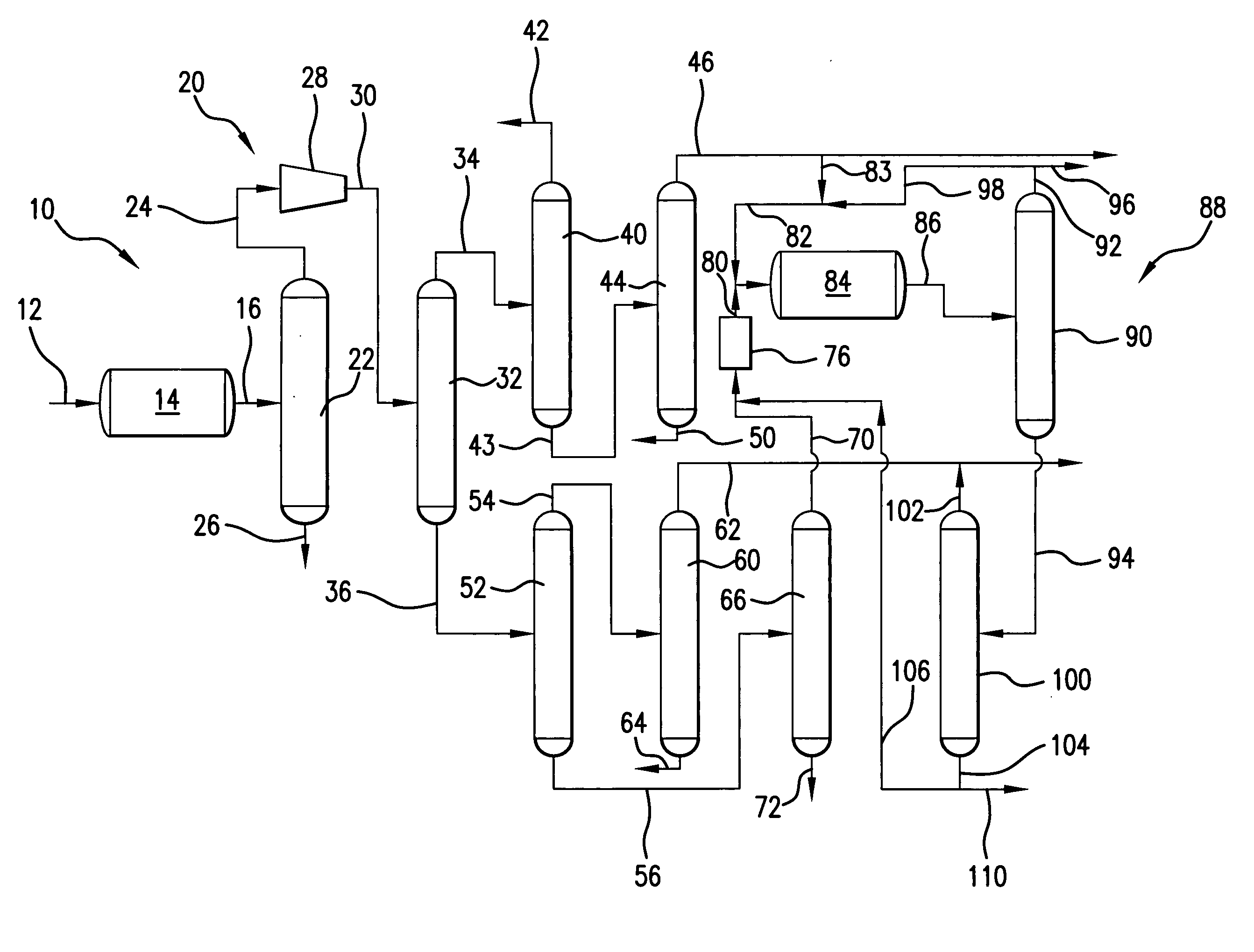

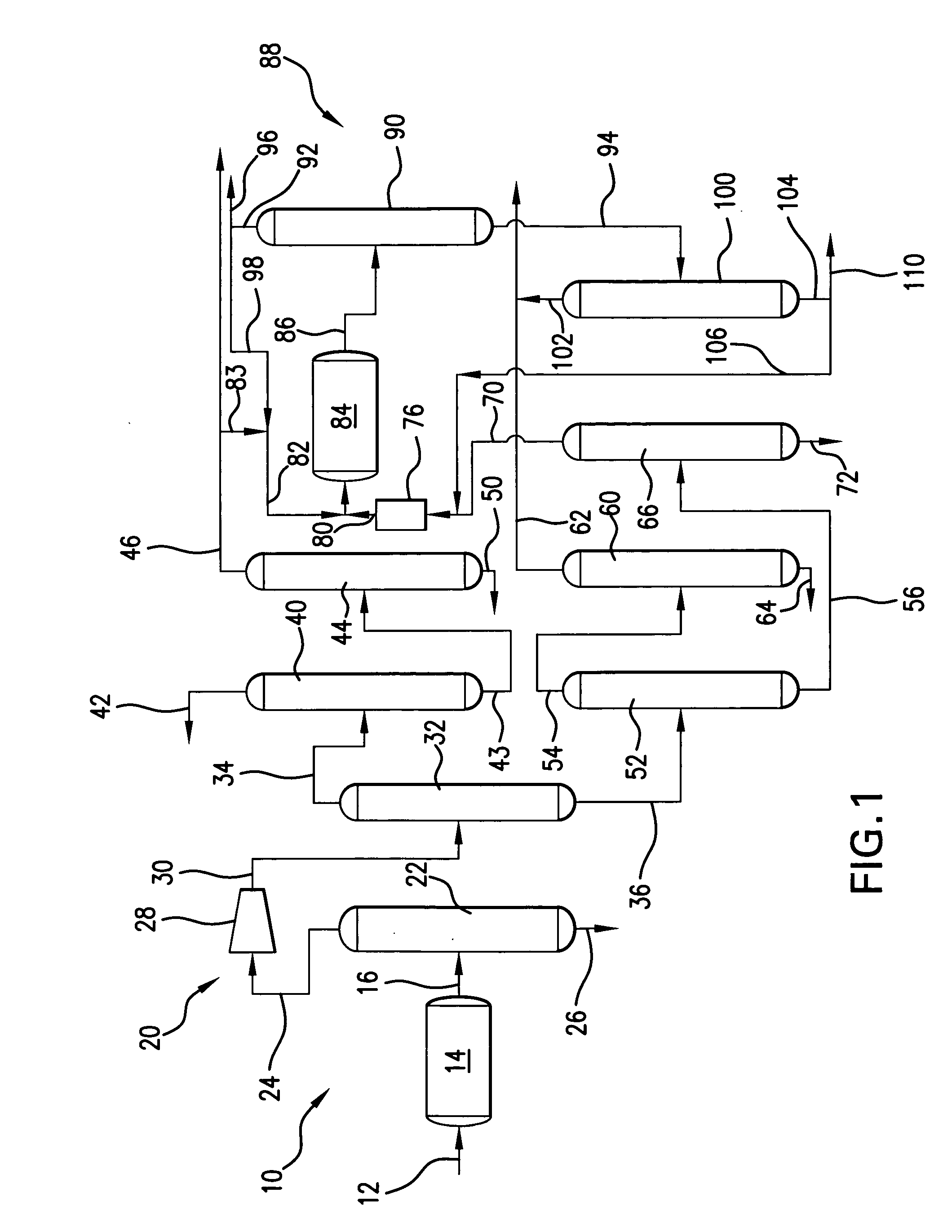

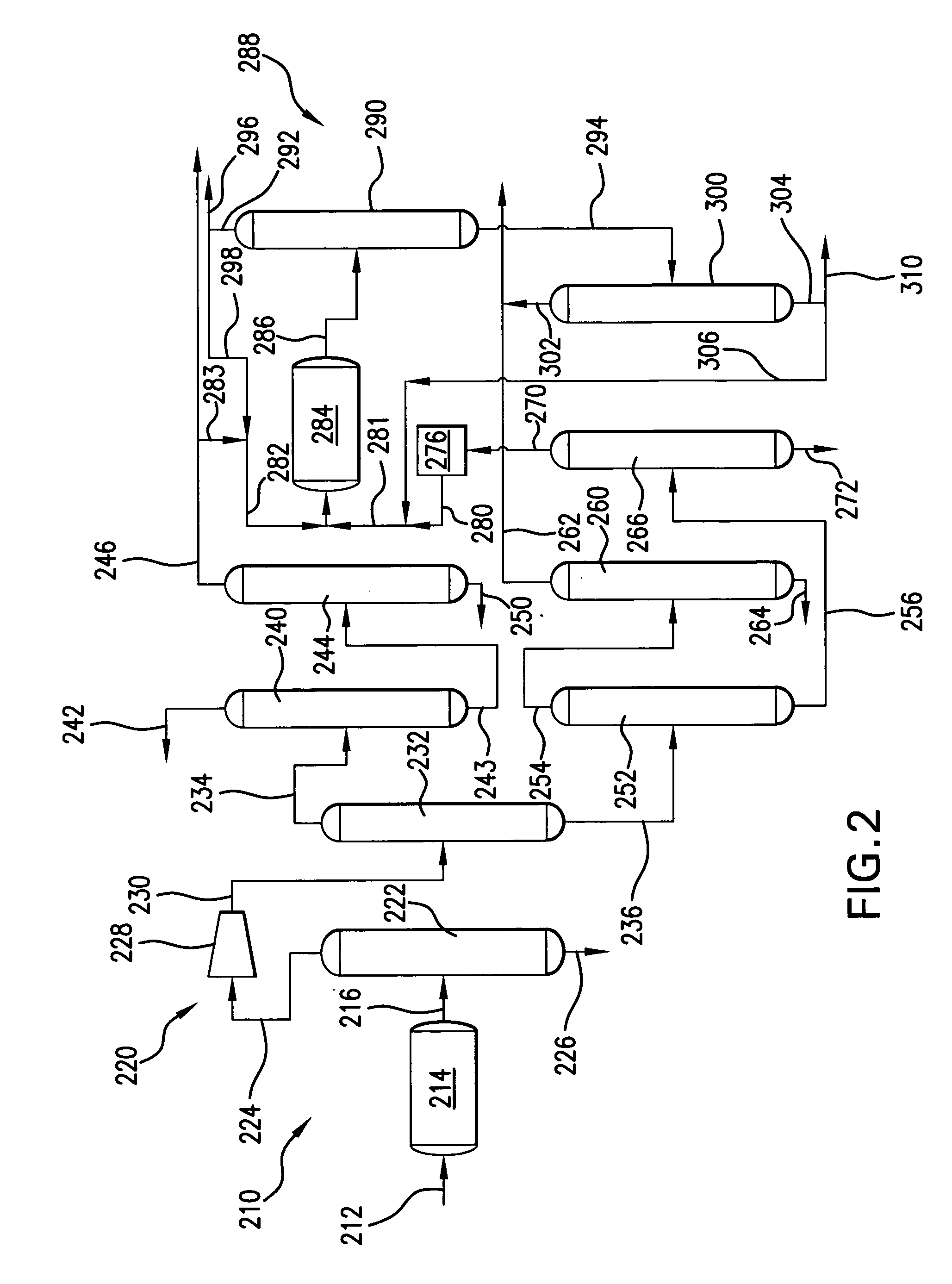

Oxygenate conversion to olefins with metathesis

InactiveUS20070203384A1Increase volumeImprove propylene yieldHydrocarbon by isomerisationOrganic chemistry methodsButeneIsomerization

Improved processing of an oxygenate-containing feedstock for increased production or yield of light olefins, particularly for increased relative yield of propylene is provided. Such processing involves oxygenate conversion to olefins and subsequent oxygenate conversion effluent stream treatment including isomerization of at least a portion of the 1-butenes to 2-butenes and metathesization of at least a portion of the 2-butenes to produce additional propylene.

