A recycling production system based on old asphalt pavement materials and its processing method

A kind of asphalt pavement and production system technology, applied in the field of recycling system, can solve the problems of low recycling efficiency, inability to be directly used, and rapid and direct separation of impurities such as stones, etc., to achieve high separation and recovery efficiency, maintain scraping effect, and improve scraping The effect of removing the effect

Active Publication Date: 2022-05-31

杭州路顺环境建设有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the deficiencies of the prior art, the present invention provides a recycling production system based on old asphalt pavement materials and its processing method, which solves the problem of the relatively viscous asphalt after the existing device melts the asphalt, and impurities such as stones in it It cannot be separated quickly and directly, the recovery efficiency is low, and the asphalt on the surface of the stone will solidify the stone after cooling, making it impossible to use directly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

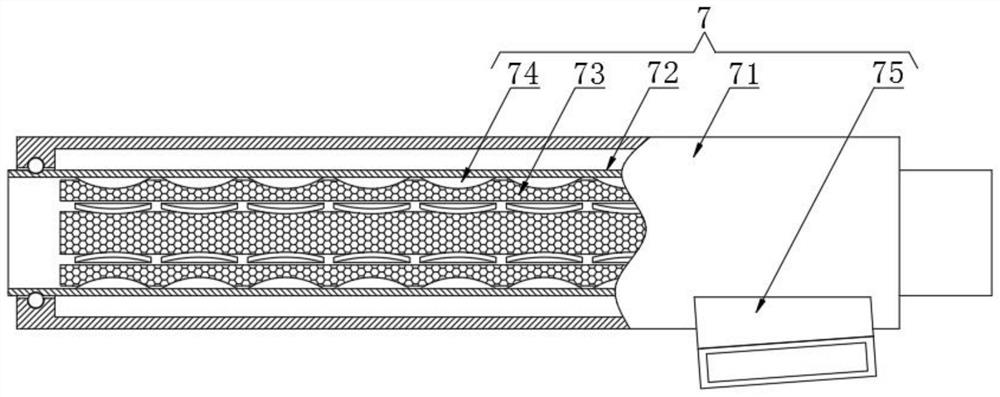

[0045] Please refer to FIG. 3, the separation assembly 7 includes an outer cylinder 71, and the inner side of the outer cylinder 71 is rotatably connected with a rotating cylinder 72, and

[0049] The top of the inner surface of the cleaning box 41 is fixedly connected with a flushing ring pipe 411 around the rotating shaft 49, and the bottom of the flushing ring pipe 411 is

