MTP (methanol to propylene) method

A technology for producing propylene and methanol from methanol, which is applied in the directions of producing hydrocarbons from oxygen-containing organic compounds, organic chemistry, etc. Catalyst bed interval, low oxygenate yield, effect of reducing oxygenate content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

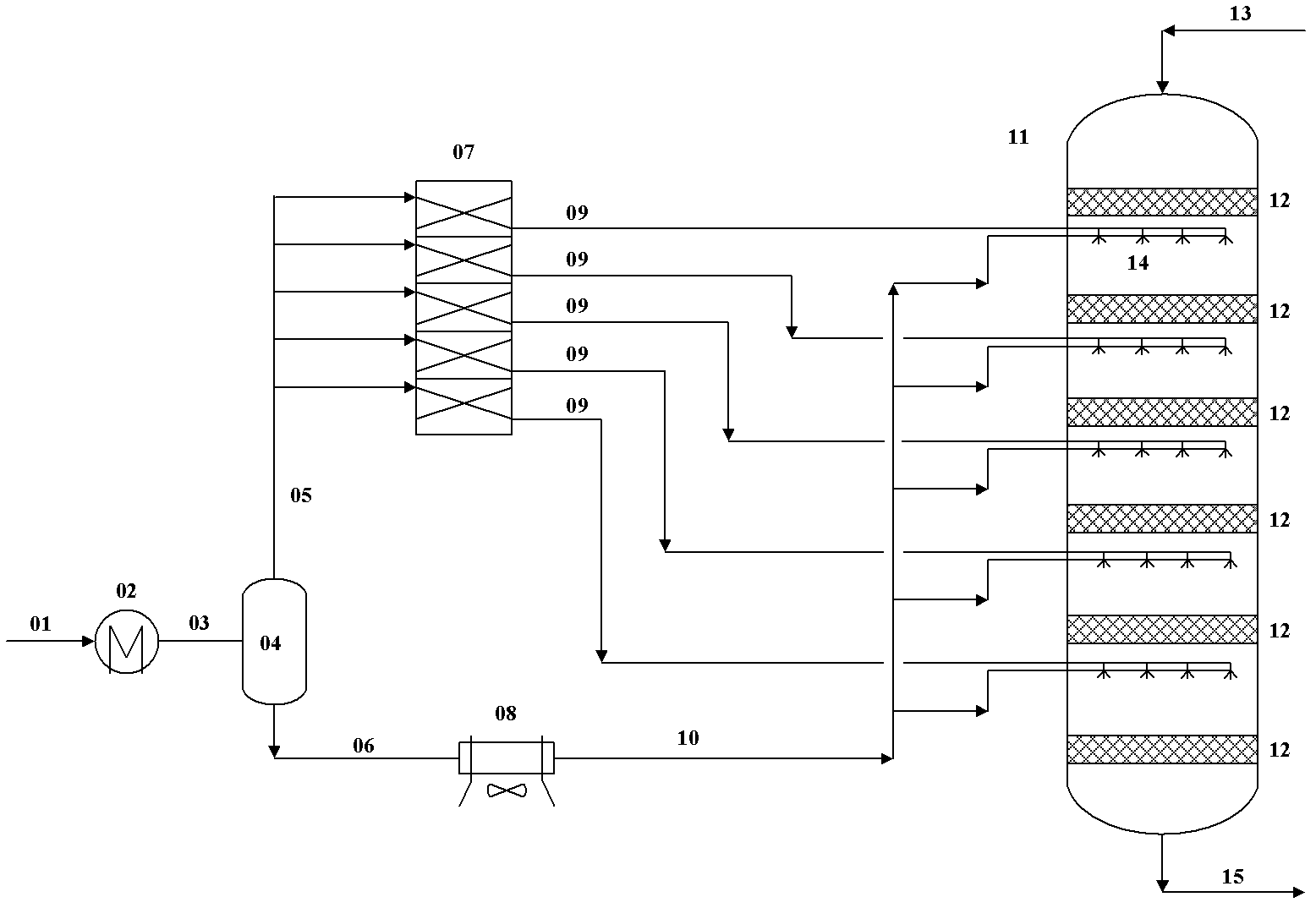

Method used

Image

Examples

Embodiment 1

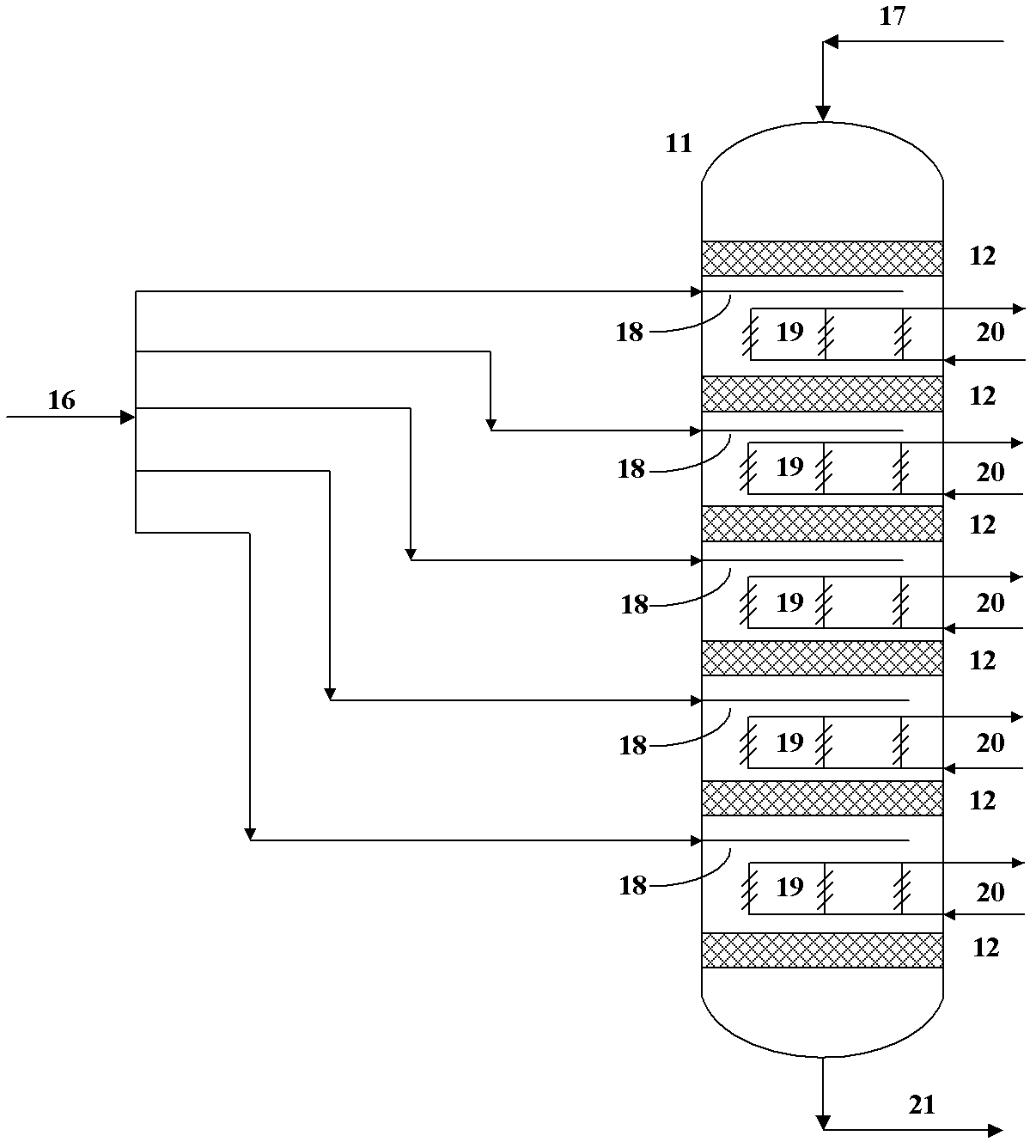

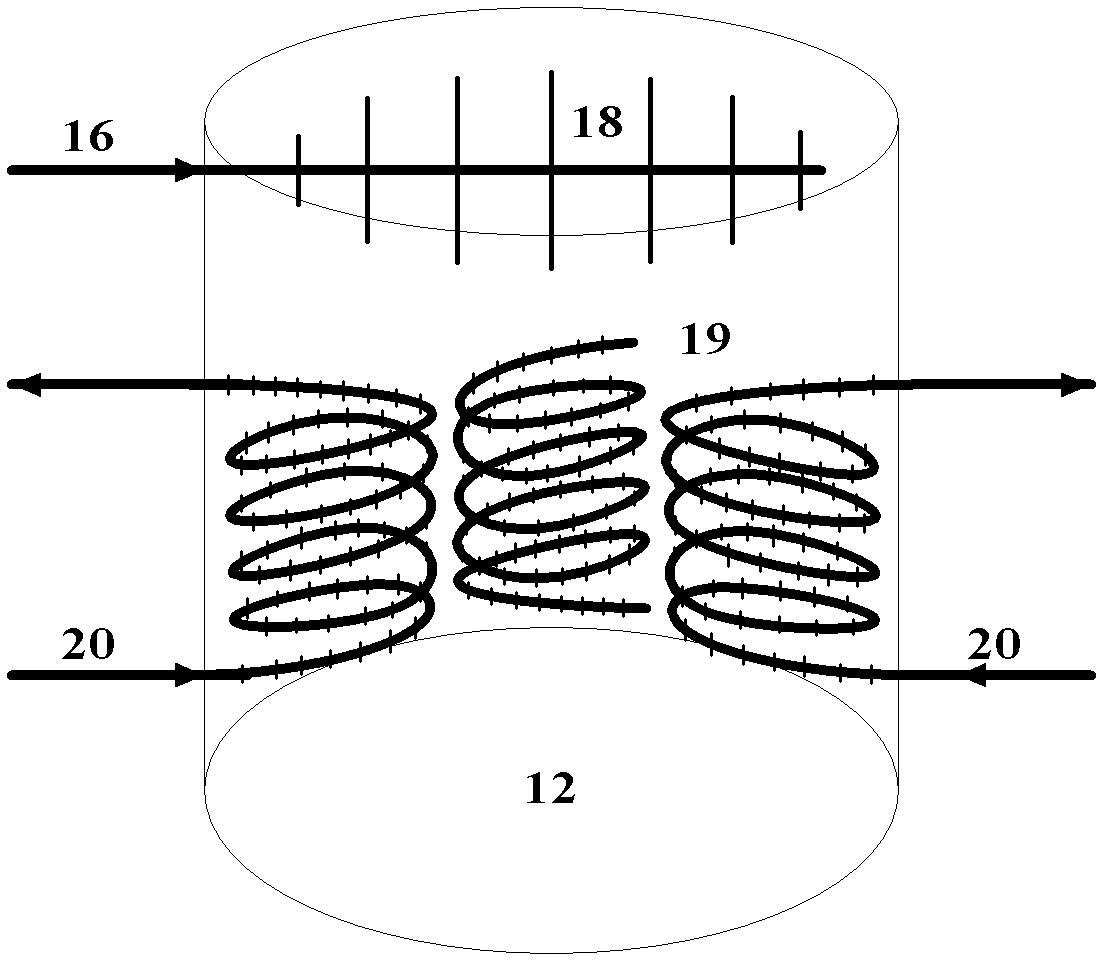

[0032] according to figure 2 As shown, the reaction adopts ZSM-5 zeolite catalyst, the reaction temperature is 470°C, the reaction pressure is 0.06MPag, the temperature of stream 16 is 156°C, and the mass flow rate of each component is: methanol 9724kg / h, dimethyl ether 29266kg / h, water 28200kg / h, the temperature of stream 17 is 