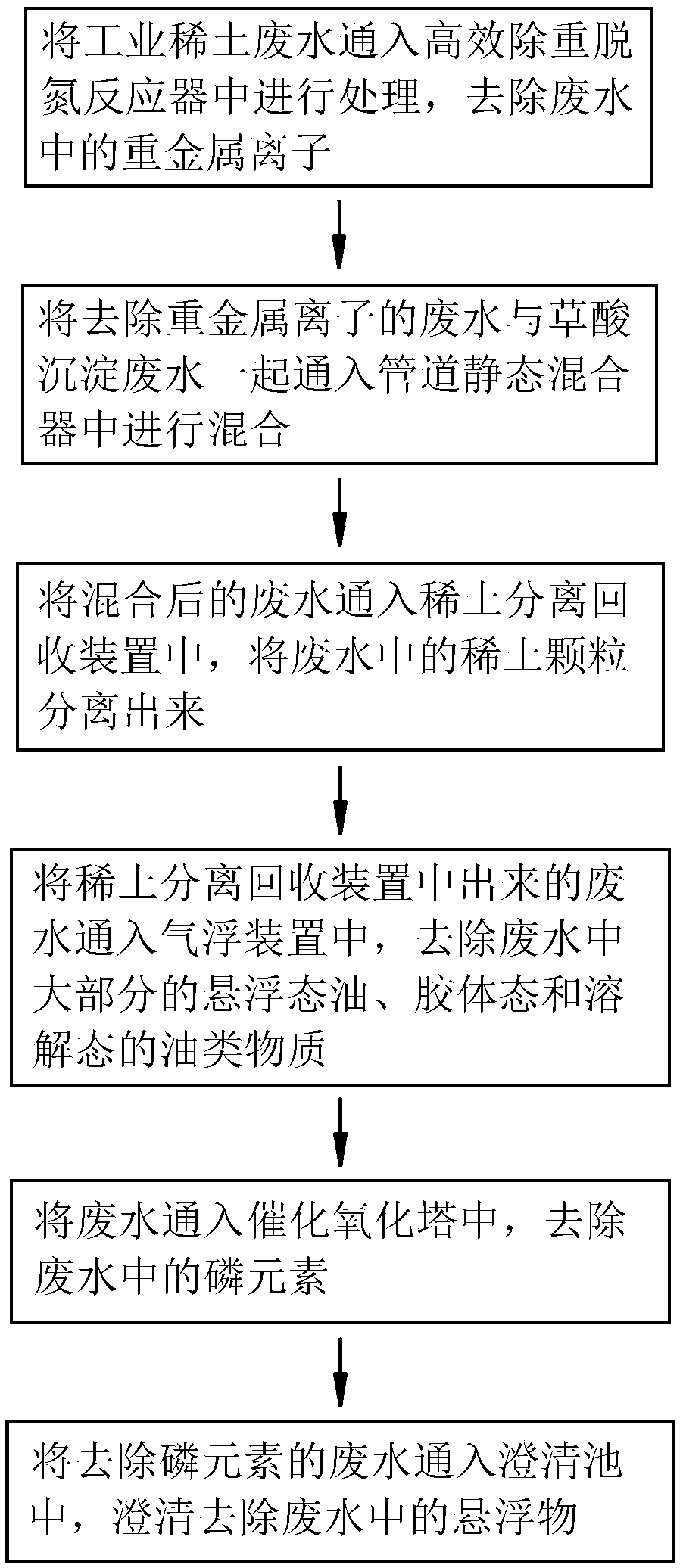

Industrial rare earth wastewater treatment process

A wastewater treatment and rare earth technology, which is applied in water/sewage treatment, flotation water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problem of filter blockage, decline in the separation ability of liquid and rare earth particles, and affect the separation effect of wastewater and separation efficiency to achieve the effect of accelerating separation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

