Reliquefaction system and process for liquefying bog by self-compression and expansion of bog

A compression expansion and reliquefaction technology, applied in the field of reliquefaction systems, can solve the problems of high energy consumption per unit volume of BOG, low process energy consumption, and many process equipment, etc., and achieves a high degree of automation, simple process, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

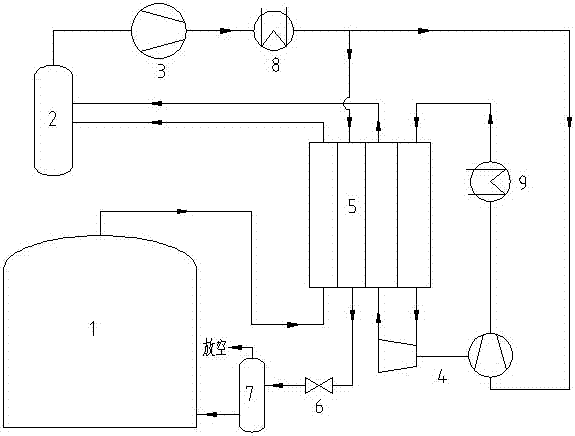

[0032] see figure 1 , the embodiment of the present invention uses BOG self-compression expansion to liquefy BOG reliquefaction system including LNG storage tank 1, BOG buffer tank 2, BOG compressor 3, turbo expander 4, heat exchanger 5, throttle valve 6, gas-liquid Separator 7 , first cooler 8 and second cooler 9 .

[0033] The heat exchanger 5 has a first flow path, a second flow path, a third flow path and a fourth flow path.

[0034] The first cooler and the second cooler are water coolers.

[0035] The BOG outlet of the LNG storage tank 1 communicates with the cold end inlet of the first flow channel of the heat exchanger 5 with a pipeline, and the hot end outlet of the first flow channel of the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com