Patents

Literature

33results about How to "High efficiency of separation and recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of separating and recovering sodium vanadate, sodium chromate and sodium carbonate from vanadium slag vanadium extraction liquor

ActiveCN107760868AHigh efficiency of separation and recoveryEasy to separateCarbonate purificationChromates/bichromatesSlagWastewater

The invention relates to a method of separating and recovering sodium vanadate, sodium chromate and sodium carbonate from vanadium slag vanadium extraction liquor. The method is characterized by comprising the following steps: firstly, separating and recovering vanadium in the vanadium slag vanadium extraction liquor by means of a calcium salt precipitation method; then concentrating and enrichingsodium vanadate and sodium carbonate in molybdenum precipitation post liquor by means of an electrodialysis process; returning fresh water obtained by electrodialysis to vanadium slag for a sodium modification and cinder roasting leaching step for recycled use; and separating and recovering sodium vanadate and sodium carbonate in strong water by means of a circular concentration-crystallization method. The method provided by the invention has the advantages of being good in separating effect of sodium vanadate, sodium chromate and sodium carbonate, simple in process, simple to operate, free of waste water and residual slag, environment-friendly and the like, and is suitable for industrialized application of vanadium slag vanadium extraction.

Owner:CENT SOUTH UNIV

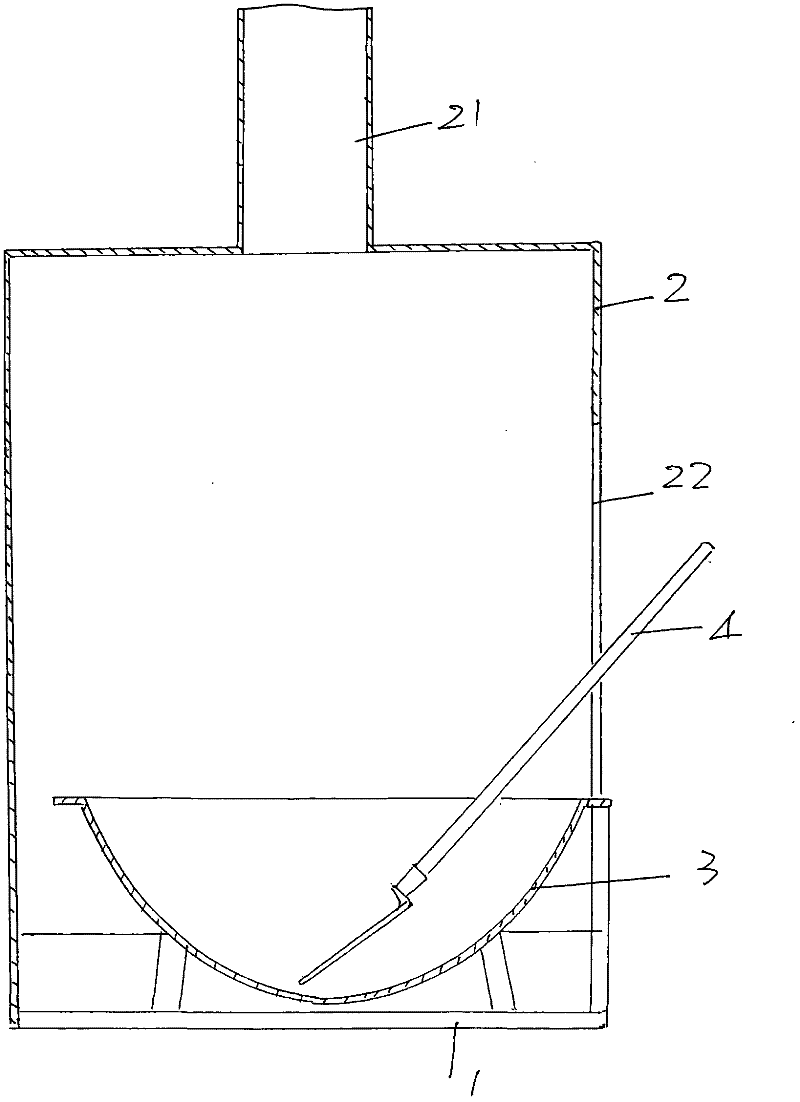

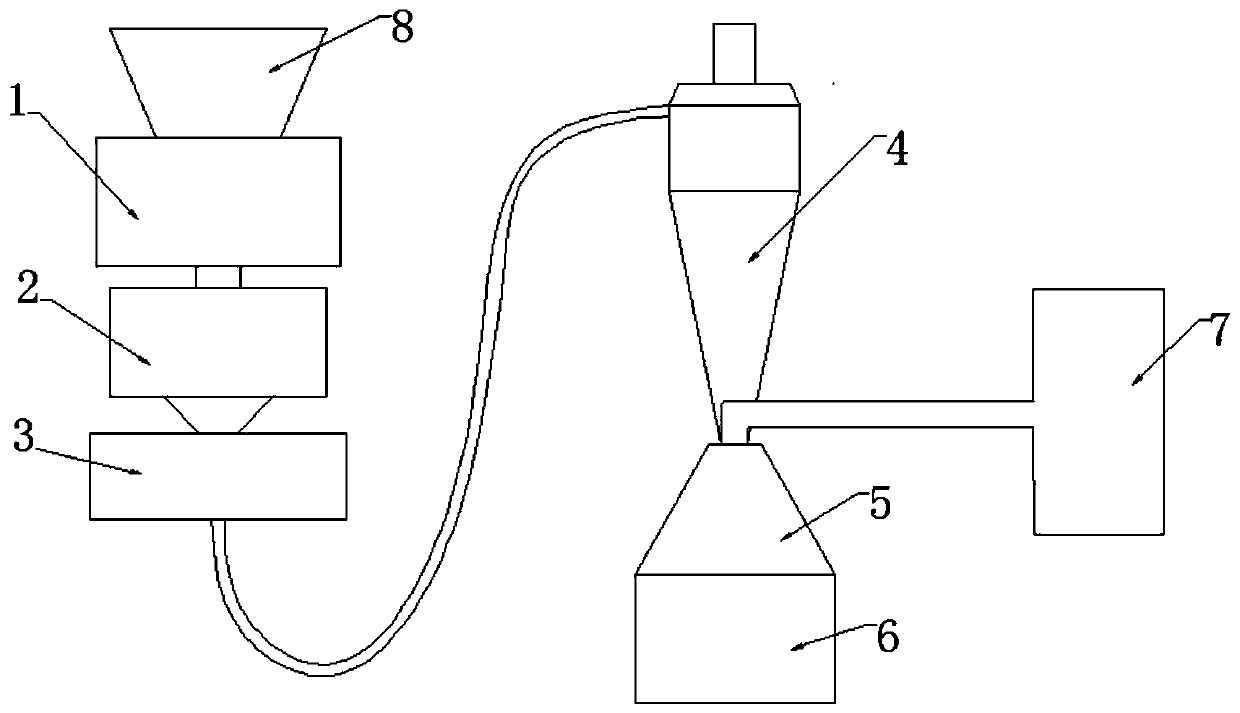

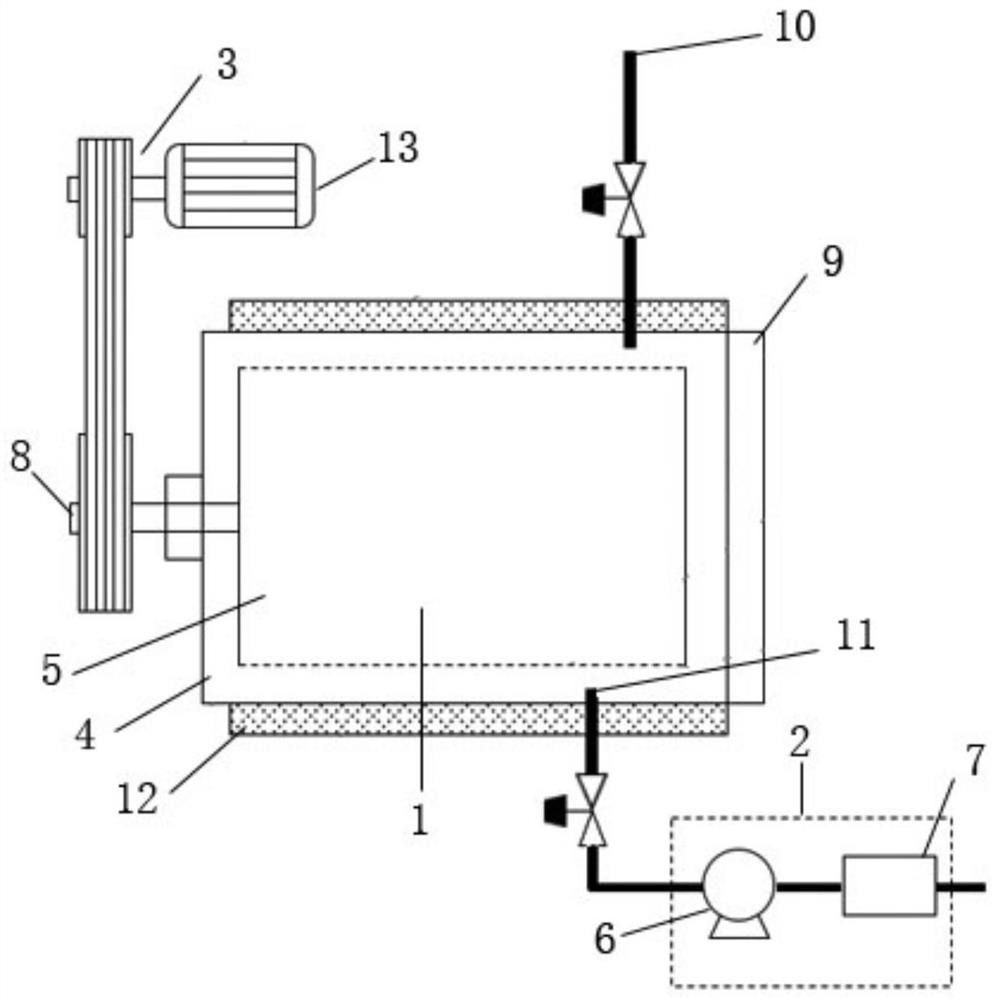

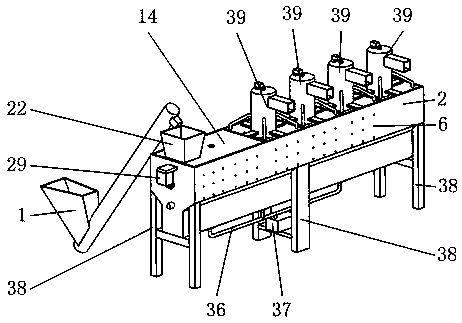

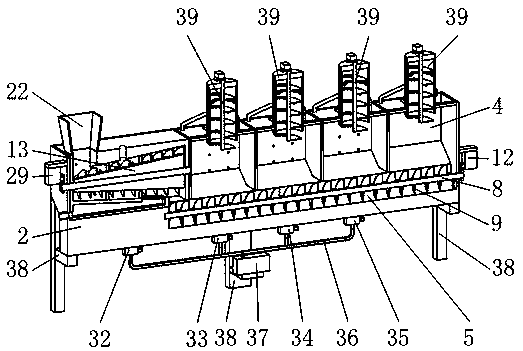

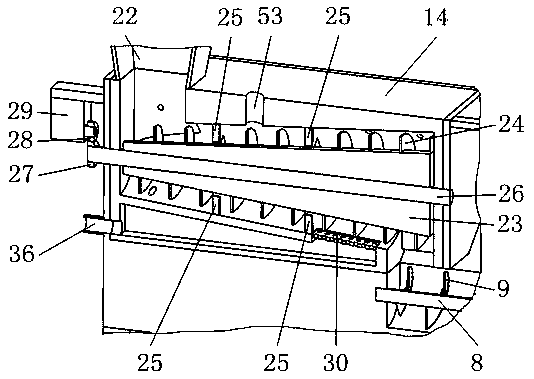

Separation settling tank

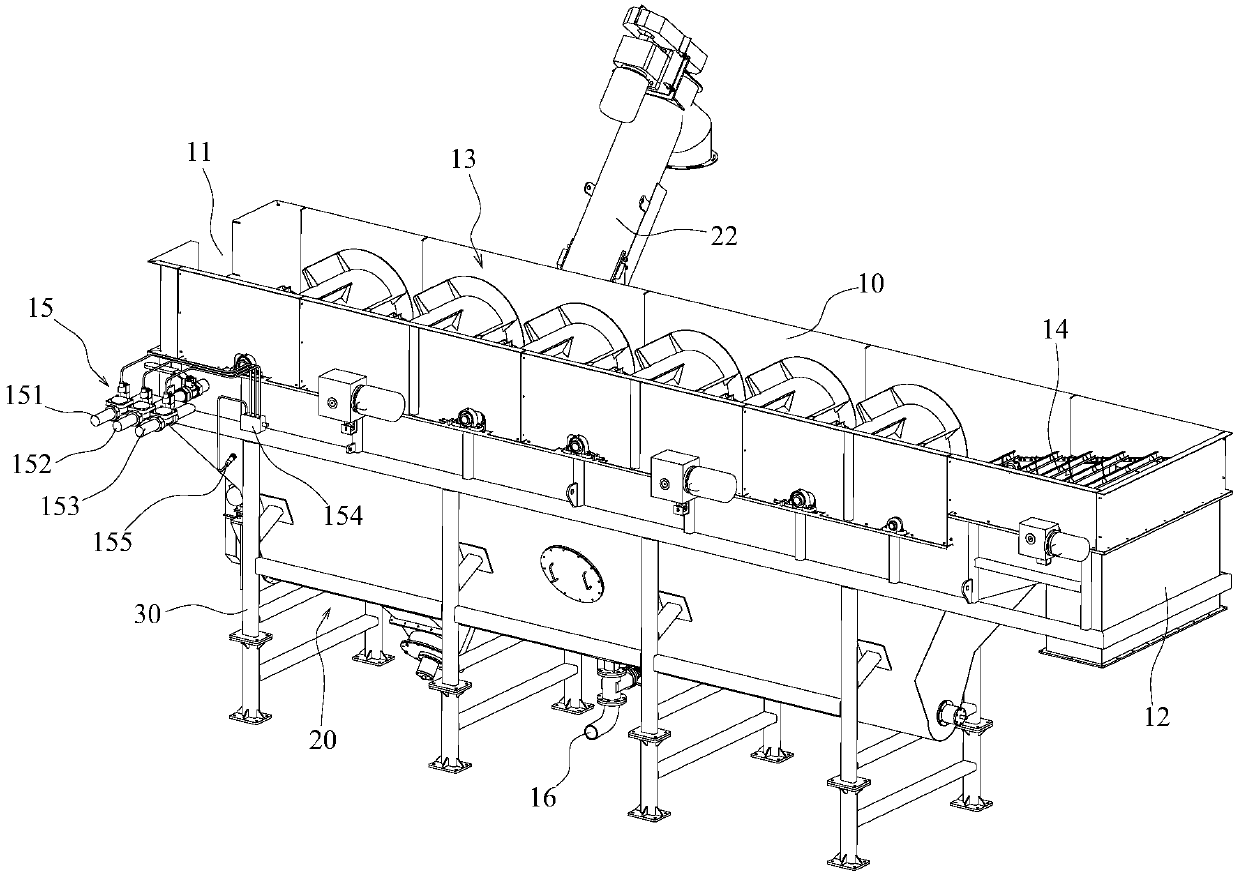

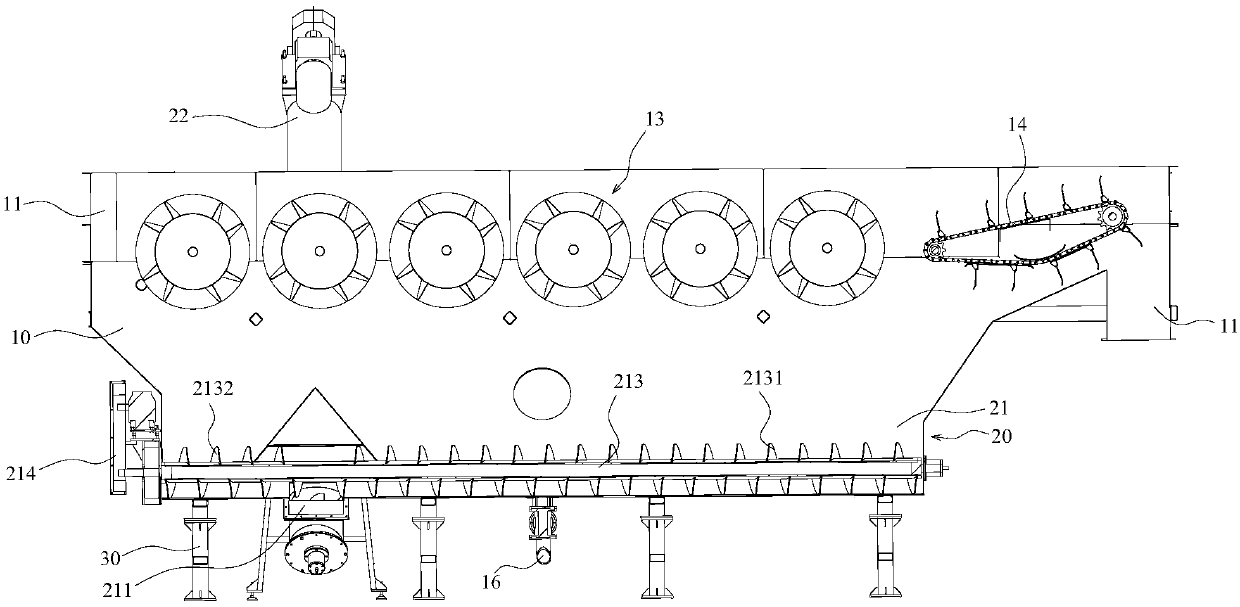

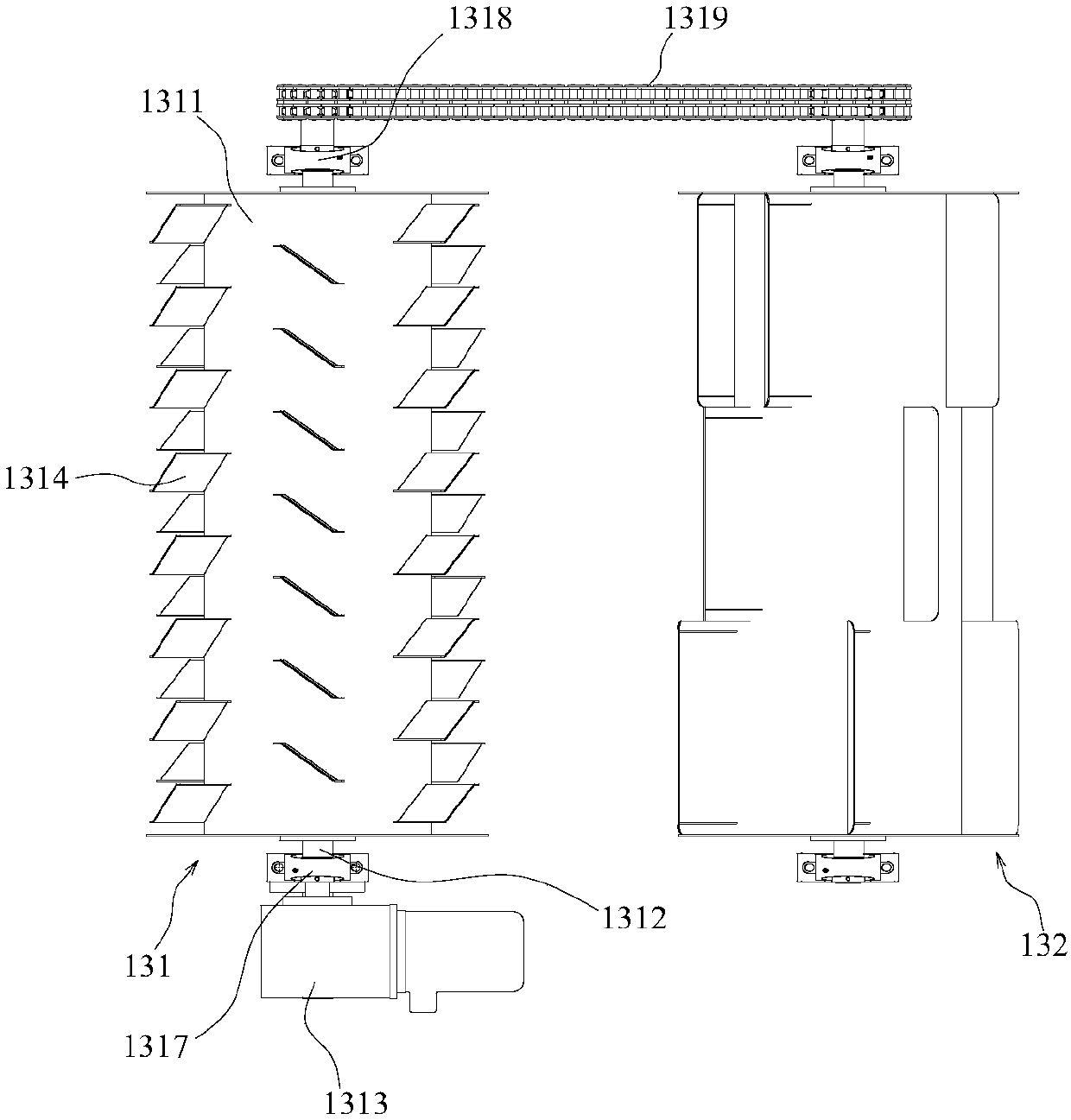

PendingCN107718367AImprove recycling efficiencyGuaranteed effectPlastic recyclingMaterial SeparationCell separation

The invention discloses a separation settling tank and belongs to the technical field of separation equipment. The separation settling tank comprises a separation tank body, a collection device arranged on the lower portion of the separation tank body and a support used for supporting the separation tank body and the collection device. The collection device communicates with the interior of the separation tank body. One end of the separation tank body is provided with a feed port. The other end of the separation tank body is provided with a storage cavity. The separation tank body is internally provided with a material separation assembly used for separating a plastic mixture and a material shifting assembly used for shifting floating materials. The material separation assembly gets closeto the feed port. The material shifting assembly gets close to the storage cavity. The separation tank body is further provided with a concentration regulation mechanism used for controlling the concentration of a separating medium in the separation tank body. The separation settling tank can automatically separate and recover the floating materials and settling materials, automatically regulationthe concentration of the separating medium and improve the recovery efficiency and quality of plastic products.

