Highly dispersed ZnO-based catalyst as well as preparation method and propane anaerobic dehydrogenation method thereof

A catalyst and highly dispersed technology, which is applied in the direction of catalyst activation/preparation, molecular sieve catalysts, and catalysts containing molecular sieves. It can solve the problems of easy loss of active components of catalysts, expensive precious metal catalysts, and environmental pollution of Cr-based catalysts. Achieve good catalysts The effect of stability, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

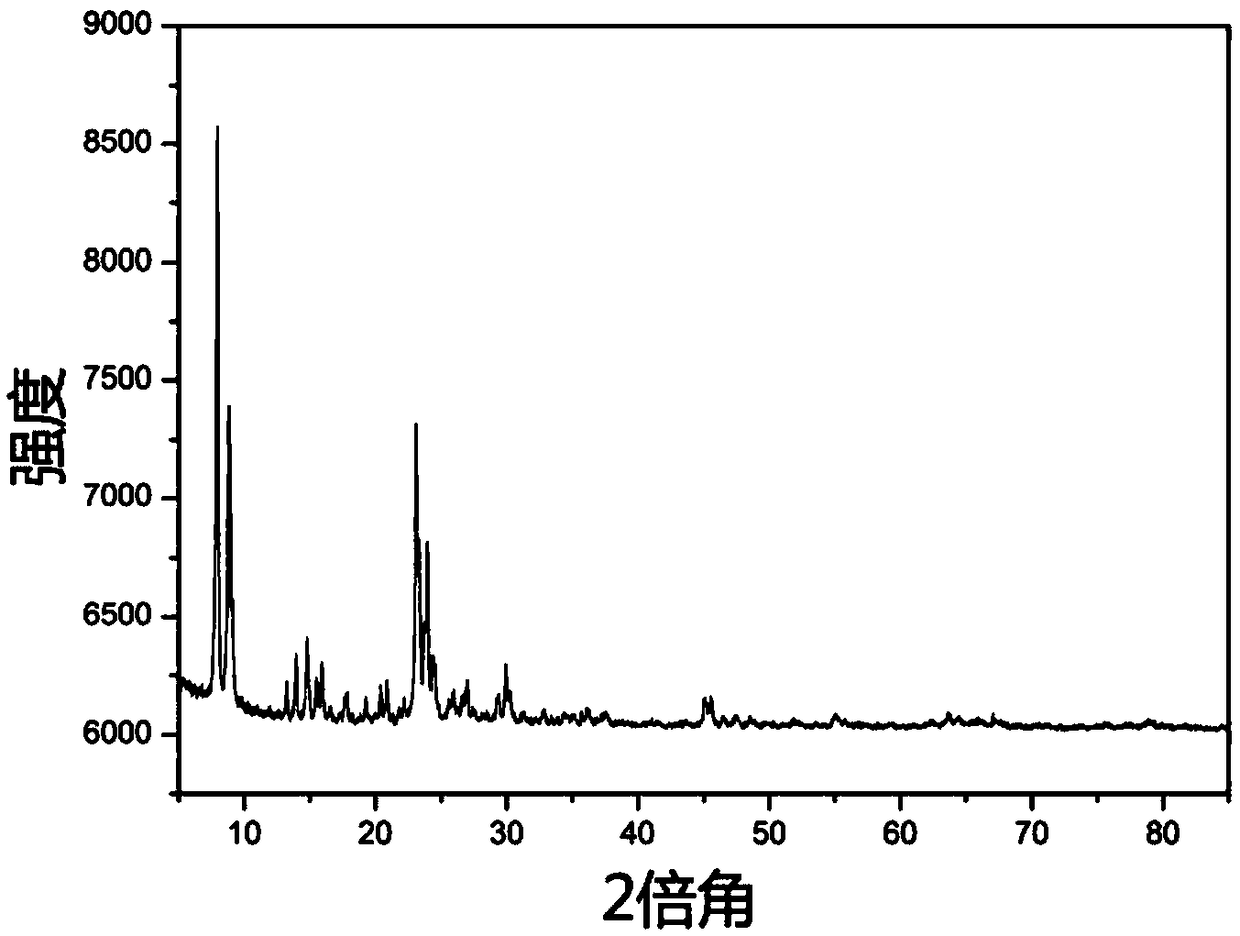

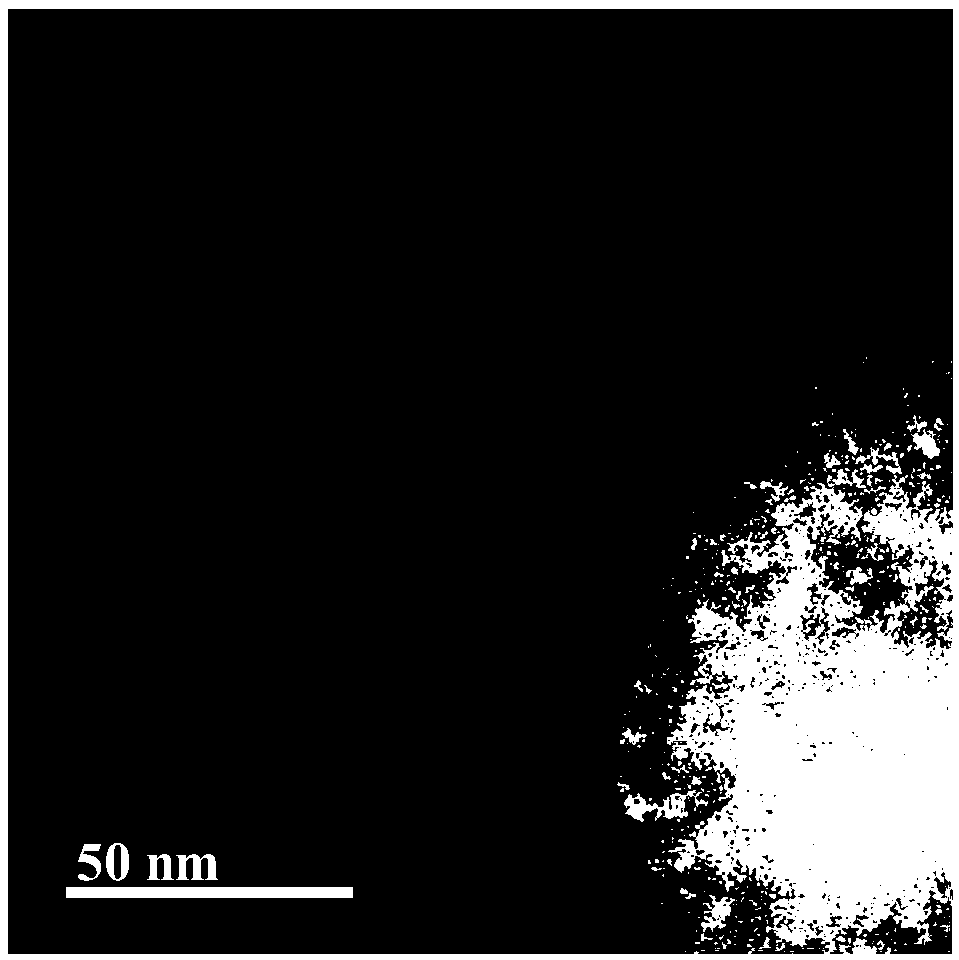

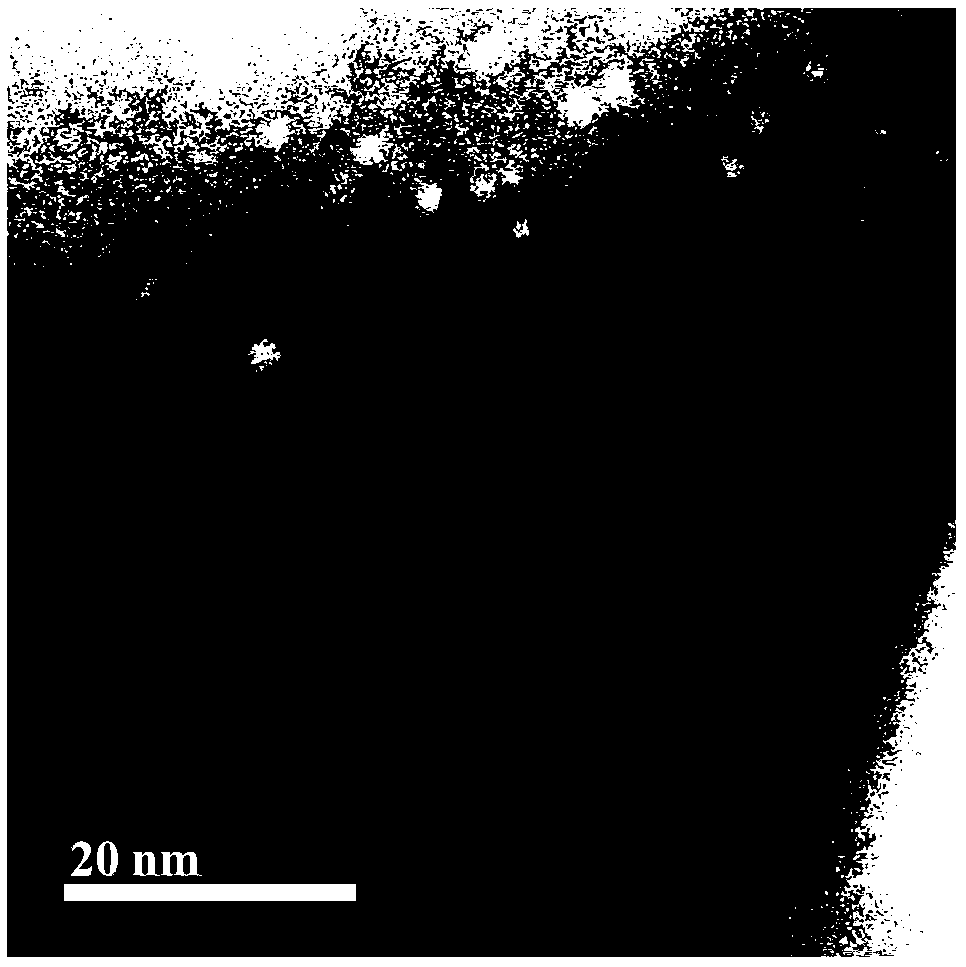

[0046] This embodiment provides a preparation method of a highly dispersed ZnO-based catalyst, wherein the mass content of ZnO is 2.8wt%, which is obtained according to the following steps:

[0047] At room temperature, weigh 5g of Silicalite-1 carrier and disperse it in 100mL of methanol, stir and sonicate to obtain a homogeneous mixture I;

