Pipe groove type liquid distributor applied to flue gas desulfurization tower

A liquid distributor and liquid distribution pipe technology, applied in the field of column internals, can solve problems such as easy blockage of small holes and difficulty in uniform flow output, and achieve the effects of reducing liquid flow rate, improving liquid distribution uniformity, and ensuring separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

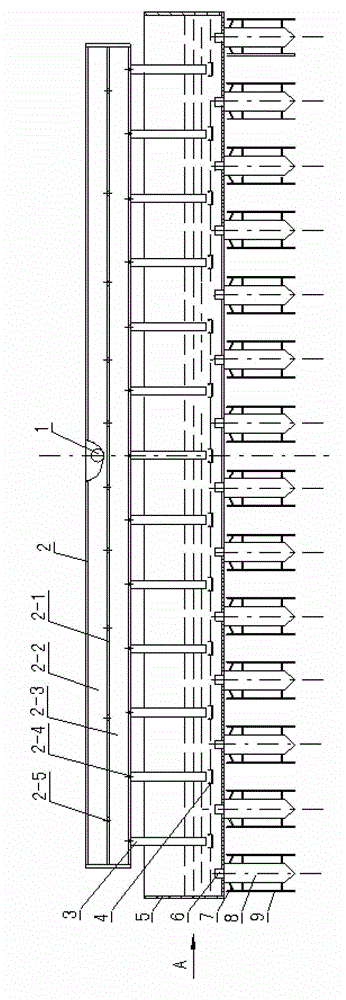

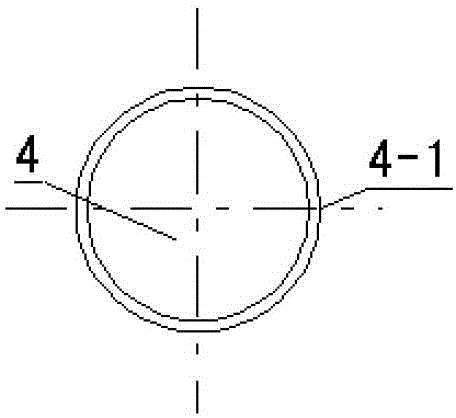

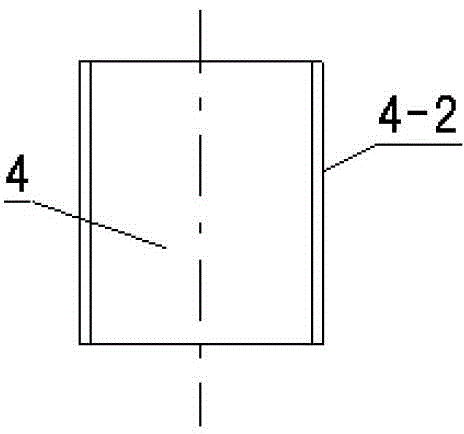

[0021] Such as figure 1 , 2 , The embodiment shown in 3 and 4, the liquid distributor is composed of a liquid inlet pipe 1, a liquid distribution pipe 2, a primary tank 5, and a secondary tank 8 connected in sequence.

[0022] The liquid distribution pipe 2 is divided into a first-stage liquid distribution pipe 2-2 and a second-stage liquid distribution pipe 2-3 connected up and down by an intermediate partition 2-1 that is axial to the liquid distribution pipe, and the liquid inlet pipe 1 is connected to At the axial bisection of the first-stage liquid distribution pipe 2-2.

[0023] The middle partition 2-1 is symmetrically arranged on both sides corresponding to the axis of the liquid inlet pipe, and the hole interval is gradually thinned. The liquid distribution holes 2-4 are arranged at equal intervals and equal diameters, and the apertures of the liquid dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com