Manufacturing method for meticulous embroidery mural

A production method and technique of meticulous painting, applied in the direction of art painting special techniques, special decorative structures, decorative arts, etc., can solve the problems of development constraints of meticulous embroidery murals, poor color persistence, complicated installation process, etc., to achieve enhanced three-dimensional effect and Texture effect, long service life, scientific and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

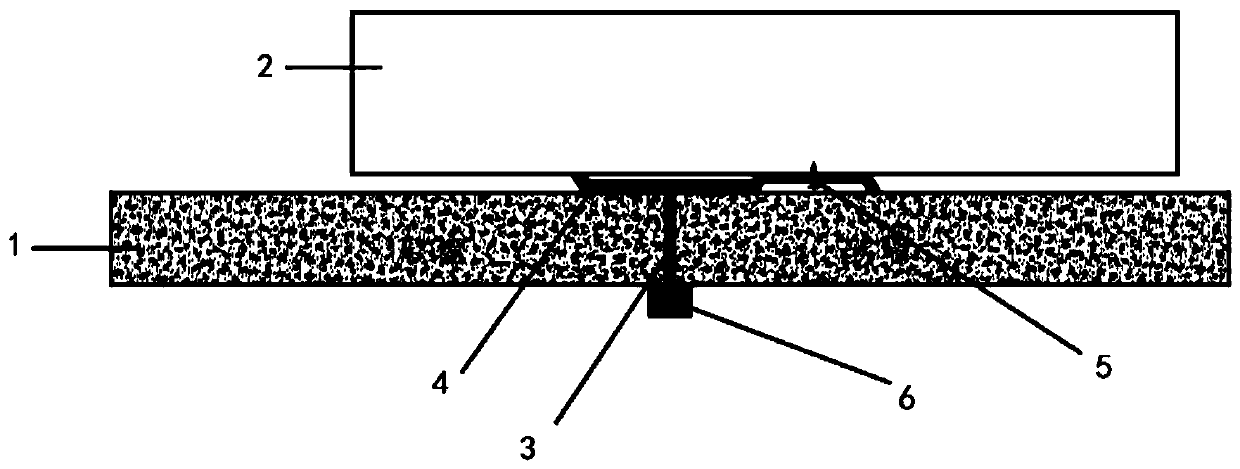

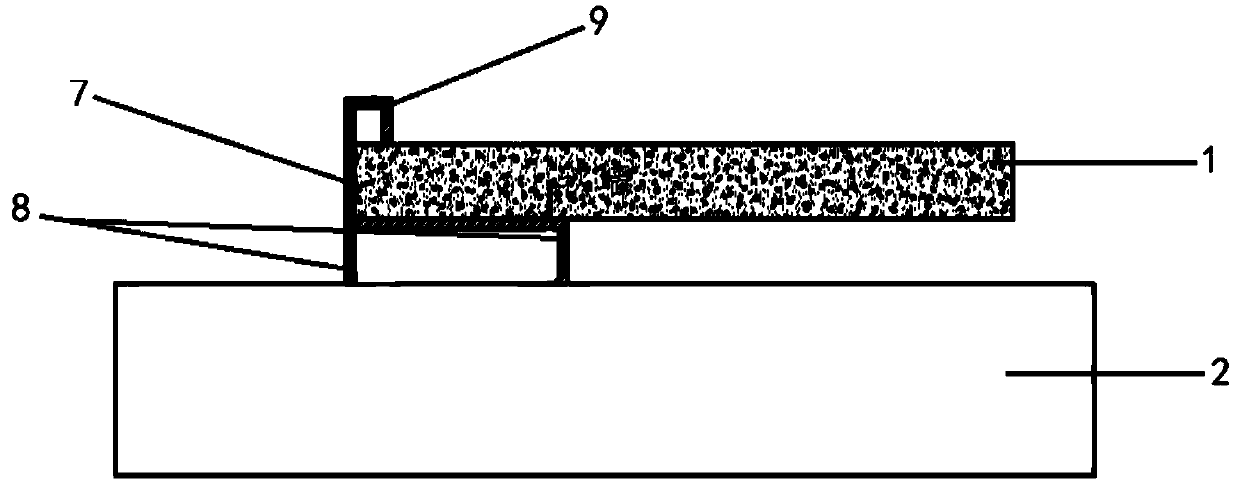

Image

Examples

Embodiment

[0034] A method for making a fine-brush embroidery mural of the present invention, comprising the steps of:

[0035] (1) Design drawings: design and draw the pattern drawings of meticulous embroidery murals, and print the designed pattern drawings according to the actual size of the pattern at 1:1;

[0036] (2) Copy: Put the printed pattern drawing on the copy table, and then put the wall covering (silk double palace fabric) on the pattern drawing, so that the pattern on the pattern drawing is copied to the wall covering;

[0037](3) Glue brushing: mix alum, glue, white Chinese painting pigment and water according to the mass ratio of (1-3):(2-5):(5-7):10 to obtain white meticulous glue, and use white meticulous brush Apply glue to the pattern part copied on the wall covering, so that the glue brushed part and the pattern part are completely overlapped, leaving no gap, and the non-pattern part is not glued, brush 2-3 times, and then dry for 12 hours;

[0038] (4) First use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com