Mechanical Chinese chestnut sheller

A shelling machine, a mechanical technology, is applied in the direction of shelling, solid separation, and separation of solids from solids with airflow. It can solve problems that affect the quality and benefit of chestnuts, vary in size, and cost a lot, and achieve High stability, reduce breakage rate, improve the effect of shelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

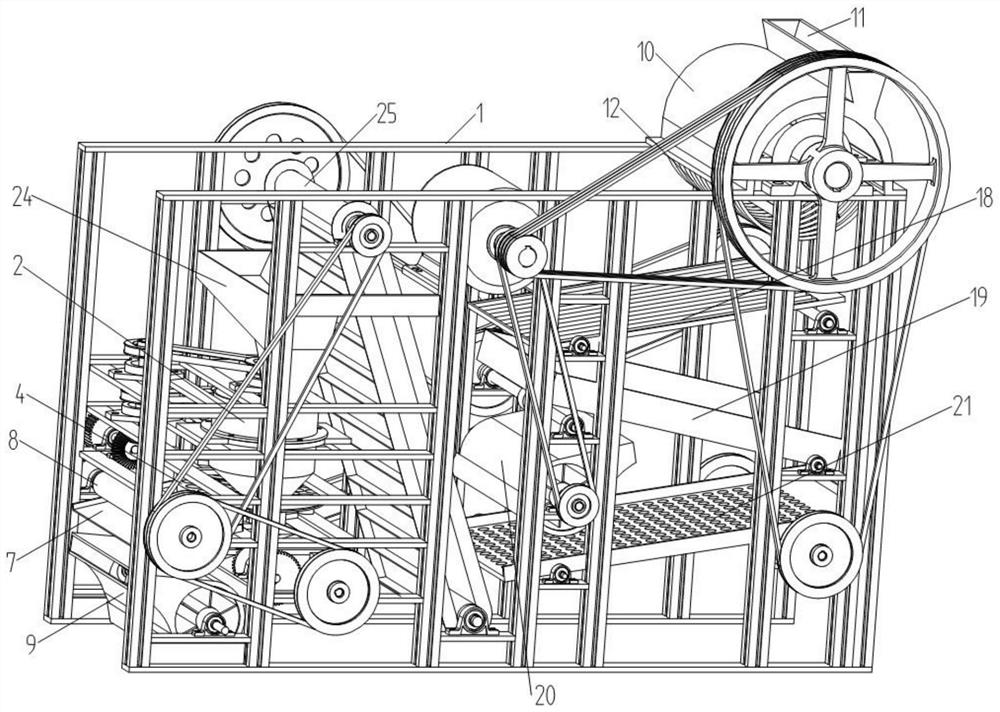

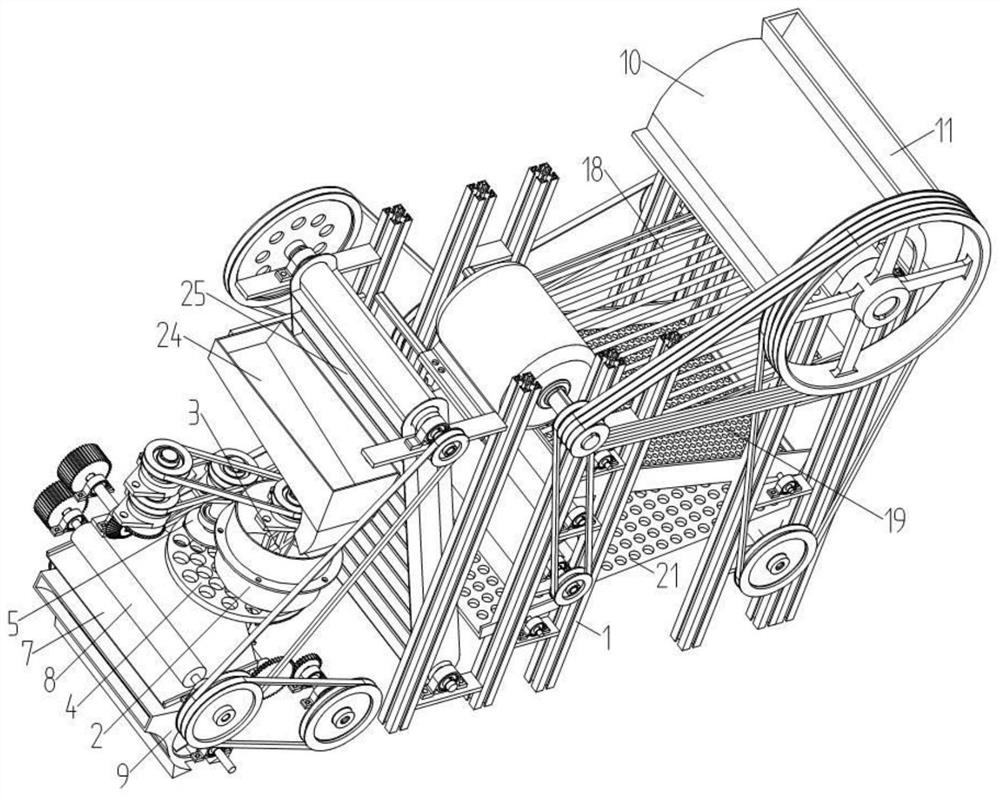

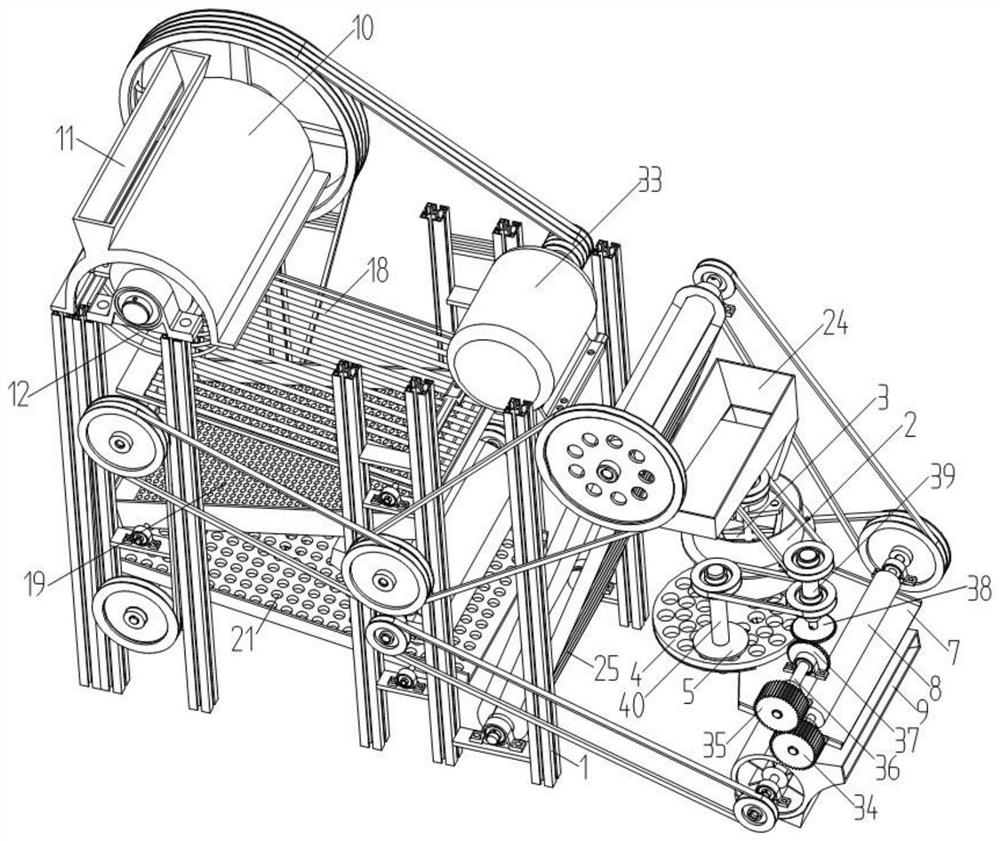

[0090] Such as figure 1 As shown, the embodiment of the present invention provides a mechanical chestnut shelling machine, comprising a frame 1, a chestnut pretreatment device is fixed on the frame 1, and the chestnut pretreatment device is used to separate chestnuts from chestnut bags and separate them chestnuts for sifting. A heating device is also fixed on the frame 1, and the heating device is fixed on the frame 1 for heating the chestnuts after screening to separate the chestnut pulp and the chestnut husk, and the heated chestnuts are scratched and rubbed by the scratch rubbing device to make them Chestnut husks are broken to realize chestnut shelling.

[0091] The scratch rubbing device includes a disc 4 with holes, a disc cutter 5 and a first driving mechanism. The perforated disc 4 is located below the outlet of the heating device, and the heated chestnuts drop from the heating device onto the perforated disc 4; support, and a plurality of through holes for placing ...

Embodiment 2

