Double-shell shellfish shelling and cleaning machine

A technology for bivalve molluscs and bivalve molluscs, applied in bivalve processing, crustacean processing, slaughtering, etc., can solve the problems of shortening shelling time, time-consuming, laborious, and dangerous, and achieve manpower saving, convenient cleaning, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

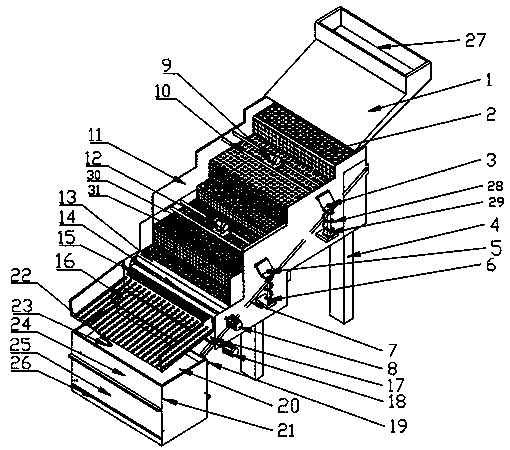

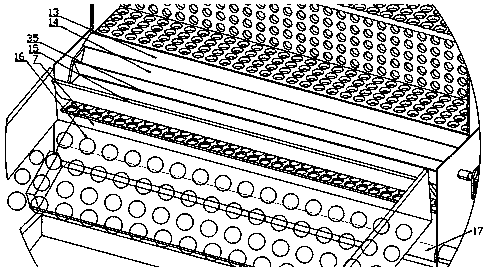

[0038] Example 1: Such as Figure 1-5 As shown, a bivalve shelling and cleaning machine includes a feeding device, a meat shell separating device, a shell meat conveying device, a shell impact device, and a shell meat cleaning device;

[0039] The feeding device is used to uniformly transport the bivalve molluscs to the first-stage meat shell separating device of the meat shell separating device;

[0040] The meat shell separating device is used to drive the sieving net to vibrate through a vibrating motor so that the bivalve molluscs jump up and down to achieve the purpose of separating the bivalve shells;

[0041] The shellfish meat conveying device is used for collecting shellfish falling from the sieving mesh and sending it into the shellfish cleaning device;

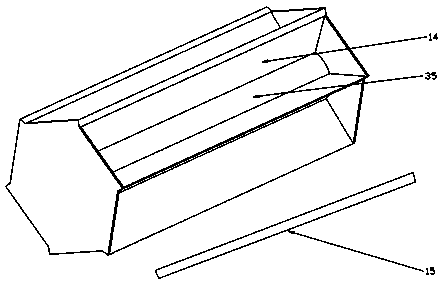

[0042] The shell impact device is used to impact a small part of the bivalve molluscs that have passed through the screening net but have not yet been shelled, so as to achieve the purpose of separating the shells;

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com