Owner:UOP LLC

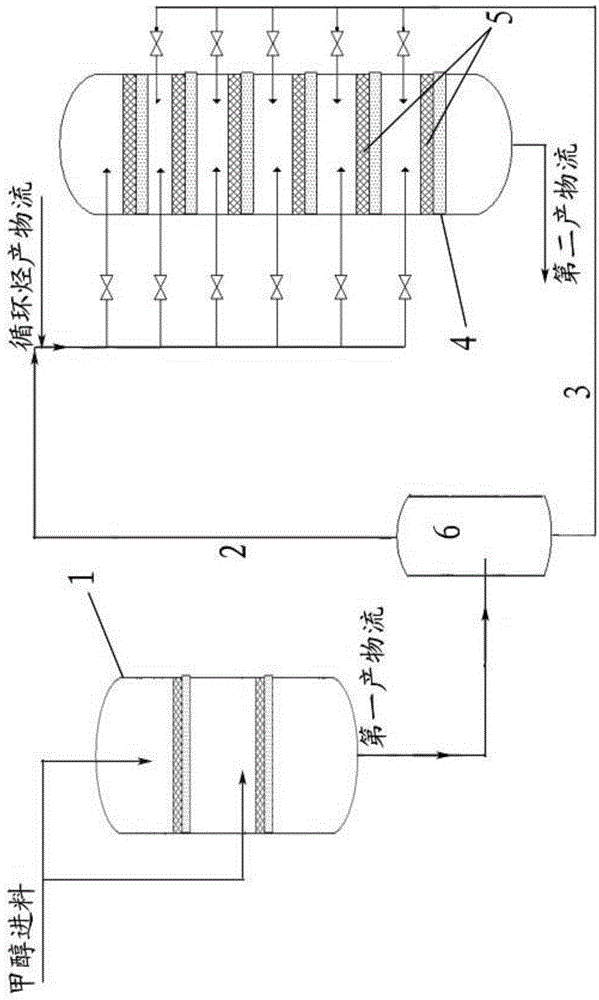

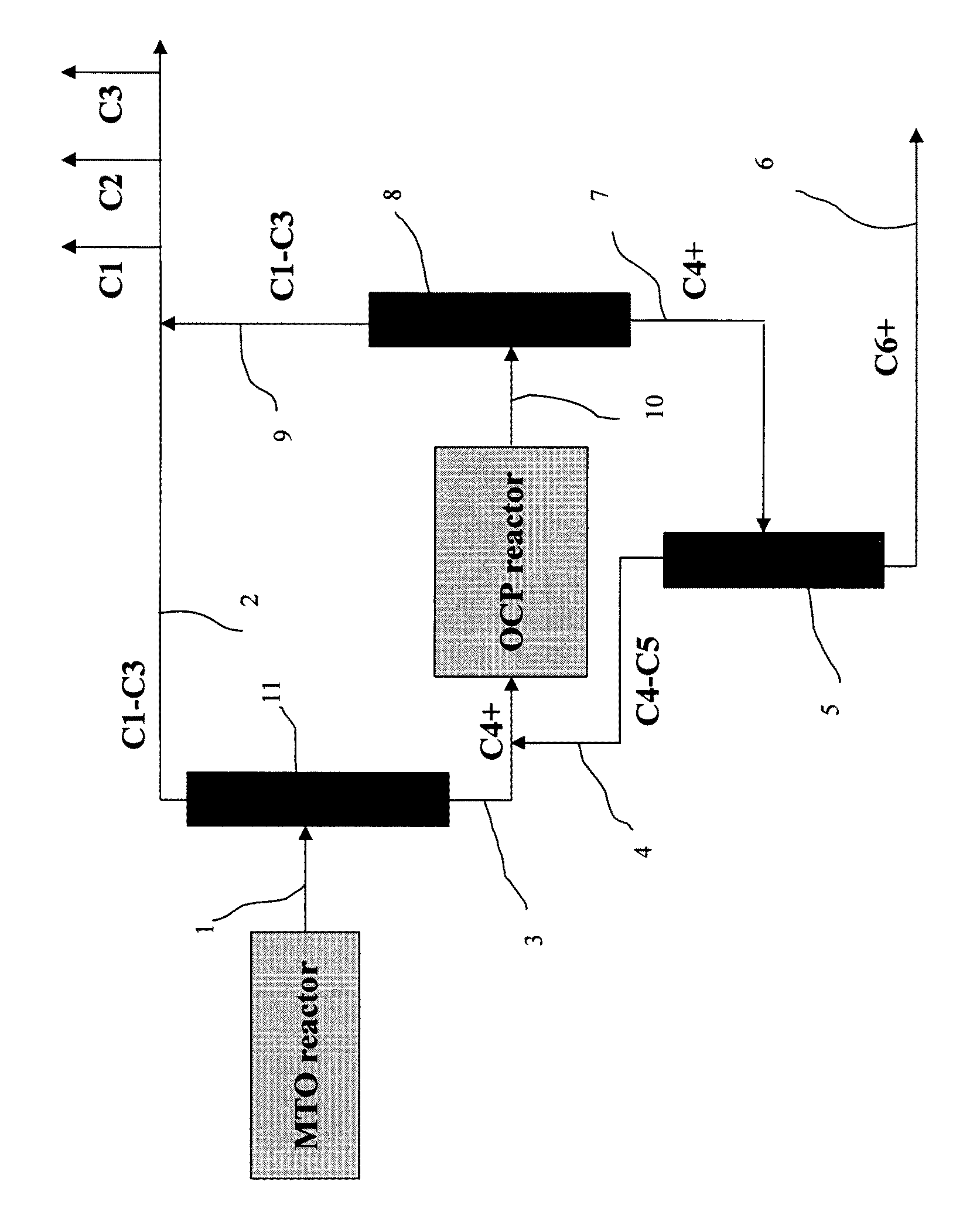

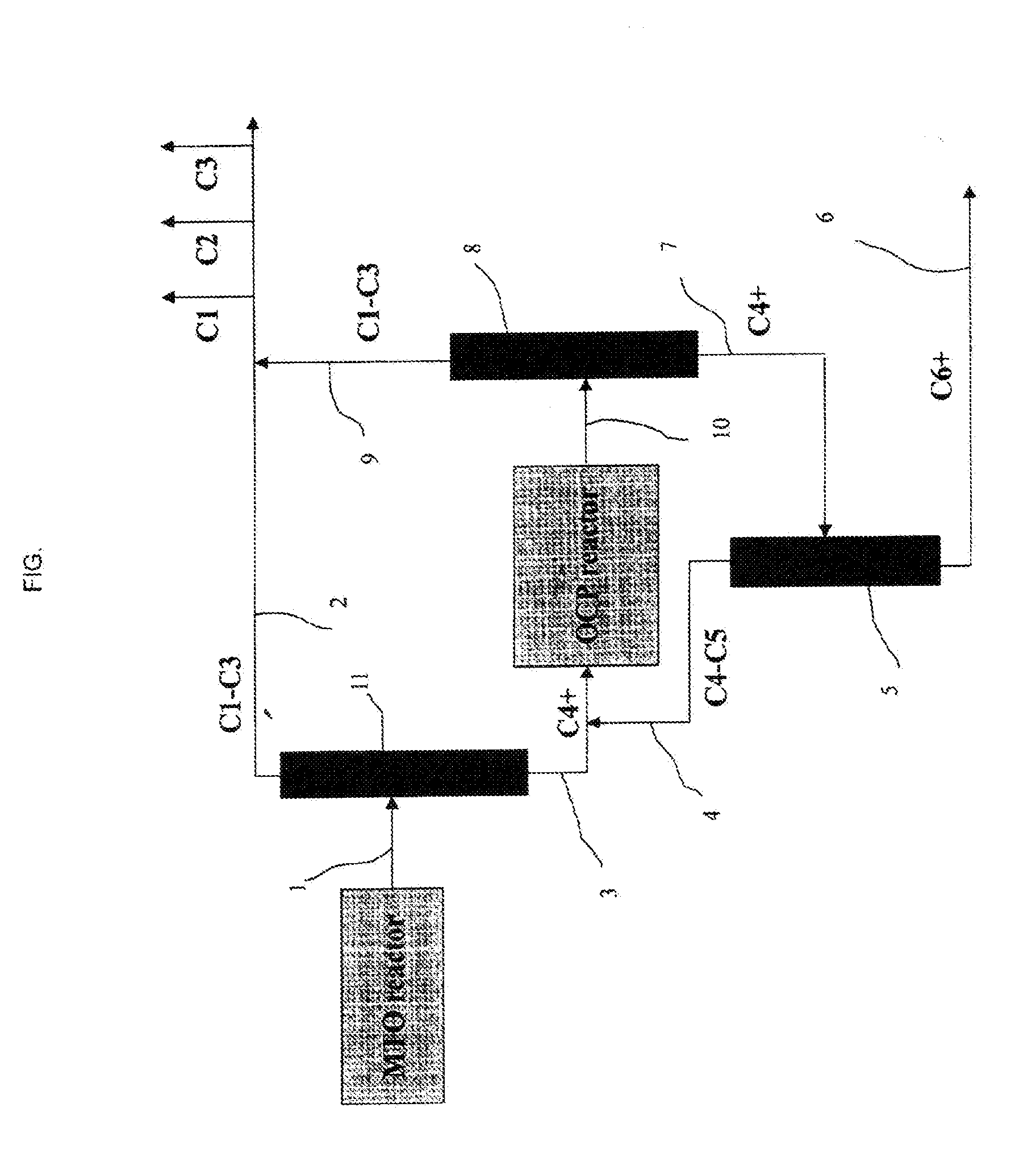

System and method of preparing propylene tail oil by value-added exploitation of methanol

PendingCN106748610AReduce energy consumptionImprove propylene yieldDistillation purification/separationHydrocarbon from oxygen organic compoundsChemistryDimethyl ether

The invention provides a system and a method of preparing propylene tail oil by value-added exploitation of methanol. The comprises a first reactor, a second reactor, a product separation unit, a c 4 hydrocarbon extraction, rectification and separation device and a heating furnace, wherein the first reactor performs dimethyl ether preparation reaction with methanol to form a first product flow; the second reactor synthesizes propylene by using a material from the heating furnace as a raw material to form a second product flow; the product separation unit receives and separates the second product flow to form propylene, c 4 hydrocarbon, a c 5 / c 6 hydrocarbon mixture and ethylene; the c 4 hydrocarbon extraction, rectification and separation device separates at least part of c 4 hydrocarbon to form a butylene product flow; and the heating furnace receives and heats at least part of first product flow, at least part of butylene product flow, at least part of c 5 / c 6 hydrocarbon mixture and at least part of ethylene. The system and the method can reprocess butylene alone, and supplement the removed butane part with the c 5 / c 6 hydrocarbon mixture; the reprocessing quantity of the tail oil is increased; the yield of propylene is increased; the value-added exploitation of the tail oil is achieved; and economic benefits are raised.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Process for preparing ethylene and propylene

InactiveUS20130245290A1Improve ethylene yieldImprove propylene yieldPreparation by oxidation reactionsMolecular sieve catalystSilicon dioxideAlkene

The present invention provides a process for preparing ethylene and propylene, comprising the step of:a) contacting a feed comprising methanol, ethanol and C4+ olefins with a catalyst, comprising ZSM-5 having a silica to alumina ratio in the range of from 40 to 100, at a temperature in the range of from 350 to 1000° C. to obtain a olefinic product comprising ethylene and propylene.