[0048] Weigh 1.5g of zinc nitrate hexahydrate and add it to mixture I, and continue to stir at 25°C for 30 minutes to fully dissolve it to obtain mixture II;

[0049] Add 8.75g of 2-methylimidazole to the mixture II, continue to stir at 25°C for 10 hours to obtain ZIF-8 / Silicalite-1, and dry the catalyst at 40°C overnight after centrifugation and washing;

[0050] Place the dried ZIF-8 / Silicalite-1 in a tube furnace under N 2 Under the atmosphere, the temperature was raised to 700 °C at a rate of 7 °C / min and kept for 2 hours to obtain ZnO@NC / Silicalite-1, which was marked as 1#.

[0051] The above-mentioned 1# catalyst is used in the ...

Embodiment 2

[0057] This embodiment provides a method for preparing a highly dispersed and stable ZnO catalyst, wherein, ZnO@NC / Silicalite-1 catalyst (1# catalyst) is prepared according to Example 1; the obtained ZnO@NC / Silicalite-1 catalyst Weigh 1g and stir in 20mL 0.3M nitric acid solution at 25°C for 30 minutes to obtain 2# catalyst. Compared with 1# catalyst, except that the catalyst was stirred in 0.3M nitric acid for 30 minutes, the rest of the preparation process and evaluation conditions All the same as in Example 1. The results of anaerobic dehydrogenation of propane with 2# catalyst are shown in Table 2.

[0058] Table 2 The reaction result (2#) of anaerobic dehydrogenation of propane

[0059] time / min

Embodiment 3

[0061] This example provides a method for preparing a highly dispersed and stable ZnO-based catalyst. ZnO@NC / Silicalite-1 catalyst (1# catalyst) is prepared according to Example 1; the obtained ZnO@NC / Silicalite-1 catalyst is called Take 1g and stir in 20mL 0.5M nitric acid solution at 25°C for 30 minutes to obtain 3# catalyst. Compared with 1# catalyst, except that the catalyst was stirred in 0.5M nitric acid for 30 minutes, the rest of the preparation process and evaluation conditions were the same. Same as Example 1. The results of anaerobic dehydrogenation of propane with 3# catalyst are shown in Table 3.

[0062] Table 3 The reaction result (3#) of anaerobic dehydrogenation of propane

[0063] time / min

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com