[0100] This embodiment is based on embodiment 1, as attached figure 1 And attached Figure 6 As shown, the heating device includes a heating bin 2 fixed on the frame 1, and the heating bin 2 is used to heat the screened chestnut to separate the chestnut pulp and the chestnut husk, and the outlet of the heating bin 2 is below the outlet of the chestnut. The perforated disk 4, the chestnut heated by the heating chamber 2 falls from the outlet of the heating chamber 2 onto the perforated disk 4; the heating chamber 2 is provided with a stirring rod 3, and the frame 1 is fixed with a second driving mechanism , the second driving mechanism is connected with the first driving mechanism through the first belt transmission mechanism, and the second driving mechanism drives the stirring rod 3 to rotate, which is used to continuously stir the chestnut during the heating process so that the chestnut is evenly heated.

[0101] A kind of mechanical chestnut shelling machine provided by th...

Embodiment 3

[0103] This embodiment is based on embodiment 1, as attached Figure 7 As shown, the lower surface of the perforated disc 4 is provided with a support plate 6 that cooperates with it, and the support plate 6 is fixed on the frame 1 for preventing the broken chestnut husk and chestnut pulp from the perforated disc 4. The opened through-holes fall arbitrarily, and a gap is provided on the support plate 6, which is used to make the broken chestnut husk and chestnut pulp fall from the position opposite to the gap of the holed disc 4;

[0104] Below the gap of the support plate 6, there is a deflector 7 fixed on the frame 1 for deriving the broken chestnut husk and chestnut pulp from the inside of the chestnut sheller. There is a round roller 8, the round roller 8 is erected on the frame 1, and one end of the round roller 8 is connected with a third drive mechanism fixed on the frame 1 for driving it to rotate, and the third drive mechanism passes through The second belt drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com