Owner:SHELL OIL CO

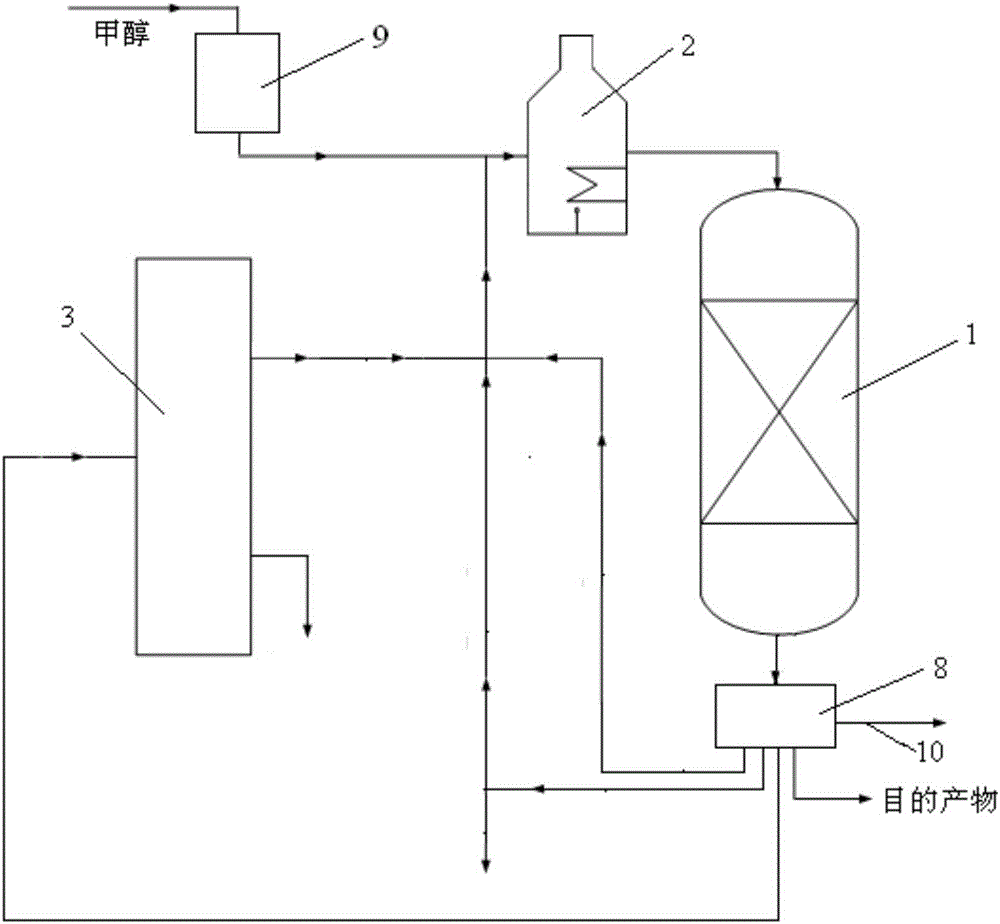

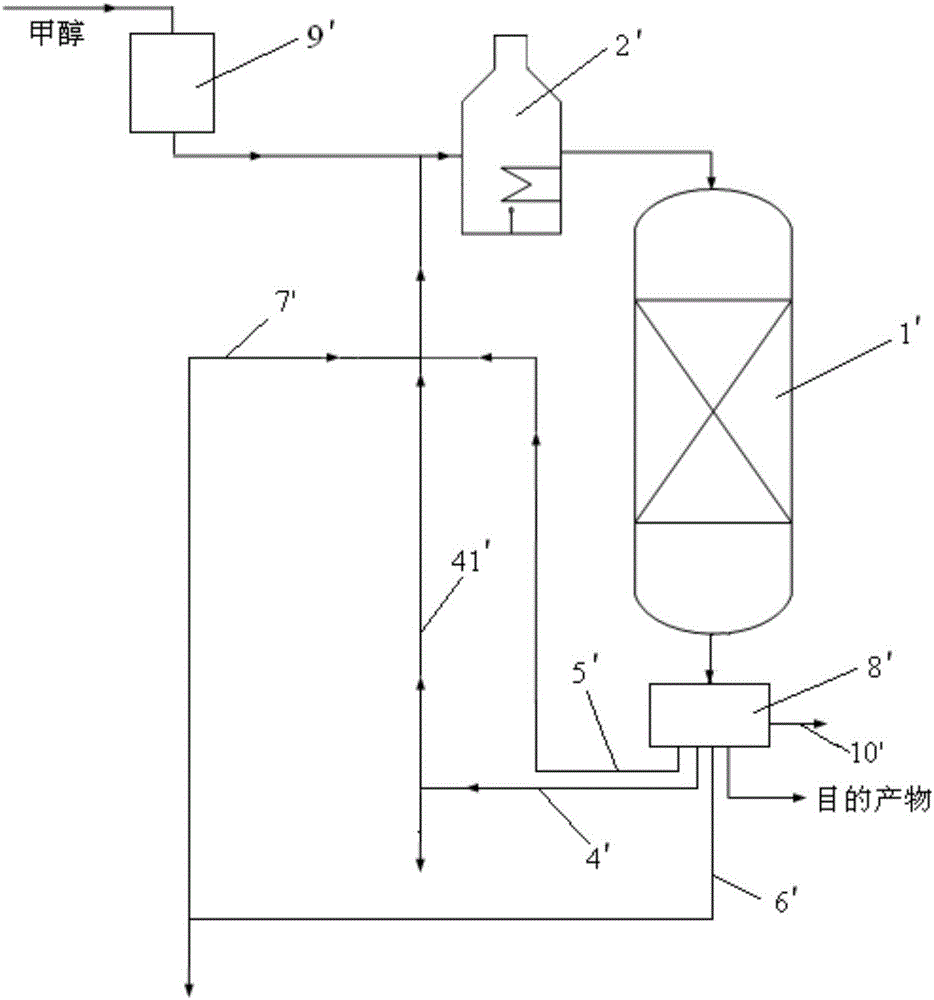

Method for preparing propylene from methanol

ActiveCN103980083AReduce carbon depositionImprove propylene yieldHydrocarbon from oxygen organic compoundsAlkaneDimethyl ether

The invention discloses a method for preparing propylene from methanol. The method comprises the step of utilizing a first reactor and a second reactor to carry out reaction for preparing propylene from methanol, wherein the first reactor is used for carrying out reaction for synthesizing dimethyl ether with methanol so as to obtain a first product flow; the second reactor is used for carrying out reaction for preparing propylene with the first product flow so as to obtain a second product flow; a plurality of catalyst bed layers are longitudinally arranged in the second reactor and are filled with first catalysts and second catalysts; the second product flow is separated to obtain circulating hydrocarbon product flows containing C2, C4, C5 and C6; and the circulating hydrocarbon product flows are sent into the second reactor again. By adopting the method, by filling two kinds of catalysts with different acidity in the reactors, the circulating hydrocarbon is partially subjected to catalytic pyrolysis on the catalyst bed layer with stronger acidity, meanwhile, secondary reactions undergone by olefin molecules, such as hydrogen transfer, aromatization and the like to generate alkane and macromolecular aromatic hydrocarbon are reduced and the yield of propylene is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Fcc catalyst additive and binder

ActiveUS20180361367A1Boost octaneIncrease productionCatalytic crackingMolecular sieve catalystsTime conditionPhosphoric acid

Provided is a process for manufacturing a Fluid Catalytic Cracking catalyst additive composition with a novel binder. The steps involve mixing an alumina source with water to make a slurry; adding to the alumina slurry an amount of P2O5 source; the slurry is then stirred and reacted under controlled temperature and time conditions to form an aluminum phosphate binder; adding to the aluminum phosphate binder a zeolite, an amount of silica binder and an amount of clay; and spray-drying the slurry to form catalyst additive particles. The catalyst additive composition comprises a about 35 wt % to about 65 wt % zeolite; about 0 wt % to about 10 wt % silica; about 15 wt % to about 50 wt % clay and an aluminum phosphate binder comprising about 2.5 wt % to 5 wt % amorphous or pseudo-boehmite alumina and about 7 wt % to 15 wt % phosphoric acid.

