Catalytic cracking prolific propylene catalyst and preparation method thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of unstable molecular sieve structure and deactivation, and achieve good hydrothermal stability, high propylene yield and propylene selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

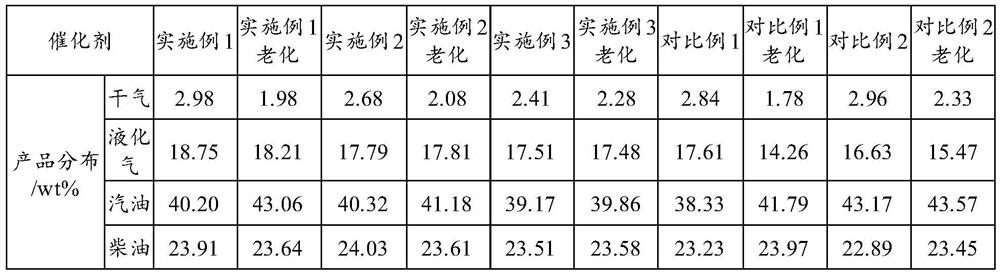

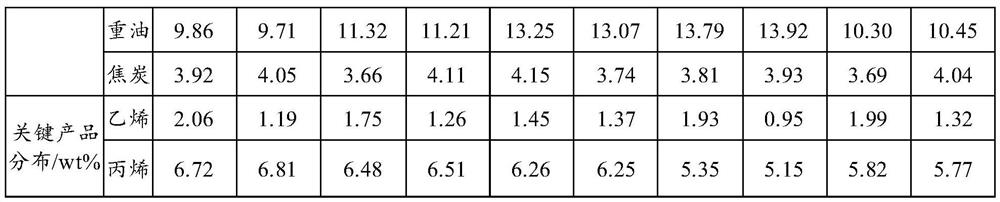

Examples

preparation example Construction

[0023] The present invention provides a kind of preparation method of catalytic cracking prolific propylene catalyst, comprises the following steps:

[0024] a) performing phosphorus modification and metal modification on the hydrogen ZSM-5 molecular sieve in turn to obtain a modified molecular sieve;

[0025] b) mixing the binder with water to obtain a precursor slurry, and then sequentially adding kaolin, pseudo-boehmite, hydrochloric acid and the modified molecular sieve obtained in step a) under stirring conditions to obtain a propylene catalyst mother liquor;

[0026] c) shaping the propylene catalyst mother liquor obtained in step b) and then roasting to obtain a catalytic cracking catalyst that can produce more propylene.

[0027] In the invention, firstly, the hydrogen type ZSM-5 molecular sieve is modified by phosphorus and metal in order to obtain the modified molecular sieve. In the present invention, the particle size of the hydrogen-type ZSM-5 molecular sieve is ...

Embodiment 1

[0054] (1) Weigh 200g of aluminum sol and dissolve it in 900g of deionized water with stirring to obtain mixed solution A.

[0055] (2) Weigh 195g of kaolin and dissolve it in mixed solution A under stirring condition, and stir at 400r / min for 1h to obtain mixed solution B.

[0056] (3) Weigh 70 g of pseudo-boehmite and add it into the mixed solution B, and stir at 400 r / min for 0.5 h to obtain the mixed solution C.

[0057] (4) Add 14 g of hydrochloric acid with a concentration of 37 wt% to the mixed solution C, stir at 400 r / min for 1 hour, and obtain the mixed solution D.

[0058] (5) Weigh 250g of zinc-phosphorus modified molecular sieve and add it into the mixed solution D, stir at 400r / min for 1.5h to obtain the propylene catalyst mother liquor; Concentration is 1wt% phosphoric acid solution (P 2 o 5 ), stirred evenly at room temperature, and roasted at 540°C for 3h after drying to obtain a phosphorus-modified molecular sieve; then impregnated the phosphorus-modified ...

Embodiment 2

[0061] Using the preparation method provided in Example 1, the difference is that: the cerium-phosphorus modified molecular sieve is used instead of the zinc-phosphorus modified molecular sieve to obtain a catalyst for catalytic cracking with high yield of propylene; the preparation method of the cerium-phosphorus modified molecular sieve is as follows: hydrogen type ZSM-5 molecular sieve Immersed in a phosphoric acid solution (P 2 o 5 ), stirred evenly at room temperature, and roasted at 540°C for 3h after drying to obtain a phosphorus-modified molecular sieve; then impregnated the phosphorus-modified molecular sieve in Ce(NO 3 ) 3 The solution was stirred evenly, dried and calcined at 540° C. for 3 hours to obtain cerium-phosphorus-modified molecular sieves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com