Prewashing device for plastic recycling

A plastic recycling and pre-cleaning technology, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of increasing the frequency of liquid medium replacement, low degree of collection automation, and reducing the density of liquid medium, so as to avoid density changes and improve flotation efficiency High, reduce the effect of the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

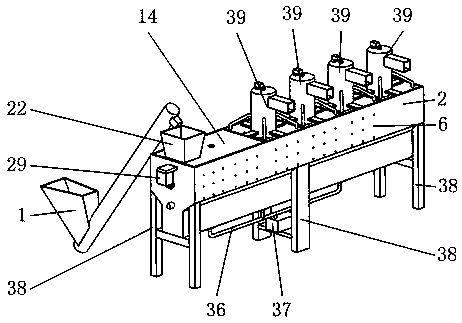

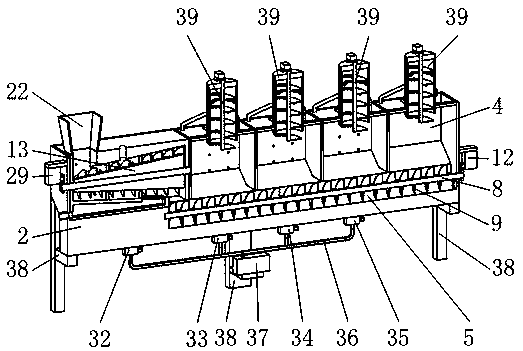

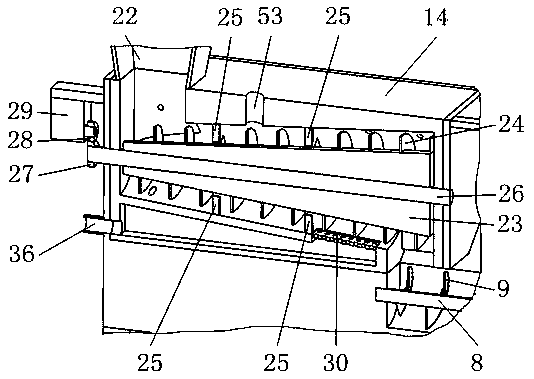

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0037] Such as figure 1 , 2 As shown, it includes a water tank 2, a rotating shaft A8, a spiral piece A9, an electric drive module A12, a cleaning mechanism 13, an electric drive module B29, and a collection mechanism 39, wherein as figure 2 , 6 As shown, the inner cavity of the water tank 2 is divided into an installation tank 3 and four continuous flotation tanks 4 along its length, and the inner bottom of the water tank 2 is provided with a transmission tank communicating with the installation tank 3 and the four flotation tanks 4 5; if figure 2 , 3 As shown, the cleaning mechanism 13 driven by the electric drive module B29 to pre-clean the plastic mixture is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com