Owner:ALBEMARLE CORP

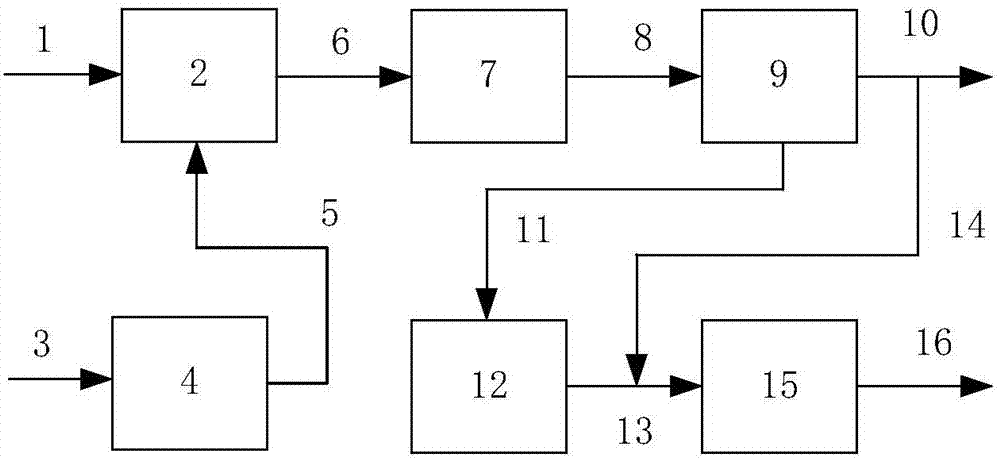

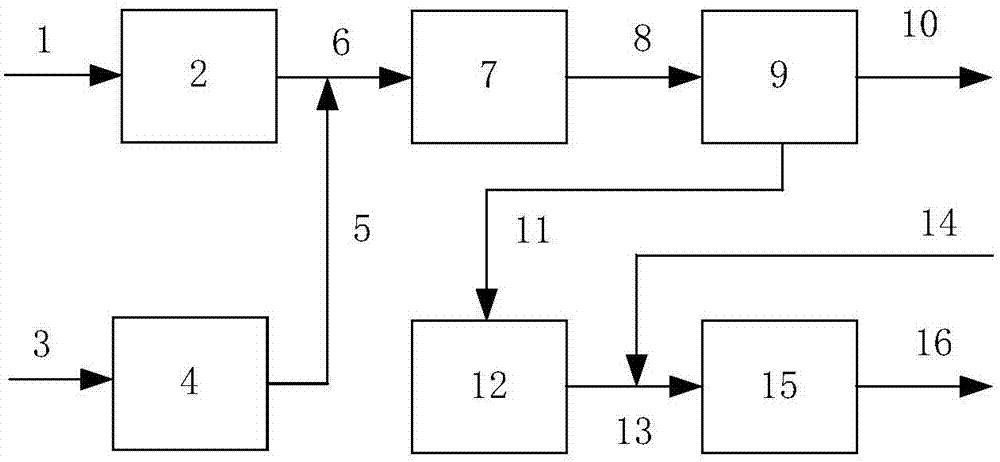

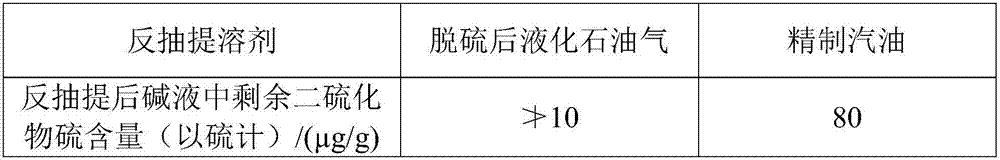

Desulfurization refining method of mixed liquefied petroleum gas

ActiveCN107201254AEasy to removeImprove propylene yieldCatalytic crackingGaseous fuelsSulfur contentHydrogen sulfide

The invention provides a refining method of mixed liquefied petroleum gas. The refining method comprises the following steps: feeding coked liquefied petroleum gas from a coking device into a riser reactor of a catalytic cracking device, and carrying out cracking reaction on the coked liquefied petroleum gas and a catalytic cracking fed material together; then distilling off mixed liquefied petroleum gas mixed with catalyzed liquefied petroleum gas from a fractionation system in the catalytic cracking device; and feeding the mixed liquefied petroleum gas into a hydrogen sulfide extraction device and a mercaptan extraction device to desorb hydrogen sulfide and mercaptan respectively. The sulfur content of the desulfurized liquefied petroleum gas product is not greater than 10 mu g / g. The refined mixed liquefied petroleum gas can be distilled to obtain a propylene product which meets the requirement of the sulfur content, and the propylene product can be used as a raw material for producing low-sulfur MTBE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst to increase propylene yields from a fluid catalytic cracking unit

ActiveUS9227181B2Improve propylene yieldCatalytic crackingMolecular sieve catalystsOrganic chemistryZSM-5 zeolite

A catalyst composition resulting in increased propylene yields during fluid catalytic cracking processes comprises (i) Y zeolite, (ii) ZSM-5 zeolite, and (iii) Beta zeolite.

Owner:BASF CORP

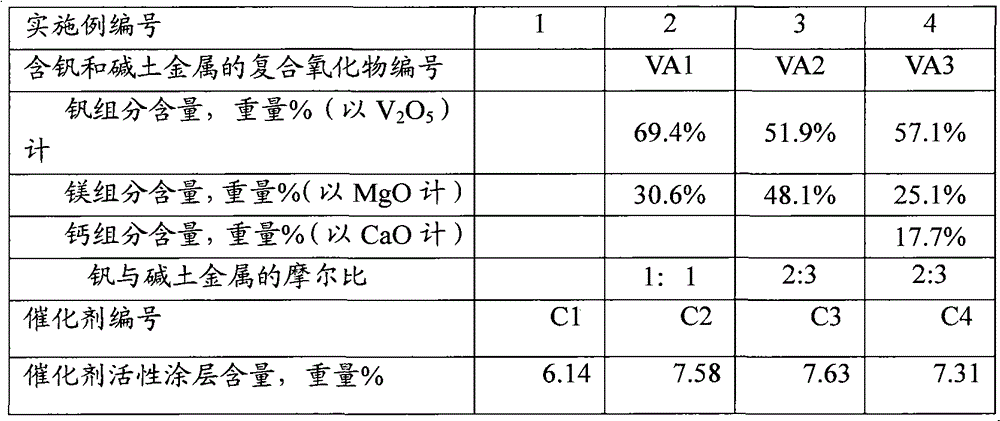

Method for reducing alkene and sulfur content in gasoline and method for producing propylene

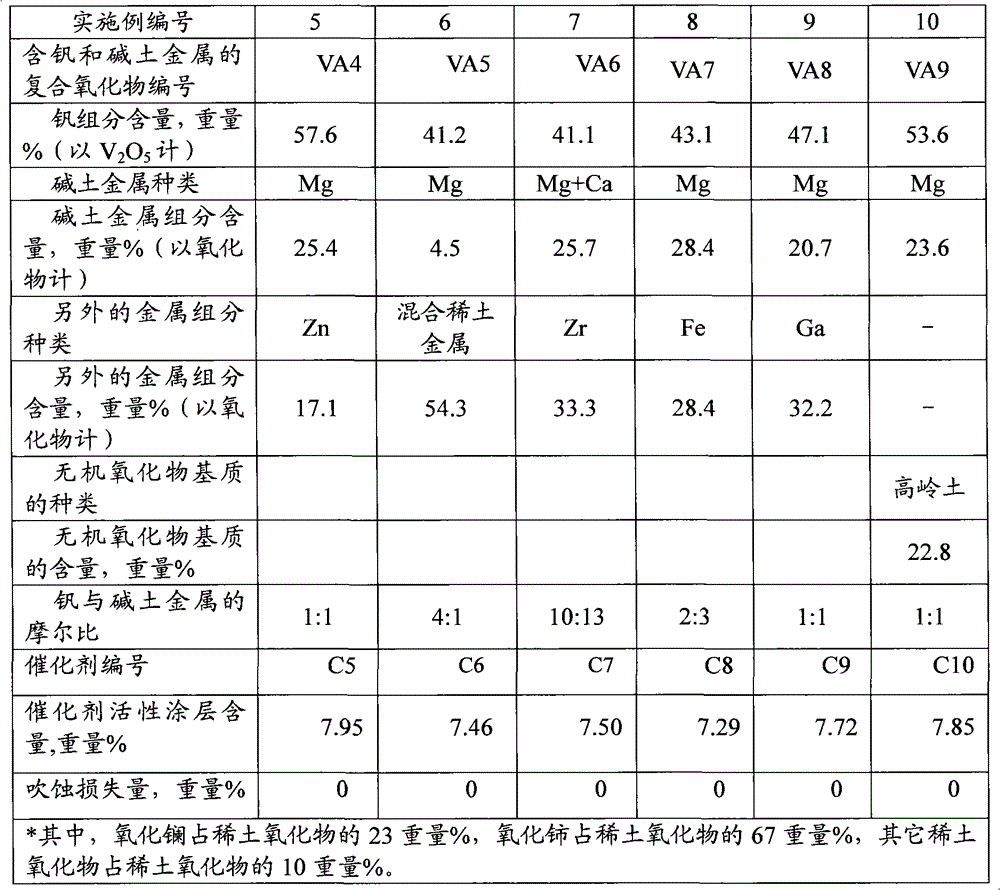

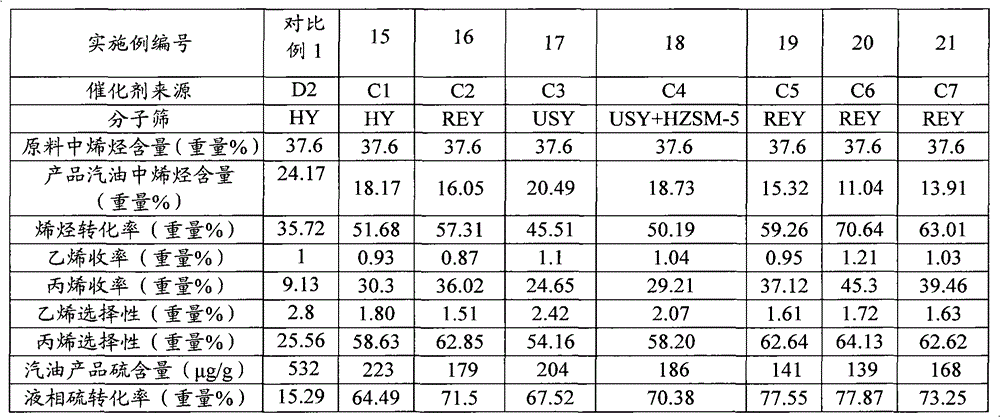

ActiveCN103058813AReduce sulfur contentReduce olefin contentMolecular sieve catalystsBulk chemical productionAlkaline earth metalContact reaction

