Direct expansion type fresh air conditioning system and control method

A fresh air conditioner and control method technology, applied in heating and ventilation control systems, heating and ventilation safety systems, refrigerators, etc., can solve problems such as poor heat transfer effect of evaporators, uneven liquid distribution, and low system performance, and achieve Improve the uniformity of liquid distribution, improve heat transfer matching, and improve the effect of system energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

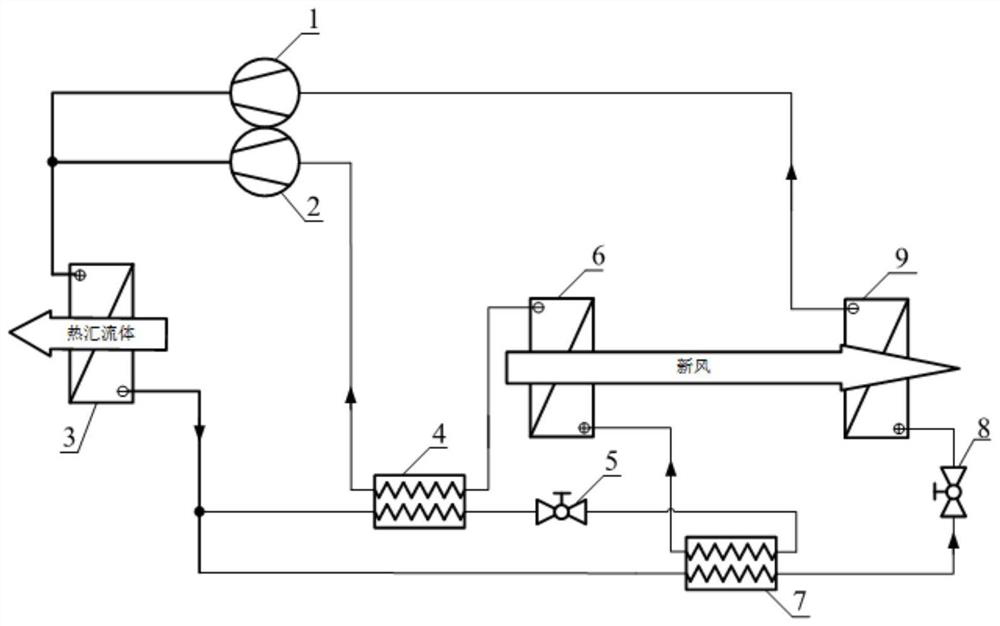

[0033] Such as figure 1 As shown, the present invention provides a direct expansion fresh air air conditioning system, including a first compressor 1, a second compressor 2, a condenser 3, a heat regenerator 4, a second throttling device 5, a second evaporator 6, Intermediate heat exchanger 7, first throttling device 8 and first evaporator 9;

[0034] The outlet of the first compressor 1 and the outlet of the second compressor 2 are connected in parallel to the inlet of the condenser 3, the outlet of the condenser 3, the intermediate heat exchanger 7, the first throttling device 8, the first evaporator 9 and The inlet of the first compressor 1 is connected in sequence, the outlet of the condenser 3, the regenerator 4, the second throttling device 5, the intermediate heat exchanger 7, the second evaporator 6, the regenerator 4 and the second compressor 2 The imports are connected in turn.

[0035] In the intermediate heat exchanger 7, the refrigerant from the first path of th...