Owner:GENOX RECYCLING TECH

Method for recovering indium from waste LCDs

InactiveCN104212983AImprove recycling efficiencyEasy to operateProcess efficiency improvementIonIndium

The invention discloses a method for recovering indium from waste LCDs. The method comprises the following steps: waste LCD panels containing indium tin oxide are dismounted, crushed and then dissolved in an acid solution, and insoluble substances are removed by filtration; the filtrate obtained in the first step is adjusted to an appropriate pH value and then stands for precipitation, and precipitates are removed by filtration; trivalent indium ions in the filtrate obtained in the second step are selectively adsorbed by aminophosphonic acid chelate resin, and then desorbed by a hydrochloric acid solution to obtain a solution containing trivalent indium ions. The method is simple to operate and friendly to the environment, has a good indium separation effect and satisfies mass production.

Owner:ZHUZHOU KENENG NEW MATERIAL CO LTD

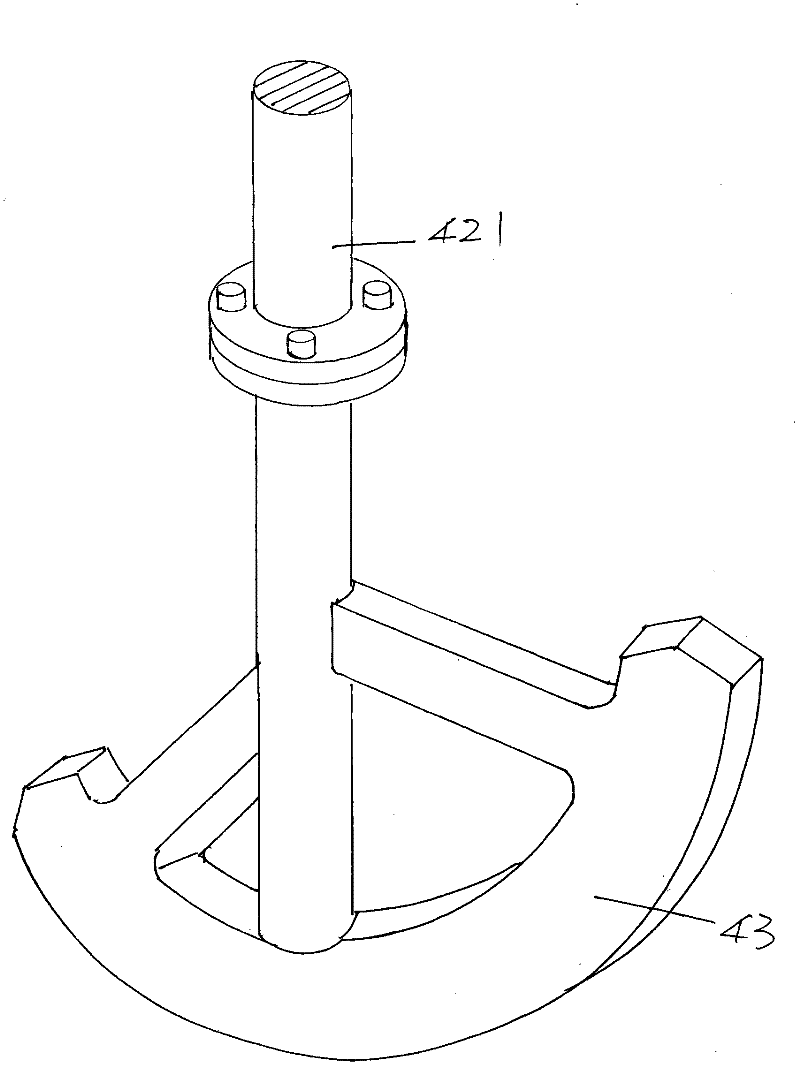

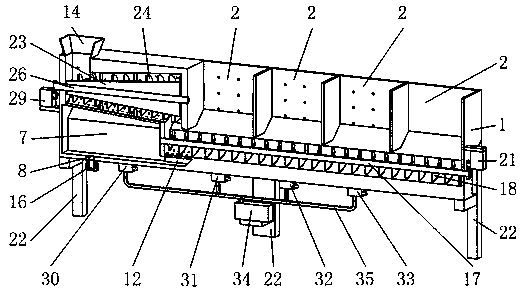

Separation and recovery mechanism for aluminum slag

InactiveCN102304622AReduce labor intensityHigh efficiency of separation and recoveryProcess efficiency improvementSlagAluminum metal

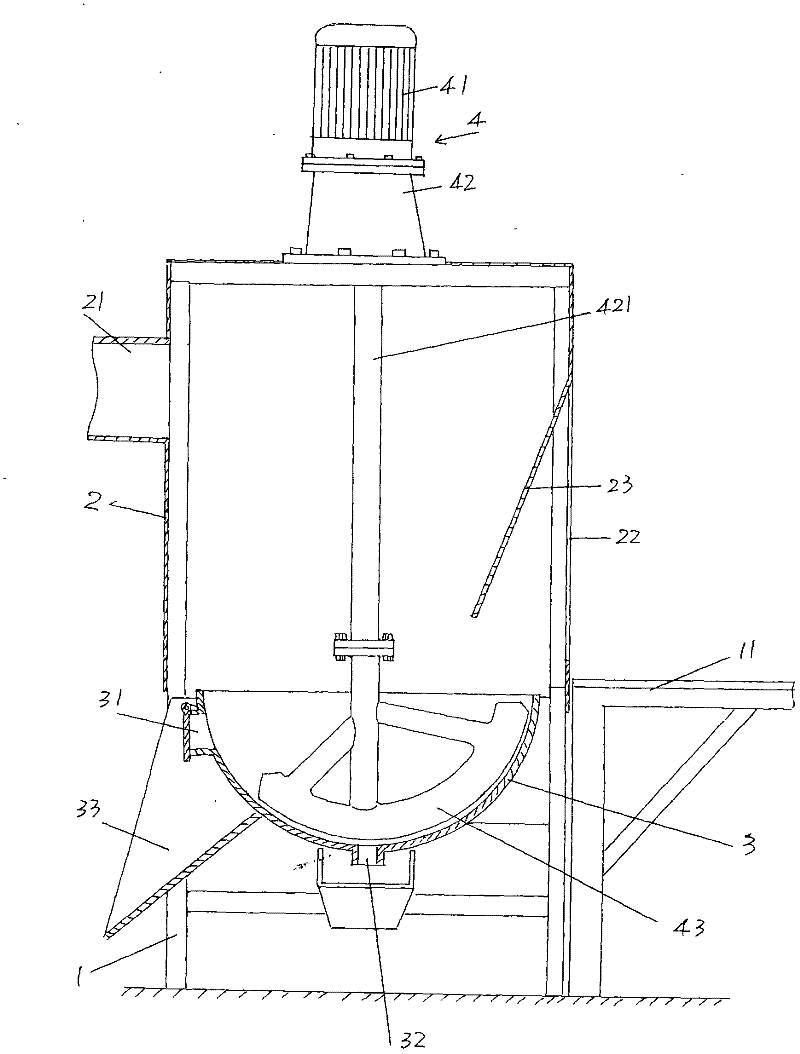

The invention relates to a separation and recovery mechanism for aluminum slag, and belongs to the technical field of aluminum slag recovery devices. The separation and recovery mechanism comprises a support, a cover with a smoke exhaust pipe and a feeding hole and a stirring pot, wherein the stirring pot is arranged on the support; and the cover is connected with the support above the stirring pot. The separation and recovery mechanism is characterized by also comprising an automatic stirring device; the automatic stirring device is arranged on the cover and extends into the stirring pot in the cantilever state; and an ash outlet is formed on the lateral part of the stirring pot, and an aluminum metal liquid outlet is formed at the bottom of the stirring pot. By the technical scheme, the labor intensity of workers can be relieved, the separation and recovery efficiency can be improved, and the environment of operating sites can be improved.

Owner:苏州卡迪亚铝业有限公司

Method for separating and reclaiming sorbic acid from waste water of sorbic acid production

InactiveCN101177389AReduce energy costsReduce recycling costsCarboxylic compound separation/purificationChemical industryDual network

The invention discloses a method for recovering sorbic acid from sorbic acid production wastewater, which belongs to the technical field of chemical industry and environment protection. The concentration of residual sorbic acid in the wastewater is between 0.5 to 1.0mg / ml. Dual-network mutual penetration quadric crosslinking modification adsorption resin (XDA-1G) is adopted to dynamically adsorb residual sorbic acid in sorbic acid production wastewater. After the adsorption is saturated, dynamic desorption and distillation is adopted for separation and recovery. The ratio of height to diameter of resin bed in the adsorption column is kept between 5 to 13, the wastewater pH is adjusted to 2.0 to 3.0, control room temperature is no more than 35 DEG C, flow rate of wastewater is controlled to 1 to 2BV per hour, 95% ethanol is used for desorption. Sorbic acid is obtained after distilling desorption liquid and removing ethanol.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Method for comprehensively treating liquid after vanadium precipitation by acid ammonium salt after vanadium extraction from vanadium slag

ActiveCN113073202AAvoid it happening againHigh efficiency of separation and recoverySulfate/bisulfate preparationProcess efficiency improvementSlagVanadium atom

The invention discloses a method for comprehensively treating liquid after vanadium precipitation by acid ammonium salt after vanadium extraction from vanadium slag. The method comprises the following steps that alkali is directly added into the liquid after vanadium precipitation, heating is performed for deamination, then a precipitant A is added into the liquid after deamination to enrich vanadium and chromium, and filtering is performed to obtain liquid after chromium removal and vanadium and chromium enriched slag; or a precipitant B is added into the vanadium-precipitated liquid to enrich vanadium, filtering is performed to obtain vanadium-removed liquid and vanadium-enriched slag, then alkali is added into the vanadium-removed liquid, heating is performed for deamination, the precipitant A is added into the deaminated liquid to enrich chromium, filtering is performed to obtain chromium-removed liquid and chromium-enriched slag, and vanadium is regenerated, separated and recycled from the obtained vanadium-enriched slag; and chromium-enriched slag and vanadium-chromium-enriched slag are regenerated and separated to recover chromium and vanadium, the concentrations of V and Cr in the chromium-removed liquid are both larger than 0.5 mg / L, so that the generation of vanadium-chromium reducing slag and ammonium-containing sodium sulfate crystal substances is avoided. The method has the advantages of short process flow, simplicity and convenience in operation, high vanadium and chromium precipitation separation and recovery efficiency, environment friendliness and the like, and is suitable for industrial application.