The invention relates to a method for reducing alkene and sulfur content in gasoline and a method for producing propylene, which comprises a step that the gasoline containing alkene and sulfur enables a contact reaction with a structured catalyst composed of a cellular carrier and an active coating, the active coating comprises a molecular sieve, a vanadium component, an alkaline earth metal component and a phosphor aluminum binder; wherein the mol ratio of vanadium and alkaline earth metal is 10:1-1:60. The method is used for cracking hydrocarbon oil containing alkene and sulfur to prepare propylene, the sulfur content and alkene content in the gasoline product can be reduced to obtain a clean gasoline is reduced, and the method has higher propylene selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for obtaining a catalyst composite

ActiveUS8728969B2Low selectivityHigh yieldMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkaline earth metal

A process for obtaining a catalyst composite comprising the following steps:a). selecting a molecular sieve having pores of 10-or more-membered ringsb). contacting the molecular sieve with a metal silicate different from said molecular sieve comprising at least one alkaline earth metal and one or more of the following metals: Ga, Al, Ce, In, Cs, Sc, Sn, Li, Zn, Co, Mo, Mn, Ni, Fe, Cu, Cr, Ti and V, such that the composite comprises at least 0.1 wt % of silicate.

Owner:TOTAL RES & TECH FELUY

Process for Obtaining Modified Molecular Sieves

ActiveUS20150259264A1Low selectivityHigh yieldMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkaline earth metal

A process may include contacting an oxygen-containing, halogenide-containing or sulphur-containing organic feedstock in an XTO reactor with a catalyst composite under conditions effective to convert the oxygen-containing, halogenide-containing or sulphur-containing organic feedstock to olefin products. The catalyst composite may include at least 10 weight percent of a modified molecular sieve. The modified molecular sieve may include at least 0.05 weight percent of an alkaline earth metal or a rare earth metal based on a weight of the modified molecular sieve. The modified molecular sieve may include at least 0.3 weight percent of P based on the weight of the modified molecular sieve.

