Separation and recycling method of manganese particles in manganese electrolytic diaphragm frame

An electrolytic diaphragm, separation and recovery technology, applied in the direction of improving process efficiency, can solve the problems of no recovery, waste of resources, and increase economic benefits of enterprises, and achieve the effect of simple method and high separation and recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

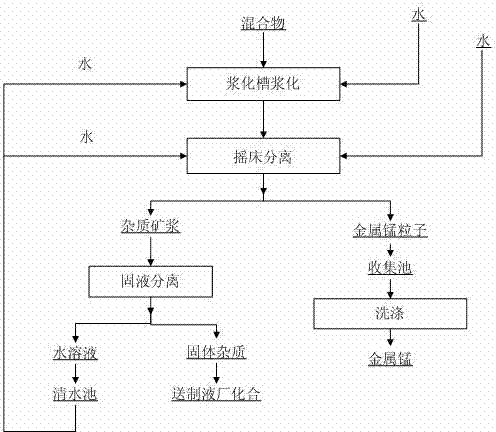

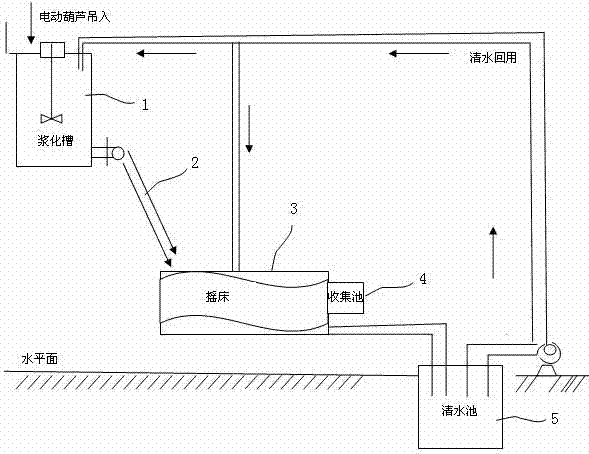

[0016] figure 1 It is a flow chart of the separation and recovery of metal manganese particles in the metal manganese electrolytic diaphragm frame of the present invention; figure 2 It is a schematic diagram of the equipment structure used in the present invention.

[0017] See figure 1 and figure 2 The method for separating and recovering metal manganese particles in the metal manganese electrolytic diaphragm frame provided by the invention comprises the following steps:

[0018] 1. Use a trolley to push the mixture containing metal manganese, manganese dioxide, calcium sulfate, and magnesium sulfate to the shaking table process every day, then use an electric hoist to lift the mixture to the small platform of the pulping tank 1, and then pour it into the pulping tank In tank 1, start the mixer and stir for half an hour.

[0019] 2. Open the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com