Embodiment 2

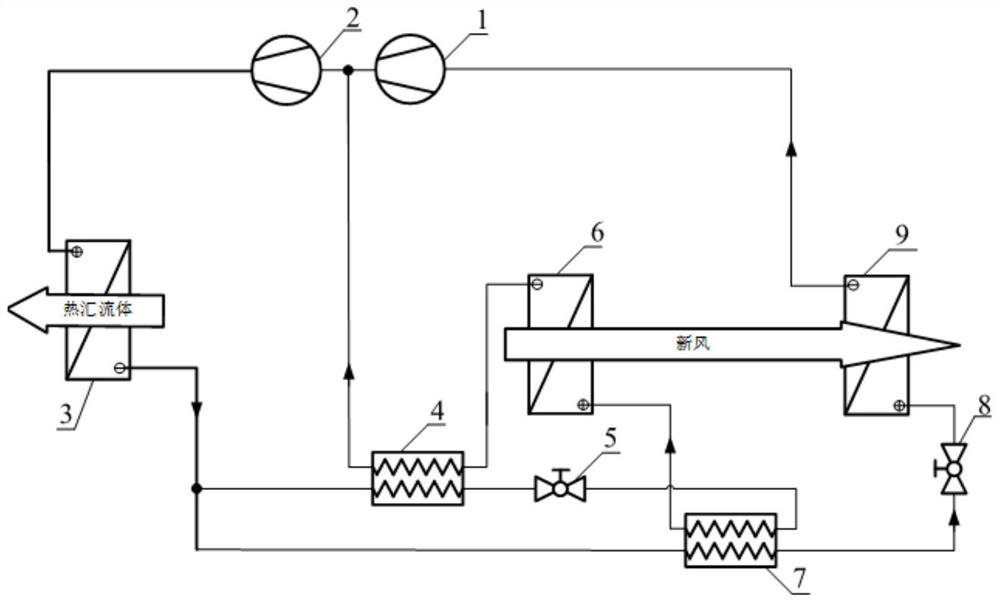

[0047] Such as figure 2 As shown, a direct expansion fresh air air conditioning system includes: a first compressor 1, a second compressor 2, a condenser 3, a heat regenerator 4, a second throttling device 5, a second evaporator 6, an intermediate exchanger The heater 7, the first throttling device 8, the first evaporator 9, the first compressor 1 and the second compressor 2 together form a two-stage compressor;

[0048] The outlet of the first compressor 1 is connected to the inlet of the second compressor 2, the outlet of the second compressor 2 is connected to the inlet of the condenser 3, the outlet of the condenser 3, the intermediate heat exchanger 7, and the first throttling device 8 , the first evaporator 9 and the inlet of the first compressor 1 are connected in sequence; the outlet of the condenser 3, the regenerator 4, the second throttling device 5, the intermediate heat exchanger 7, the second evaporator 6, and the regenerator 4 and the inlet of the second compr...

Embodiment 3

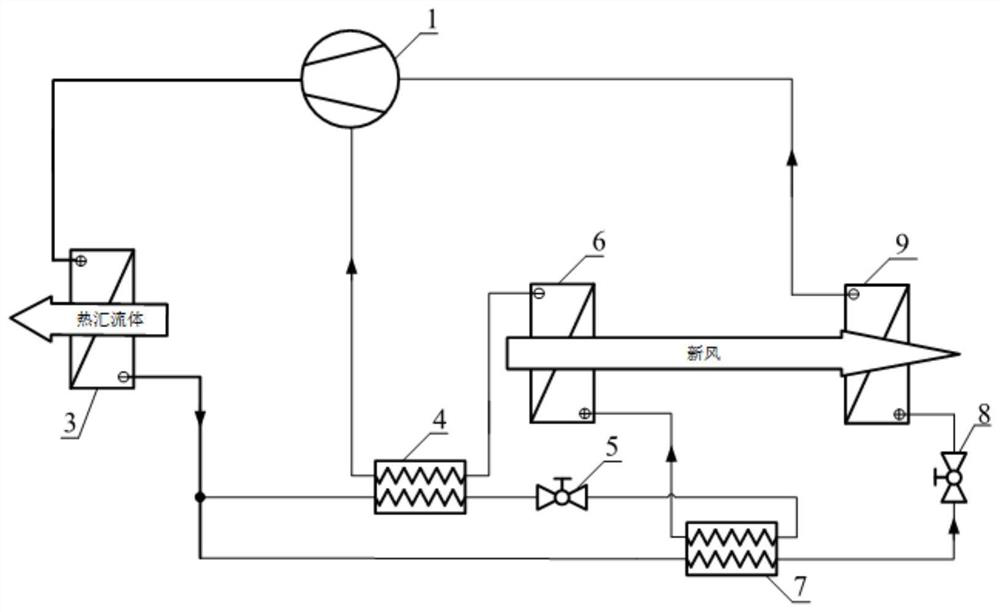

[0061] Such as image 3 As shown, a direct expansion fresh air air conditioning system includes: a first compressor 1, a condenser 3, a regenerator 4, a second throttling device 5, a second evaporator 6, an intermediate heat exchanger 7, a first A throttling device 8 and a first evaporator 9, and the first compressor 1 is a quasi-two-stage compressor;

[0062] The outlet of the first compressor 1 is connected to the inlet of the condenser 3, the outlet of the condenser 3, the intermediate heat exchanger 7, the first throttling device 8, the first evaporator 9 and the suction port of the first compressor 1 in sequence The outlet of the condenser 3, the regenerator 4, the second throttling device 5, the intermediate heat exchanger 7, the second evaporator 6, the regenerator 4 and the inlet of the first compressor 1 are connected in sequence.

[0063] In the intermediate heat exchanger 7, the refrigerant from the first path of the condenser 3 exchanges heat with the refrigerant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com