A kind of skid device and process method for gas injection and production gas collection and transportation in salt cavern gas storage

A gas storage, gas injection and production technology, which is applied in the fields of mining fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problems of long construction period, high production cost, and many construction personnel, and achieve improved safety and Reliability, reduce equipment investment, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

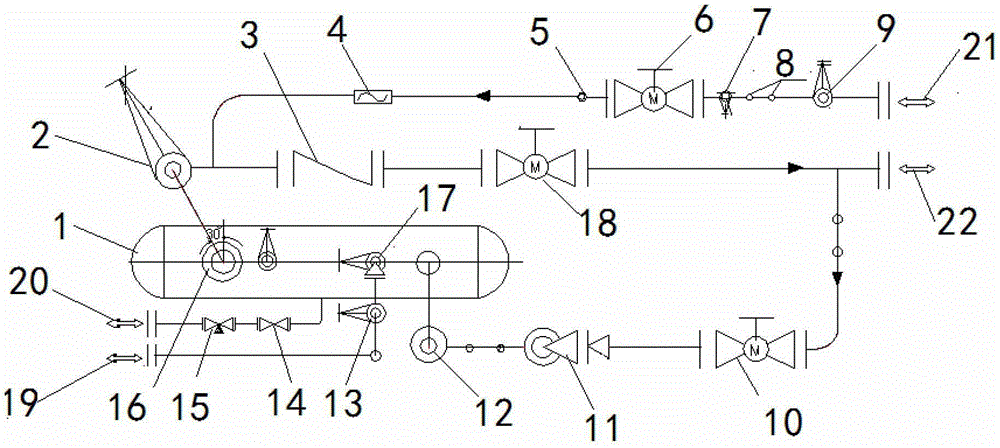

[0031] Embodiment 1: as figure 1 as shown,

[0032] The invention belongs to the application technology in the field of natural gas gathering and transportation of salt cavern underground gas storage, and relates to a skid device for collecting and transporting gas for injection and production of salt cavern gas storage.

[0033] Optimize the process flow of Jintan underground gas storage and realize skid-mounted well site equipment. Through the optimization of the process flow and the research on the skid-mounted equipment at the well site, equipment investment and production costs can be effectively reduced, the injection-production efficiency of the underground gas storage can be improved, and the safety and reliability of the gas storage equipment can be improved.

[0034] Aiming at the problems existing in the construction and operation of Jintan gas storage, the single well well site process and equipment were optimized, mainly including the following aspects: hydrate p...

Embodiment 2

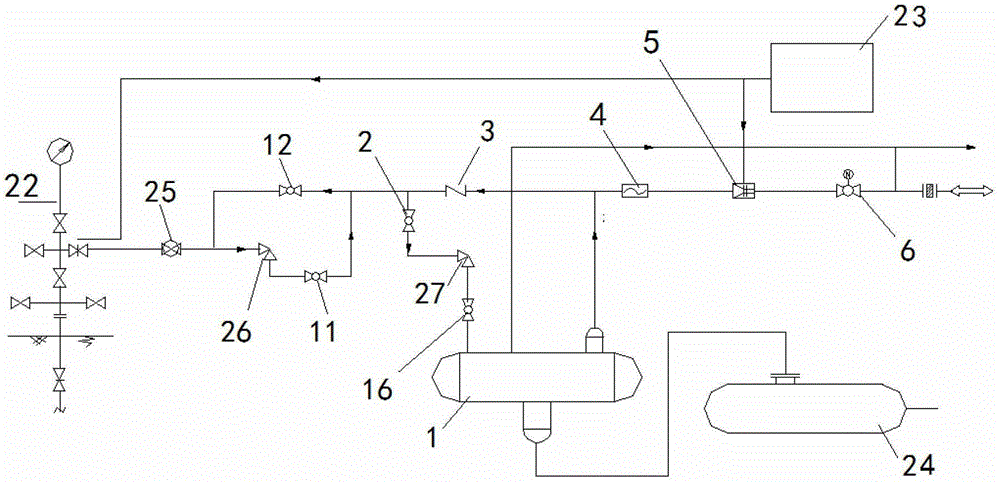

[0051] A kind of skid device for gas injection and production in salt cavern gas storage, such as figure 2 As shown, the first-stage throttling and pressure regulating valve includes a first angle throttle valve 26, the main function of which is to regulate the pipeline flow without adjusting the pressure, so as to avoid excessive gas production flow and keep the salt chamber stable;

[0052] The two-stage throttling and pressure regulating valve includes the second angle throttle valve 27, which mainly regulates the gas pressure in the pipeline, adjusts the pressure to 10MPa, and enters the well site dehydration device to keep the pressure in the well site separator, valves, pipelines, etc. within the design pressure range of the equipment.

[0053] The horizontal gravity separator 1 is connected with the safety valve 16 and the normal pressure sewage tank 24; the other end of the safety valve 16 is connected with the second angle throttle valve 27, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com