System and method of preparing propylene tail oil by value-added exploitation of methanol

A technology of propylene tail oil and methanol, which is applied in the direction of ether preparation, hydrocarbon production from oxygen-containing organic compounds, dehydration of hydroxyl-containing compounds to prepare ether, etc., can solve the problem of reducing the amount of C4 hydrocarbons back to refining, not being able to fully utilize the increased production of propylene, and not increasing Solve problems such as tail oil utilization, achieve value-added utilization, reduce energy consumption, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

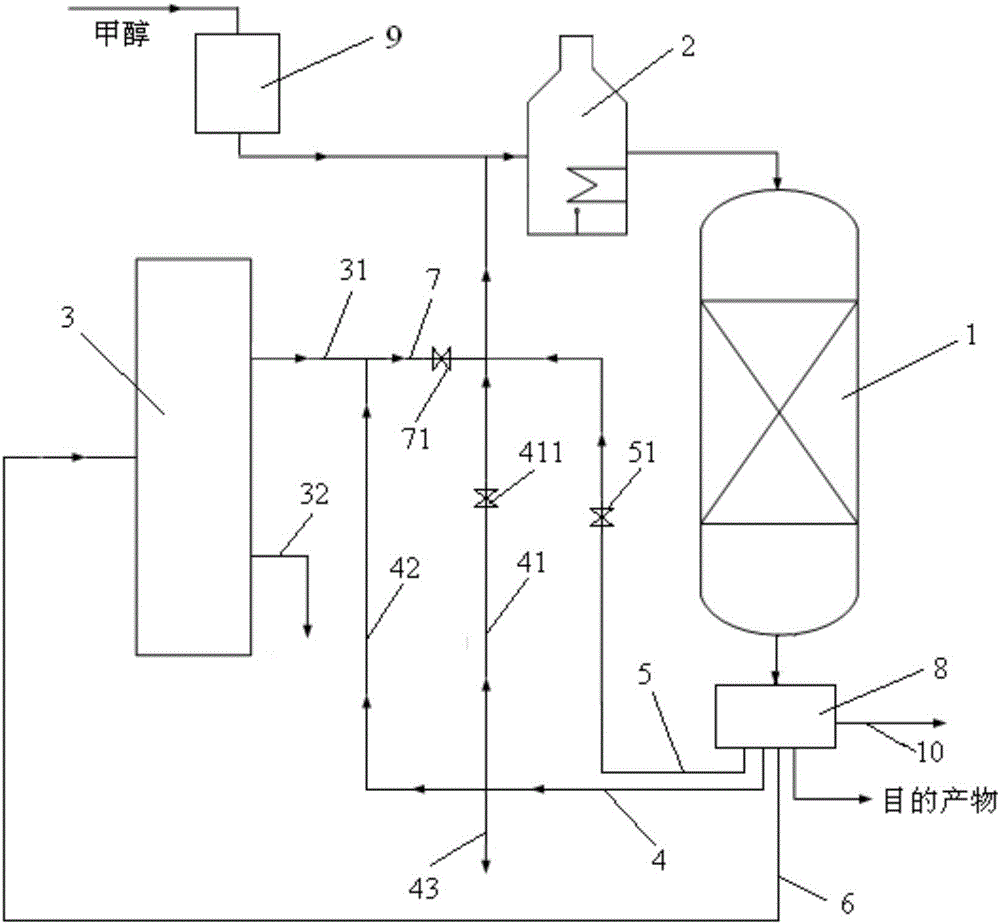

[0112] 205t / h methanol input such as figure 2 In the shown system, it operates according to the above-mentioned operation process, wherein, the flow rate of the first branch pipe 41 restricted by the first restricting flowmeter 411 is 145t / h, and the flow rate of the second refining pipe 7 restricted by the second restricting flowmeter 71 The flow rate is 56t / h, and the flow rate on the third byproduct outlet pipe 5 controlled by the third restrictive flow meter 51 is 10t / h, and 56.8t / h of propylene is obtained, and the yield of propylene is 27.71wt%.

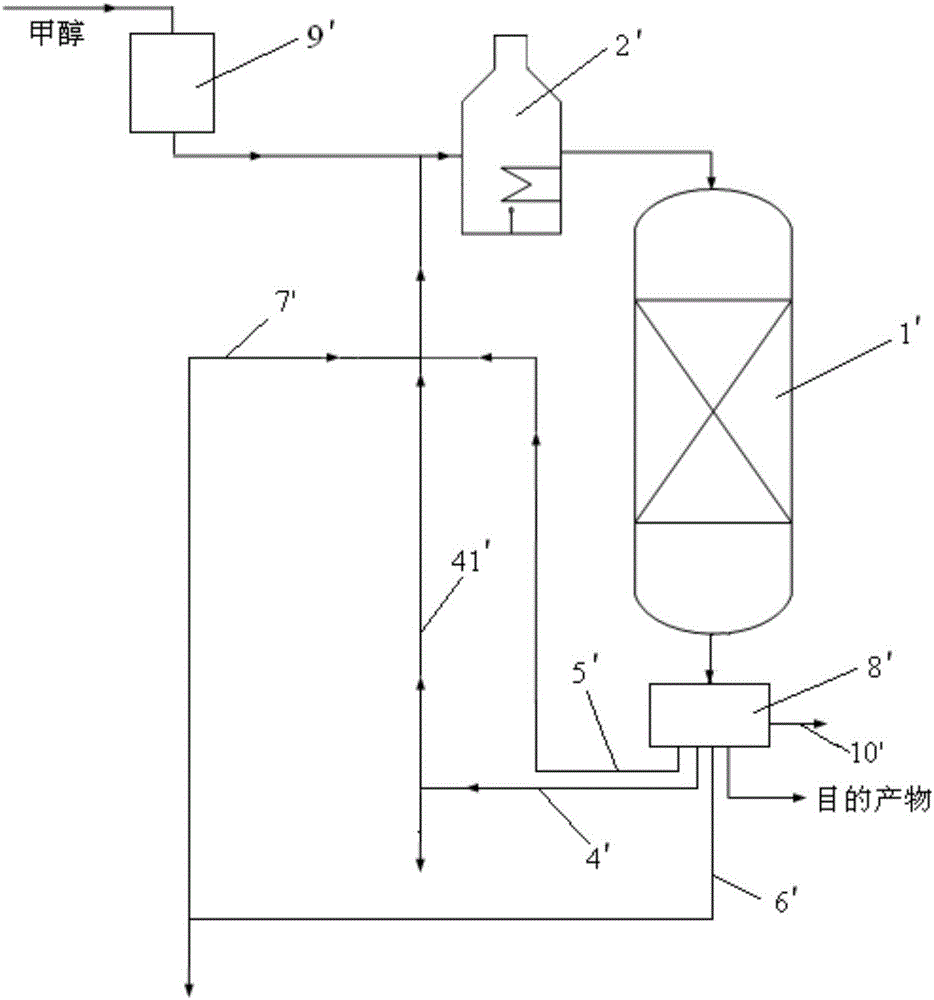

[0113] Such as image 3 The system of the prior art shown, the operation process is as follows:

[0114] Methanol is input into the first reactor 9' for methanol-to-dimethyl ether reaction to obtain the first product stream (dimethyl ether / methanol), and the first product stream from the first reactor 9' is heated by the heating furnace 2' and then input into the second Propylene is synthesized in the second reactor 1' to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com