Owner:CENT SOUTH UNIV +1

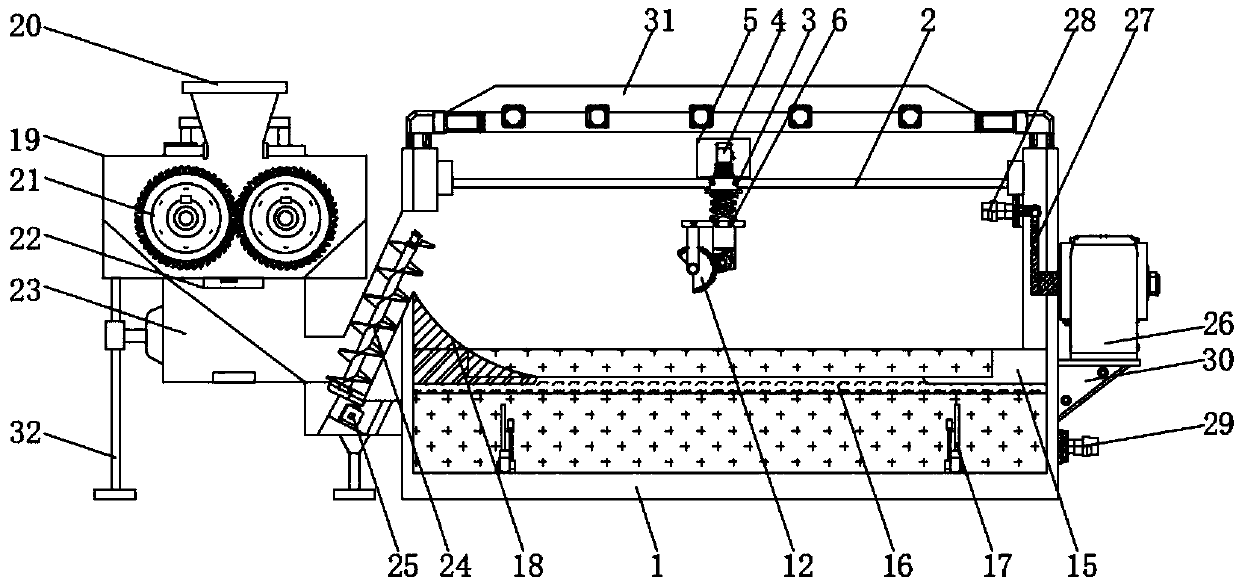

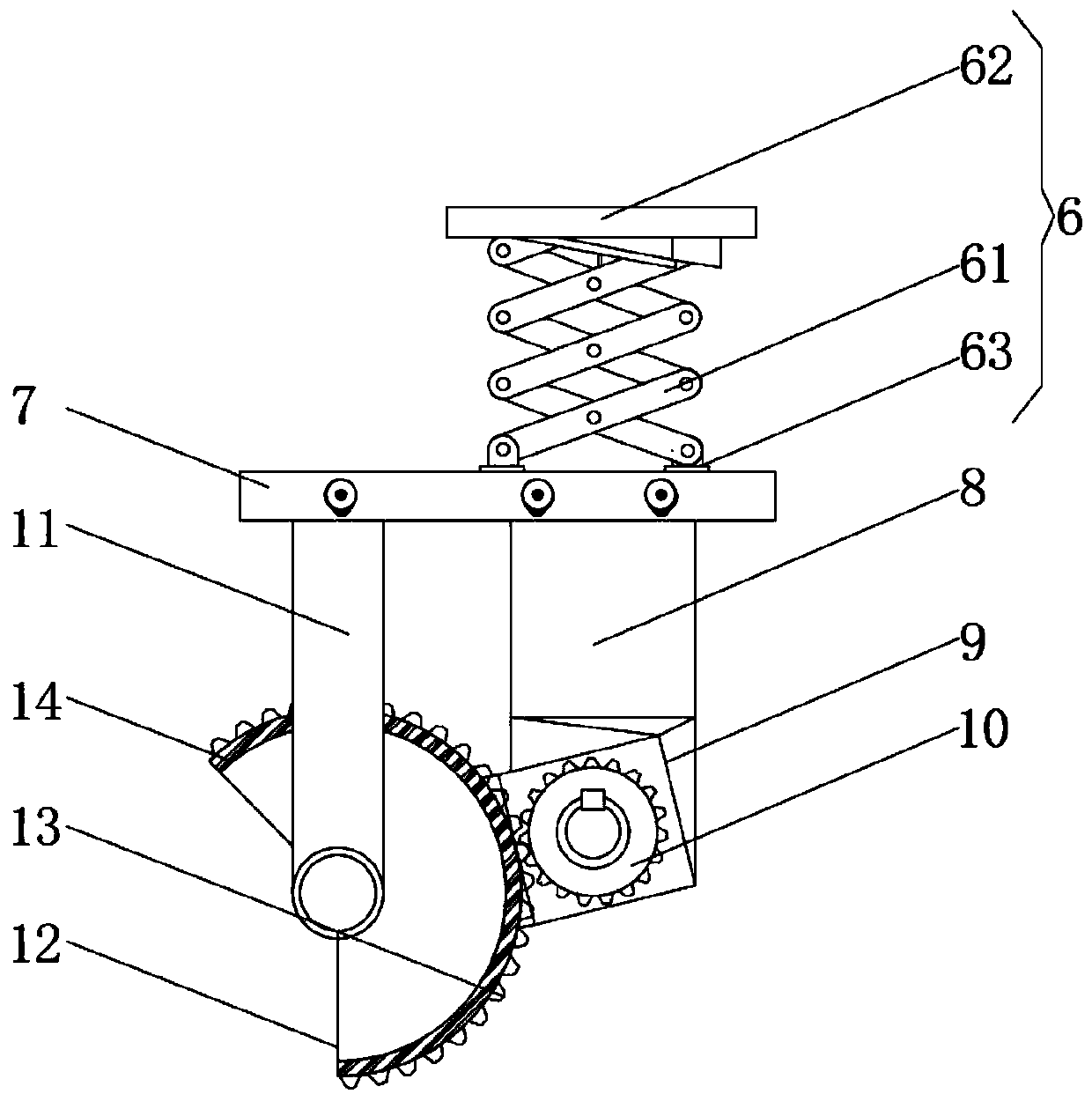

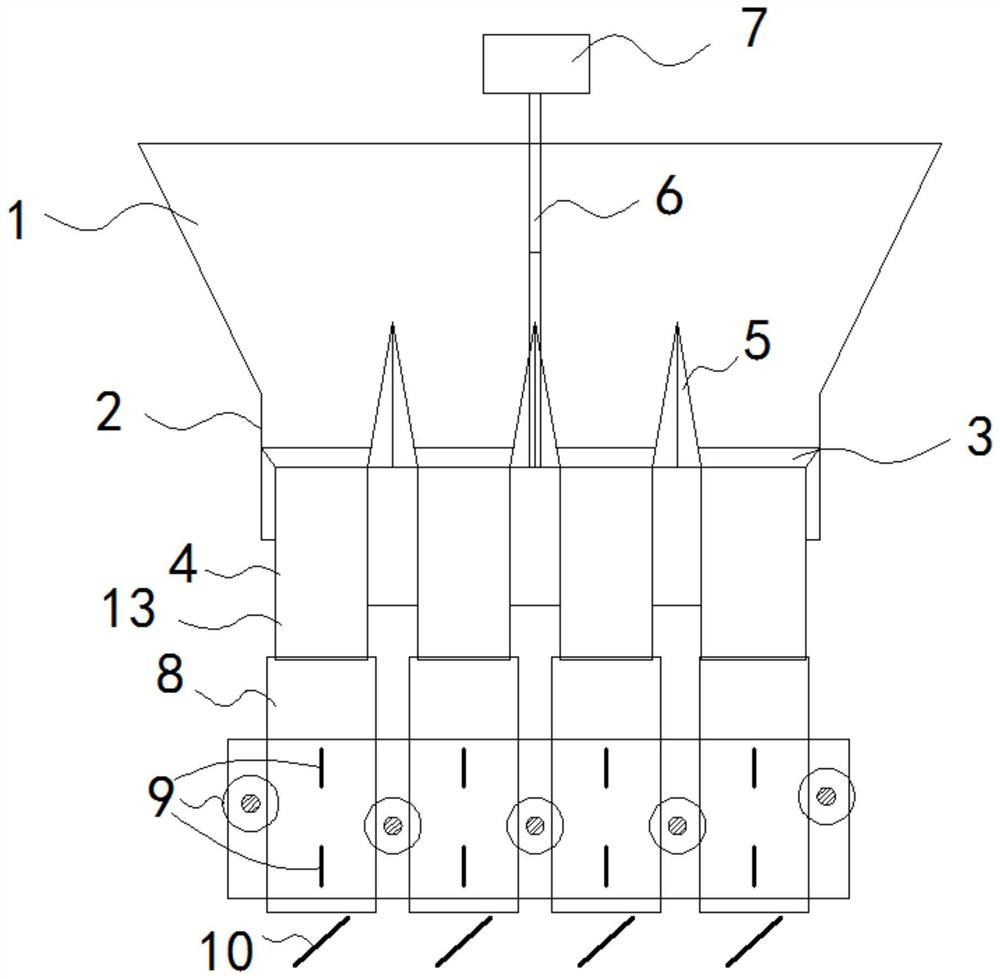

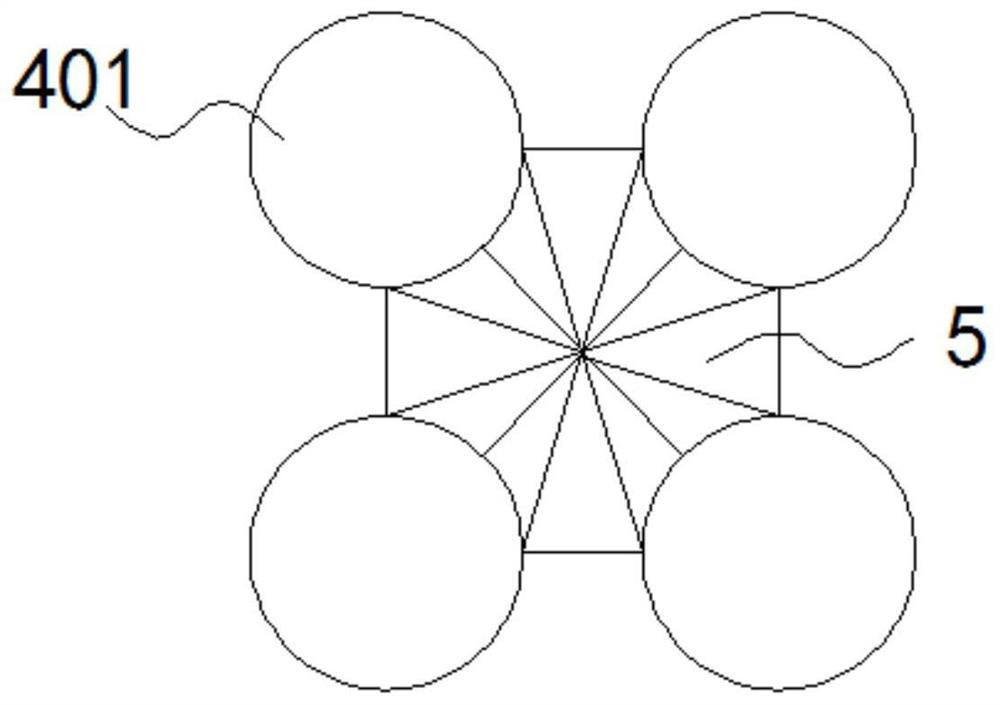

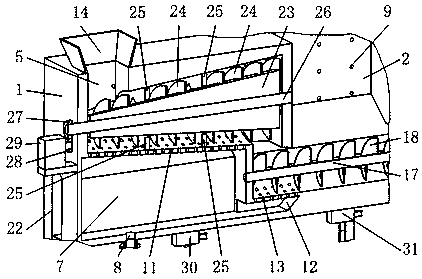

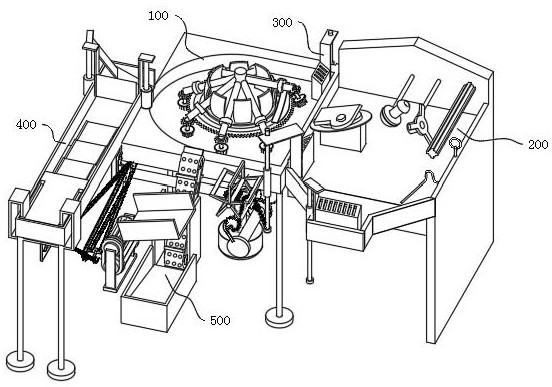

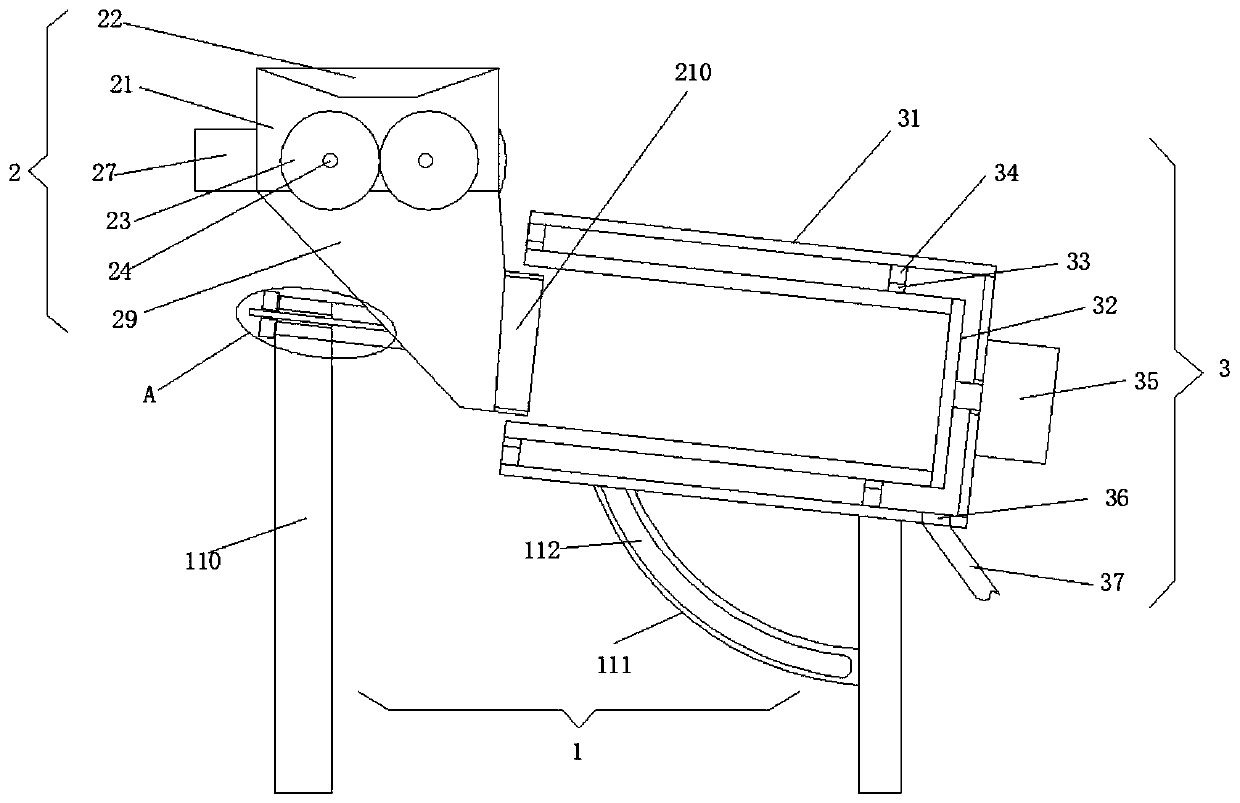

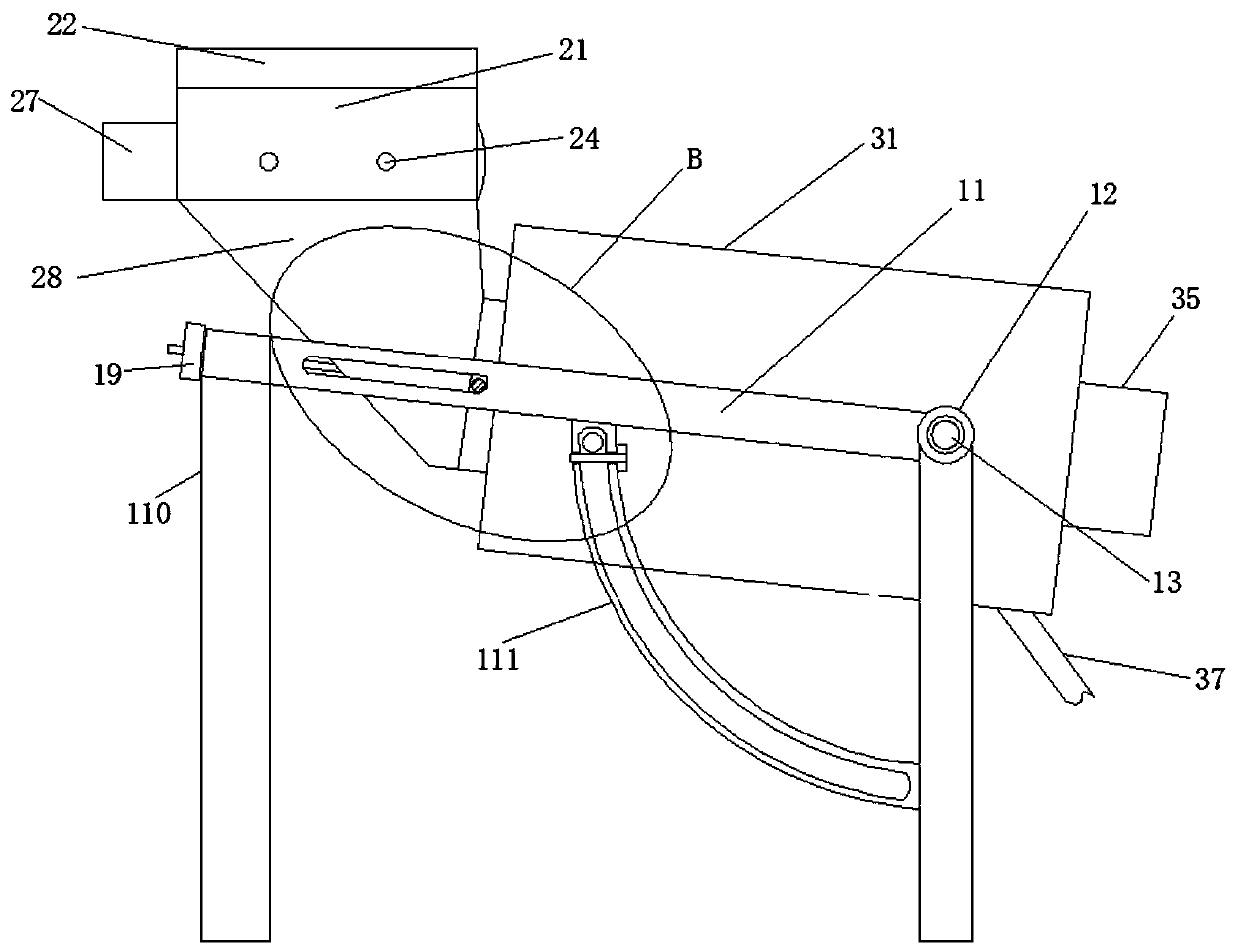

Integrated recovery equipment for waste integrated circuit plates

InactiveCN109550772ATo achieve the purpose of crushing and dissolvingEasy to recycleSolid waste disposalTransportation and packagingEngineeringDissolution

The invention discloses integrated recovery equipment for waste integrated circuit plates. The integrated recovery equipment comprises a separating work box and a crushing machine box; a linear guiderail is arranged above the inner wall of the separating work box; the outer side of the linear guide rail is glidingly connected with a linear guide rail sliding block; a stepping motor is mounted atthe top of the linear guide rail sliding block; a motor box is arranged at the top of the linear guide rail sliding block and is located on the outer side of the stepping motor; a scissor-fork liftingdevice is mounted at the bottom of the linear guide rail sliding block; the bottom of the scissor-fork lifting device is fixedly connected with a mounting bottom frame; the bottom of the mounting bottom frame is fixedly connected with a connecting rack; the bottom of the connecting rack is fixedly connected with a waterproof motor box; and a rotating motor is arranged inside the waterproof motorbox. The invention relates to the technical field of recovery of the waste integrated circuit plates. By the aid of the integrated recovery equipment for the waste integrated circuit plates, the purposes of crushing and dissolving the waste integrated circuit plates are achieved, the waste integrated circuit plates are decomposed after being crushed and are convenient to separate and recover, andplastic after dissolution is separated and fished.

Owner:萧桂颖

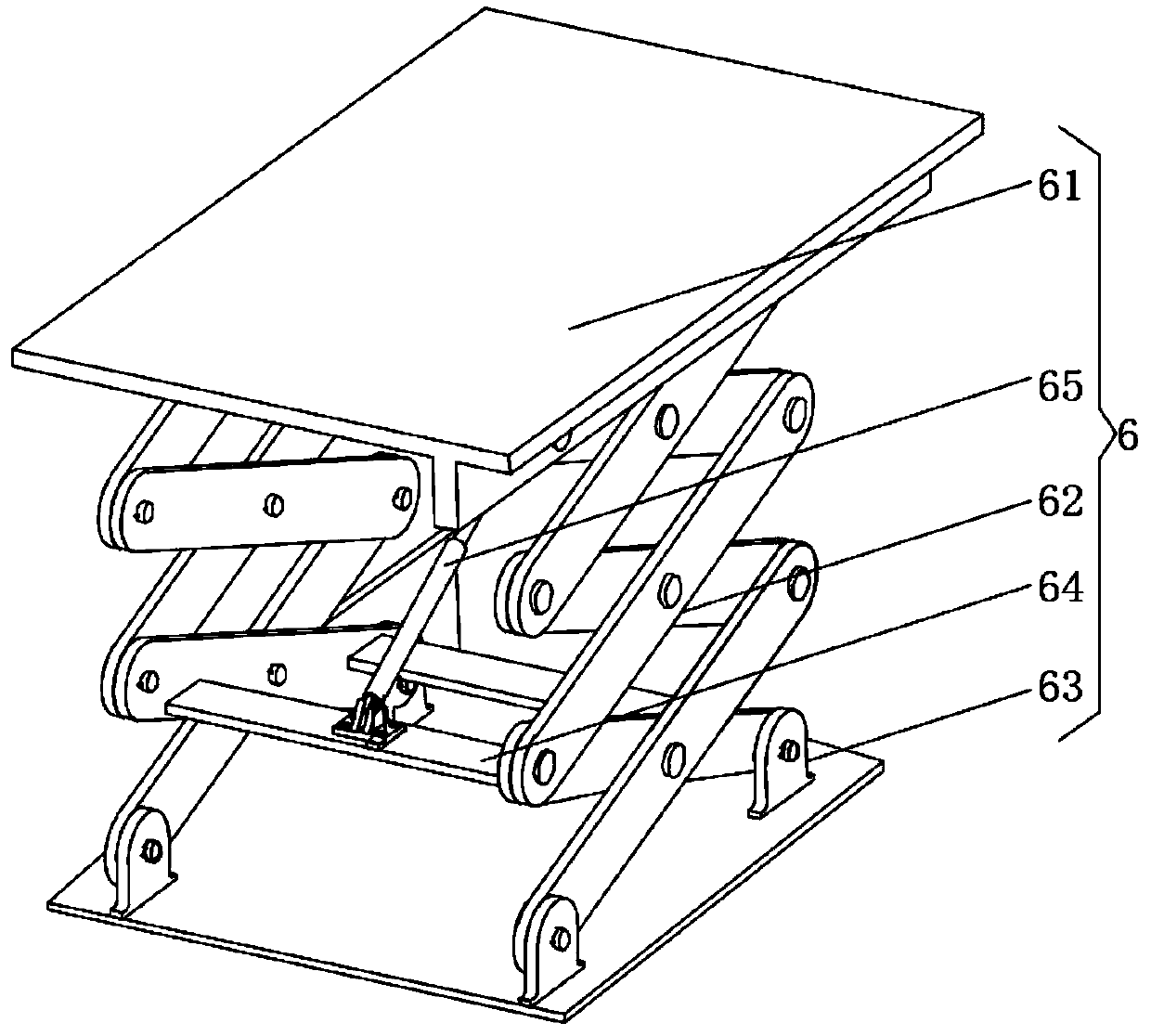

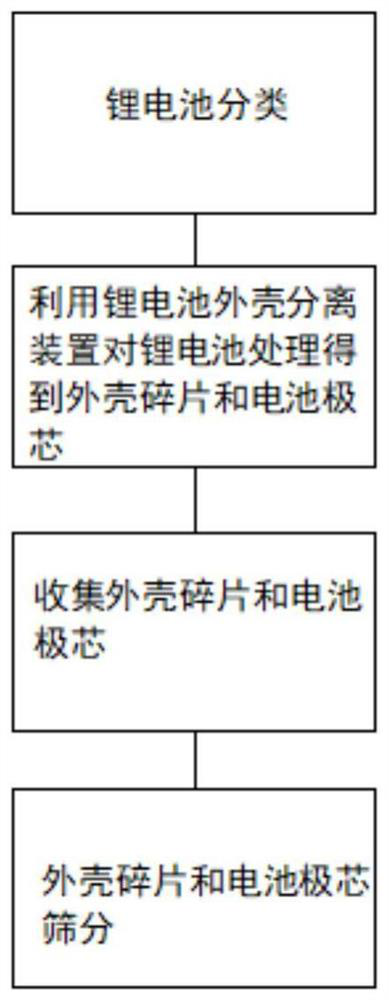

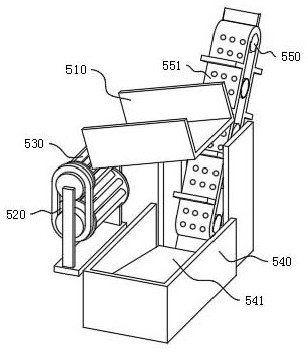

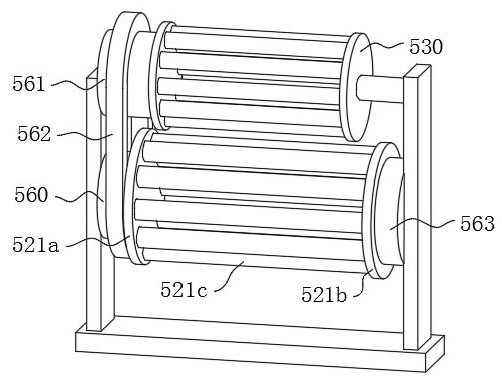

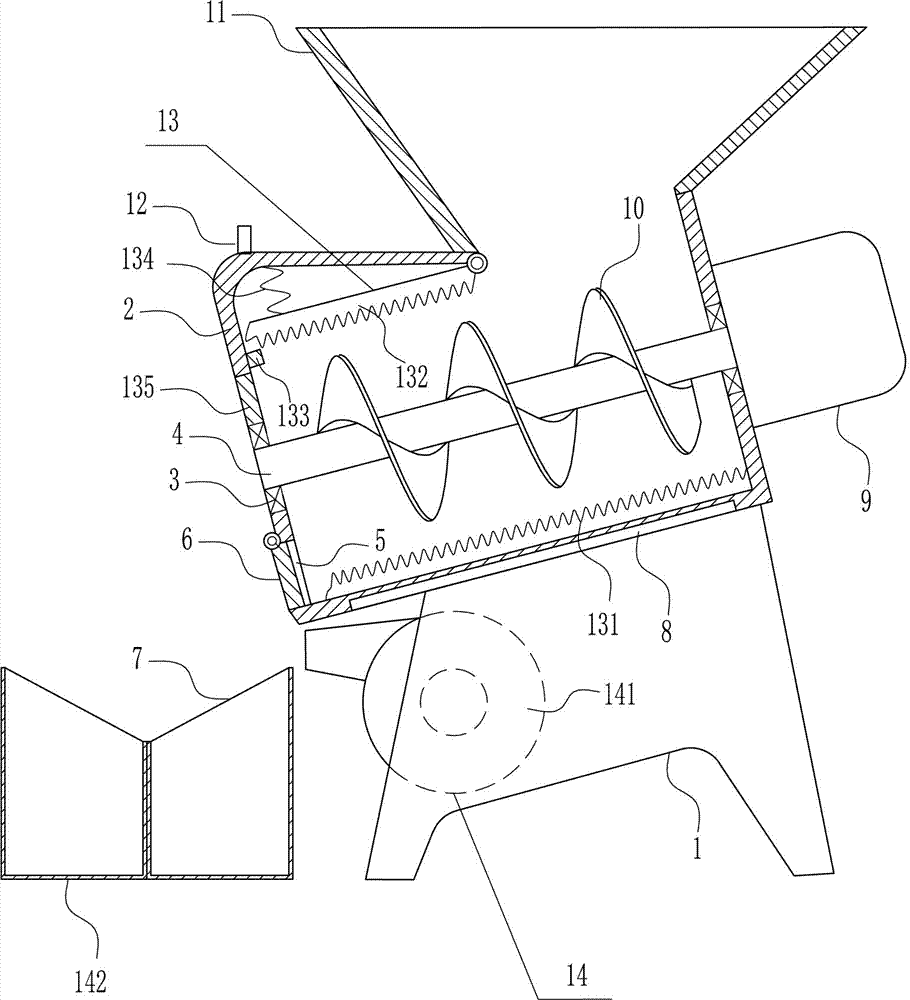

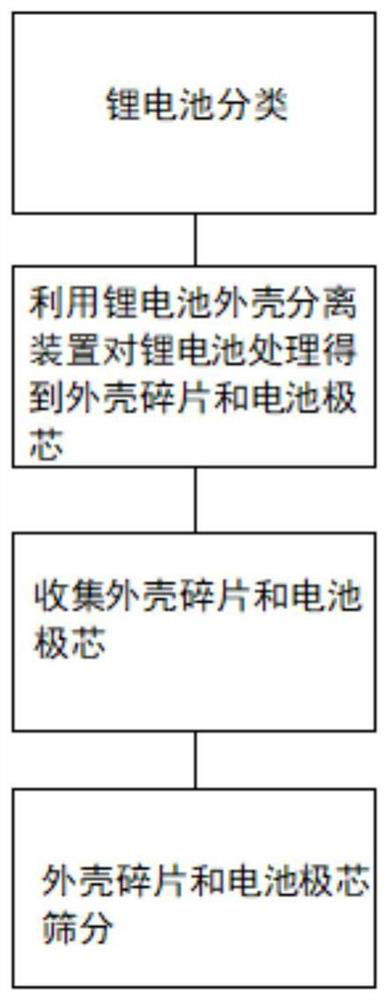

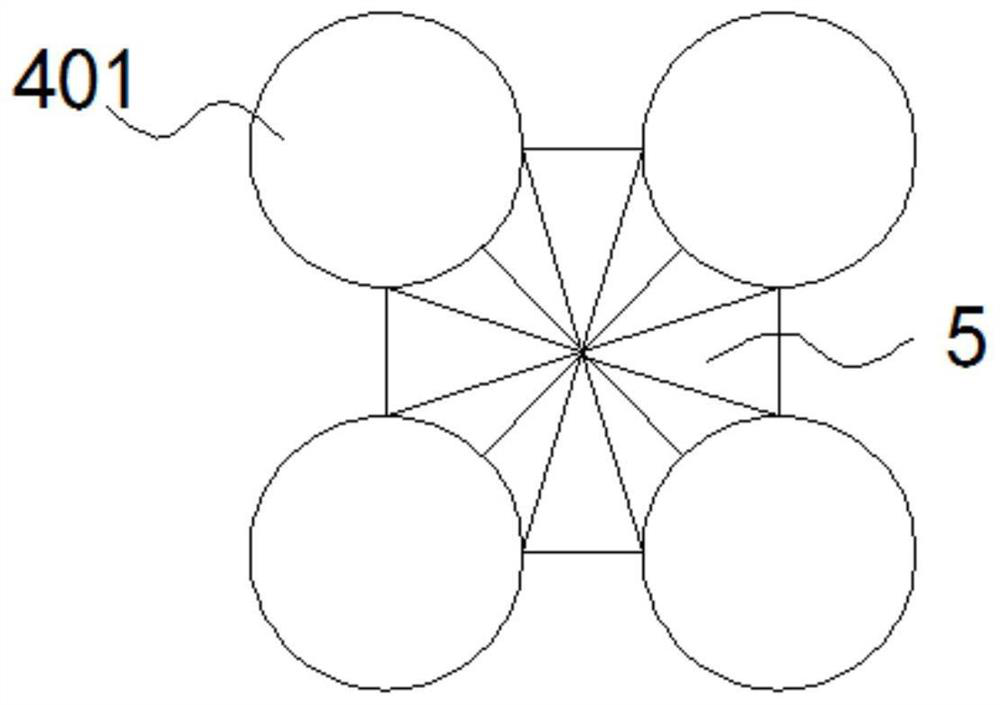

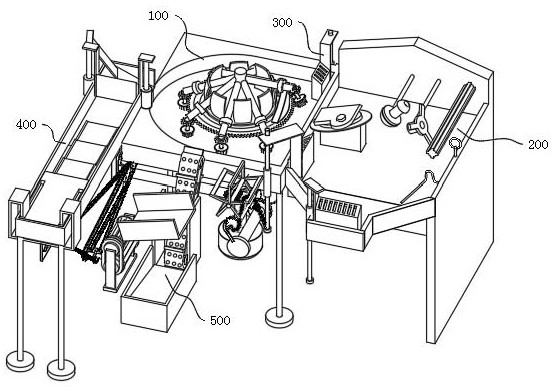

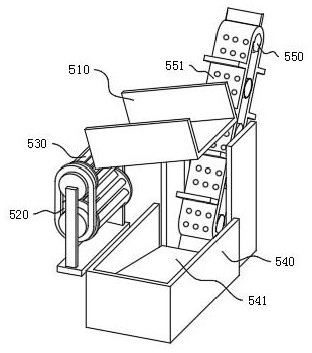

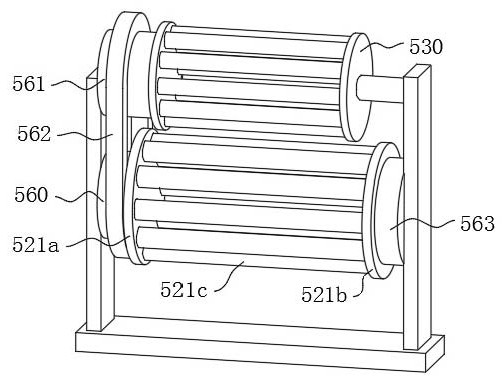

Efficient separation and recovery process for lithium battery

ActiveCN111653845AHigh efficiency of separation and recoveryReduce difficultyWaste accumulators reclaimingBattery recyclingPhysical chemistryBattery cell

