Treatment system and recycling method for phenolic resin based copper clad laminate

A phenolic resin and treatment system technology, applied in recycling technology, plastic recycling, mechanical material recycling, etc., can solve the problems of environmental hazards, waste of resources, high cost of exhaust gas treatment, and achieve the effect of improving the crushing effect and improving the grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

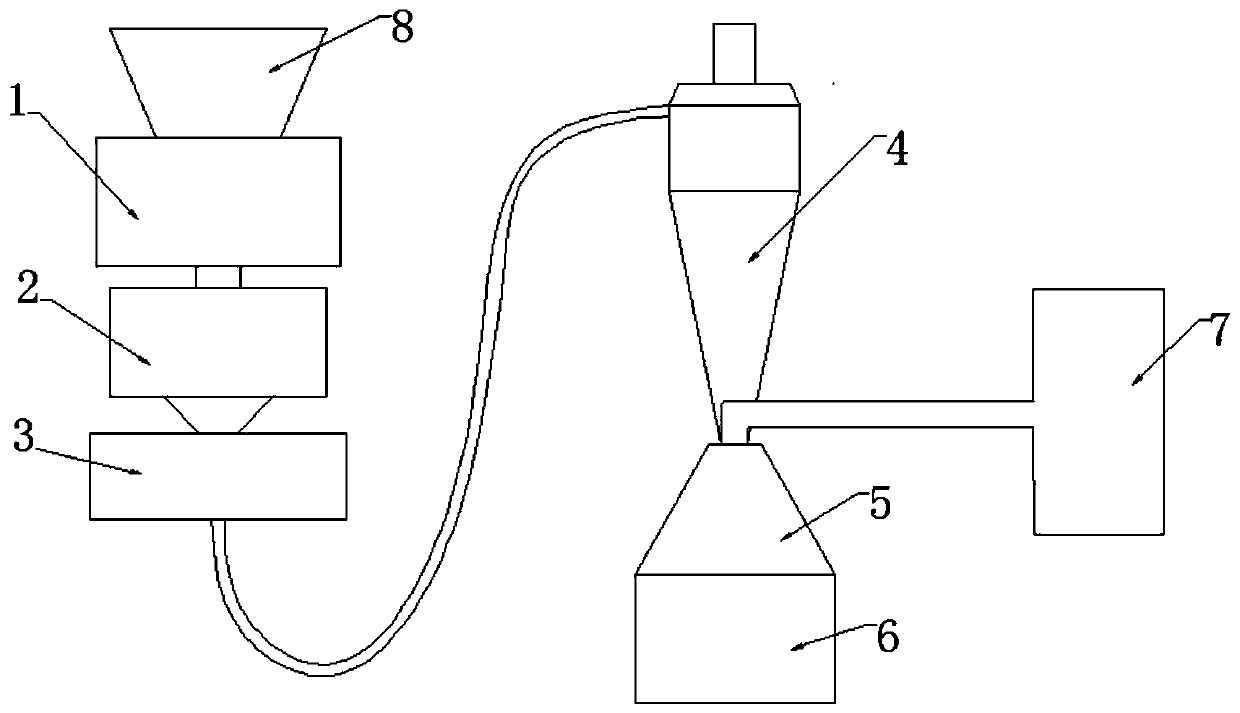

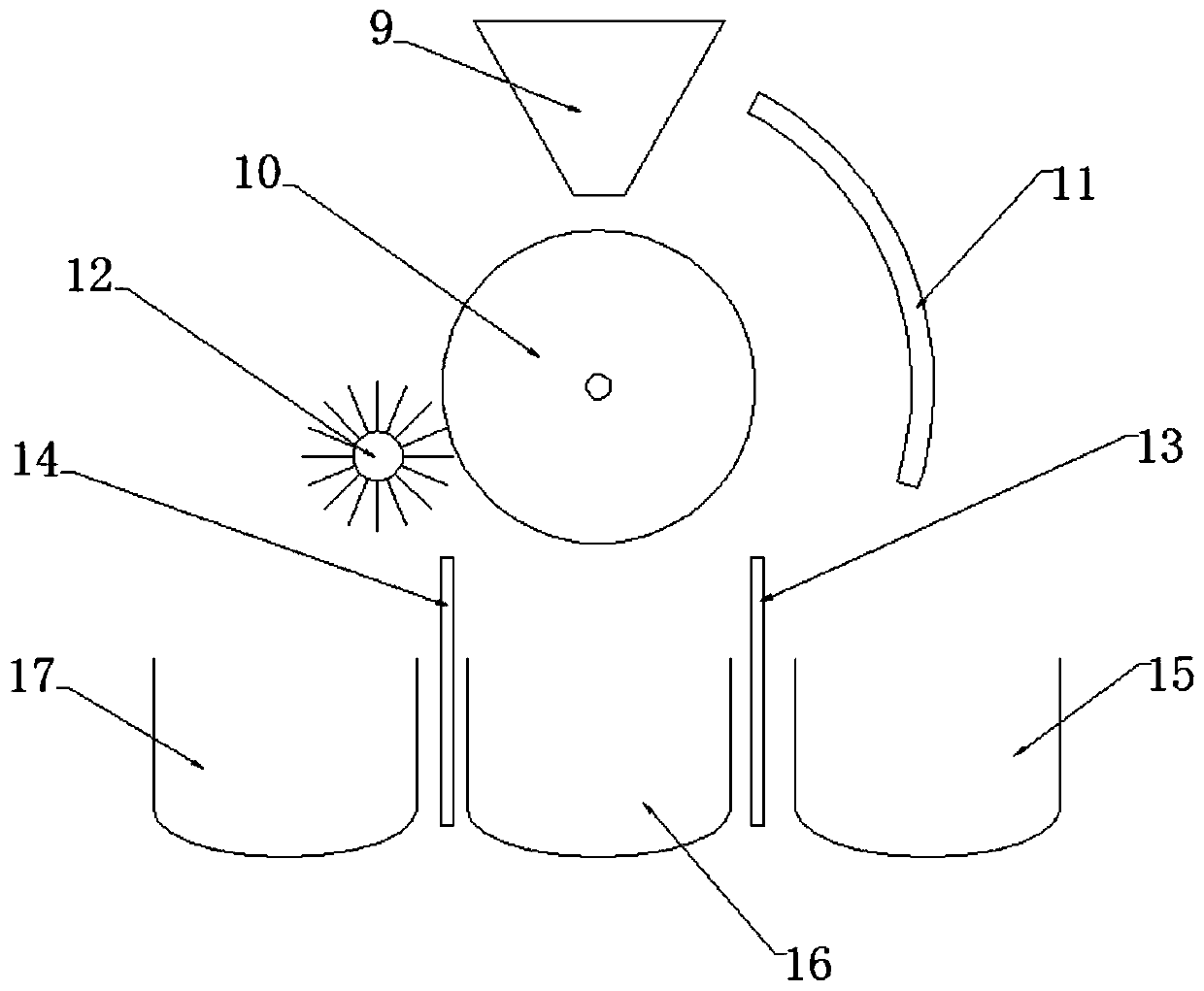

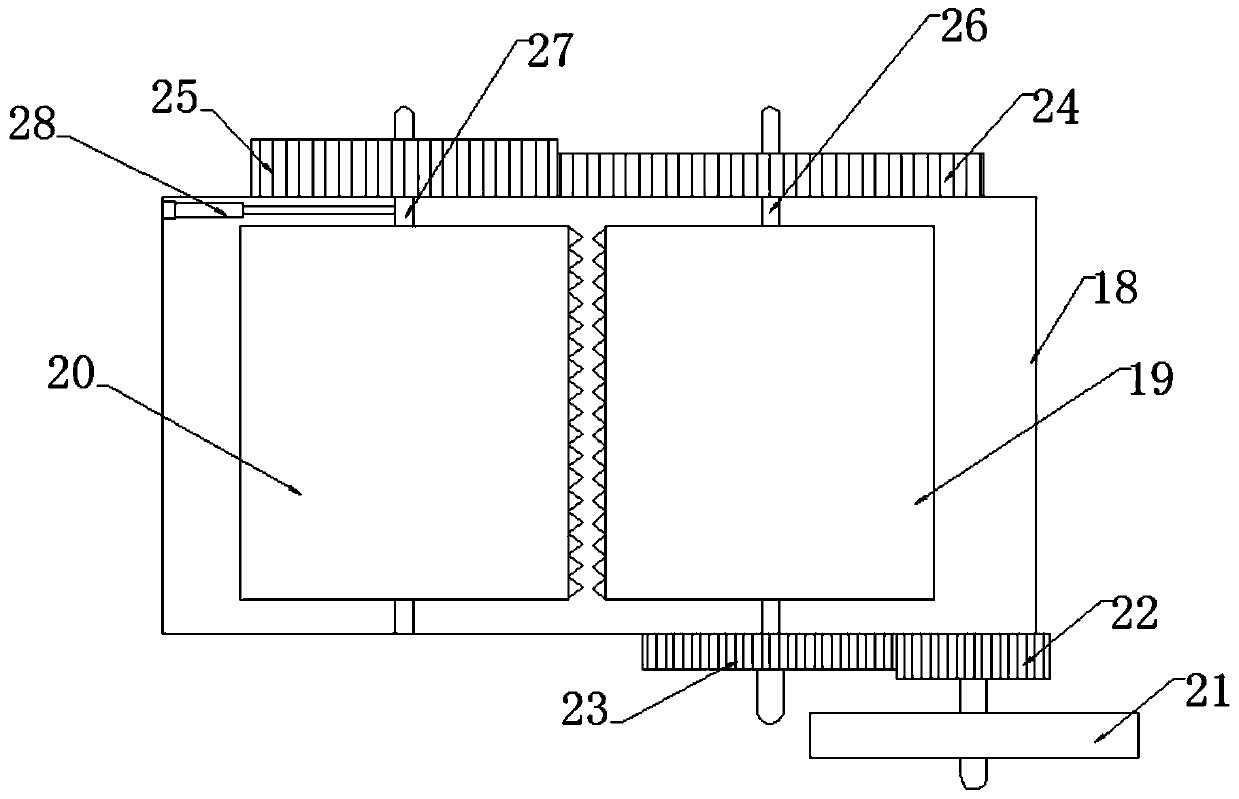

[0035] The processing system of a kind of phenolic resin base copper-clad laminate as the embodiment of the present invention, such as figure 1 , figure 2 and image 3 As shown, the treatment system includes a primary crusher 1, a secondary crusher 2, a pulverizer 3, a cyclone separator 4 and