Dielectrophoresis separation system for recycling precious metals

A technology of dielectrophoresis and precious metals, applied in the field of separation, can solve the problems of low particle concentration, low degree of industrial automation, large investment required, etc., and achieve the effect of reducing environmental pollution and reducing electrothermal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment, the present invention is further described; Following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

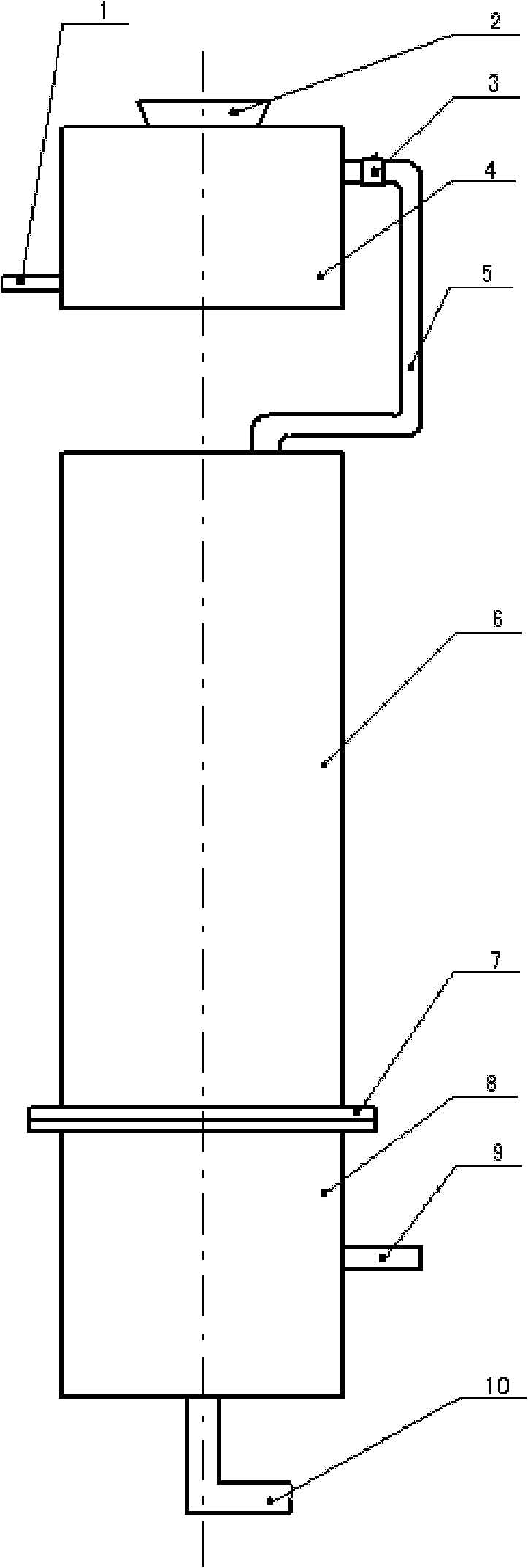

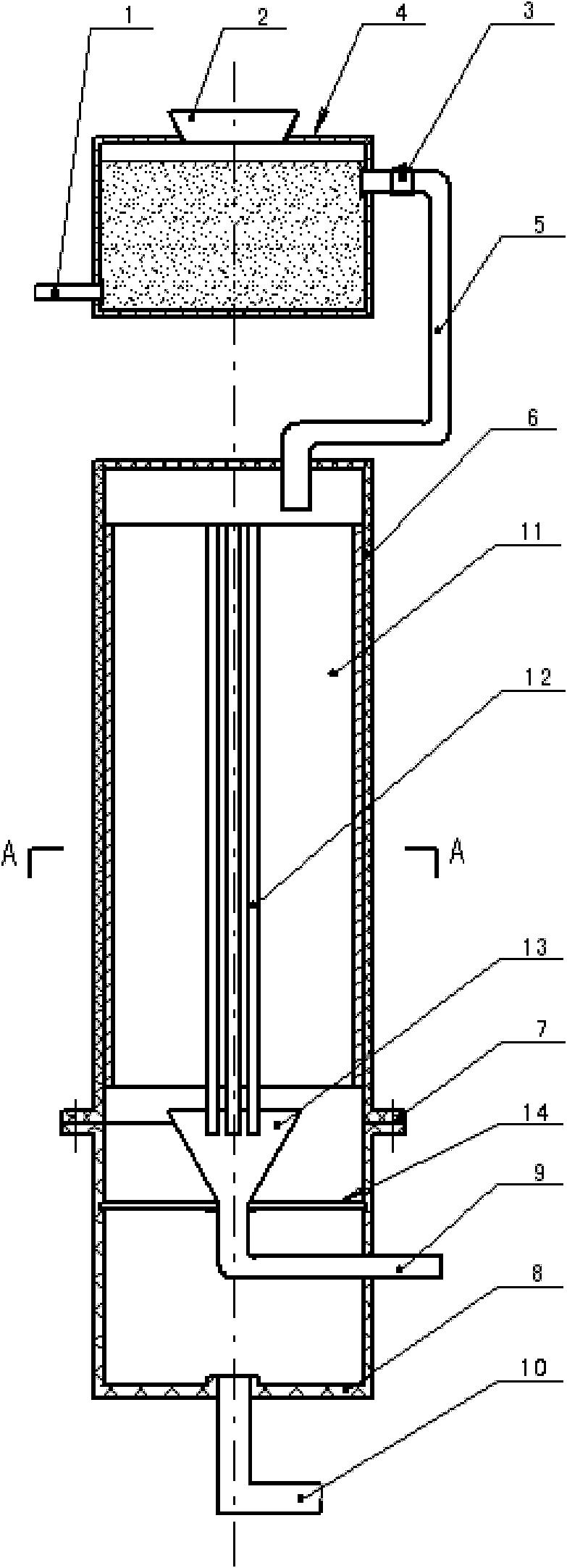

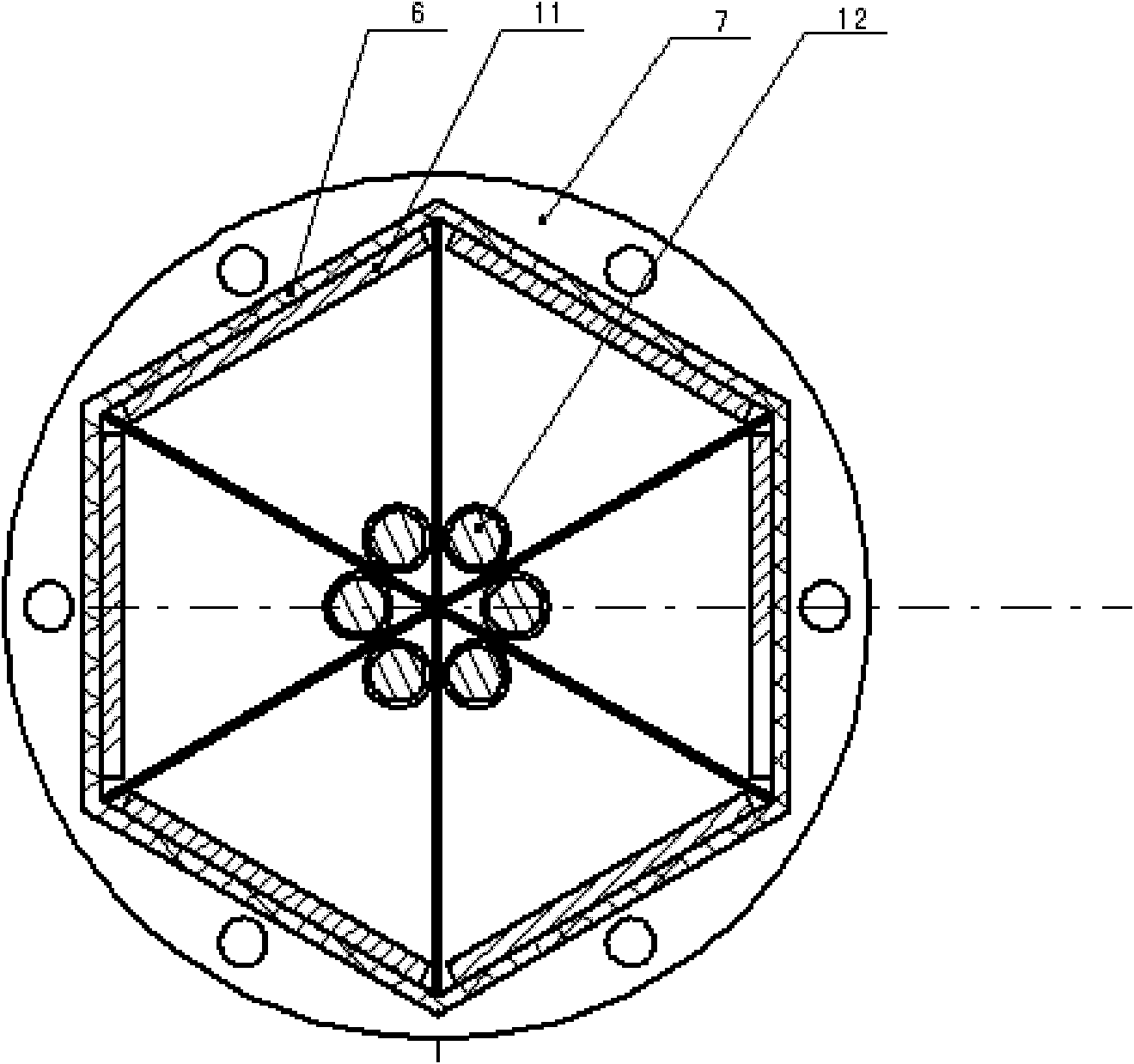

[0019] A dielectrophoresis separation system for recovering precious metals, comprising a mixing box 4, a separation chamber 6 and a collection chamber 8, the mixing box is located above the separation chamber, and its discharge pipe 5 communicates with the separation chamber, and the lower end of the separation chamber is the same as The shaft is equipped with a collection chamber, which outputs the separated precious metal through the output pipe 9. The specific structure is:

[0020] The mixing box is provided with a material inlet 2, which is used to put in the mixed material. The lower part of the mixing box is provided with a water inlet pipe 1, through which water is pumped into the mixing box. Water washes the separated materials in the mixing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com