The invention discloses an efficient separation and recovery process for lithium batteries. The efficient separation and recovery process comprises the following steps: 1, classifying the shapes of collected waste lithium batteries; 2, removing the shell of the lithium battery by using a lithium battery shell separation device; 3, collecting shell fragments and battery pole cores falling from thelithium battery shell separation device by using a collector; and 4, filtering the shell fragments and the battery pole core by using a vibrating screen device to finish separation and recovery of theshell material and the battery pole core. According to the method, firstly, collected waste lithium batteries are subjected to shape classification to classify cylindrical lithium batteries, and thecylindrical lithium batteries are subjected to special separation, so that the separation and recovery efficiency is improved. And secondly, the lithium battery shell is vertically cut and beveled byutilizing the lithium battery shell separation device, so that the lithium battery shell is in a sheet shape, the lithium battery shell is conveniently separated from the battery pole core, the laterrecovery difficulty is reduced, and the separation and recovery efficiency is improved.

Owner:广西华政新能源科技有限公司

Treatment system and recycling method for phenolic resin based copper clad laminate

InactiveCN110883987ARaise the gradeImprove crushing effectAdditive manufacturing apparatusPlastic recyclingElectrostatic separationSeparation technology

Owner:广州雅居乐固体废物处理有限公司

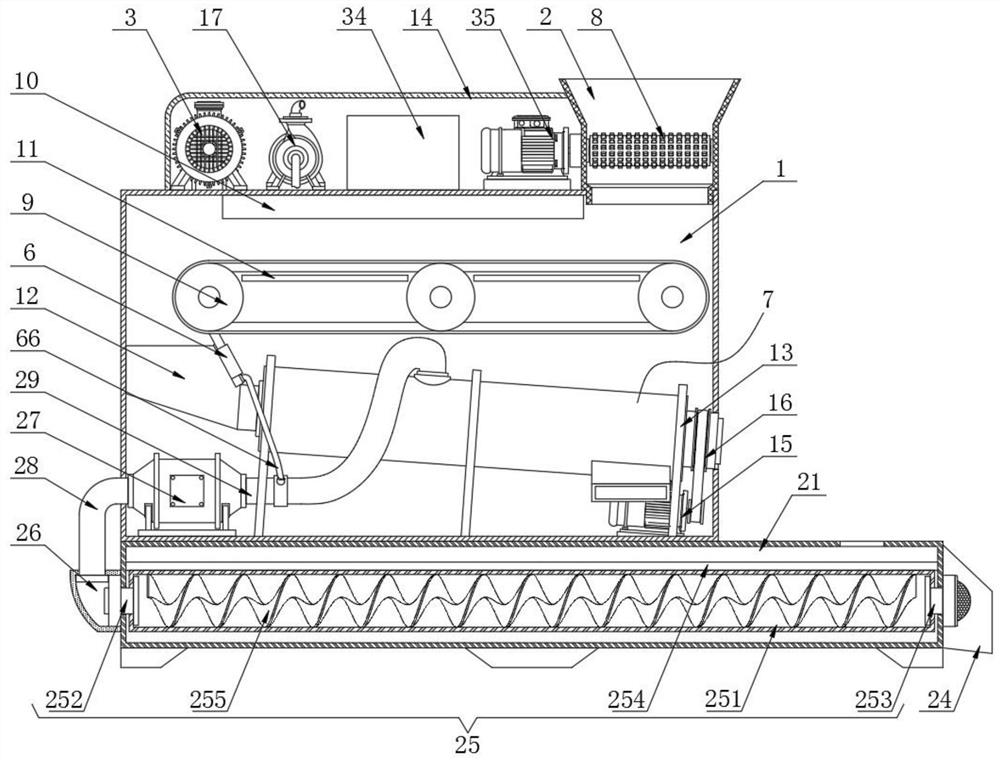

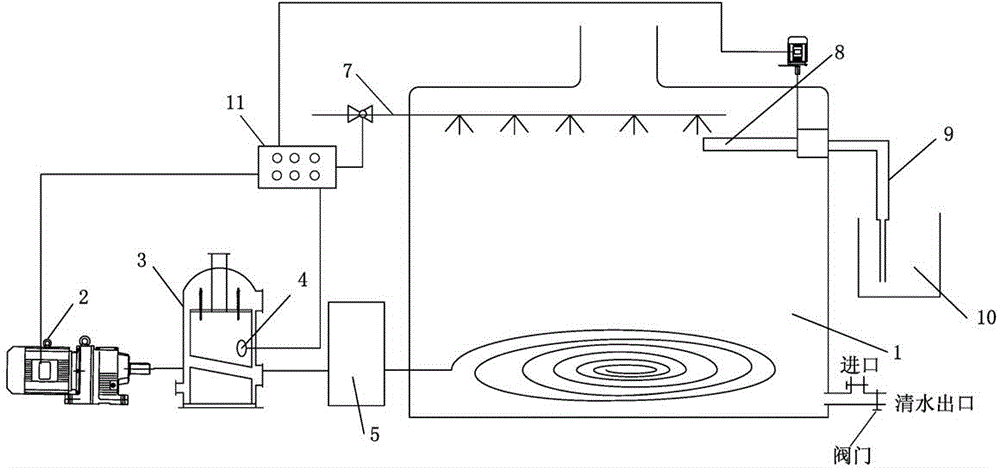

Plastic cleaning floatation device

The invention belongs to the field of floatation devices, and particularly relates to a plastic cleaning floatation device. The plastic cleaning floatation device comprises a floatation base, a spiralblade A, a spiral blade B and the like, wherein the upper surface of the floatation base is provided with four continuous flotation tanks, and the bottoms of the four floatation tanks are provided with a delivery tank communicating with the four floatation tanks. By means of the plastic cleaning floatation device, waste plastic can be pre-cleaned before being floated, the pre-cleaned waste plastic mixture enters the floatation tanks to be floated, it is guaranteed that the floated plastic is cleaner, rapid recovery of the plastic is facilitated, the additional process of cleaning the plasticindependently is omitted, and the efficiency of plastic recovery is improved. After the pre-cleaned plastic mixture enters a liquid medium, large-area contamination caused by the plastic mixture to the liquid medium can be reduced, it is avoided that the density of the liquid medium changes as the liquid medium is contaminated by silt, the efficiency of plastic separation and recovery is improved,the replacement frequency of the floatation liquid medium is reduced, and thus the cost of the floatation liquid medium is reduced.

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

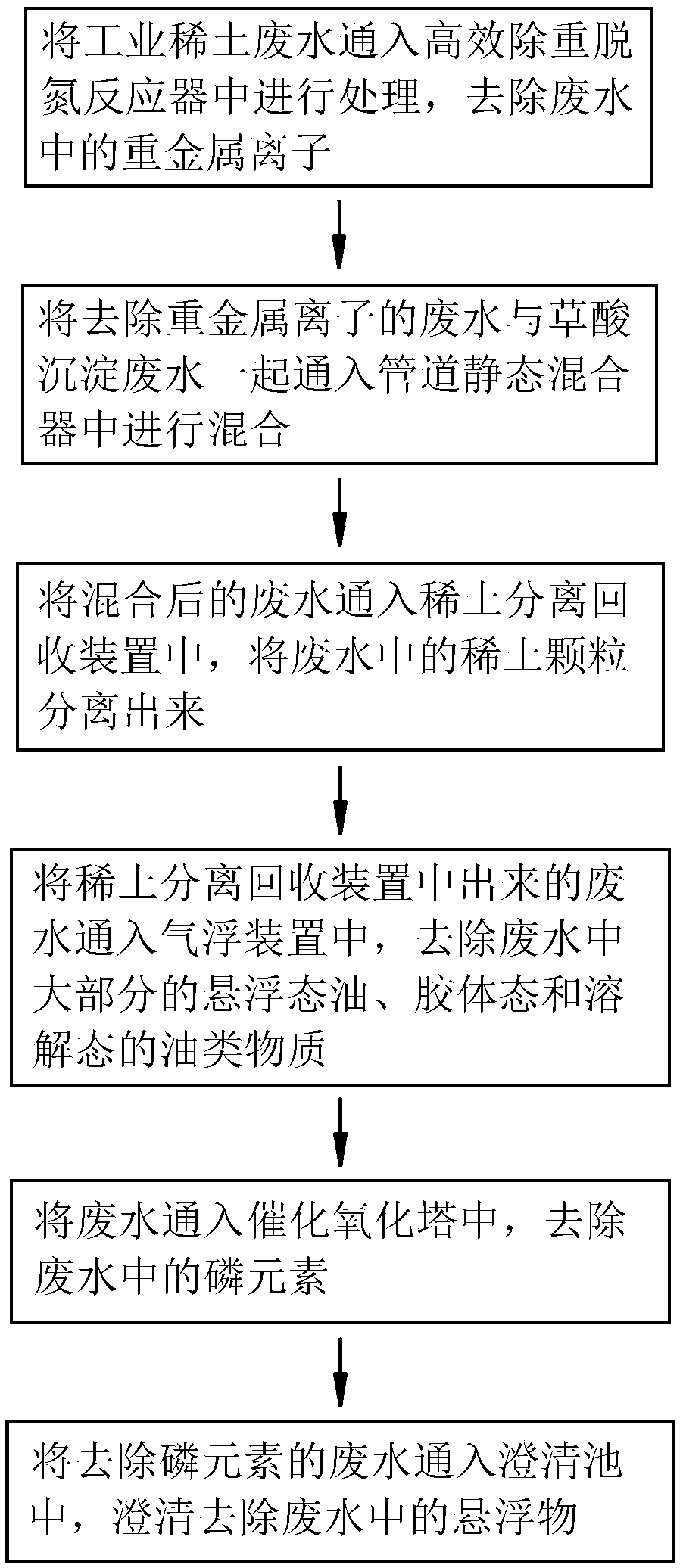

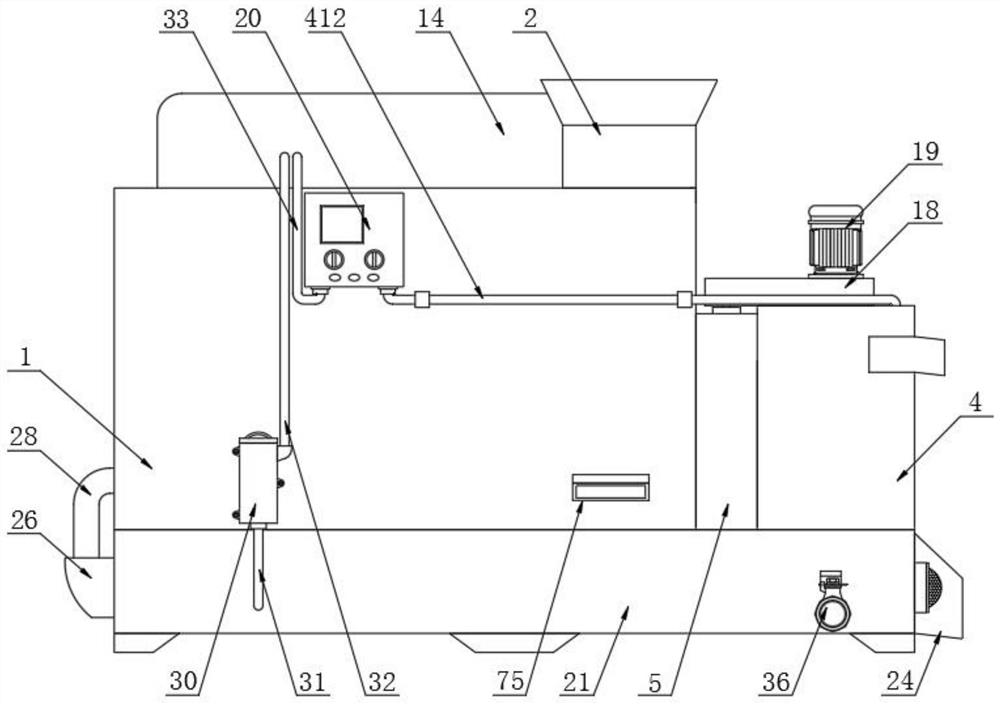

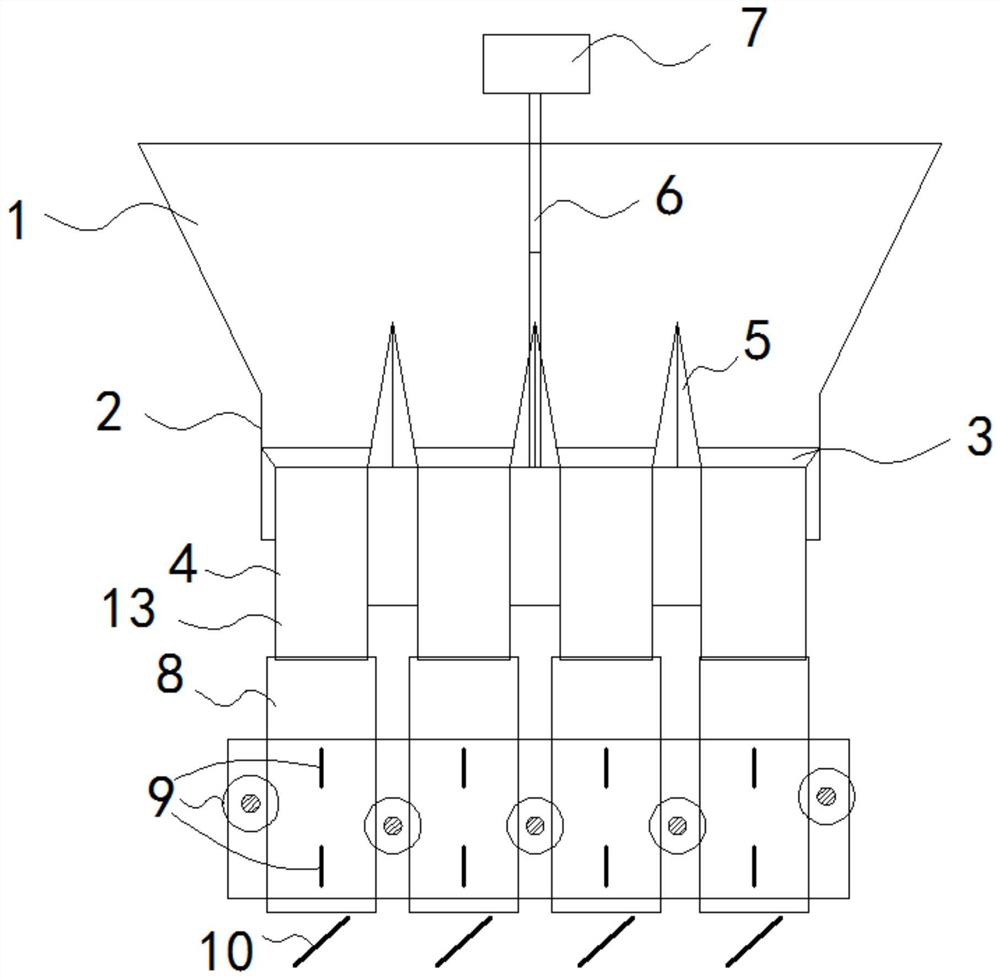

Industrial rare earth wastewater treatment process

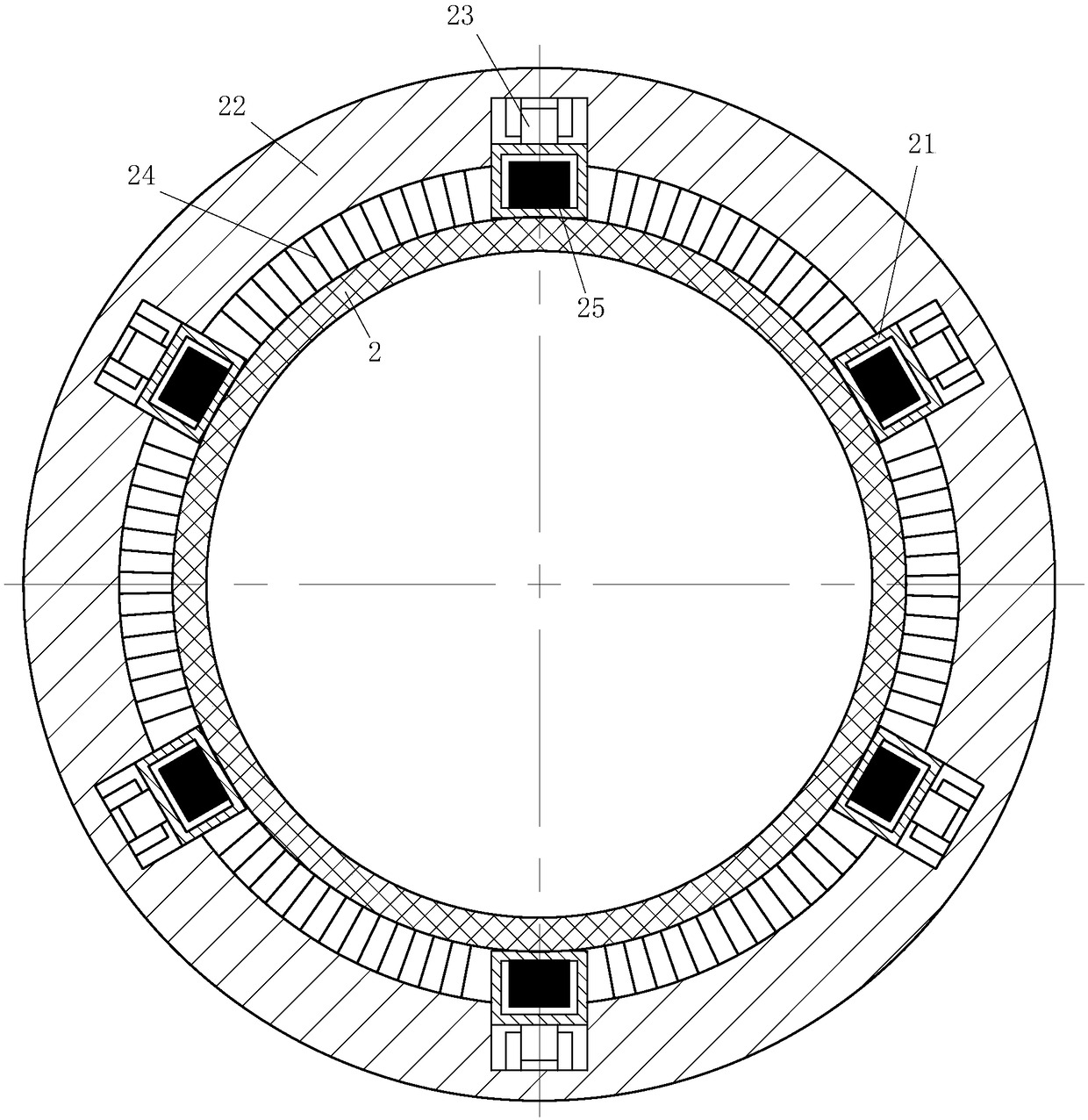

ActiveCN109095645AHigh efficiency of separation and recoveryEasy to separateWater contaminantsTreatment involving filtrationRare earthEngineering

The invention belongs to the technical field of industrial wastewater treatment and particularly relates to an industrial rare earth wastewater treatment process. In the process, a rare earth separation and recovery device comprises a casing, a waste liquor tank, a filter net, a liquor inlet disc, a transition barrel, a discharging door, a gear ring, a rotary arm, a motor, a fixed sleeve, an electric cylinder and a material box. The left end of the liquor inlet disc is hinged on the left inner wall of the casing, the right end of the discharging door is hinged at one end of the rotary arm through a spherical surface, gear teeth on the transition barrel are meshed with gear teeth on the gear ring, so that the transition barrel can rotate around the rotation axis while rotating around the hinged position at the left end of the liquor inlet disc, water liquor in the filter net is continuously rolled, thus, the inner surface of the filter net cannot extrude rare earth particles through constant rolling, the condition that liquor cannot penetrate through the filter net conveniently due to blockage of the filter net by rare earth particles is avoided, separation of liquor and the rare earth particles in the waste liquor is accelerated, and the rare earth separation and recovery efficiency is improved.