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

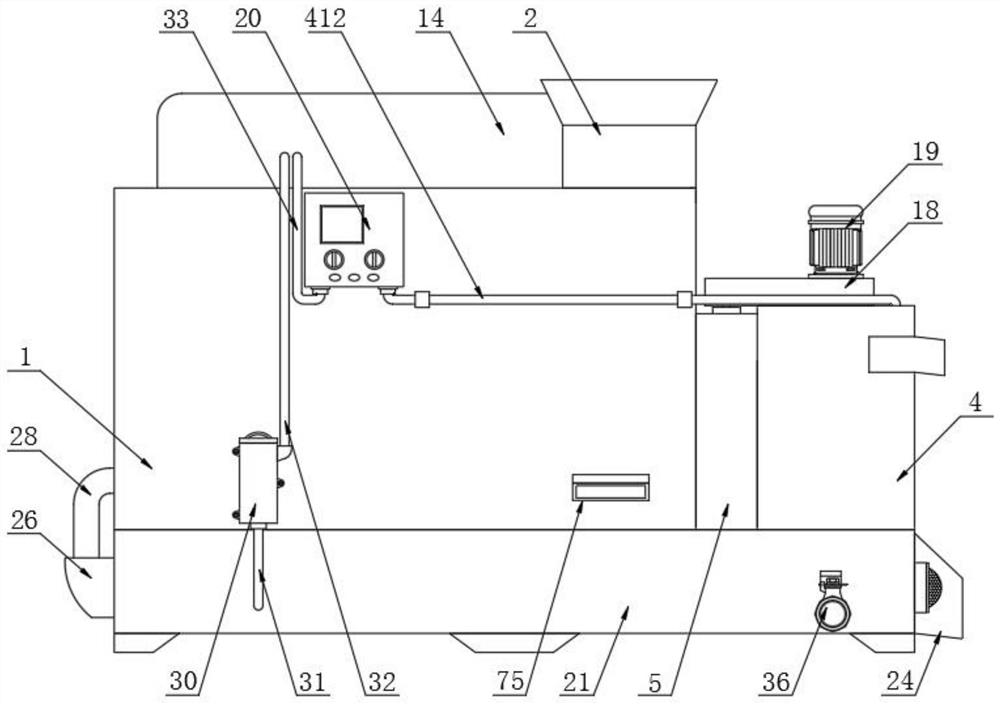

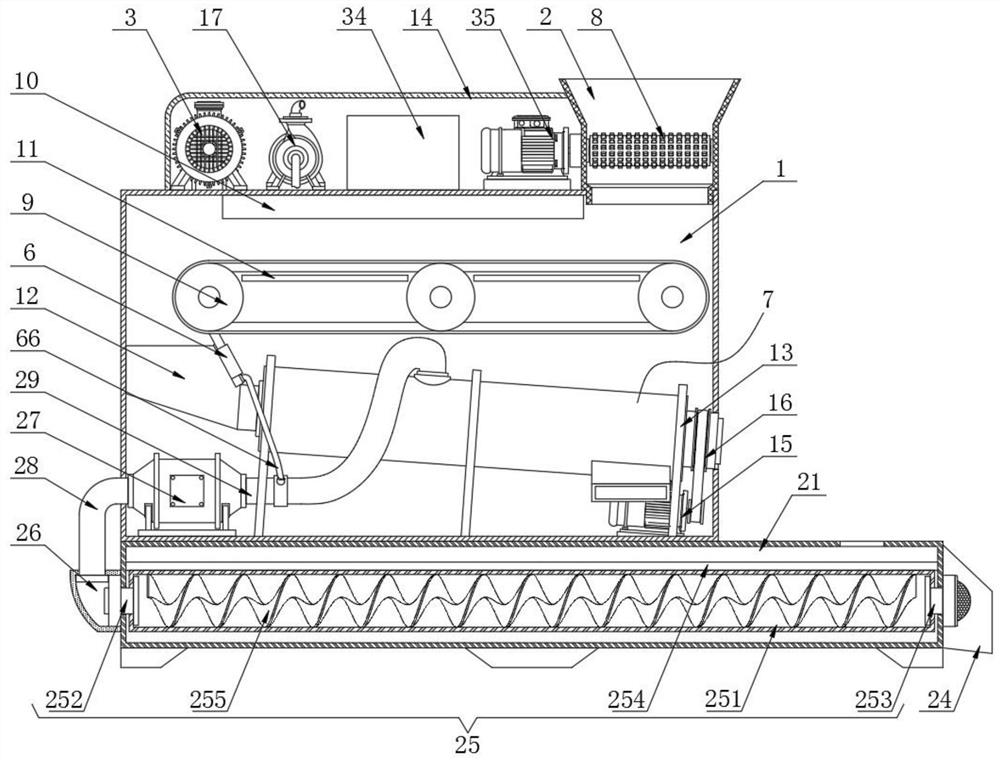

The invention discloses a regeneration cycle production system based on old asphalt pavement materials and its processing method. The right side of the top of the recovery box is fixedly connected with an upper hopper, and the top of the recovery box is fixedly connected with a drive motor, a water pump, The microwave control main unit and the first motor, the top of the recovery box and the outer part of the first motor, the drive motor, the water pump and the microwave control main unit are fixedly connected with a dust cover. The present invention relates to the technical field of recovery systems. The regeneration cycle production system and its treatment method based on old asphalt pavement materials first set crushing rollers to break large pieces of waste asphalt into small pieces, and then discharge them into the separation assembly after being melted by microwave heating. The cylinder can throw out the melted asphalt, retain the stones and transport them out, and then realize the preliminary separation and recovery of asphalt and stones. Compared with simple gravity filtration separation, its separation and recovery efficiency is higher and more thorough.

Description

A recycling cycle production system based on old asphalt pavement materials and its processing method technical field The present invention relates to the technical field of recovery system, be specially a kind of regeneration cycle production system based on old asphalt pavement material. system and how to deal with it. Background technique Now all kinds of roads in China are basically asphalt roads, and the asphalt pavement material is made of molten asphalt and certain large Small stones are mixed and mixed, and then compacted to form asphalt roads. Asphalt roads have a certain service life. After a certain age, it needs to be repaired or re-laid, and the resulting old asphalt concrete pavement waste needs to be treated. The most common treatment method is to discard the waste directly as garbage, and re-use new materials to pave the road. The concrete and asphalt still have great utilization value, and the direct abandonment results in a great waste of resource...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01C19/10E01C19/05E01C19/08

CPCE01C19/1004E01C19/05E01C19/08Y02W30/91

Inventor 朱校军

Owner 杭州路顺环境建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com