Owner:TOTAL RES & TECH FELUY

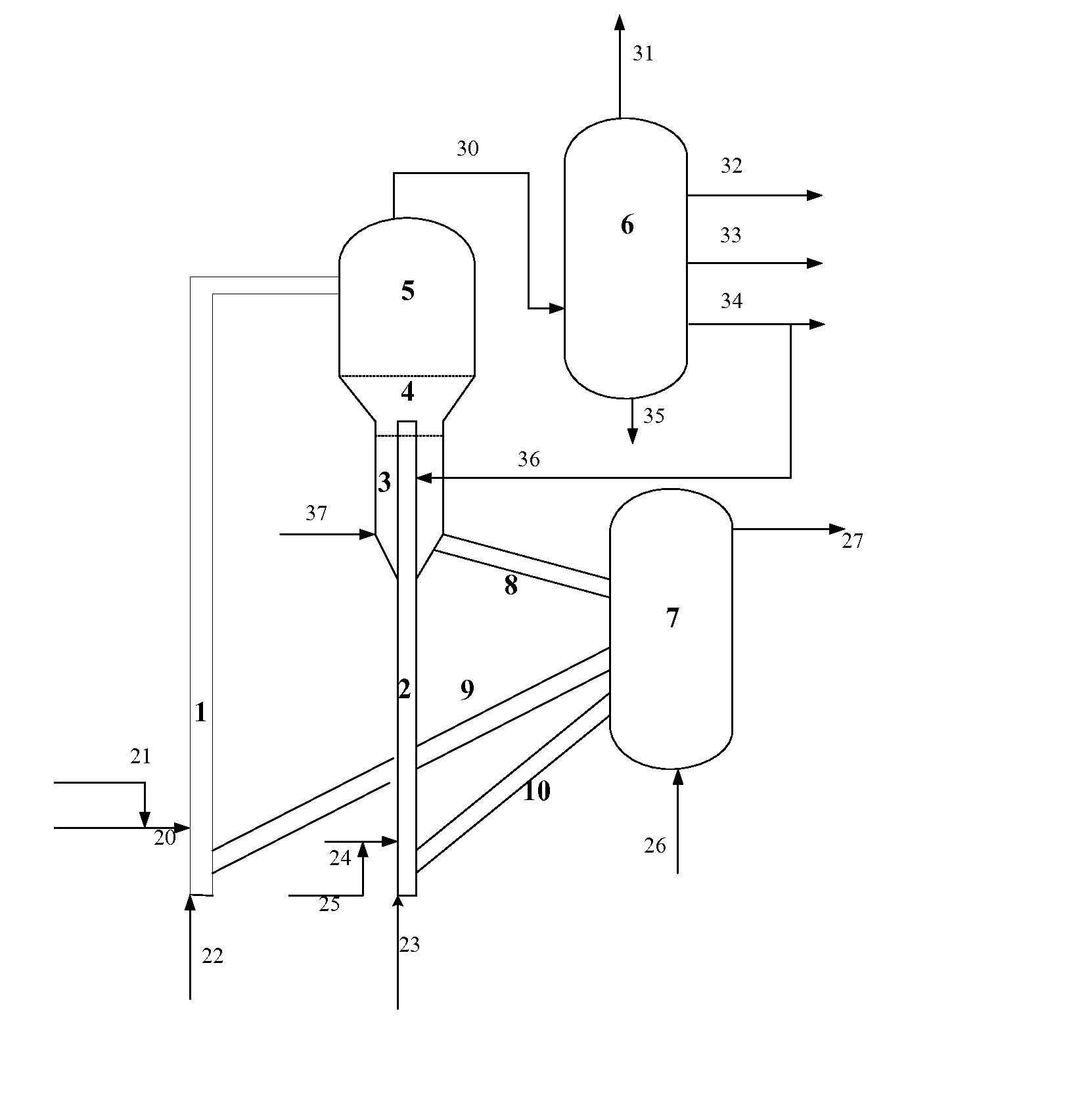

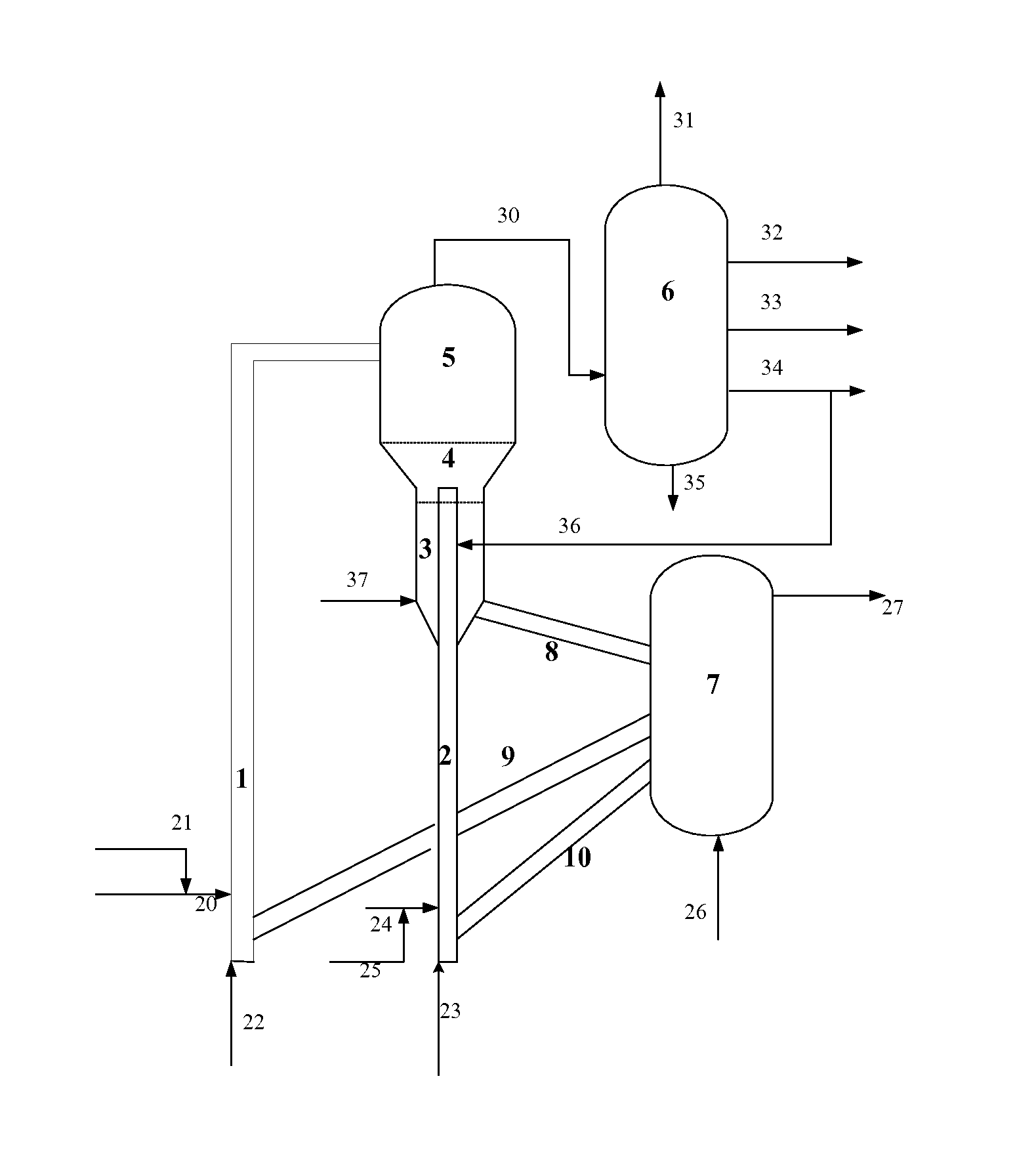

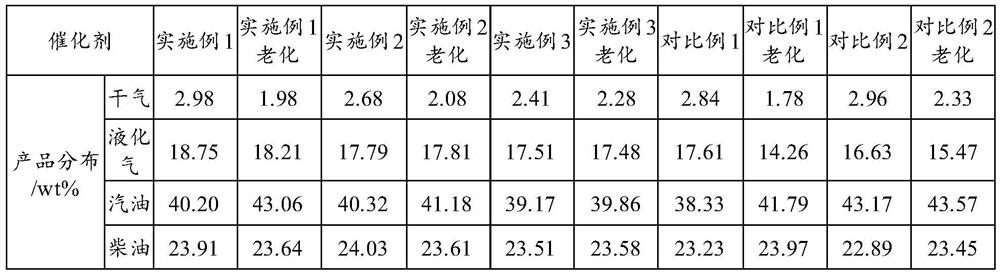

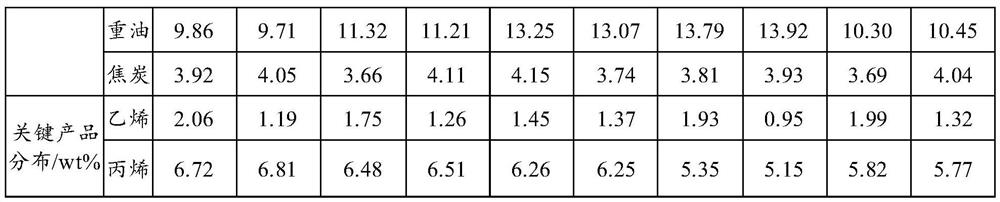

Catalytic conversion process

ActiveUS8696887B2Improve propylene yieldReduce yieldCatalytic crackingMolecular sieve catalystsCatalytic transformationGasoline

A catalytic conversion process which comprises catalytic cracking reaction of a hydrocarbon feedstock contacting with a medium pore size zeolite enriched catalyst in a reactor, characterized in that reaction temperature, weight hourly space velocity and catalyst / feedstock ratio by weight are sufficient to achieve a yield of fluid catalytic cracking gas oil between 12% and 60% by weight of said feedstock, wherein said weight hourly space velocity is between 25 h−1 and 100 h−1, said reaction temperature is between 450° C. and 600° C., and said catalyst / feedstock ratio by weight is between 1 and 30. This invention relates to a catalytic conversion process, especially for heavy feedstock oil to produce higher octane gasoline and an enhanced yield of propylene. More particularly, the invention relates to a process to utilize petroleum oil resources efficiently for decreasing the yield of dry gas and coke significantly.