Owner:LONGNAN JINGLI NONFERROUS METAL CO LTD

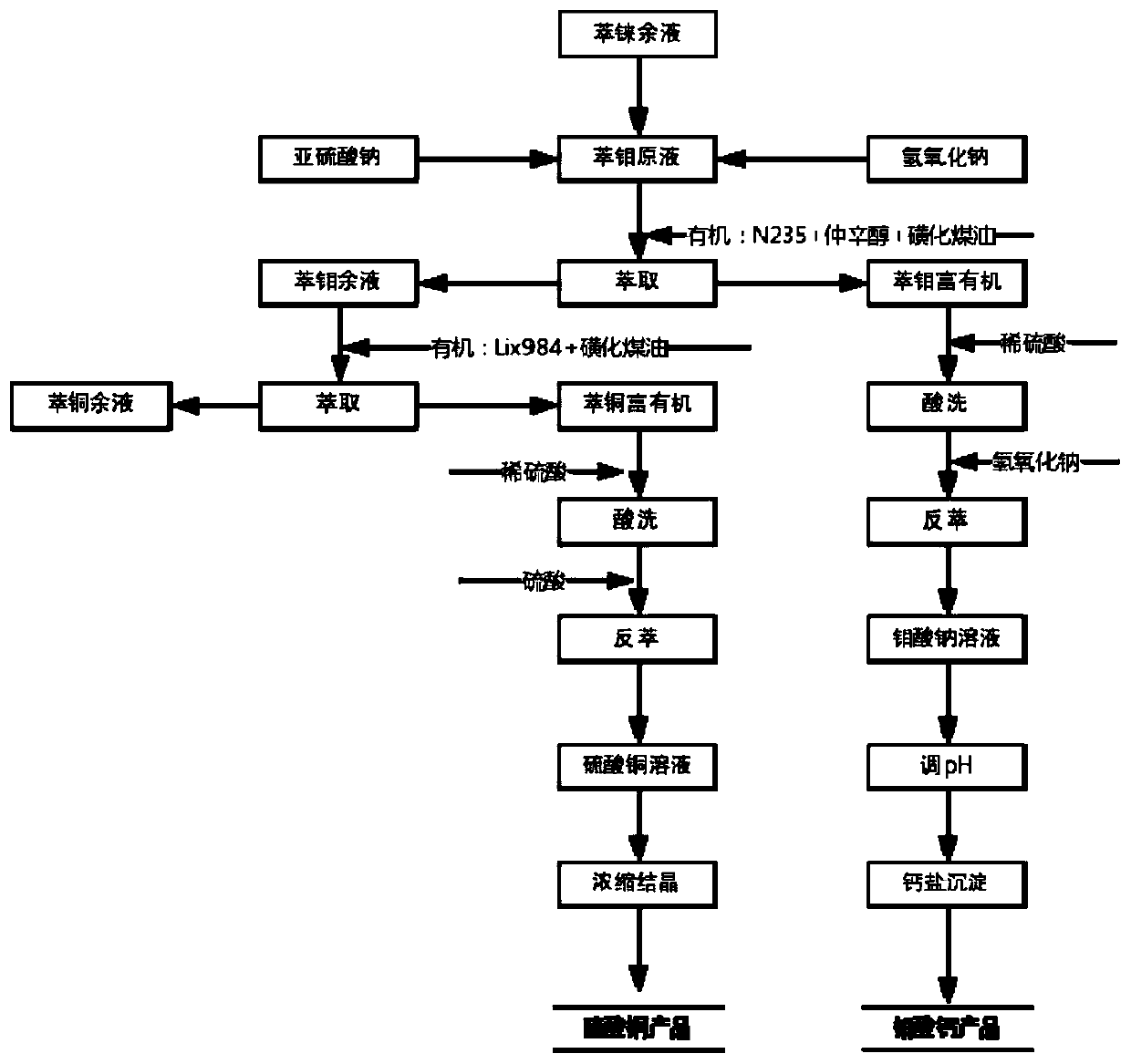

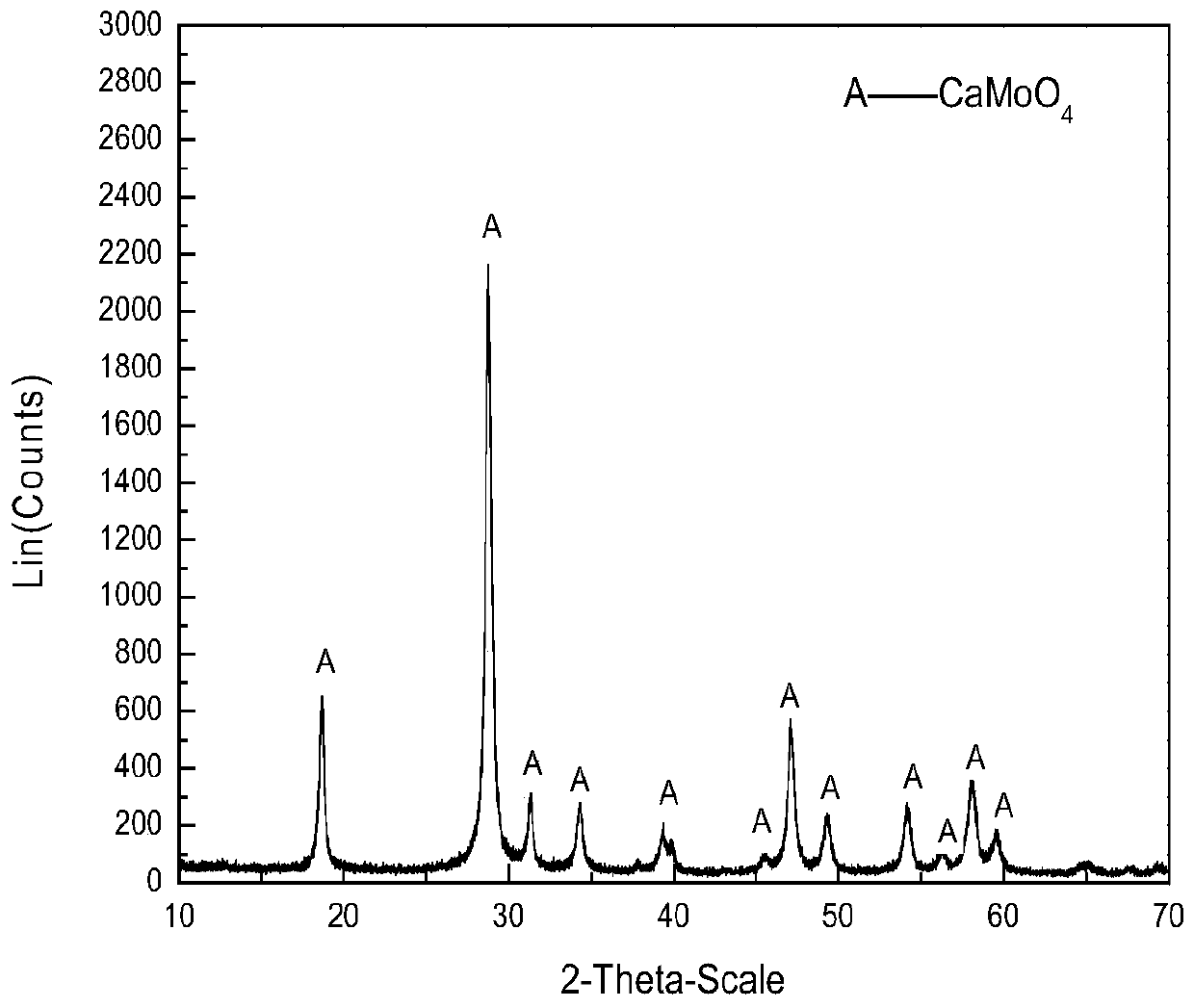

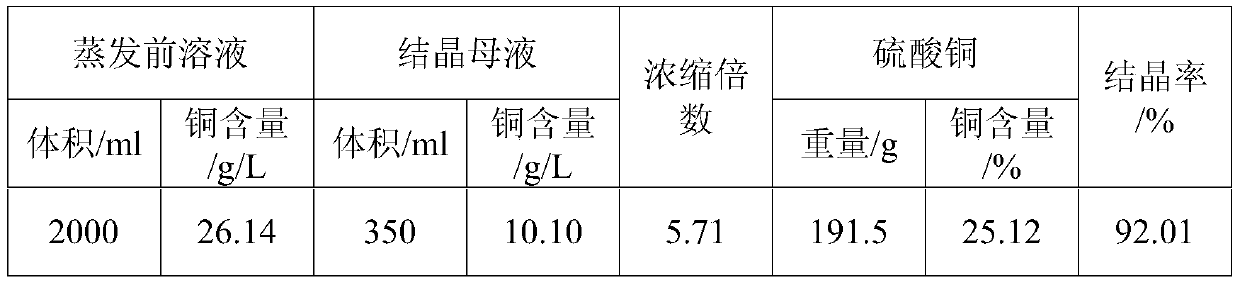

Method for separating and recovering molybdenum and copper from rhenium extraction raffinate

InactiveCN110484752AHigh efficiency of separation and recoveryHigh purityMolybdeum compoundsProcess efficiency improvementRheniumSulfite salt

The invention belongs to the field of hydrometallurgy and particularly relates to a method for separating and recovering molybdenum and copper from rhenium extraction raffinate. The method comprises the following steps of adopting sodium sulfite as a reducing agent to adjust the acidity of the rhenium extraction raffinate, adding alkali to adjust the pH of the rhenium extraction raffinate, and performing extraction to obtain a sodium molybdate solution; and directly performing copper extraction on molybdenum raffinate to obtain a copper sulfate solution. The extraction rate of molybdenum in raw materials is 86 percent or more, and the extraction rate of copper is more than 99.3 percent. With adoption of the technical scheme, the method for separating and recovering molybdenum and copper from the rhenium extraction raffinate has the characteristics of unique process, smooth flow and high molybdenum and copper separation and recovery efficiency, iron removal is not needed in the whole extraction and back extraction process, waste residues are not generated, the purity of a back extraction solution is high, the impurity content is low, and the subsequent recovery and purification of molybdenum and copper are convenient; and molybdenum and copper in the rhenium extraction raffinate are effectively recovered, and therefore the treatment difficulty of heavy metal ions in waste wateris greatly reduced.

Owner:JIANGXI COPPER

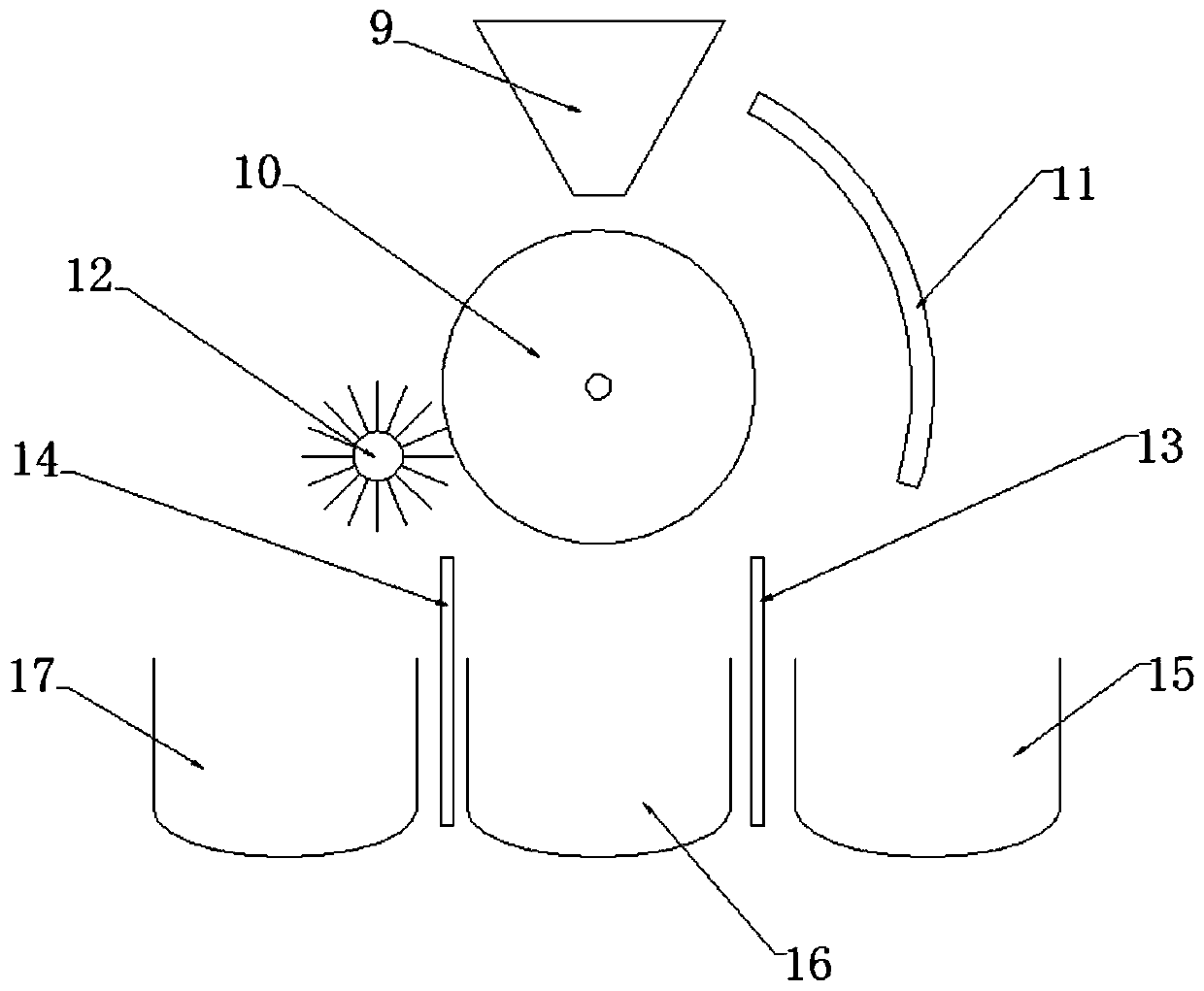

Pupa and cocoon separation recycling method

ActiveCN111593415AMeet the needs of modern productionNo manual operationSilk reelingSilk cocoons cleaning/classifyingProcess engineeringIndustrial engineering

The invention relates to a pupa and cocoon separation recycling method. The method comprises the following steps that silkworm pupas and silkworm cocoons conveyed out of a reeling machine are separated; and the separated silkworm pupas and silkworm cocoons are fed into an end groping apparatus to be subjected to end groping. According to the pupa and cocoon separation recycling method, manual operation is not needed, time and labor are saved, the separation recycling efficiency is high, the speed is uniform, and factory modern production needs can be well met.

Owner:岳西十行机械设备有限公司

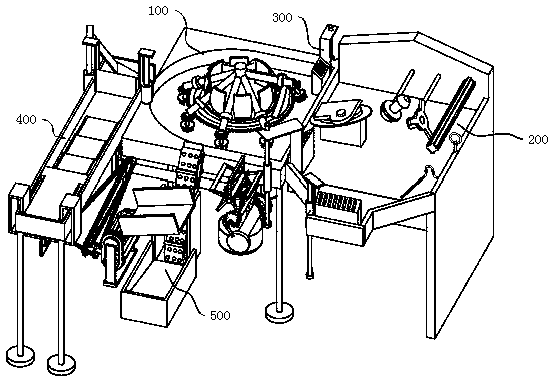

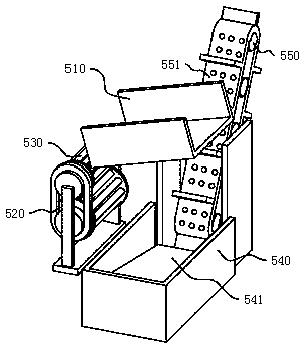

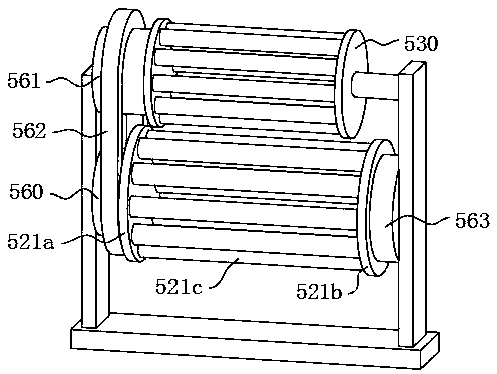

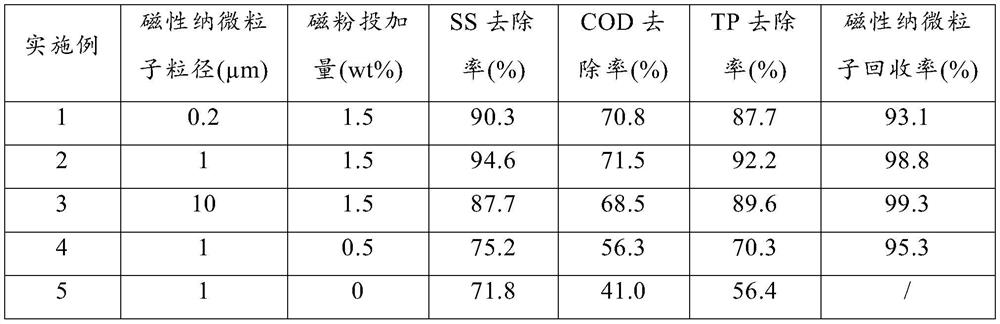

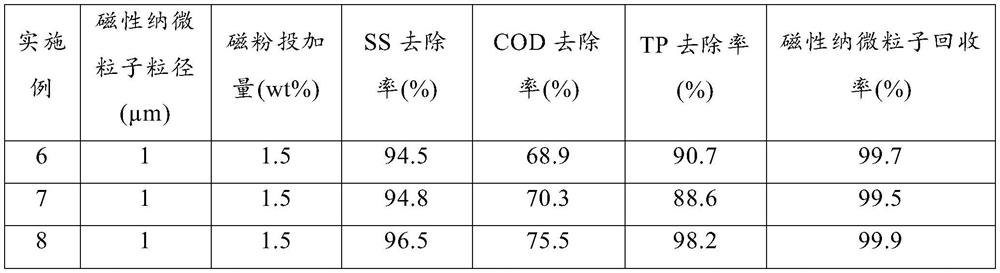

Magnetic coagulating sedimentation sewage treatment system and method based on low-density magnetic particles

ActiveCN113683167AHigh efficiency of separation and recoveryPromote growthWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFlocculationWater treatment system

The invention provides a magnetic coagulating sedimentation sewage treatment system and method based on low-density magnetic particles. The sewage treatment system comprises a magnetizing flocculation zone, a settling zone and a magnetic separation zone, low-density magnetic particles with the particle size of 100 nm-20 [mu]m are added into the magnetizing flocculation zone, on one hand, macromolecular pollutants in water are adsorbed through the large specific surface area of the low-density magnetic particles, on the other hand, flocculation particles are adsorbed through the low-density and low-hardness magnetic particles, the floc growth and precipitation rate is accelerated, the flocculation effect is improved, and the abrasion to equipment is reduced; meanwhile, large-particle-size magnetic powder with the particle size of 50-500 [mu]m is added into the magnetic separation zone, and the separation and recovery efficiency of the low-density magnetic particles is improved through adsorption of the large-particle-size magnetic powder to the low-density magnetic particles. The system and the method are suitable for combined system overflow pollution treatment, first rain treatment and sewage advanced treatment.

