Efficient separation and recovery process for lithium battery

A separation and recycling, lithium battery technology, applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of separation difficulty, simplicity and rudeness, reducing separation and recycling efficiency, etc., to improve separation and recycling efficiency, reduce difficulty, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

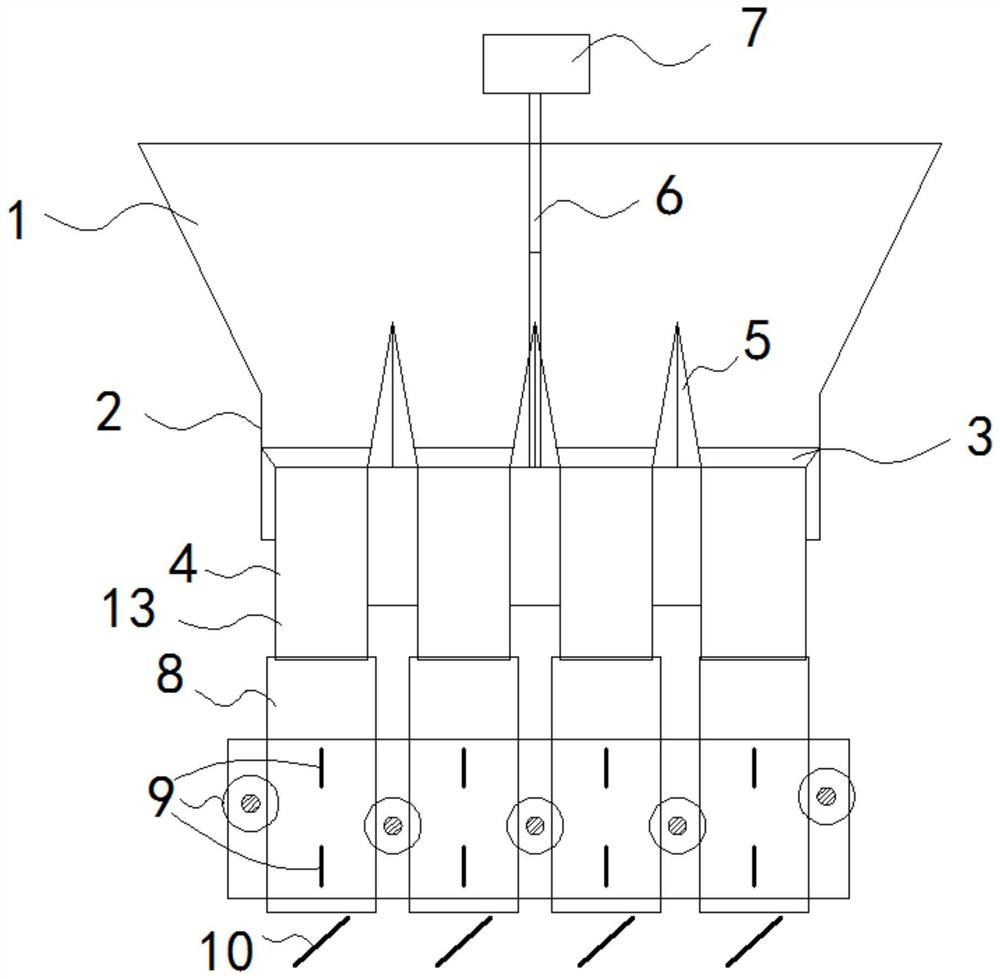

[0047] Such as Figure 1~4 Shown, a kind of described lithium battery case separation device, wherein, comprises:

[0048] A conical silo 1 for receiving cylindrical waste lithium batteries, the silo 1 having a cylindrical lower end 2;

