Agricultural peanut shelling and separating device

A separation device and shell breaking device technology, which is applied in the direction of shelling, solid separation, pod removal, etc., can solve the problems of low shelling efficiency, time-consuming, and insufficient screening and separation, so as to facilitate collection and save working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

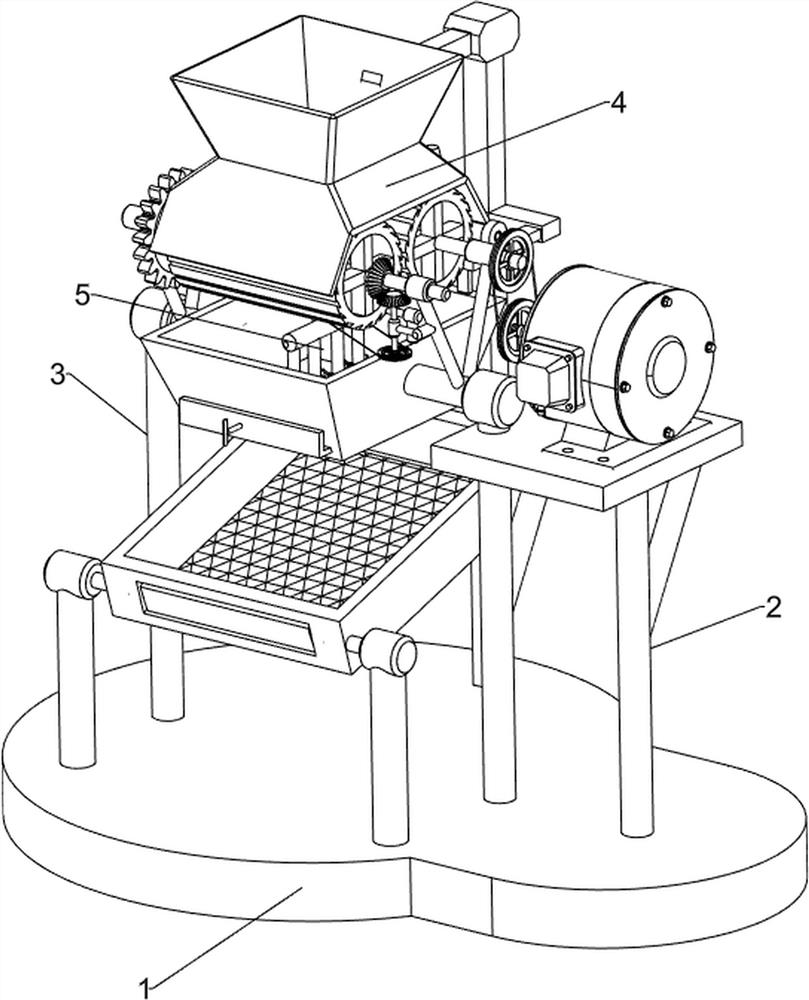

[0023] like figure 1 As shown, an agricultural peanut shelling and separating device includes a base 1, a first bracket 2, a first fixing bracket 3, a shell breaking device 4 and a breaking device 5, and the right side of the top of the base 1 is provided with a first bracket 2 , the left side of the top of the base 1 is provided with a first fixed frame 3, the top of the base 1 is provided with a cracking device 4, the cracking device 4 is located between the first bracket 2 and the first fixing frame 3, and the lower side of the cracking device 4 is provided with Break up device 5.

[0024] When peanuts need to be shelled and separated, at first, the peanuts are placed in the shell breaking device 4, and then the shell breaking device 4 and the breaking device 5 are started, and the peanuts slide down along the shell breaking device 4, and the shell breaking device 4 pairs Peanuts are squeezed into broken shells, and the shelled peanuts fall downwards on the breaking device...