Owner:CHINA CONSTR THIRD BUREAU GREEN IND INVESTMENT CO LTD

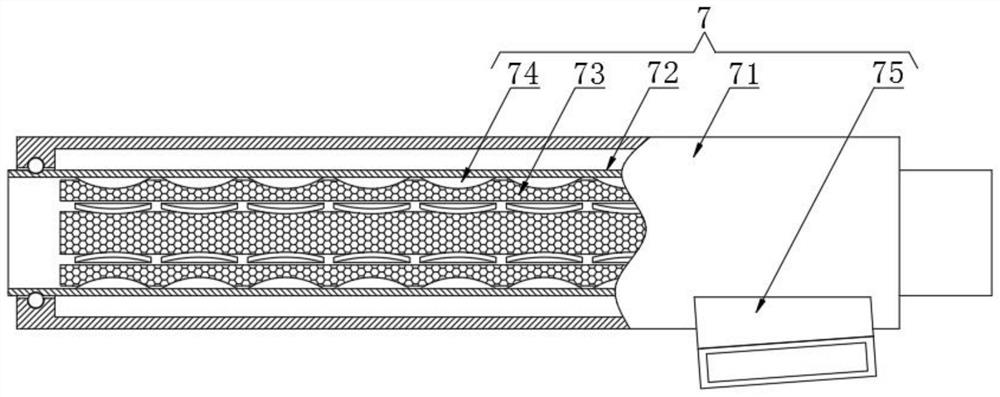

Hydrogen isotope extraction assembly for hydrogen-containing mixed gas under high-temperature conditions

ActiveCN110627019AAchieve direct separationEasy extractionNuclear energy generationHydrogen isotopesElectrical conductorCopper electrode

The invention discloses a hydrogen isotope extraction assembly for hydrogen-containing mixed gas under high-temperature conditions. The hydrogen isotope extraction assembly comprises an air inlet pipeline, a separation device and a collection pipeline which are connected in sequence; the separation device comprises a proton conductor ceramic membrane; the structures of the two ends of the proton conductor ceramic membrane are the same and are mutually symmetrical; the proton conductor ceramic membrane is provided with a copper electrode cylinder, the upper end of the copper electrode cylinderis provided with a flange electrode slice, the inner side and the outer side of the copper electrode cylinder are sleeved with an inner side insulating cylinder and an outer side insulating cylinder respectively, the upper portion of the inner side insulating cylinder is connected with an upper insulating ring in sleeving mode, the upper end of the inner side insulating cylinder is connected witha copper gasket, and an end flange is arranged on the upper side of the copper gasket. The problems in the prior art that, the temperature difference required for hydrogen separation of hydrogen-containing mixed gas is too large, the requirement for the mechanical property of existing materials is high, and hydrogen prepared through separation contains too many impurities can be solved, the condition requirement is low, the separation efficiency is high, and reliability is high.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A method for separating and recycling pupa cocoons

ActiveCN111593415BMeet the needs of modern productionNo manual operationSilk reelingSilk cocoons cleaning/classifyingProcess engineeringIndustrial engineering

The invention relates to a method for separating and recovering chrysalis cocoons, which comprises the following steps: separating silkworm chrysalis and silk cocoons sent out by a silk reeling machine; sending the separated silk cocoons back to a threading device for threading. A chrysalis provided by the invention The cocoon separation and recovery method does not require manual operation, saves time and effort, has high separation and recovery efficiency and uniform speed, and can better meet the needs of modern production in factories.

Owner:岳西十行机械设备有限公司

A recycling production system based on old asphalt pavement materials and its processing method

ActiveCN113293672BAchieve separationAchieve recyclingSolid waste managementRoads maintainenceThermodynamicsElectric machine

Owner:杭州路顺环境建设有限公司

Auxiliary recovery device for used battery of computer

InactiveCN107123838AReduce floatingIncrease frictionWaste accumulators reclaimingBattery recyclingEngineeringConductor Coil

The invention belongs to the field of computers, in particular to an auxiliary recycling device for computer waste batteries. The technical problem to be solved by the present invention is to provide an auxiliary recovery device for computer waste batteries that can save resources, protect the environment, save manpower, and have high separation and recovery efficiency. In order to solve the above technical problems, the present invention provides such an auxiliary recycling device for waste computer batteries, which includes a bottom frame, a separation box, a first bearing seat, a first rotating shaft, a discharge door cover, a first collection frame, a heating plate, The first motor, twisting paddles, etc.; the upper part of the underframe is equipped with a separation box by bolts, the lower end of the separation box is embedded with a heating plate, and the middle of the right end surface of the separation box is equipped with a first motor by bolts. In the present invention, the plastic of the outer layer of the waste computer battery is heated to 70 to 95 degrees Celsius by a heating plate to expand and soften, and then the outer plastic layer of the waste computer battery is rubbed off from the inner granular battery by a rubbing device.

Owner:孝感市伊莱迦电子科技有限公司

Differential air bubble separation device for grease

InactiveCN102949865BFull recoveryImprove recycling efficiencyLiquid separationOil and greaseLiquid state

The invention discloses a device and a method, relating to the separation and recycling of greases in waste liquid in the field of environmental protection. According to the distribution characteristics of greases in liquid-state objects such as water, slurry and the like, especially the existing form characteristics of greases in kitchen waste, greases are separated by using discrepant bubbles with different frequencies, sizes and temperatures, so that the efficiency of grease separation can be improved, the energy consumption can be reduced, and the device can run automatically without being limited by seasons and temperatures.

Owner:BEIJING HAOHAI TIANJI TECH +1

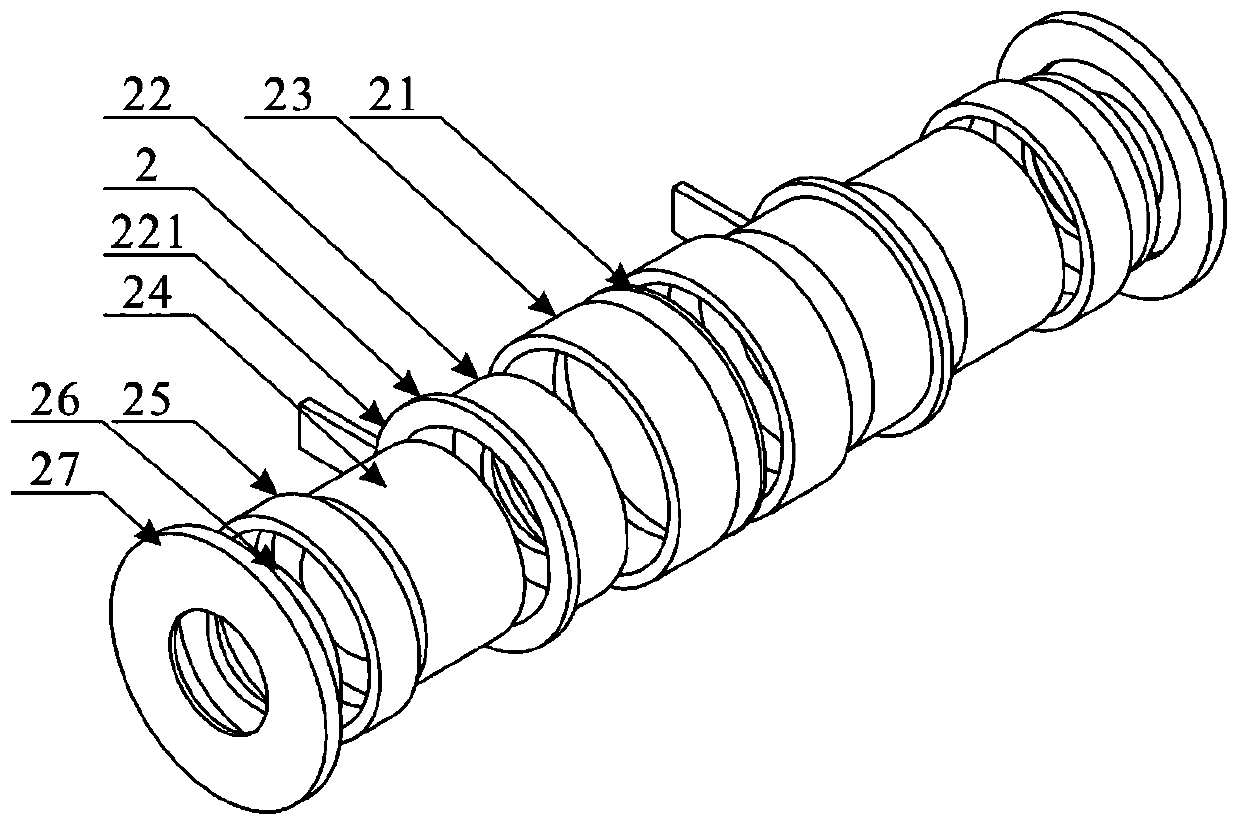

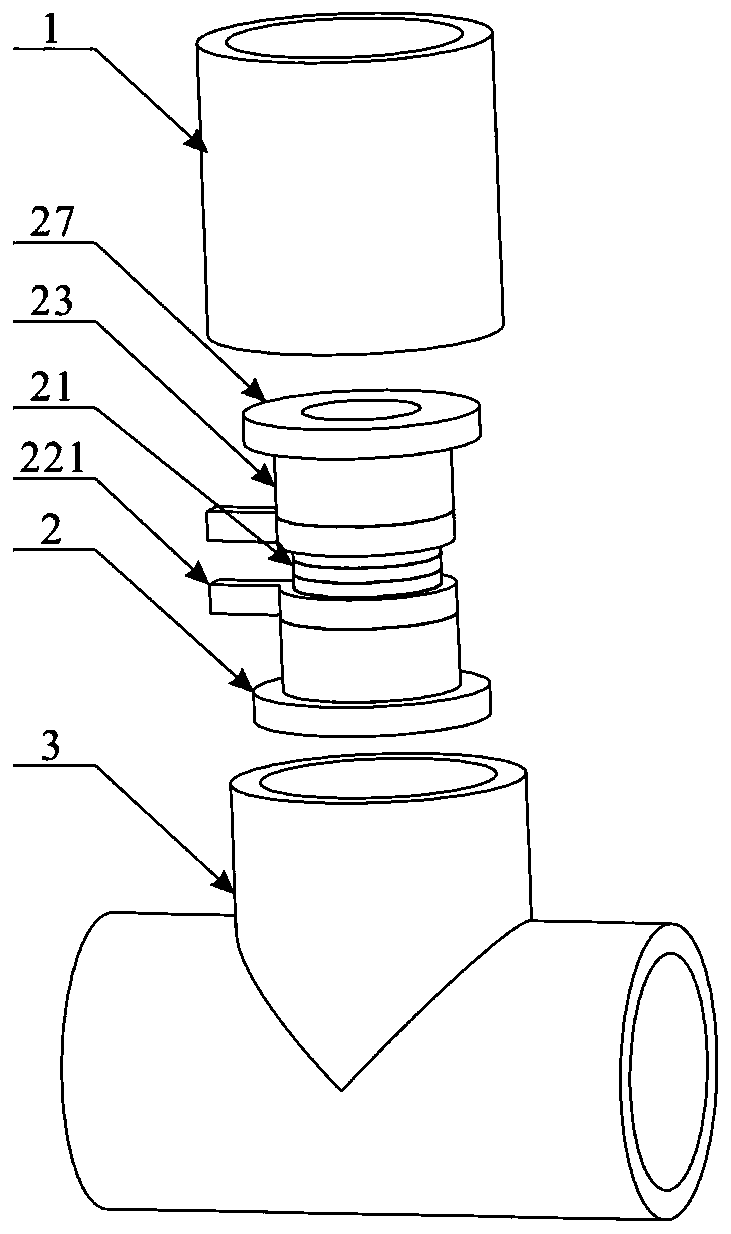

High-efficiency separation and recovery process for lithium batteries

ActiveCN111653845BHigh efficiency of separation and recoveryReduce difficultyWaste accumulators reclaimingBattery recyclingMechanical engineeringBattery cell

The invention discloses a high-efficiency separation and recovery process for lithium batteries, comprising: step 1, classifying the collected waste lithium batteries in shape; step 2, using a lithium battery shell separation device to remove the shell of the lithium battery; step 3, using a collector to collect Shell fragments and battery pole cores falling from the lithium battery shell separation device; step 4, use a vibrating screen device to filter the shell fragments and battery pole cores to complete the separation and recovery of shell materials and battery pole cores. The invention first classifies the collected waste lithium batteries by shape, classifies the cylindrical lithium batteries, and performs special separation on the cylindrical lithium batteries to improve the efficiency of separation and recovery. Secondly, the lithium battery casing is vertically cut and obliquely cut using the lithium battery casing separation device, so that the lithium battery casing forms a sheet shape, which facilitates the separation of the lithium battery casing and the battery pole core, reduces the difficulty of later recycling, and improves the efficiency of separation and recycling. efficiency.

