Differential air bubble separation device for grease

A differentiated, oil-based technology, applied in the field of oil-water separation and oil-recovery devices, can solve the problems of pipeline and equipment blockage, reduce the quality of protein feed and fertilizer, and achieve the effect of reducing equipment load, reducing labor, and preventing oil from solidifying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

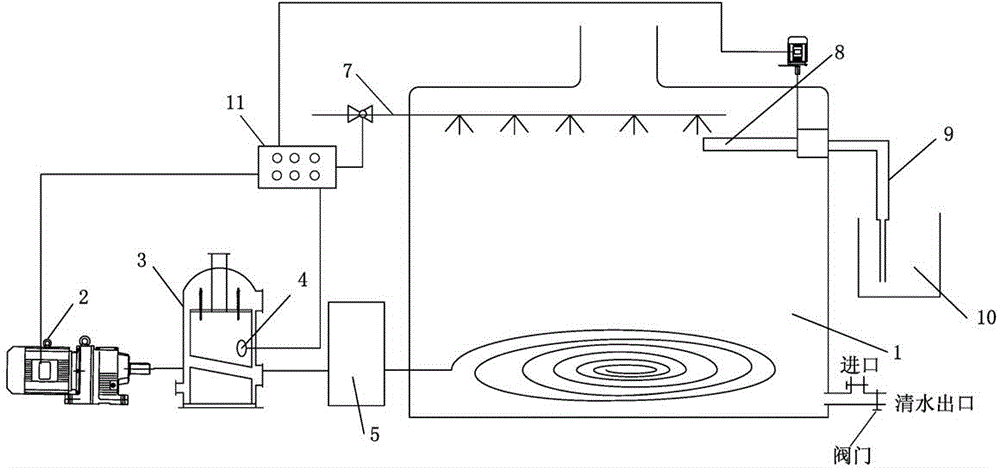

[0008] The differential air bubble separation device for kitchen waste grease involved in the present invention is realized through the following steps:

[0009] The oil-water mixture in the food waste treatment process enters the storage tank (1) through the inlet, and stops the water when it enters about 10mm below the defoamer (7), and it is connected to the difference on the other side of the storage tank (1) The bubble generator (5) starts to work, and the differential bubble generator (5) can generate bubbles of 4 different particle sizes within the particle size of 10~100μm through the control of the frequency conversion motor (2), which are placed in the storage tank (1) Bubble release (6) at the bottom to release. And the air bubble releaser (6) also controls the temperature of the storage tank (1) through the connected hot air stove (3) and temperature controller (4), so as to prevent the grease from solidifying and improve the efficiency of grease collection.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com