469°C, the mass flow rate of each component is: methanol 1819kg / h, dimethyl ether 3721kg / h, water 25841kg / h, hydrocarbon 56753kg / h, and the reaction pressure is 0.1MPa(g). Stream 16 is sent to each stage separately without cooling or heating of the stream. The reactor can generate 450KW medium-pressure steam through the internal heat exchanger to adjust the inlet temperature of the fixed-bed catalyst in each section. Compared with [Comparative Example 1], after 16000kg / h water is switched from high temperature stream 17 to chilled stream 16, the heating load of stream 17 can be reduced by 2828KW. Experimental studies have shown that due to the promo...

Embodiment 2

[0034] according to figure 2 As shown, the reaction adopts ZSM-5 zeolite catalyst, the reaction temperature is 470°C, the reaction pressure is 0.06MPag, the temperature of stream 16 is 153°C, and the mass flow rate of each component is: methanol 9724kg / h, dimethyl ether 29266kg / h, water 28200kg / h, the temperature of stream 17 is 469°C, the mass flow rate of each component is: methanol 1819kg / h, dimethyl ether 3721kg / h, water 25841kg / h, hydrocarbon 56753kg / h, and the reaction pressure is 0.05MPa(g). Stream 16 is sent to each stage separately without cooling or heating of the stream. The reactor can generate 343KW medium-pressure steam through the internal heat exchanger to adjust the inlet temperature of each fixed-bed catalyst. Compared with [Comparative Example 1], after 16000kg / h water is switched from high temperature stream 17 to chilled stream 16, the heating load of stream 17 can be reduced by 2828KW. According to the above reaction temperature, reaction pressure, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com