Catalytic cracking catalyst for producing propylene as well as preparation method and application method thereof

A catalytic cracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low propylene selectivity, achieve high propylene selectivity, good wear resistance, and high conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

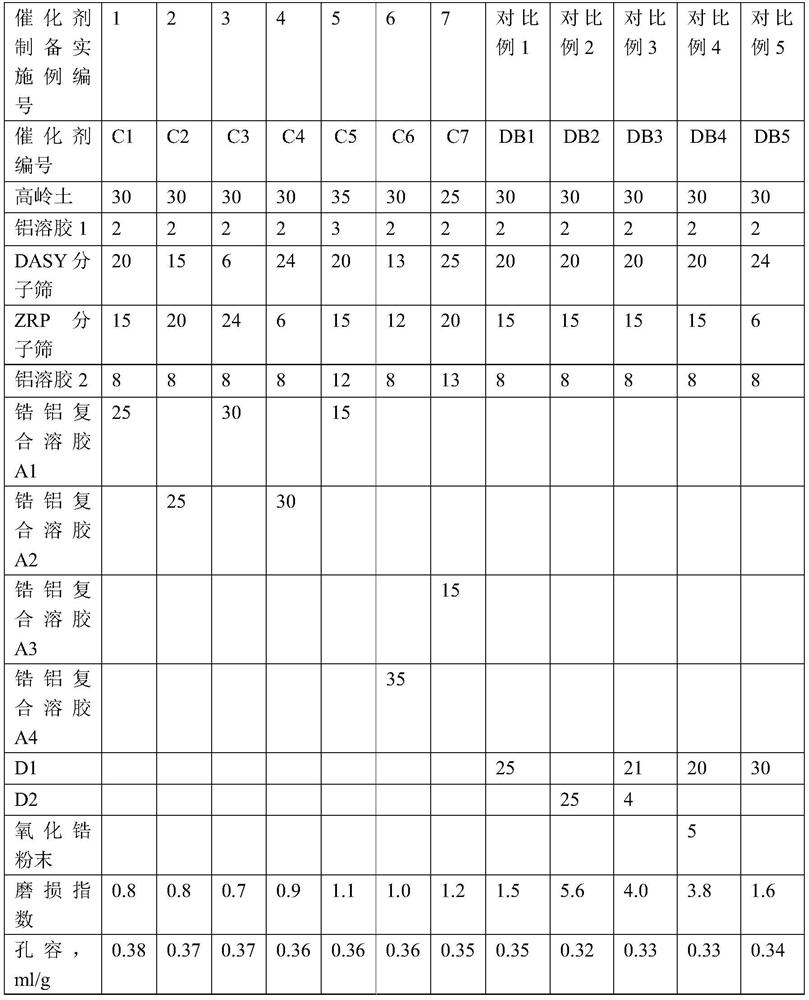

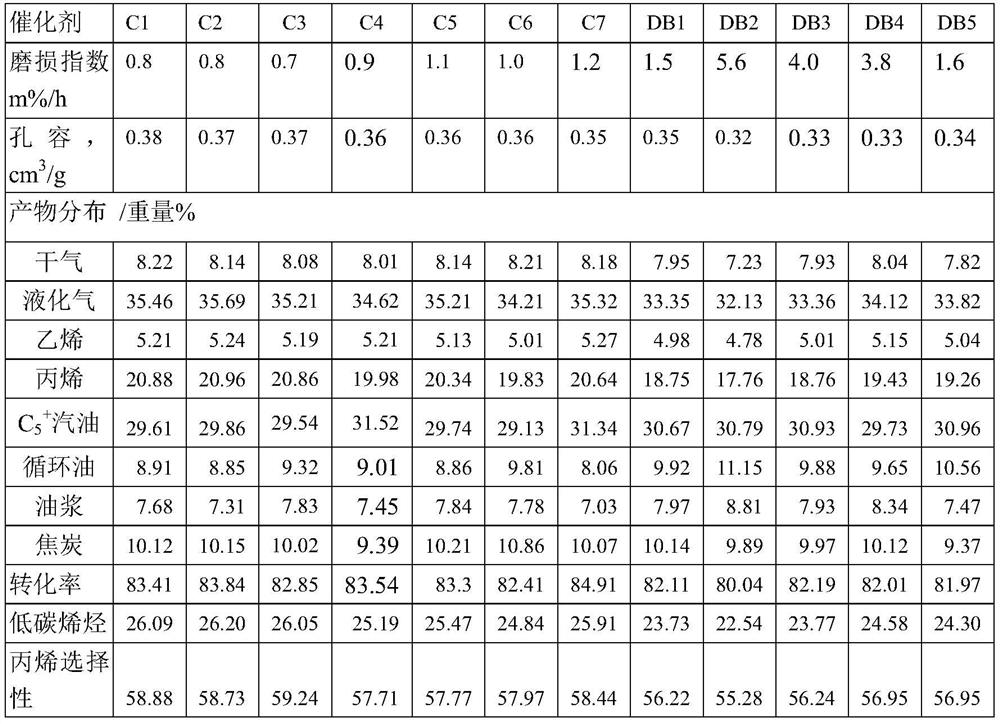

Examples

Embodiment approach

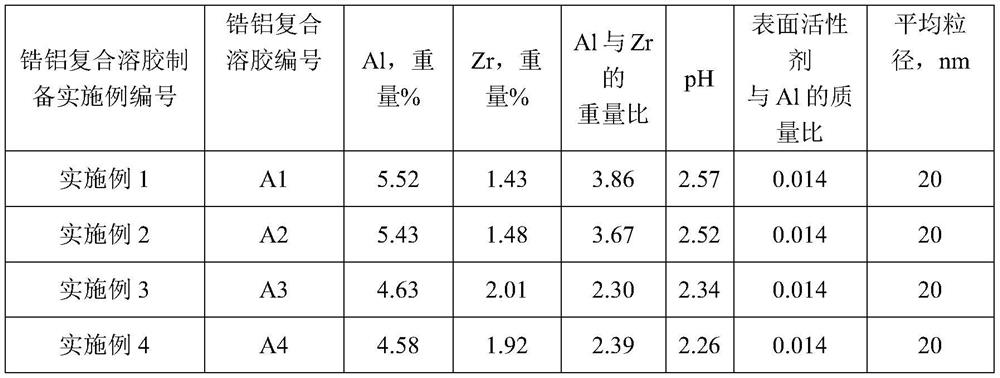

[0040] According to the catalyst preparation method provided by the present invention, one embodiment, the preparation method of the zirconium-aluminum composite sol includes the following steps:

[0041] The mixture containing alumina precursor, zirconium dioxide precursor, acid, surfactant and water is acidified and hydrolyzed; the conditions of said acidified hydrolysis include: the temperature is 10-100°C, and the time is 0.2-5h. Preferably, the acidification hydrolysis conditions include: the temperature is 10-60° C., and the time is 0.5-2 h. More preferably, the temperature is 20-45° C., and the time is 0.5-1 h.

[0042] In the method for preparing the zirconium-modified composite sol of the present invention, there is no particular limitation on the specific method for obtaining the mixture, but in order to further improve the performance of the obtained zirconium-aluminum composite sol, preferably, the alumina precursor, zirconium dioxide The precursor, acid and water ...

specific Embodiment approach A

[0050] The method for preparing the zirconium modified composite sol of the present invention, a specific embodiment A, includes: adding the alumina precursor to the acid solution, and dispersing for 10-60min, the dispersion is preferably carried out in a homogenizer, and then adding The aqueous solution of the precursor of zirconium dioxide is dispersed for 10-60 minutes. The dispersion is preferably carried out in a homogenizer to obtain a first mixture; a surfactant is added to the first mixture for acidification and hydrolysis.

specific Embodiment approach B

[0051] According to the preparation method of zirconium modified composite sol according to the present invention, a specific embodiment B, the method includes: under stirring conditions, adding alumina precursors and zirconia precursors to the acid solution, and continuing to stir for 10-60min , to obtain the first mixture; adding a surfactant to the first mixture for acidification and hydrolysis.

[0052] According to the preparation method of the zirconium-modified composite sol of the present invention, the product of the above acidification and hydrolysis is the zirconium-aluminum composite sol, which can be directly used to prepare the catalyst. Preferably, the method further includes: reacting the product obtained by the acidification hydrolysis under ultrasonic conditions (this invention is called ultrasonic treatment). The product obtained after ultrasonic treatment was used to prepare the catalyst.

[0053] According to a preferred embodiment of the method for prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com