Owner:广西华政新能源科技有限公司

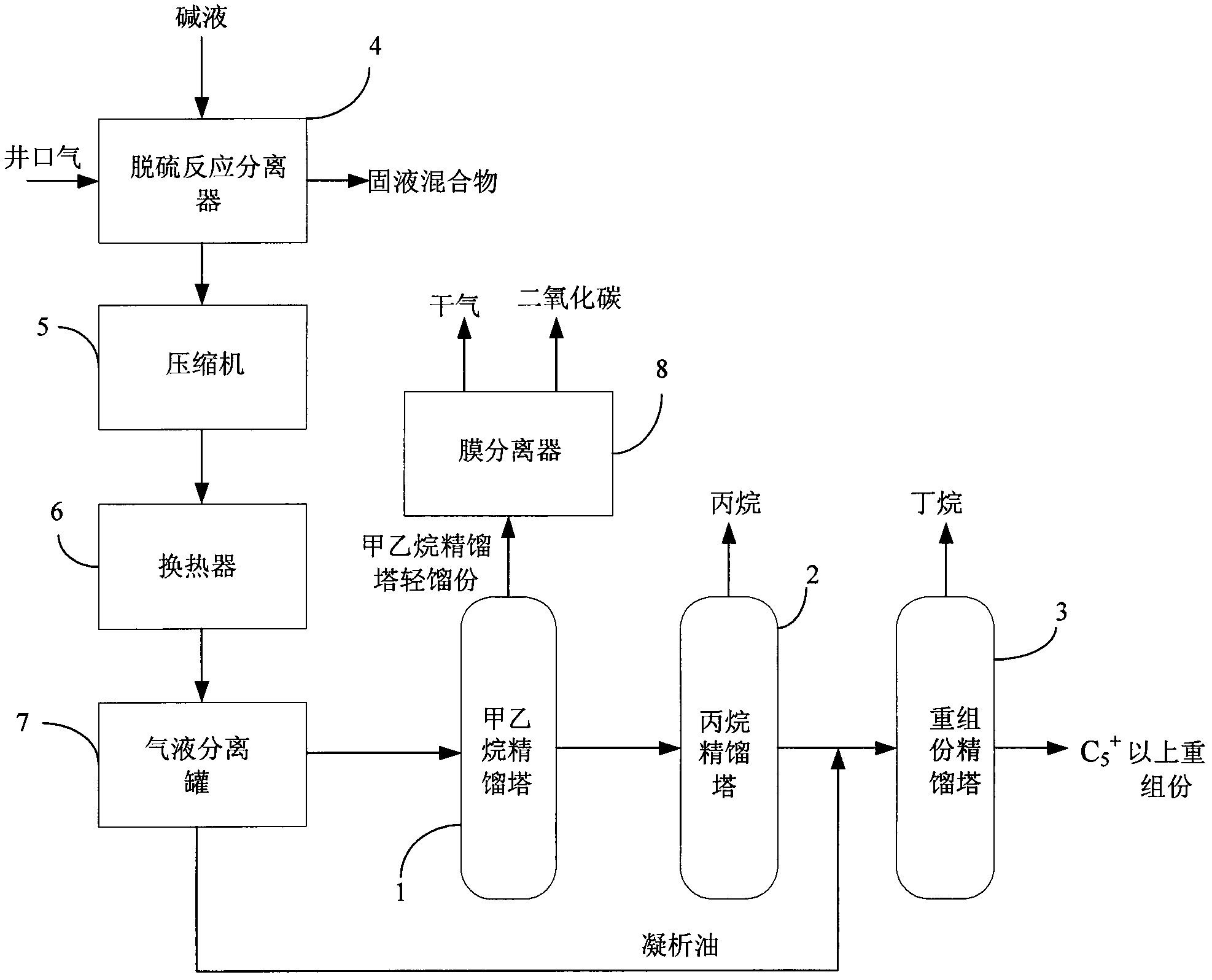

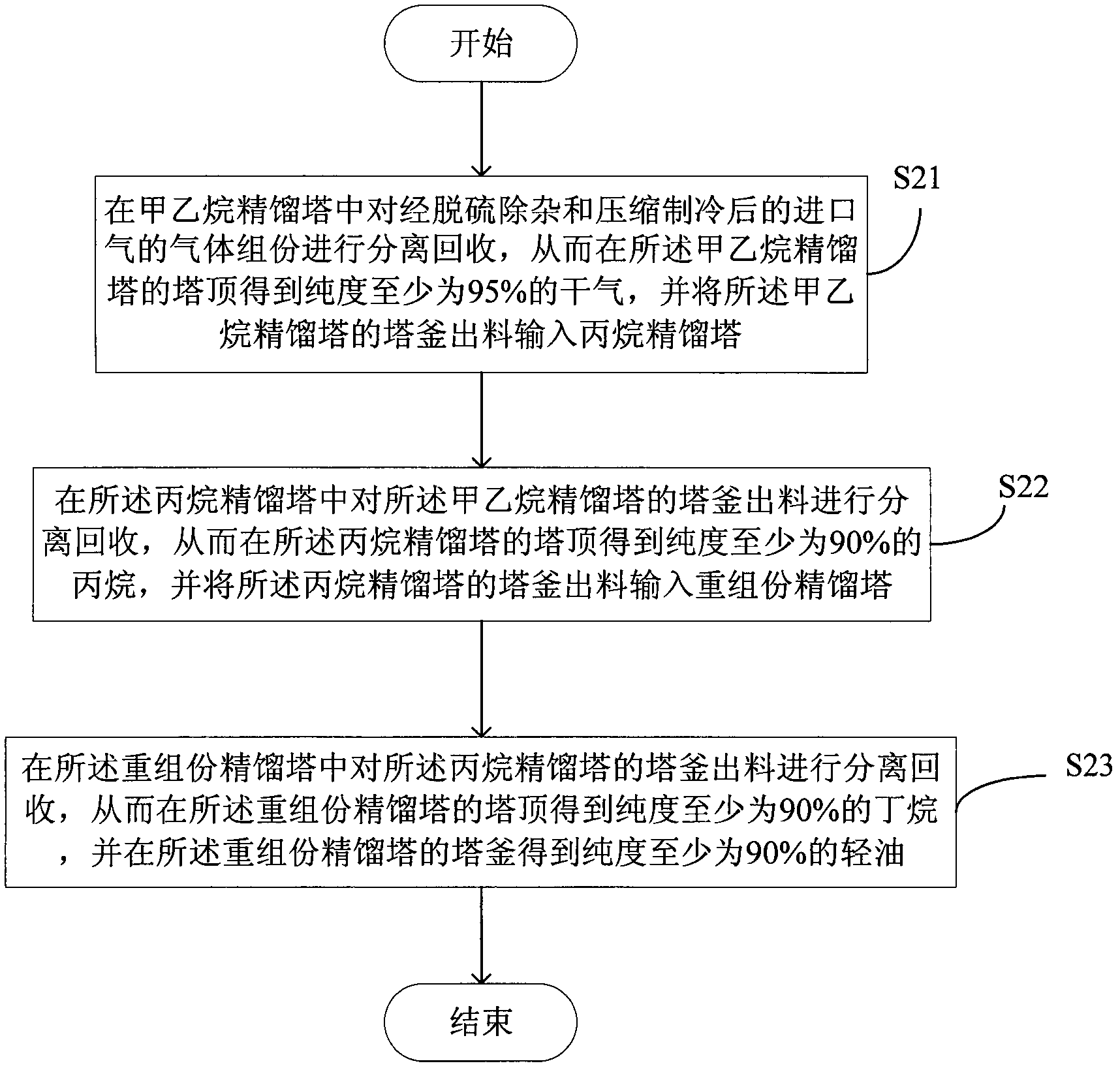

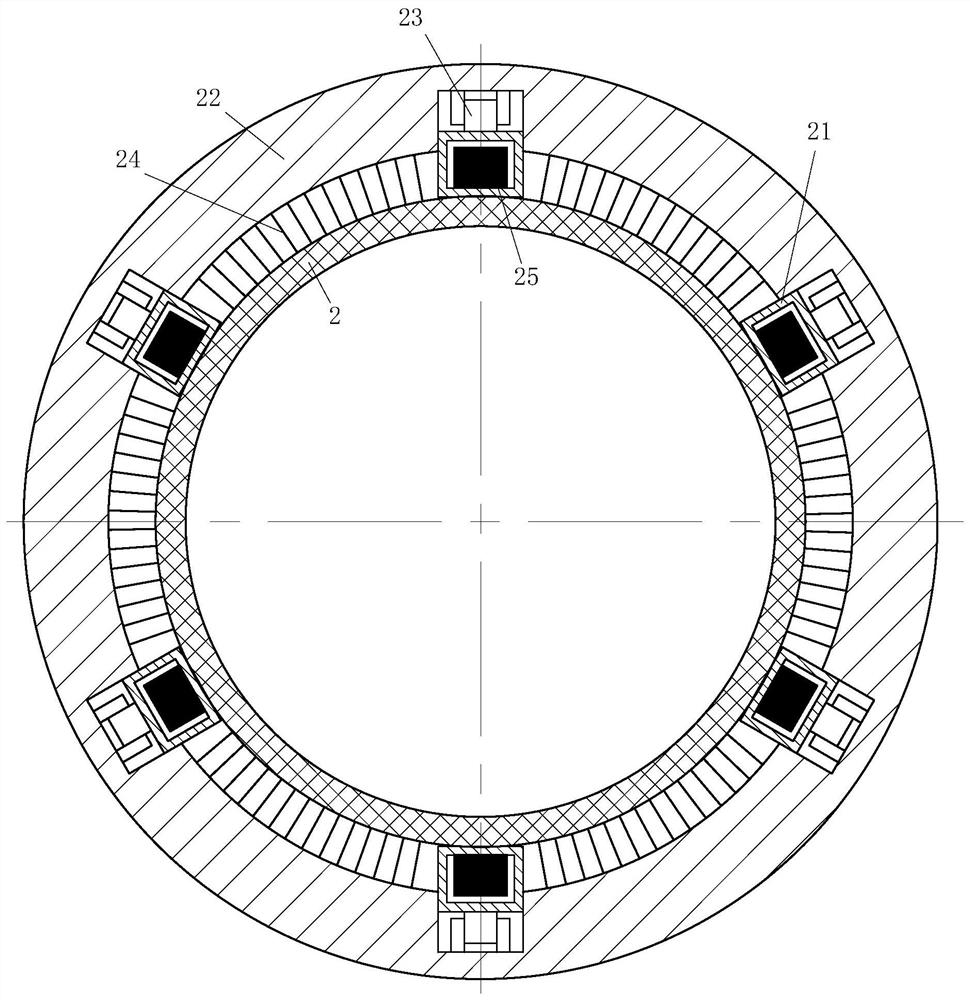

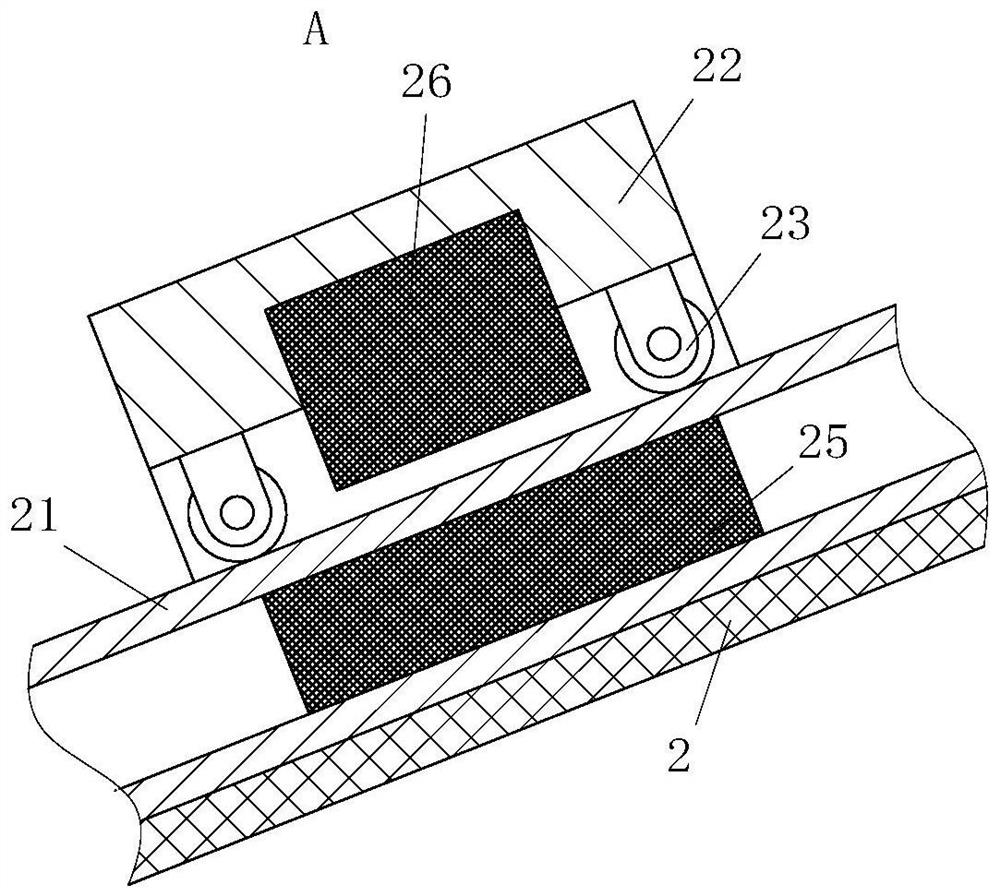

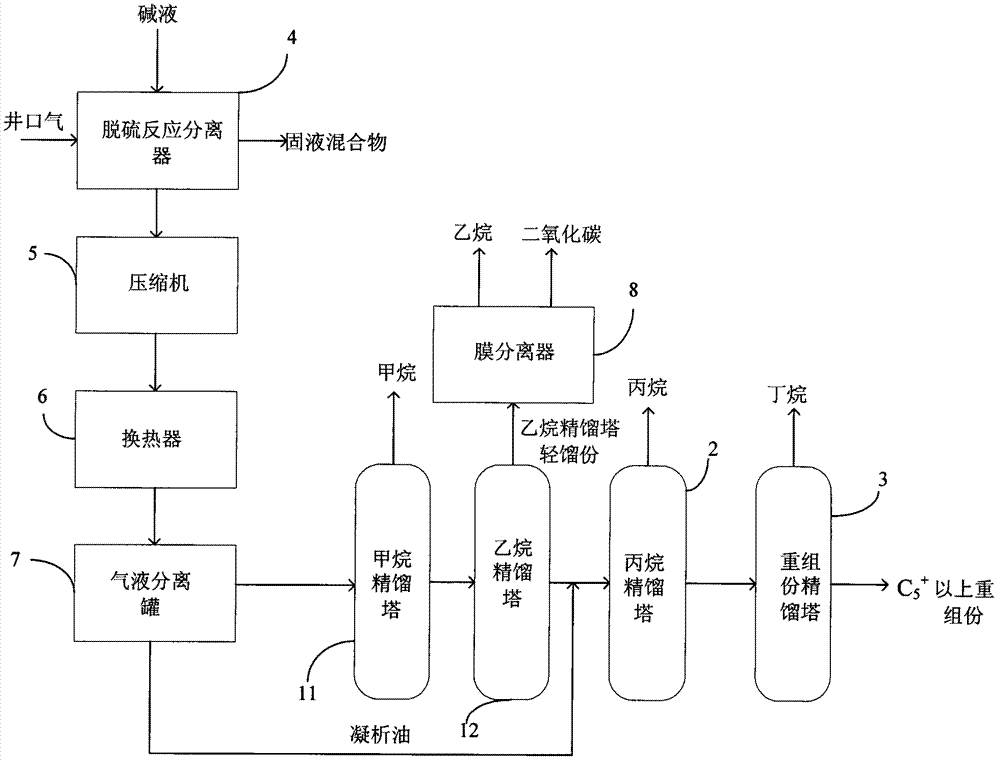

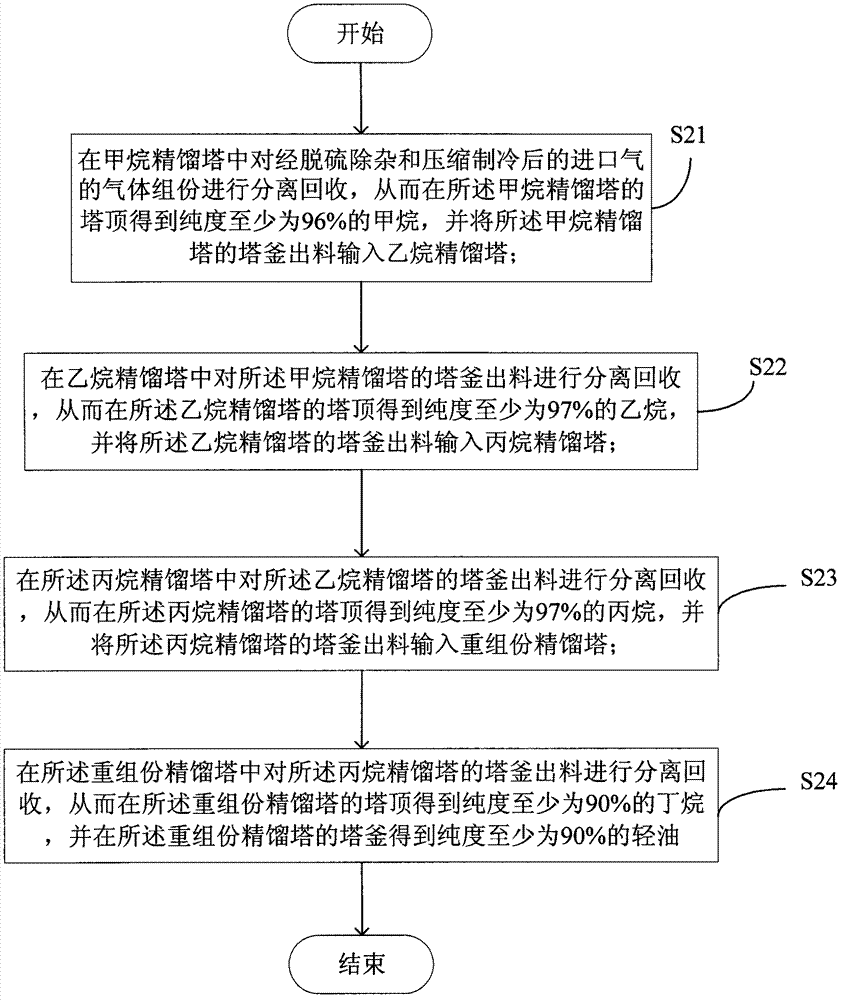

Skid-mounted bradenhead gas three-tower separation and recycling device and method

ActiveCN102051196BRealize skid-mountedHigh efficiency of separation and recoveryGaseous fuelsLiquid hydrocarbon mixture recoveryTowerLiquid nitrogen

The invention relates to a skid-mounted bradenhead gas three-tower separation and recycling device and method. The device in the invention comprises a methane and ethane rectification tower, a propane rectification tower and a heavy component rectification tower which are connected mutually, wherein the methane and ethane rectification tower is used to receive the gas component of the bradenhead gas after desulfurization purification and compression refrigerating, dry gas of which purity is at least 95% can be obtained from the top of the methane and ethane rectification tower; the material discharged from the bottom of the methane and ethane rectification tower is introduced in the propane rectification tower; propane of which purity is at least 90% can be obtained from the top of the propane rectification tower, the material discharged from the bottom of the propane rectification tower is introduced in the heavy component rectification tower; and butane of which purity is at least 90% can be obtained from the top of the heavy component rectification tower, and light oil of which purity is at least 90% can be obtained from the bottom of the heavy component rectification tower. Based on the different components and contents of the bradenhead gas, the liquid nitrogen low temperature rectification method is adopted for separation and recycling, thus the entire device is skid-mounted, the separation and recycling efficiency is higher and four types of products, namely dry gas (methane and ethane), liquefied gas (propane and butane) and light oil (C5<+>) can be obtained finally.

Owner:天津凯德实业有限公司

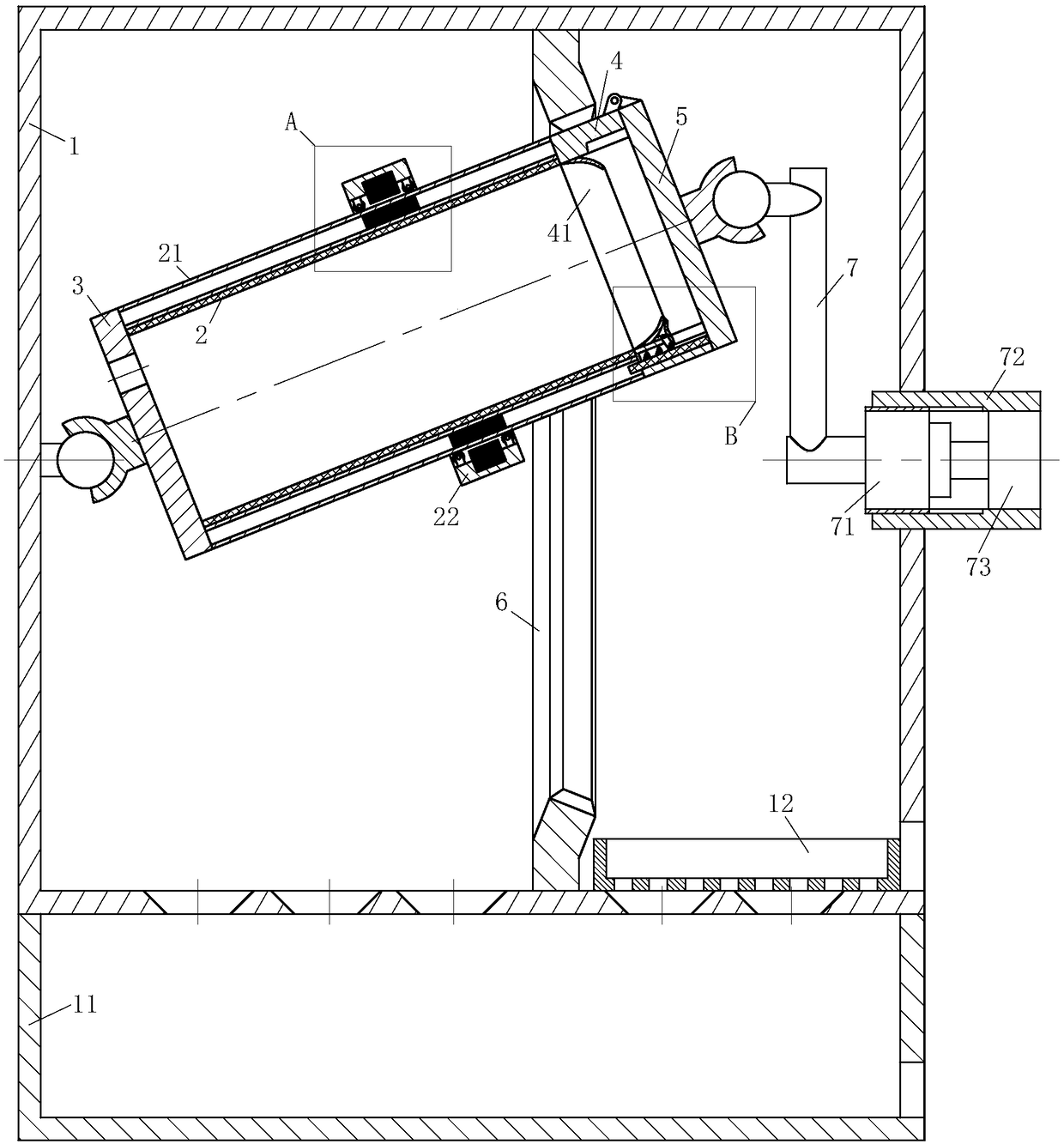

A rare earth particle separation and recovery device

ActiveCN109091936BKeep rollingHigh efficiency of separation and recoveryMoving filtering element filtersElectric machineEngineering

The invention belongs to the technical field of separation and recovery devices and particularly relates to a rare earth particle separation and recovery device. The device comprises a casing, a wasteliquid tank, a filter net, a liquid inlet disc, a transition barrel, a discharging door, a gear ring, a rotating arm, a motor, a fixed sleeve, an electric cylinder and a material box. The left end ofthe liquid inlet disc is hinged to the inner wall of the left end of the casing, the right end of the discharging door is hinged to one end of the rotating arm through a spherical surface, the otherend of the rotating arm is fixedly connected with one end of a rotating shaft of the motor, gear teeth on the transition barrel are meshed with gear teeth on the gear ring, so that the transition barrel rotates around own rotating axis while rotating around the hinged position of the left end of the liquid inlet disc, constant rolling of a waste liquid in the filtering net is further guaranteed, the inner surface of the filtering net cannot extrude rare earth particles through constant rolling, the condition that the liquid cannot conveniently penetrate through the filtering net due to blockage of the filtering net by the rare earth particles is further prevented, separation of the liquid and the rare earth particles in the waste liquid is accelerated, and the rare earth separation and recovery efficiency is further improved.

Owner:山东域潇有色新材料有限公司

Skid-mounted bradenhead gas four-tower separation recovery device and method thereof

ActiveCN102121370BRealize skid-mountedHigh efficiency of separation and recoveryGaseous fuelsFluid removalProcess engineeringTower

Owner:天津凯德实业有限公司

A method for separating and recovering vanadium, chromium and sodium carbonate from vanadium slag extracting vanadium

ActiveCN107760868BHigh efficiency of separation and recoveryEasy to separateCarbonate purificationChromates/bichromatesSlagWastewater

The invention relates to a method of separating and recovering sodium vanadate, sodium chromate and sodium carbonate from vanadium slag vanadium extraction liquor. The method is characterized by comprising the following steps: firstly, separating and recovering vanadium in the vanadium slag vanadium extraction liquor by means of a calcium salt precipitation method; then concentrating and enrichingsodium vanadate and sodium carbonate in molybdenum precipitation post liquor by means of an electrodialysis process; returning fresh water obtained by electrodialysis to vanadium slag for a sodium modification and cinder roasting leaching step for recycled use; and separating and recovering sodium vanadate and sodium carbonate in strong water by means of a circular concentration-crystallization method. The method provided by the invention has the advantages of being good in separating effect of sodium vanadate, sodium chromate and sodium carbonate, simple in process, simple to operate, free of waste water and residual slag, environment-friendly and the like, and is suitable for industrialized application of vanadium slag vanadium extraction.