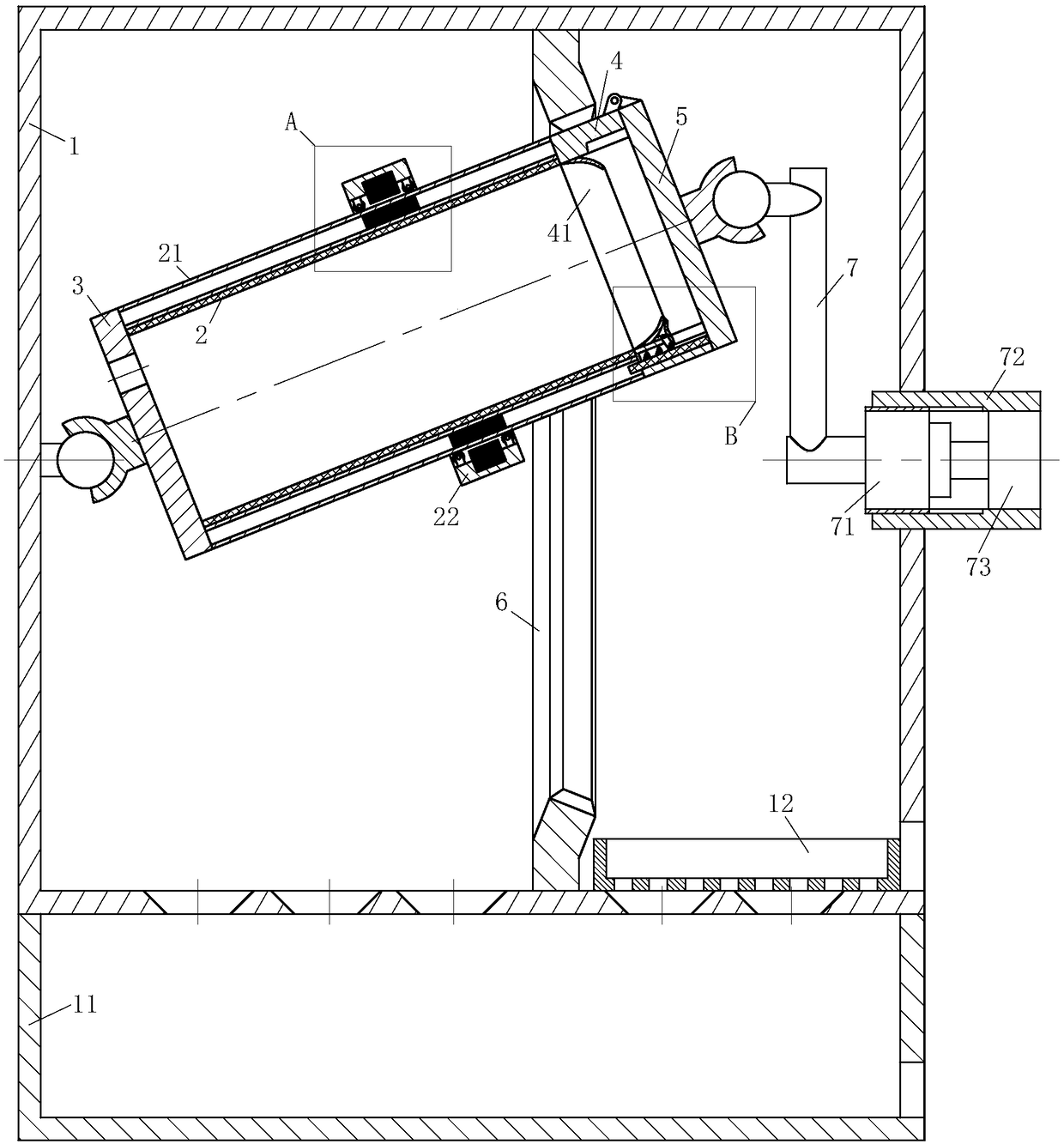

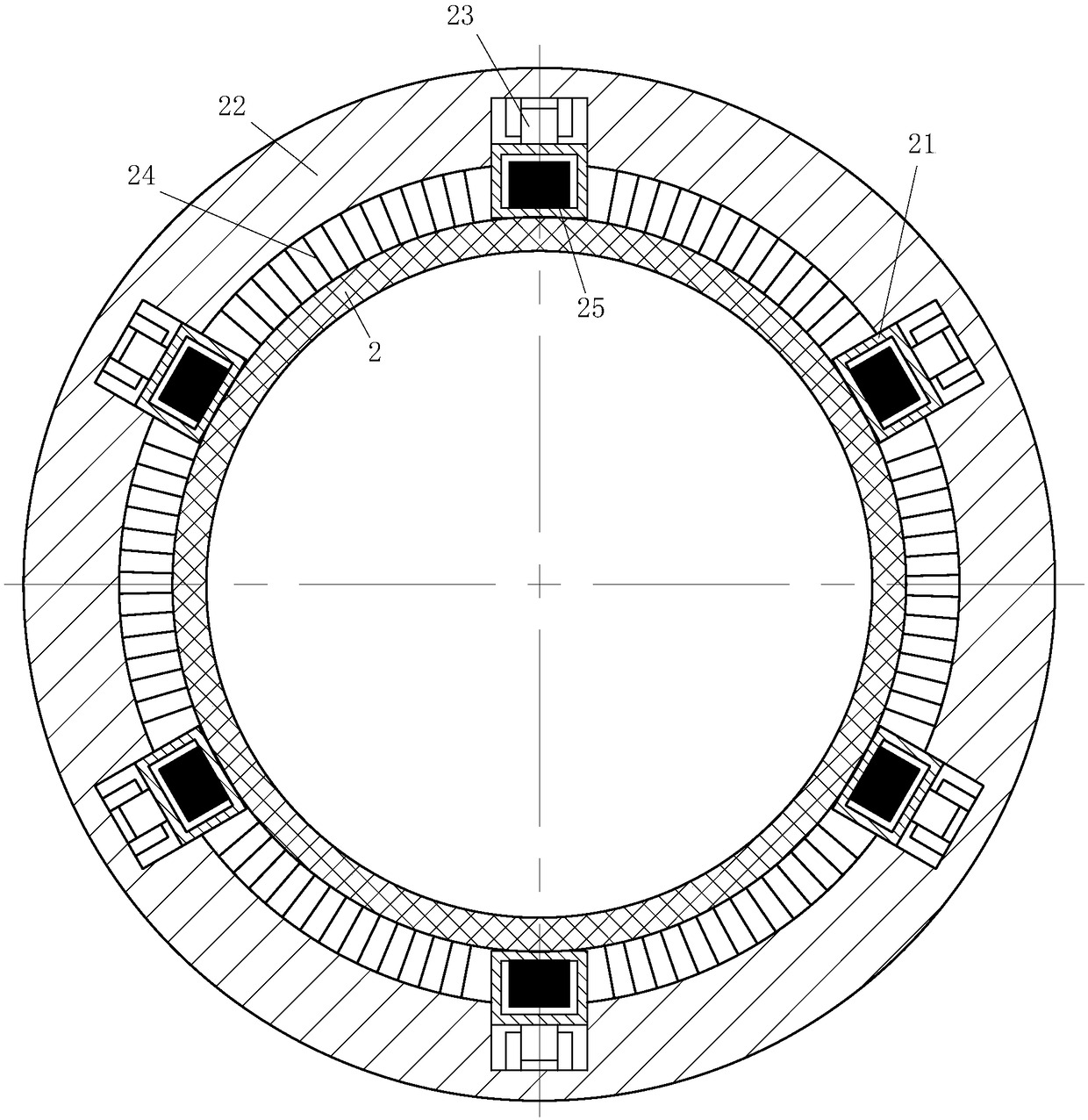

[0041] As an embodiment of the present invention, the rectangular slideway 21 is a non-magnetic material, a rectangular slideway is arranged inside the rectangular slideway 21, and a No. 1 magnet 25 is arranged in the rectangular slideway in the rectangular slideway 21; The No. 2 magnet 25 can slide in the rectangular chute in the rectangular slideway 21; the No. 2 magnet 26 is fixedly connected in the rectangular chute of the annular brush plate 22; during use, the two ends of the filter screen 2 are constantly swinging from side to side , the No. 1 magnet 25 slides in the rectangular slideway 21, and then attracts the No. 2 magnet 26 on the ring-shaped brush plate 22 through the magnetic force of the magnet, and then accelerates the moving speed of the ring-shaped brush plate 22, so that the ring-shaped brush plate 22 The bristles 24 have a stronger brushing force on the rare earth particles on the filter screen 2, thereby reducing the probability of rare earth particles adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com