Waste cotton-polyester blended fabric separating and recycling device and recycling process and application thereof

A separation and recovery, polyester-cotton blending technology, which is applied in the field of waste polyester-cotton blended fabric separation and recovery devices, can solve problems such as the operation failure of separation equipment, and achieve the effects of reducing the amount of acid hydrolyzate, enhancing the removal effect, and improving the separation and recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

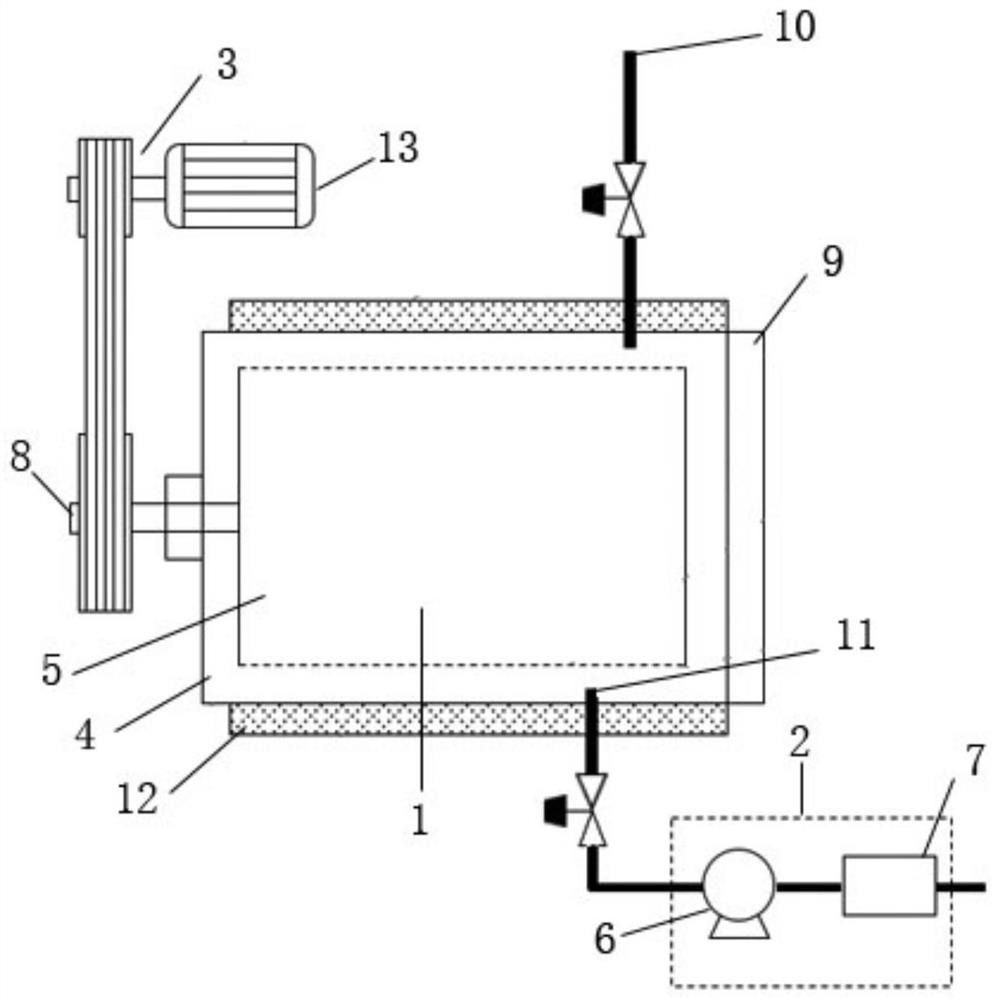

[0042] Embodiment 1 The first aspect provides a kind of waste polyester-cotton blended fabric separation and recovery device: as figure 1 As shown, the drum type separation device is composed of a horizontal rotatable reactor 1, a filter system 2 and a power system 3; the horizontal rotatable reactor 1 is composed of an outer cylinder 4 and an inner cylinder 5; the outer cylinder 4 is cylindrical, and the axial It is horizontally fixed on the bracket; the outer cylinder 4 is provided with a cylinder cover 9, a liquid inlet pipe 10, and a liquid discharge pipe 11; The cylinder body is detachably and fixedly connected by quick-opening bolts; the drain pipe 11 is arranged at the lower part of the cylinder body, and the starting end of the drain pipe 11 is arranged between the outer cylinder 4 and the inner cylinder 5, and the drain pipe 11 is also provided with Turn the valve to control the liquid flow rate, and the outside of the cylinder is wrapped with a heating element 12; th...

Embodiment 2

[0049] The specific implementation of this embodiment is the same as in Example 1, except that the acid solution is an aqueous acetic acid solution with a concentration of 10wt%, and the mass ratio of the aqueous acetic acid solution to waste polyester-cotton blended fabric is 20:1; waste and old polyester-cotton blended fabric The mass ratio of medium polyester / cotton is 65:35; in step (3), the reaction temperature is 150°C.

[0050] In the present embodiment, the recovery rate of polyester is 99%, and the recovery rate of cotton fiber cellulose powder is 81%.

[0051] Can know by embodiment 1~2, a kind of waste polyester-cotton blended fabric separation and recovery device provided by the present invention and its application, the separation and recovery method technology that provides in the application cooperates the separation and recovery device in the application, can effectively It avoids the occurrence of entanglement between textiles and stirring paddles, reduces equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com