Desulfurization refining method of mixed liquefied petroleum gas

A liquefied petroleum gas and refining method technology, applied in the refining field of hydrocarbon materials, can solve the problems of difficulty in obtaining deep desulfurization effect, unfavorable separation of hydrocarbon phase and alkali phase, unfavorable and other problems, and achieve reduced operating costs, convenient operation, and effective significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

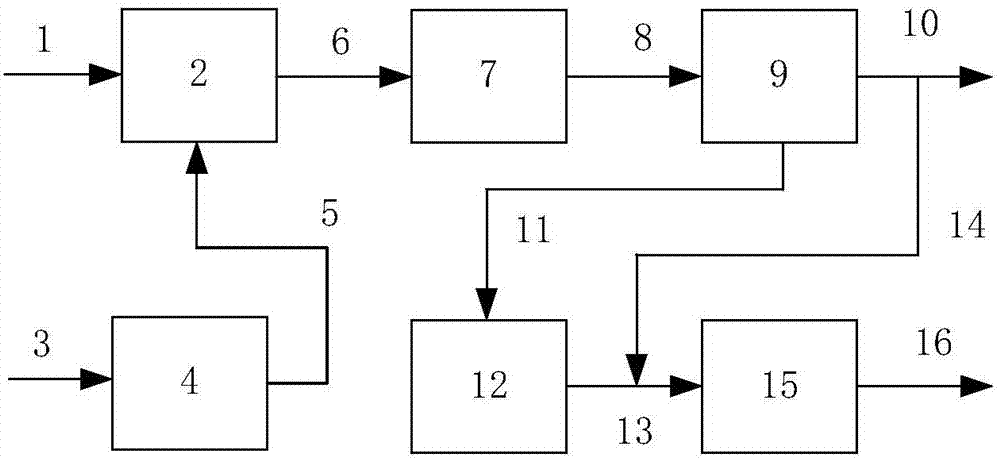

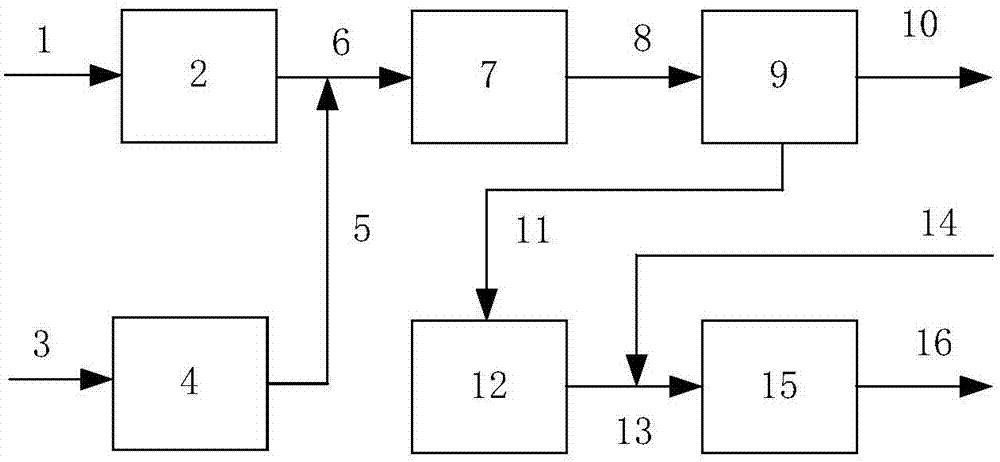

Method used

Image

Examples

Embodiment 1

[0028] A refinery produces coking liquefied petroleum gas from the coking unit, and the sulfur content is reduced to about 3000mg / m after treatment with alcohol amine 3 , and then the sulfur content was reduced to 200mg / m3 after lye extraction 3 ~300mg / m 3 about.

[0029] The refinery produces catalytic liquefied petroleum gas from the catalytic cracking unit, which is treated with alcoholamines to reduce the sulfur content to about 200mg / m 3 , and then the sulfur content was reduced to 5mg / m3 after lye extraction 3 .

[0030] According to the present invention, the coked liquefied petroleum gas produced in the coking unit is connected to the riser reactor of the catalytic cracking unit through a pipeline, and injected through a nozzle, and the coked liquefied petroleum gas and the catalytic cracking raw material are cracked together in the riser. Subsequently, the mixed liquefied petroleum gas is distilled from the fractionation system of the catalytic cracking unit, and ...

Embodiment 2

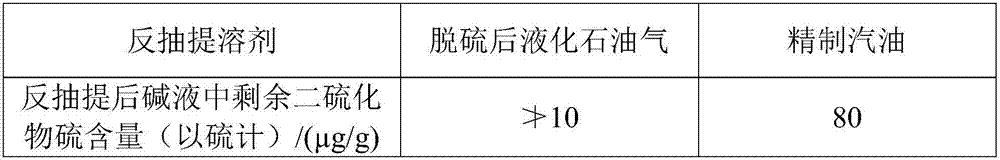

[0034] This example is used to illustrate the effect of using liquefied petroleum gas after alkali extraction and desulfurization as a back extraction solvent for removing disulfides in alkali liquor.

[0035] In this embodiment, sodium hydroxide solution is used as the lye of the liquefied petroleum gas alkali extraction unit, and its mass fraction is 20%, and 200 μg / g~500 μg / g of sulfonated cobalt phthalocyanine (commercially available) is dissolved in the lye Sold product), as an oxidation catalyst to oxidize and regenerate the lye that has absorbed mercaptan.

[0036] The operation steps of extraction and desulfurization refining are as follows:

[0037] The sodium hydroxide lye is contacted with the liquefied petroleum gas after removing hydrogen sulfide through the alcohol amine solution (40% MDEA solution) in the extraction system, the mercaptan in the liquefied petroleum gas is transferred into the lye, and the liquefied petroleum gas after desulfurization The gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com