Preparation method for honeycomb carrier catalyst for gasoline conversion

A technology of honeycomb carrier and catalyst, which is applied in the field of preparation of honeycomb carrier catalyst, which can solve the problems of poor firmness and easy falling off of molecular sieve composition coating, and achieve the effects of good activity and selectivity, not easy falling off, and high conversion rate of olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In the method for preparing a honeycomb carrier catalyst for gasoline conversion provided by the present invention, the coating slurry is preferably prepared by a method comprising the following steps:

[0015] (1) mixing the molecular sieve with water and grinding to obtain a molecular sieve slurry having a molecular sieve particle diameter d90 of 1 to 10 microns;

[0016] (2) mixing the molecular sieve slurry obtained in step (1), the silicon oxide component and the dispersant solution; wherein the content of the dispersant in the dispersant solution is 1 to 10% by weight, and the weight ratio of the dispersant solution to the molecular sieve dry basis is 0.01~20:100. The silicon oxide component is silicon oxide with a particle diameter of less than 100nm and / or a precursor substance that can form silicon oxide with a particle diameter of less than 100nm. The particle diameter of the silicon oxide component is preferably 1-60nm, more preferably 5-60nm.

[0017] Where...

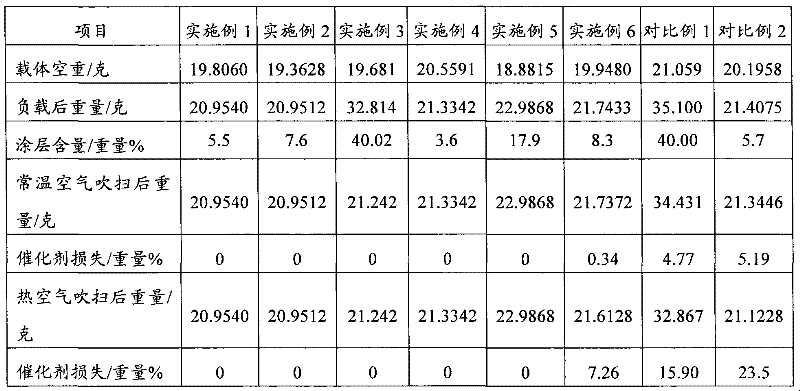

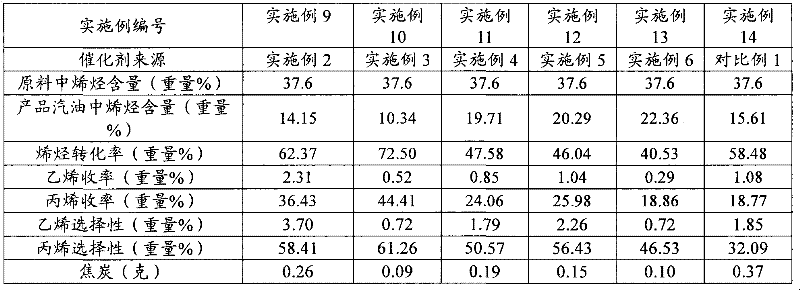

Embodiment 1

[0026] Mix 108 grams (on a dry basis, the same below) of HY-type molecular sieve powder (d90=14 microns, industrial grade, product of Sinopec Catalyst Qilu Branch) with 68.76 grams of deionized water, and wet ball mill it into a molecular sieve slurry. d90=5 microns; Add 180 grams of water glass (containing silicon oxide 15% by weight, produced by Sinopec Catalyst Qilu Branch Company in the slurry, the modulus is 3.2, the particle diameter is 1~5nm, and the average particle diameter is 3nm.), to oxidize The add-on of silicon water glass is 25% by weight of molecular sieve weight, stirs 10 minutes, adds polyethylene glycol solution 3.24 grams (the weight percentage of polyethylene glycol is 2% by weight), the add-on of this solution is molecular sieve weight 3% by weight, stirred for 20 minutes to obtain a catalyst coating preparation mixture slurry (coating slurry), and the molecular sieve content in the slurry was 30% by weight.

[0027] Prepare the mixed slurry coating honey...

Embodiment 2

[0030] 120 grams of rare earth Y-type molecular sieve powder (d90=12 microns, RE 2 o 3 Content 3% by weight, product of Sinopec Catalyst Qilu Branch) mixed with 252 grams of deionized water, wet ball milled into a slurry, molecular sieve particle diameter d90=8 microns in the slurry; add 96 grams of silica gel (containing silicon oxide 15 % by weight, the product of Sinopec Catalyst Qilu Branch Company, the viscosity of silica gel is 600cst (25°C viscosity), the particle diameter is 5~15nm, and the average particle diameter is 12nm), and the addition of silicon oxide is 12% by weight of molecular sieve weight, stirring 15 minutes; Add 12 grams of polyacrylic acid solution (polyacrylic acid content is 1% by weight), the polyacrylic acid solution add-on is 10% by weight of molecular sieve weight, stirs 30 minutes, obtains catalyst coating slurry, wherein molecular sieve content is 25% by weight. The obtained catalyst coating slurry is filled with all pores of the honeycomb carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com