A spray falling film evaporator and its liquid level control method

A falling-film evaporator and falling-film evaporation technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of uneven spraying, high cost, and large energy consumption, and achieve high utilization efficiency , high energy efficiency ratio, and the effect of saving heat exchange materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

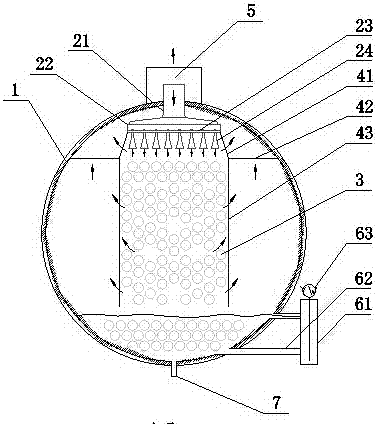

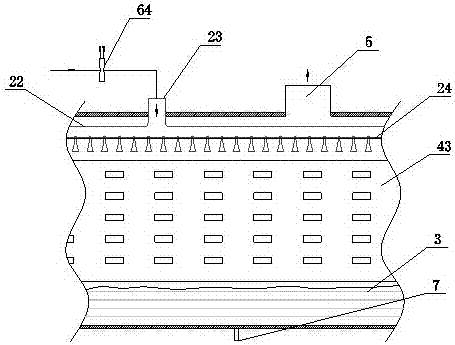

[0034] A spray falling film evaporator, comprising a cylinder body 1, a spray refrigerant distribution system, a refrigerant flow deflector assembly, a refrigerant liquid level control system, a falling film evaporation heat exchange tube 3, a gas refrigeration Agent outlet 5 and return oil outlet 7.

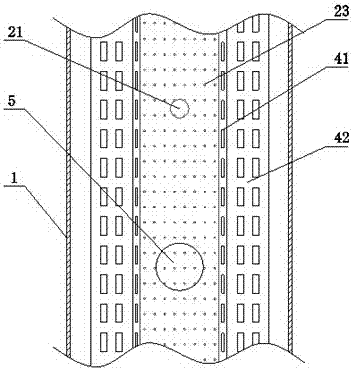

[0035] The spray refrigerant distribution system includes a refrigerant liquid inlet pipe 21 arranged at the upper end of the cylinder, a refrigerant distributor upper cover 22 connected to the refrigerant liquid inlet pipe 21 and a refrigerant distributor equal distribution plate 23 A plurality of small holes are arranged on the equal distribution plate 23 of the refrigerant distributor, and the refrigerant speed-up diffusion device is a refrigerant speed-up diffusion nozzle 41 installed on the small holes. The refrigerant speed-up diffusion nozzle 41 is a reducer plus an expander, a Venturi tube or an expander. The radial cross-section of the refrigerant speed-up diffusion no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com