Skid-mounted bradenhead gas three-tower separation and recycling device and method

A separation and recovery, wellhead gas technology, applied in distillation purification/separation, liquid hydrocarbon mixture recovery, gas fuel and other directions, can solve the problem of the average recovery rate of propane less than 60%, and achieve the effect of high separation and recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the following examples further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

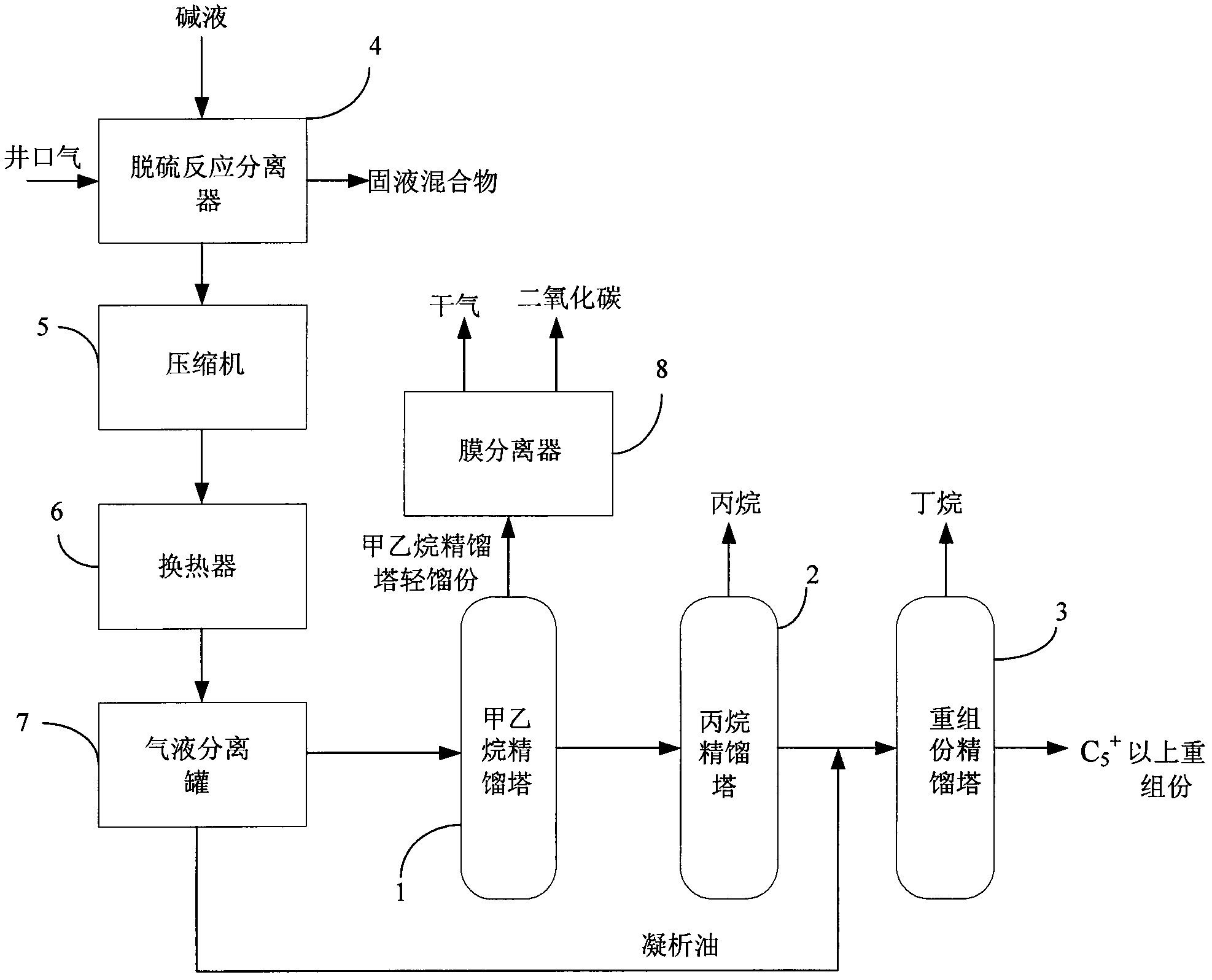

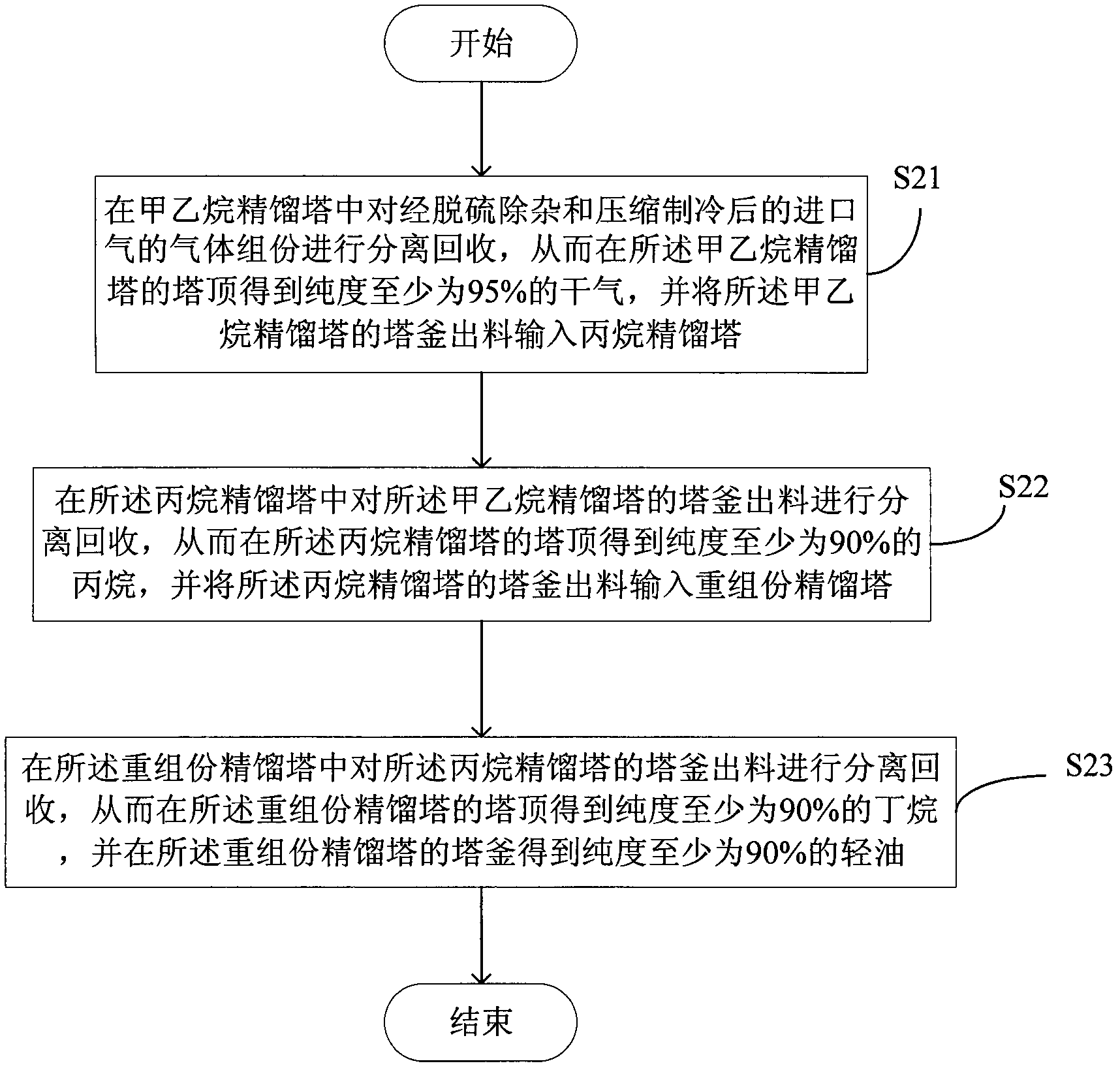

[0025] Such as figure 1 Shown, in the skid-mounted wellhead gas three-tower separation and recovery device of the present invention, it mainly comprises interconnected methane ethane rectifying tower 1, propane rectifying tower 2 and heavy component rectifying tower 3, to the wellhead gas Separation and recovery of associated gas from remote oilfields, volatile gas from oil tanks, volatile gas from gas stations, torch gas, coal bed methane and natural gas. According to the composition and content of the raw gas, the separation method of liquid nitrogen low-temperature rectification is used to form three types Chemical energy products: dry gas (C 1 +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com