Owner:CHINA PETROCHEMICAL CORP +1

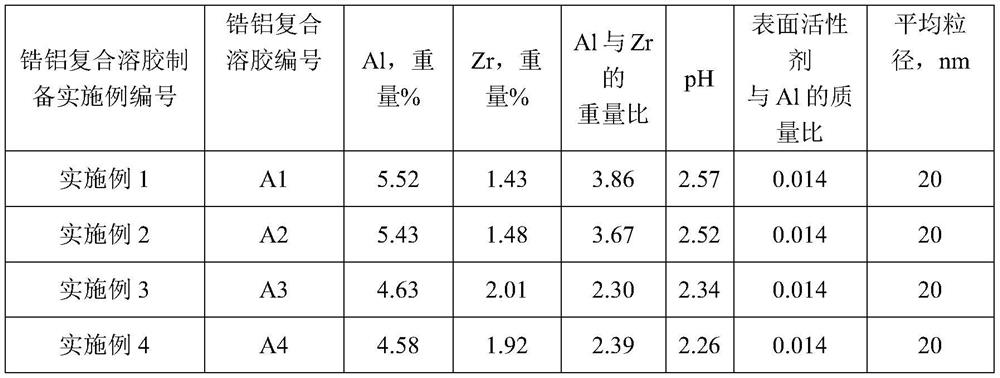

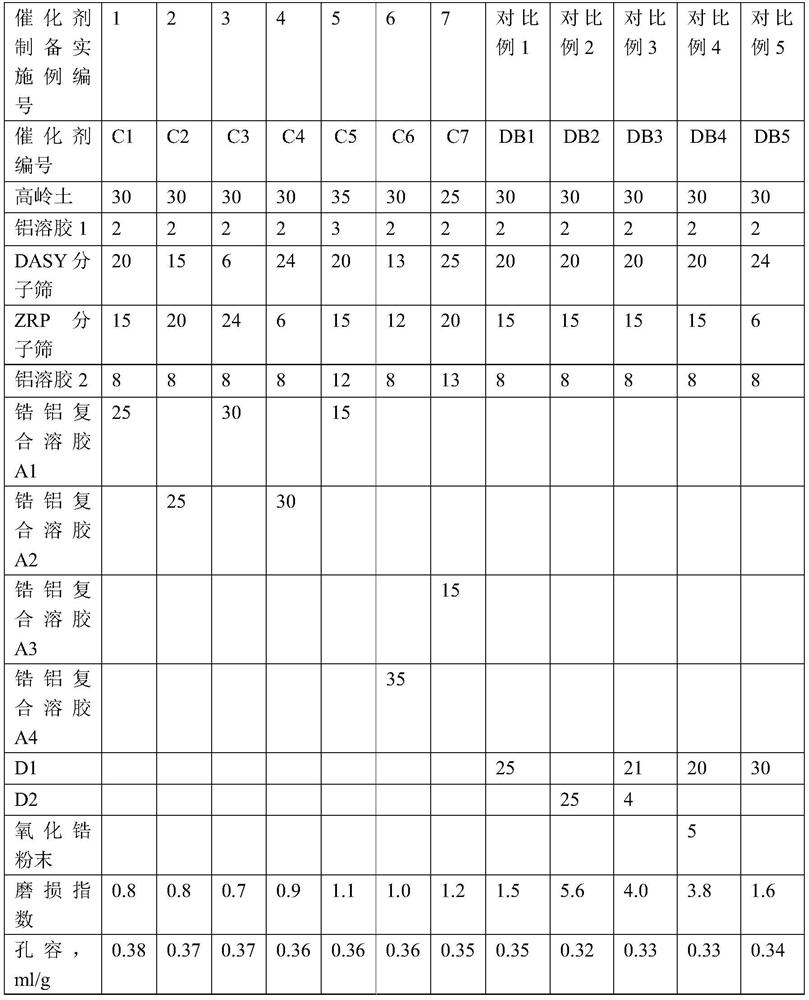

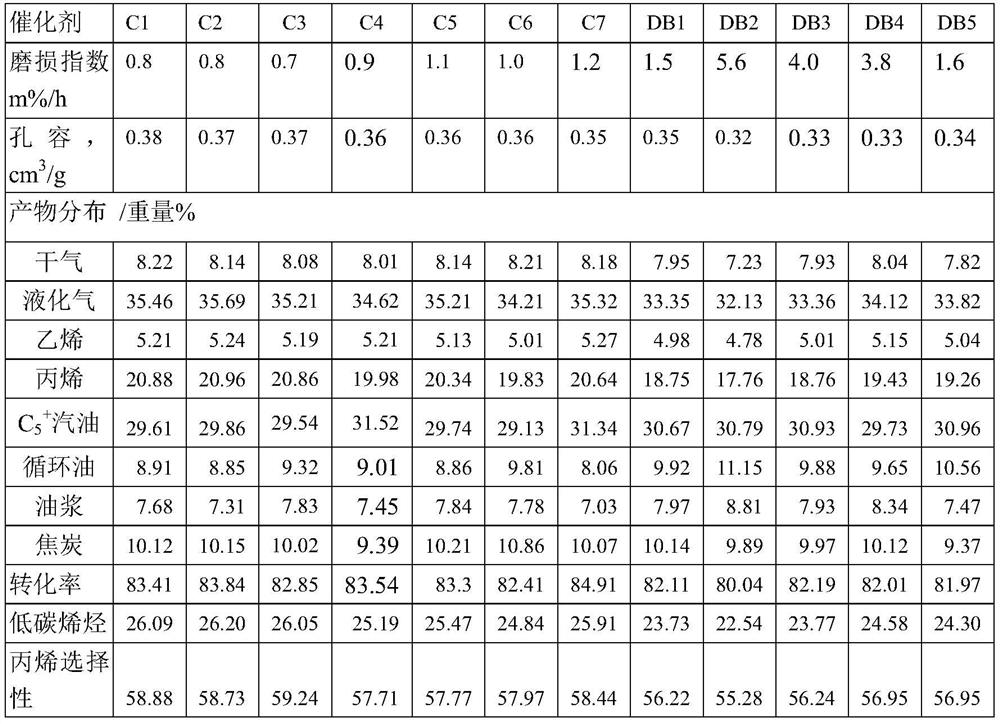

Catalytic cracking catalyst for producing propylene as well as preparation method and application method thereof

ActiveCN112473732AImprove wear resistanceHigh cracking activityMolecular sieve catalystsHydrocarbon oil crackingPtru catalystHigh activity

The invention belongs to the technical field of catalytic cracking catalysts and discloses a catalytic cracking catalyst for producing propylene as well as a preparation method and an application method of the catalytic cracking catalyst. The catalyst comprises natural minerals, zirconium-aluminum composite sol, other inorganic oxide binders, a Y-type molecular sieve and an MFI structure molecularsieve. The preparation method of the catalyst comprises the following steps: mixing and pulping the MFI structure molecular sieve, the Y-type molecular sieve, the natural minerals, the zirconium-aluminum sol and other inorganic oxide binders, and carrying out spray drying. The catalyst has good strength and high activity, is used for catalytic cracking of hydrocarbon oil, and has high raw material conversion rate and high propylene yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking apparatus and process

ActiveUS9234143B2Increase productionHeavy oil conversion is effectively increasedTreatment with plural serial cracking stages onlyCatalytic crackingFuel oilChemistry

Owner:CHINA PETROCHEMICAL CORP

Process for production of C3 olefin in a fluid catalytic cracking unit

ActiveUS9573865B2Improve propylene yieldReduce capacityCatalytic crackingHydrocarbon by hydrocarbon crackingFluidized bedLift line

A process for increasing the yield of C3 olefin in fluidized bed catalytic cracking of hydrocarbon feedstocks is disclosed. C4 fraction produced from the cracking of hydrocarbon feedstock in the primary reaction zone (riser), optionally with external source of C4 stream is fed into the stripper which acts as a secondary reaction zone at an elevated temperature and at an optimum WHSV. The elevated temperature is achieved by injecting a part of the regenerated catalyst from regenerator, which is at a higher temperature, directly into the stripper through a dedicated additional lift line. This raises the activity of catalyst inside the stripper. The direct injection of regenerated catalyst into the stripper, besides producing higher yields of propylene, improves the stripping efficiency leading to enhanced recovery of strippable hydrocarbons.

Owner:INDIAN OIL CORPORATION

Catalytic cracking prolific propylene catalyst and preparation method thereof