Owner:CENT SOUTH UNIV

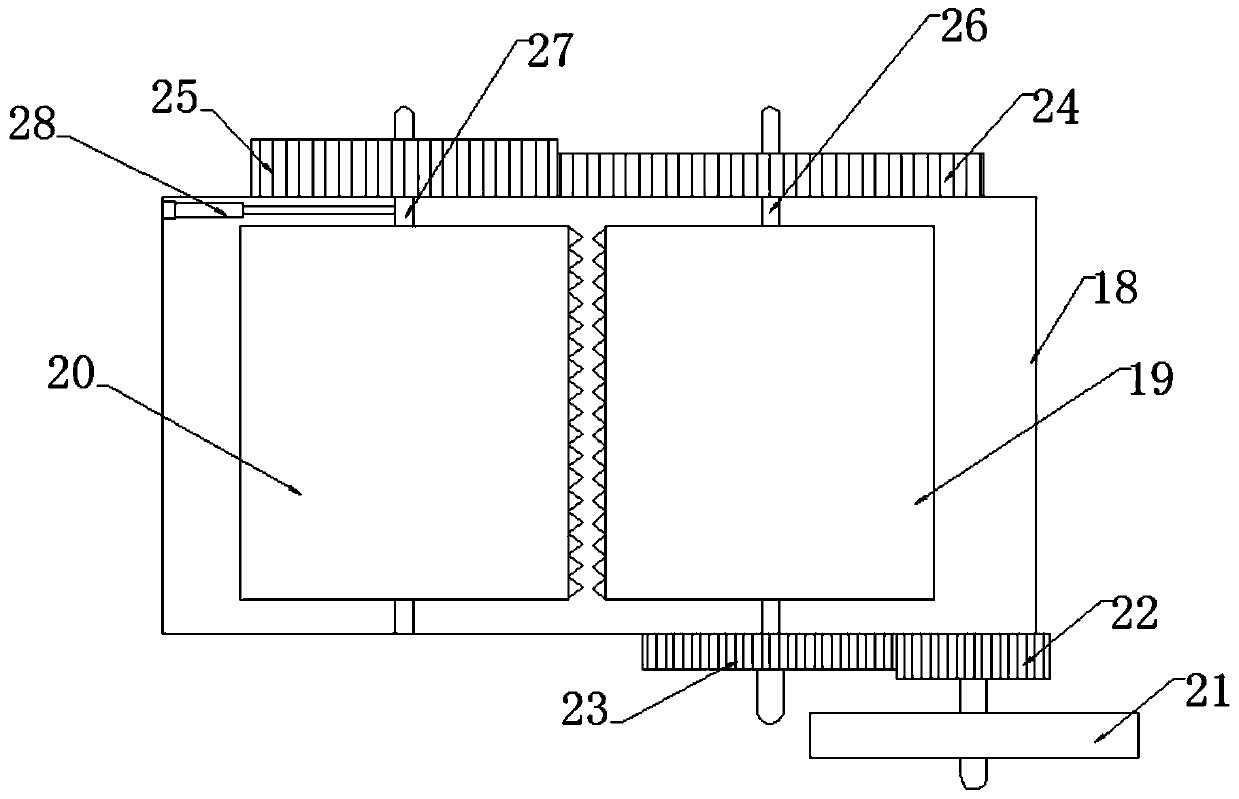

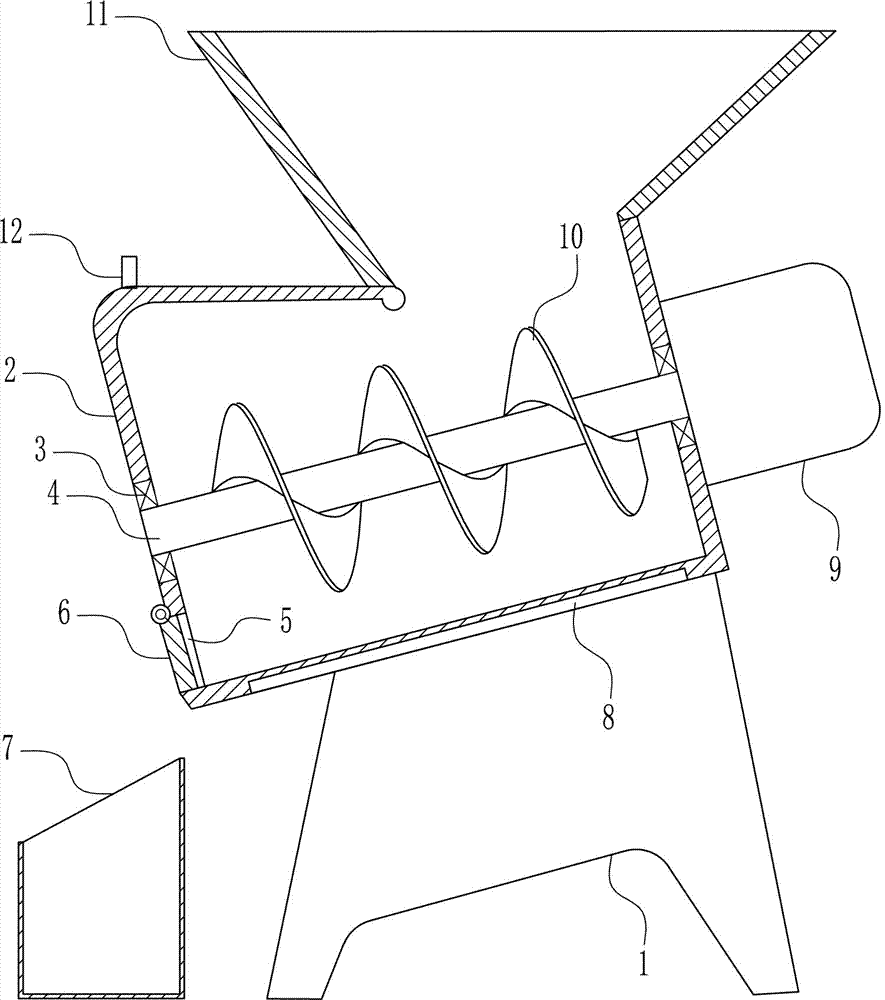

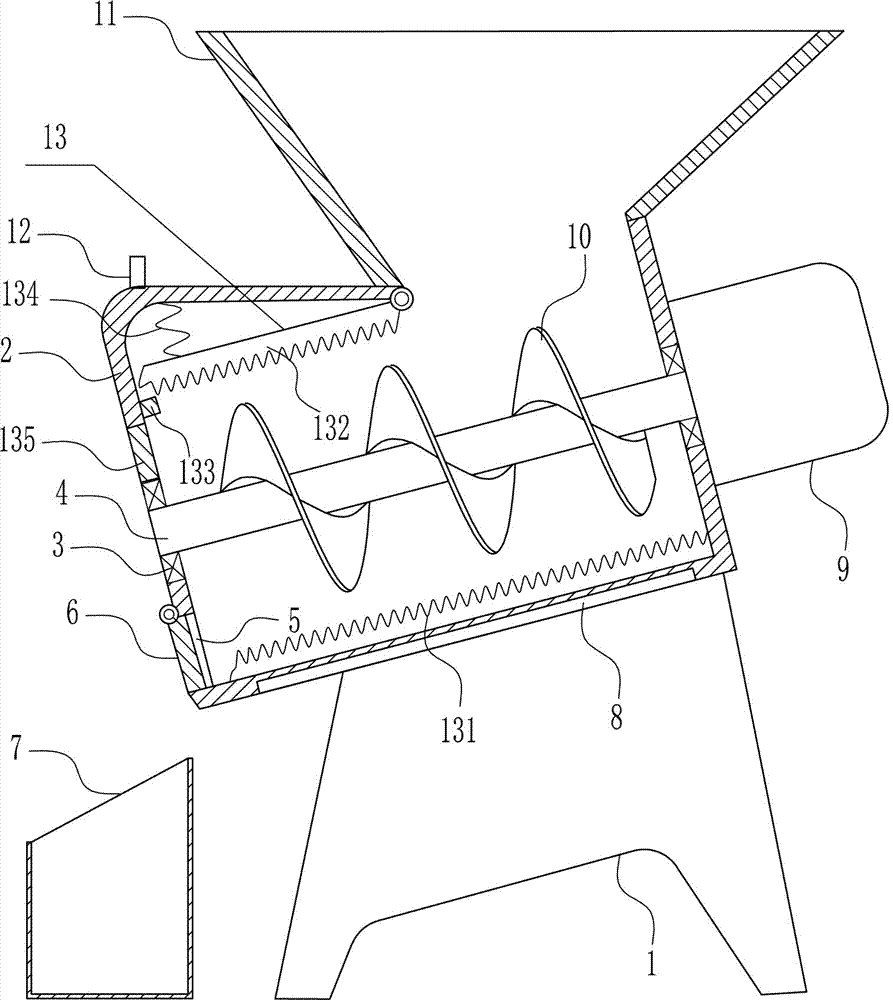

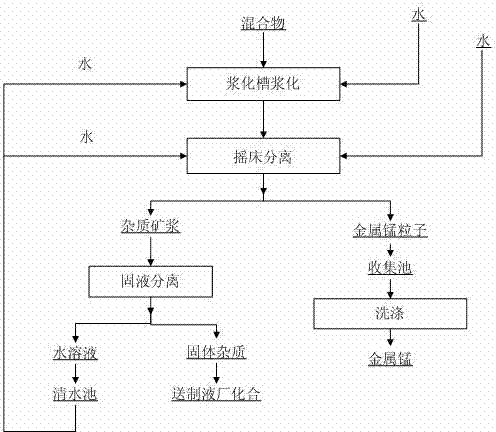

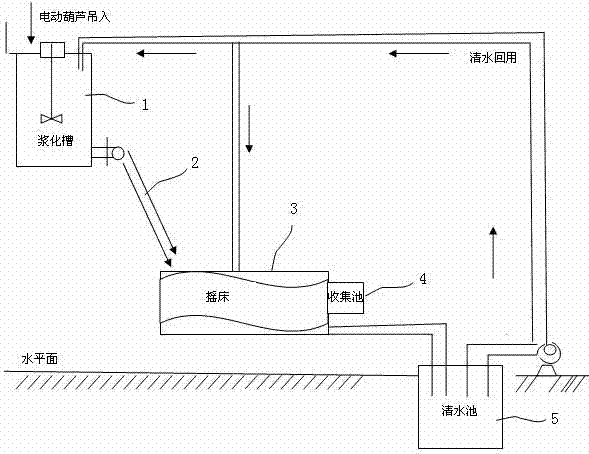

Separation and recycling method of manganese particles in manganese electrolytic diaphragm frame

ActiveCN102251262BSimple methodHigh efficiency of separation and recoveryProcess efficiency improvementElectrolysisSulfate

The invention discloses a separation and recycling method of manganese particles in a manganese electrolytic diaphragm frame. The method comprises the following steps: a) washing the electrolytic diaphragm frame to obtain a mixture containing manganese particles, manganese dioxide, calcium sulfate and magnesium sulfate, wherein the mixture is used as a raw material; b) pouring the mixture in a slurry groove, and adding water to stir; c) ensuring the stirred mixture slurry to flow in a shaker, and separating; and d) arranging a collection pool at the bottom of the shaker to recycle manganese particles. In the separation and recycling method provided by the invention, the shaker is used to separate manganese particles and impurities according to the density difference of the manganese particles and impurities, thus the aim of recycling manganese particles can be achieved; and the method is simple and the separation and recycling efficiency is high.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

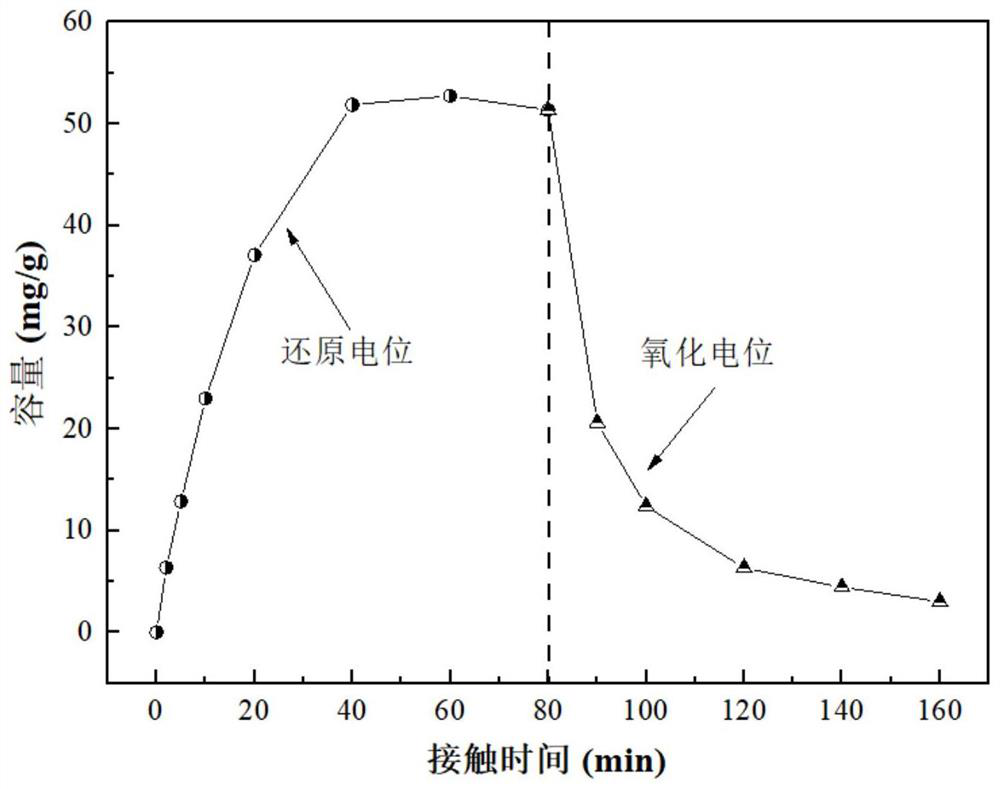

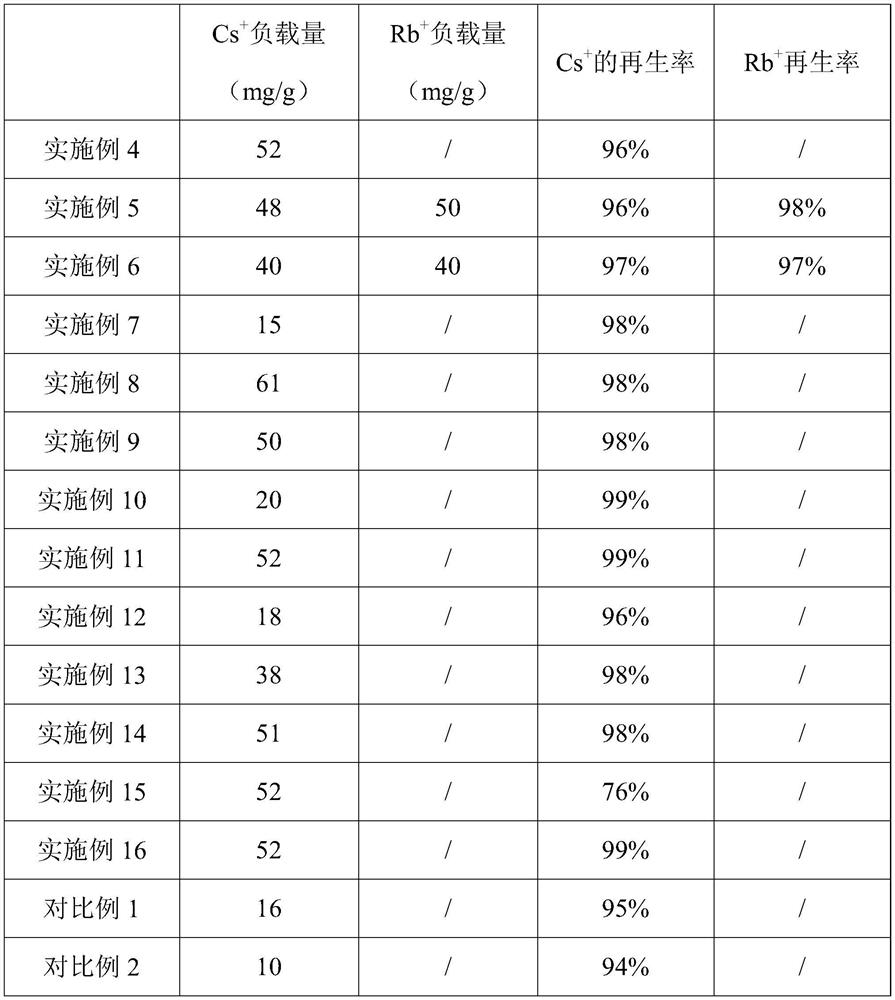

Method for recovering rubidium and cesium in salt lake brine by using heteropolyacid salt electrode

ActiveCN114672654AAchieve captureAchieve releaseProcess efficiency improvementHeteropoly acidRubidium

The invention relates to a method for recovering rubidium and cesium in salt lake brine by using a heteropolyacid salt electrode, which comprises the following steps: (1) placing the heteropolyacid salt electrode in the salt lake brine, and applying a reduction potential to obtain the heteropolyacid salt electrode loaded with alkali metal ions; (2) putting the heteropolyacid salt electrode loaded with the alkali metal ions in the step (1) into regeneration liquid, and applying oxidation potential to realize release of the alkali metal ions; the heteropolyacid salt electrode in the step (1) contains a vanadium source; the valence state of vanadium in the vanadium source is + 5. According to the heteropolyacid salt electrode, valence state changes of central elements of the heteropolyacid salt electrode are regulated and controlled through potential, so that alkali metal ions are captured and released, other chemical reagents do not need to be added in the regeneration process, and harmless recovery of rubidium and cesium resources in the salt lake brine is achieved; the heteropolyacid salt electrode is low in preparation cost, high in ion exchange capacity, low in energy consumption in the metal ion recovery process and free of secondary pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A pupa cocoon separation and recovery device

ActiveCN111472051BMeet the needs of modern productionHigh efficiency of separation and recoverySilk cocoons cleaning/classifyingWater flowEngineering

The invention relates to a chrysalis and cocoon separation and recovery device, which includes a material guide and a material distribution member. The material guide is provided with a material passage for the material to flow. The shape of the material part is columnar, and the distribution part is installed horizontally, and the material outflow direction at the outlet of the material guide part intersects with the length direction of the distribution part. Time-saving and labor-saving, high separation and recovery efficiency and uniform speed, which can better meet the needs of modern production in factories.

Owner:岳西十行机械设备有限公司

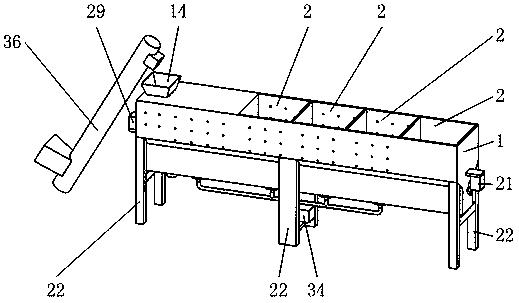

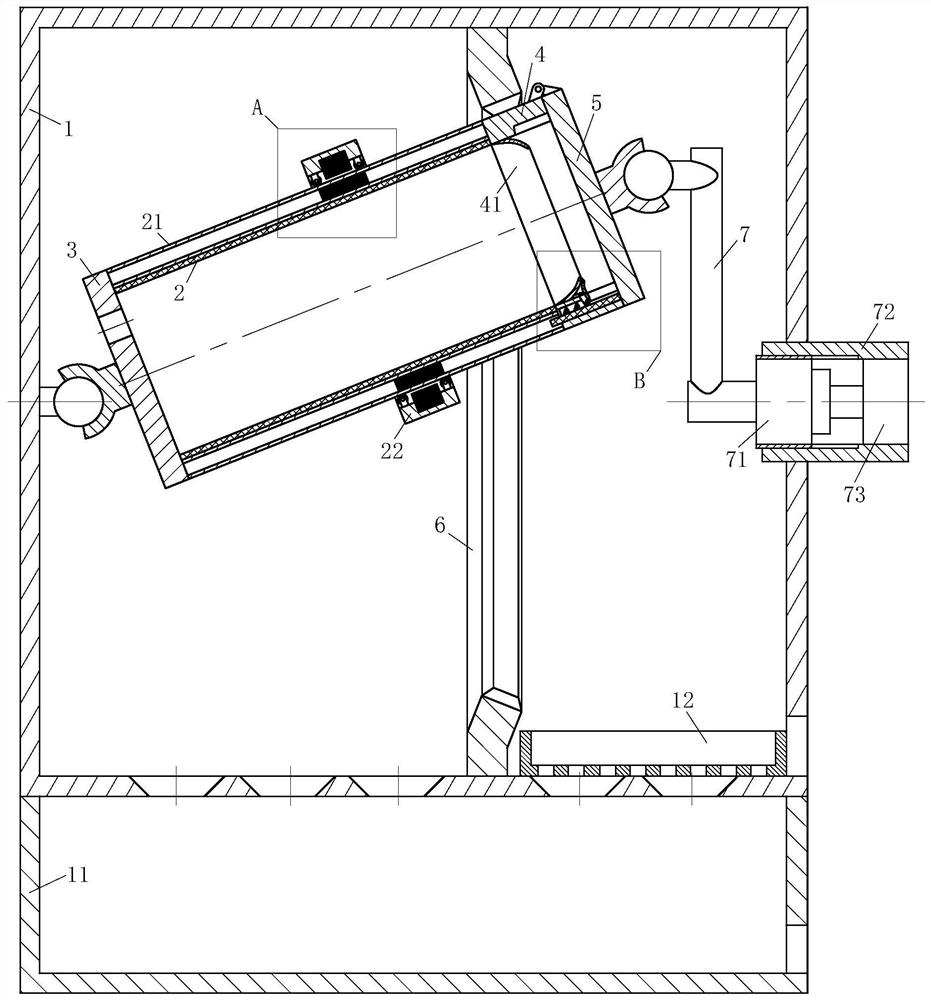

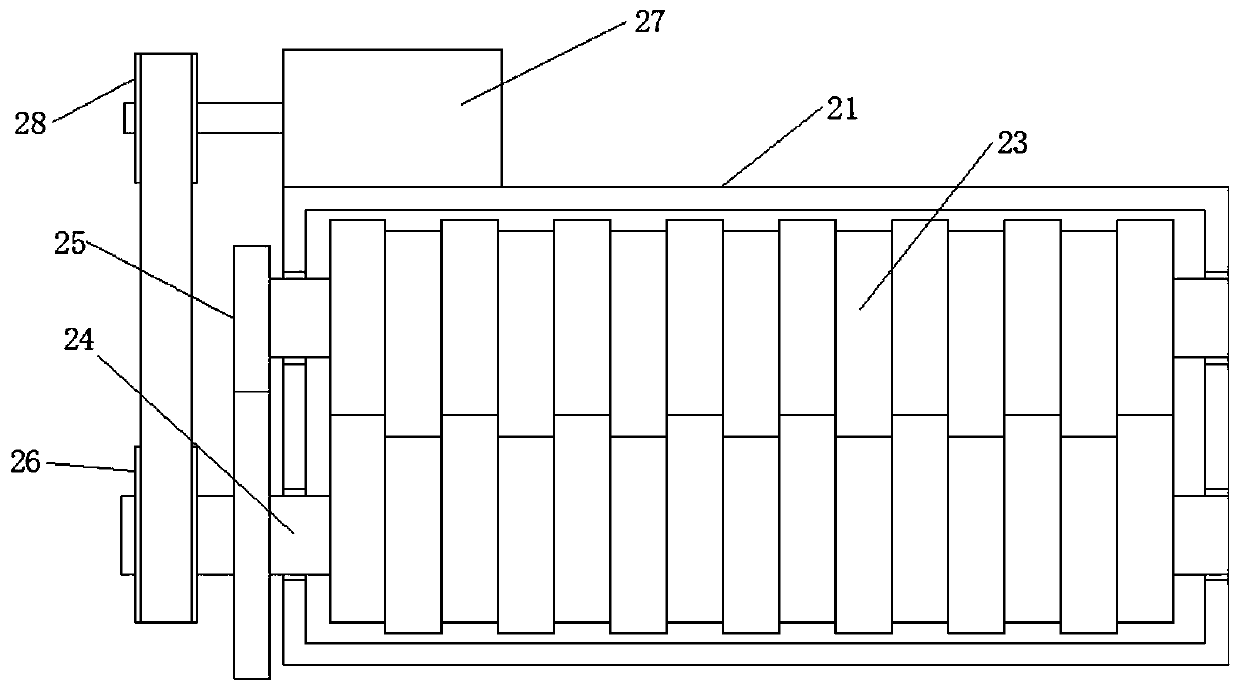

Waste cotton-polyester blended fabric separating and recycling device and recycling process and application thereof

ActiveCN113862839AAvoid tanglesEfficient and fast acid hydrolysisPlastic recyclingTextile disintegration and recoveryPolyesterFilter system

The invention belongs to the field of B01J19 / 00 of IPC classification, and provides a waste cotton-polyester blended fabric separating and recycling device and a recycling process and application thereof. The separating and recycling device is a drum-type separating device, and the drum-type separating device mainly comprises a horizontal rotatable reaction kettle (1), a filtering system (2) and an electric power system (3). The recycling process method mainly comprises the following steps of (1) configuring the drum-type separating device; (2) placing waste polyester cotton and an acidolysis solution; (3) performing mixed acidolysis; (4) filtering and collecting a product; (5) rinsing and spin-drying a fabric; (6) centrifugally drying the fabric; and (7) crushing and drying a filtered product. The separating and recycling method and process provided by the invention are matched with the separating and recycling device provided by the invention, so that the entanglement phenomenon of the textile fabric and a stirring paddle can be effectively avoided, and the phenomena of equipment blockage, mechanical failure and the like are reduced.

Owner:FUJIAN SAILON TECH CO LTD

Prewashing device for plastic recycling

InactiveCN110948742AReduce cleaningHigh efficiency of separation and recoveryPlastic recyclingThermodynamicsLiquid medium

The invention belongs to the field of flotation devices, and particularly relates to a prewashing device for plastic recycling. The device comprises a water tank, a spiral piece A, a washing mechanism, a collecting mechanism, and the like, wherein an inner cavity of the water tank is divided into a mounting groove and four continuous flotation grooves in the length direction of the water tank, andtransmission grooves communicating with the mounting groove and the four flotation grooves are formed in the bottom in the water tank. According to the prewashing device for plastic recycling, a flotation liquid medium is single, the problem of mutual pollution and dilution of the liquid medium does not exist, the flotation effect of the prewashing device is obvious, the flotation efficiency is high, and the cost of the single flotation liquid medium is low.

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

A medical waste recycling device with a solid-liquid separation device and a method of using the same

ActiveCN107900081BSimple structureEasy to separateSolid waste disposalTransportation and packagingMedical wasteEngineering

The invention discloses a medical waste recovery device with a solid-liquid separation device, which includes a frame, a feeding device and a separation device. Both the feeding device and the separation device are installed on the frame, and the feeding device includes a crushing bin. The top of the crushing bin is fixedly connected with a hopper, and there are two toothed rollers arranged symmetrically inside the crushing bin. The two toothed rollers are meshed and tangent, and the centers of both ends of the two toothed rollers are fixedly connected to the rotating shaft, and the rotating shafts are movably connected to the crushing bin. The two shafts on the same side of the toothed rollers run through the wall of the crushing bin and extend to the outside of the crushing bin, and the two shafts extending to the outside of the crushing bin are fixedly connected with gears, and the gears on the two shafts are connected to each other. Engagement, the bottom of the crushing bin is fixedly connected with a feeding pipe, and the end of the feeding pipe away from the crushing bin is connected with a connecting pipe.

Owner:袁永春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com