Embodiment 2

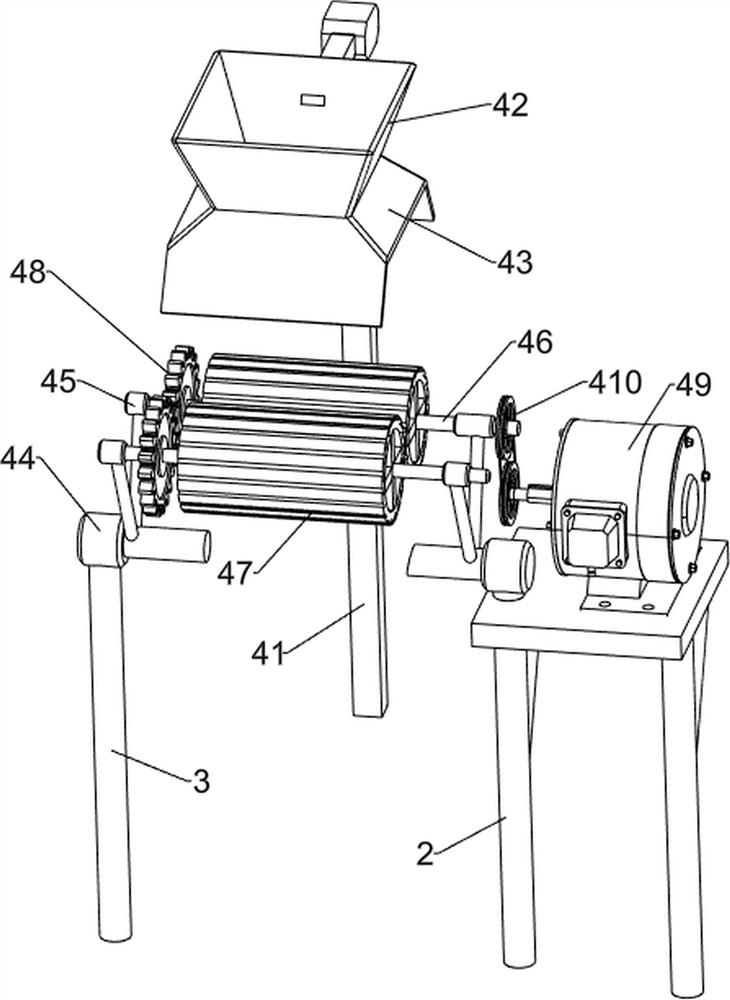

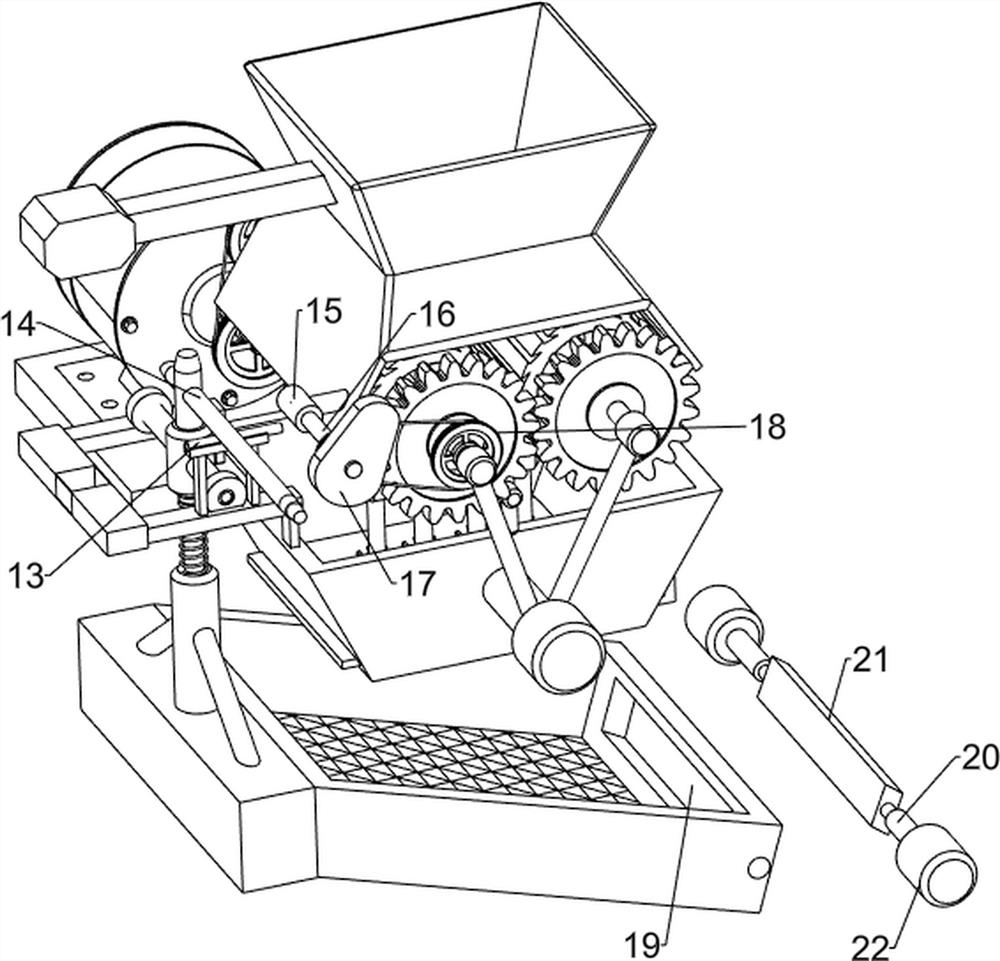

[0026] like figure 2 and image 3 As shown, an agricultural peanut shelling and separating device, on the basis of Embodiment 1, the shell breaking device 4 includes a second support 41, a lower hopper 42, a shielding frame 43, a first mounting frame 44, a first bearing Seat 45, first rotating shaft 46, crushing roller 47, circular gear 48, servo motor 49 and first belt transmission mechanism 410, the top of base 1 is provided with second support 41, and second support 41 is positioned at first support 2 and first fixed Between the frame 3, the upper end of the second support 41 is provided with a lower hopper 42, the lower hopper 42 is in an inverted cone shape, and the discharge opening of the lower hopper 42 is provided with a shielding frame 43, and the top of the first support 2 is close to the first fixed frame 3. Both sides are provided with a first mounting frame 44, and the tops of the two first mounting frames 44 are symmetrically provided with a first bearing seat...

Embodiment 3

[0031] like Figure 4 and Figure 5 As shown, an agricultural peanut shelling and separating device, on the basis of Embodiment 1 and Embodiment 2, also includes a third fixed frame 6, a guide sleeve 7, a sliding rod 8, a support 9, and a screening frame 10 1. The elastic sliding sleeve 11 and the elastic member 12, the third fixed frame 6 is symmetrically arranged on both sides of the top of the second mounting frame 51, the guide sleeve 7 is arranged between the third fixed frame 6, and the sliding rod is arranged in the guide sleeve 7 8. Supports 9 are arranged symmetrically on the front side of the base 1, and a screening frame 10 is installed in a rotating manner between the two supports 9. The screening frame 10 is located under the sliding baffle 53, and an elastic sliding sleeve 11 is provided on the rear side of the top of the screening frame 10. , the lower end of the sliding rod 8 is connected with the elastic sliding sleeve 11, and an elastic member 12 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com