PendingCN114225958AImprove propylene yield and propylene selectivityGood hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sievePetrochemical

The invention provides a catalytic cracking prolific propylene catalyst and a preparation method thereof. The preparation method comprises the following steps: a) sequentially carrying out phosphorus modification and metal modification on a hydrogen type ZSM-5 molecular sieve to obtain a modified molecular sieve; b) mixing a binder with water to obtain precursor slurry, and sequentially adding kaolin, pseudo-boehmite, hydrochloric acid and the modified molecular sieve obtained in the step a) under a stirring condition to obtain propylene catalyst mother liquor; and c) molding the propylene catalyst mother liquor obtained in the step b), and roasting to obtain the catalytic cracking productive propylene catalyst. Compared with the prior art, the preparation method provided by the invention has the advantages that the hydrogen type ZSM-5 molecular sieve is adopted as the raw material, modification treatment is carried out in cooperation with specific steps, the overall better interaction is realized, and the prepared catalytic cracking prolific propylene catalyst has higher propylene yield and propylene selectivity, and is good in hydrothermal stability; the catalyst can be better used in the field of petrochemical catalytic cracking.

Owner:SHANDONG JINGBO PETROCHEM

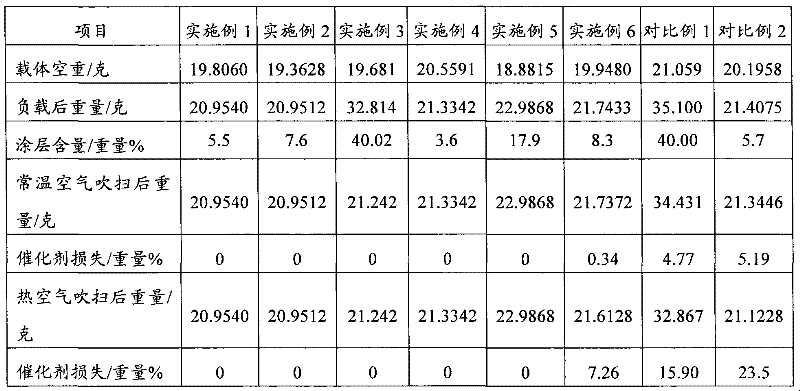

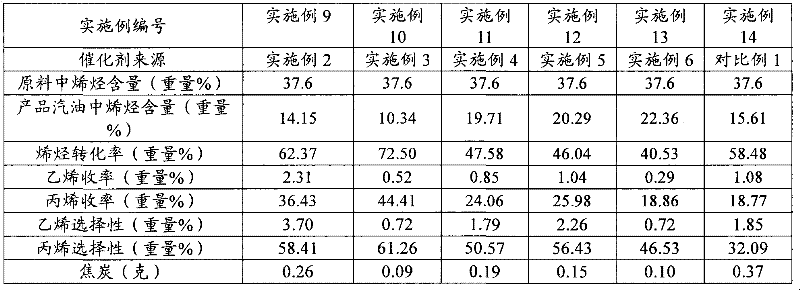

Preparation method for honeycomb carrier catalyst for gasoline conversion

ActiveCN102451735AAvoid crackingHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

The present invention relates to a preparation method for a honeycomb carrier catalyst for gasoline conversion. The method comprises the following step, wherein the step comprises: coating a honeycomb carrier by a coating slurry, the coating slurry comprises a molecular sieve, a silicon oxide component and water, the coating slurry contains or does not contain the dispersing agent. With adopting the weight of the coating slurry as the reference, the weight of the molecular sieve is 3-60% of the weight of the coating slurry. The particle diameter of the silicon oxide component is less than 100 nm. The particle diameter d90 of the molecular sieve is 1-10 mum. The molecular sieve composition-containing honeycomb carrier catalyst prepared by the method of the present invention has the solid coating, and the prepared gasoline conversion catalyst has high olefin conversion rate and high propylene yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com