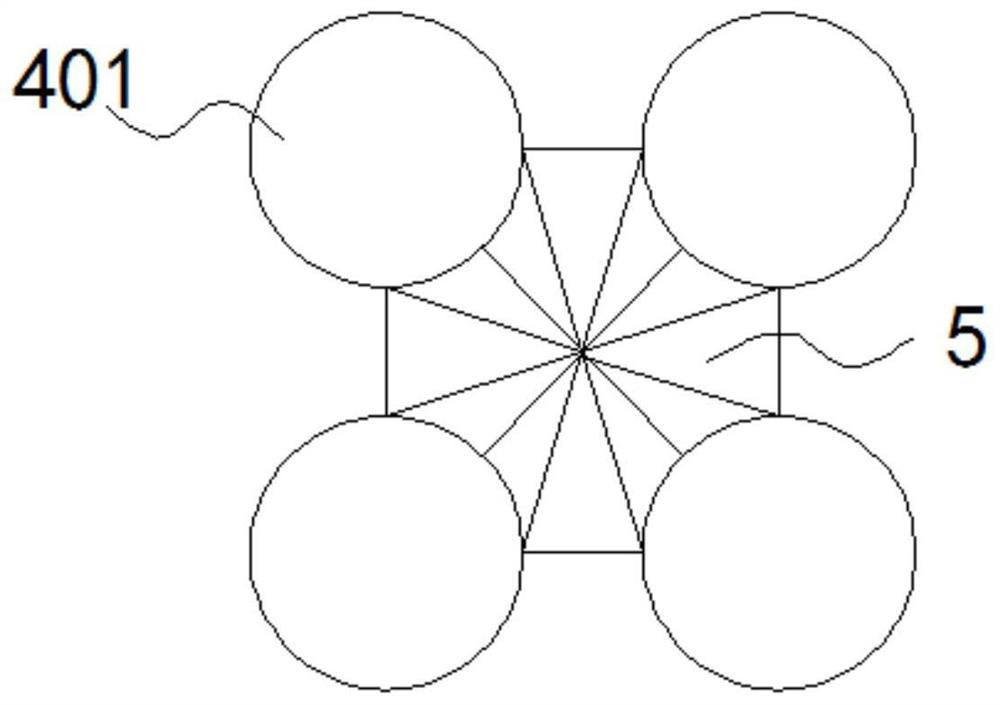

[0049] The unloading mechanism includes an adapter part 3, a feed part 4, a material guide part 5 and a drive part; the adapter part 3 is a tapered cylinder structure, and the size is just adapted to the bottom of the cylindrical lower end 2 of the silo. The inner wall is slidingly attached to the inner wall of the cylindrical lower end 2 of the silo; the lower material part 4 is connected to the lower end of the adapter part 3, and the lower material part 4 is a cylindrical structure with multiple vertically downward circles inside. The hole 401, the round hole 401 is adapted to the shape of the lithium battery to allow the lithium battery to pass downward, the lower end of the blanking part 4 is provided with a tubular extension 13, and eac...

Embodiment 2

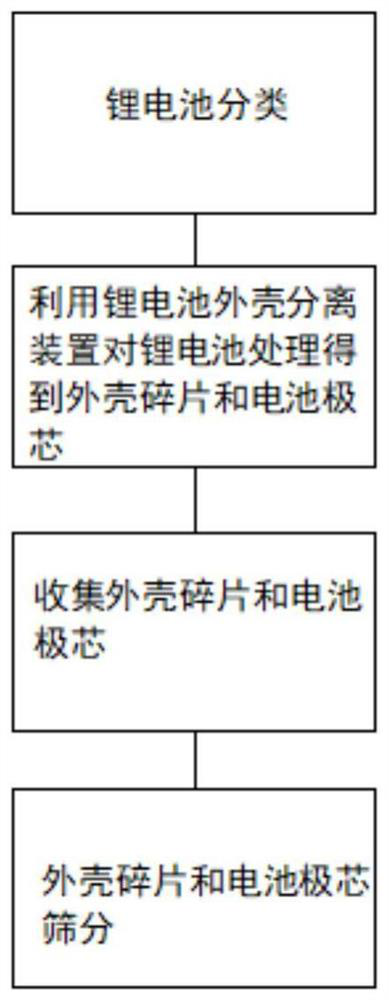

[0068] A high-efficiency separation and recovery process for lithium batteries, comprising:

[0069] Step 1. Classify the collected waste lithium batteries by shape, classify the cylindrical lithium batteries, and classify the cylindrical lithium batteries according to the diameter.

[0070] Step 2, according to the cylindrical diameter, design the corresponding lithium battery shell separation device to remove the shell of the lithium battery, such as Figure 1~4 As shown, the lithium battery case separation device includes:

[0071] A conical silo 1 for receiving cylindrical waste lithium batteries, the silo 1 having a cylindrical lower end 2;

[0072] The unloading mechanism includes an adapter part 3, a feed part 4, a material guide part 5 and a drive part; the adapter part 3 is a tapered cylinder structure, and the size is just adapted to the bottom of the cylindrical lower end 2 of the silo. The inner wall is slidingly attached to the inner wall of the cylindrical lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com