a separation device connected in sequence, and the gas outlet of the cyclone separator 4 is also connected with a pulse bag filter. 7. The separation device includes a vibrating screen 5 and an electrostatic separator 6, the feed port of the vibrating screen 5 communicates with the solid discharge port of the cyclone separator 4, and the feed port of the electrostatic separator 6 is arranged below the vibrating screen 5 , the electrostatic separator 6 is provided with a phenolic resin collection container 17, an intermediate product collection container 16 and a copper powder collection container 15 arranged horizontally in sequence, and the discharge port of the intermediate product co...

Embodiment 2

[0040] As a method for recycling phenolic resin-based copper-clad laminates according to an embodiment of the present invention, the method uses the processing system for phenolic resin-based copper-clad laminates as described in Example 1, including the following steps:

[0041] (1) Crushing the phenolic resin-based copper-clad laminate in a hammer crusher to obtain pulverized material A with a particle size of 0.1-40 mm;

[0042] (2) Shearing and crushing the pulverized material A in step (1) in a double-roller crusher to obtain pulverized material B with a particle size of 0.05 to 20 mm;

[0043] (3) Input the pulverized material B obtained in step (2) into a pulverizer for grinding to obtain pulverized material C with a particle size of 0.05 to 3 mm;

[0044] (4) The pulverized material C obtained in step (3) is input into a cyclone separator to separate and obtain phenolic resin dust and particle pulverized material D, and the phenolic resin dust enters the dust removal d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com