A spray falling film evaporator and its liquid level control method

A falling-film evaporator and falling-film evaporation technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of uneven spraying, high cost, high energy consumption, etc., and achieve the energy efficiency ratio of the unit. High efficiency, high utilization efficiency, and the effect of saving heat exchange materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

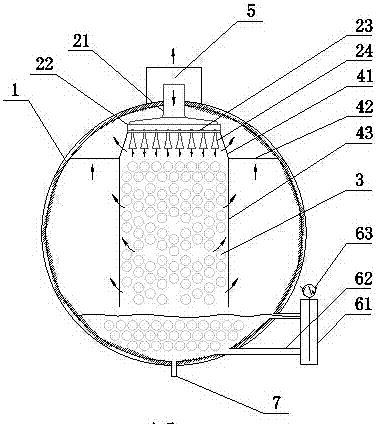

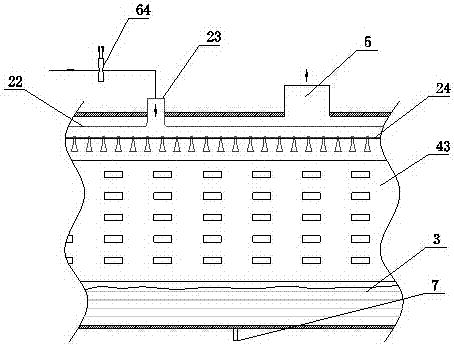

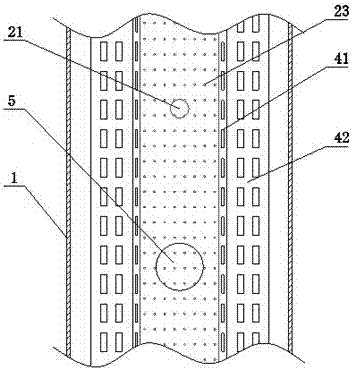

[0033]A spray falling film evaporator, comprising a cylinder body 1, a spray refrigerant distribution system, a refrigerant flow deflector assembly, a refrigerant liquid level control system, a falling film evaporation heat exchange tube 3, a gas refrigeration agent outlet 5

[0034] and oil return outlet 7.

[0035] The spray refrigerant distribution system includes a refrigerant liquid inlet pipe 21 arranged at the upper end of the cylinder, a refrigerant distributor upper cover 22 connected to the refrigerant liquid inlet pipe 21 and a refrigerant distributor equal distribution plate 23 A plurality of small holes are arranged on the equal distribution plate 23 of the refrigerant distributor, and the refrigerant speed-up diffusion device is a refrigerant speed-up diffusion nozzle 41 installed on the small holes. The refrigerant speed-up diffusion nozzle 41 is a reducer plus an expander, a Venturi tube or an expander. The radial cross-section of the refrigerant speed-up dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com