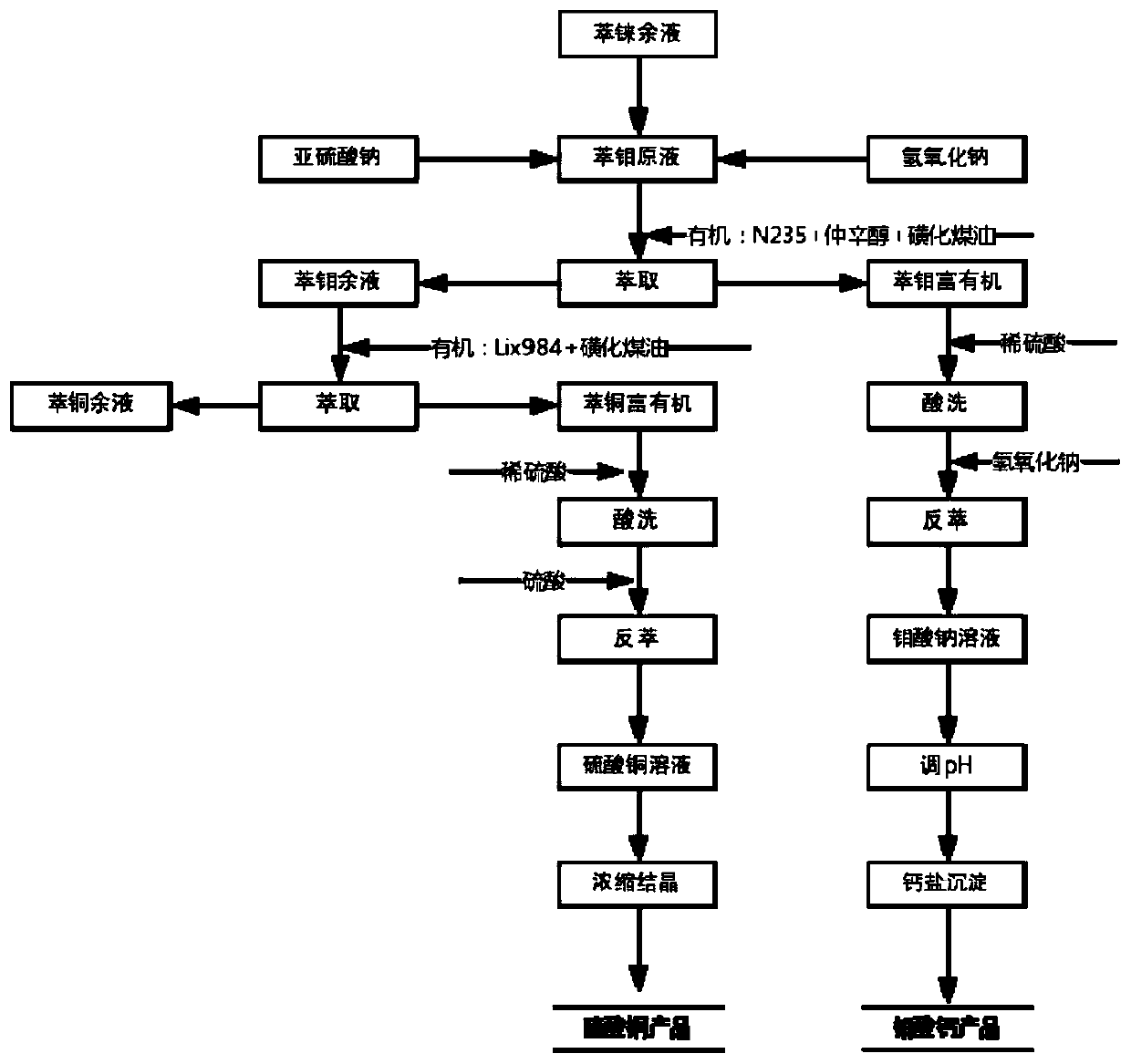

Method for separating and recovering molybdenum and copper from rhenium extraction raffinate

A technology for separation and recovery of raffinate, applied in chemical instruments and methods, copper sulfate, molybdenum compounds, etc., can solve the problems of clogging the extraction tank, unfavorable extraction and stripping process, affecting the extraction process, etc., to achieve smooth process, reduce Handling difficulty, unique craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

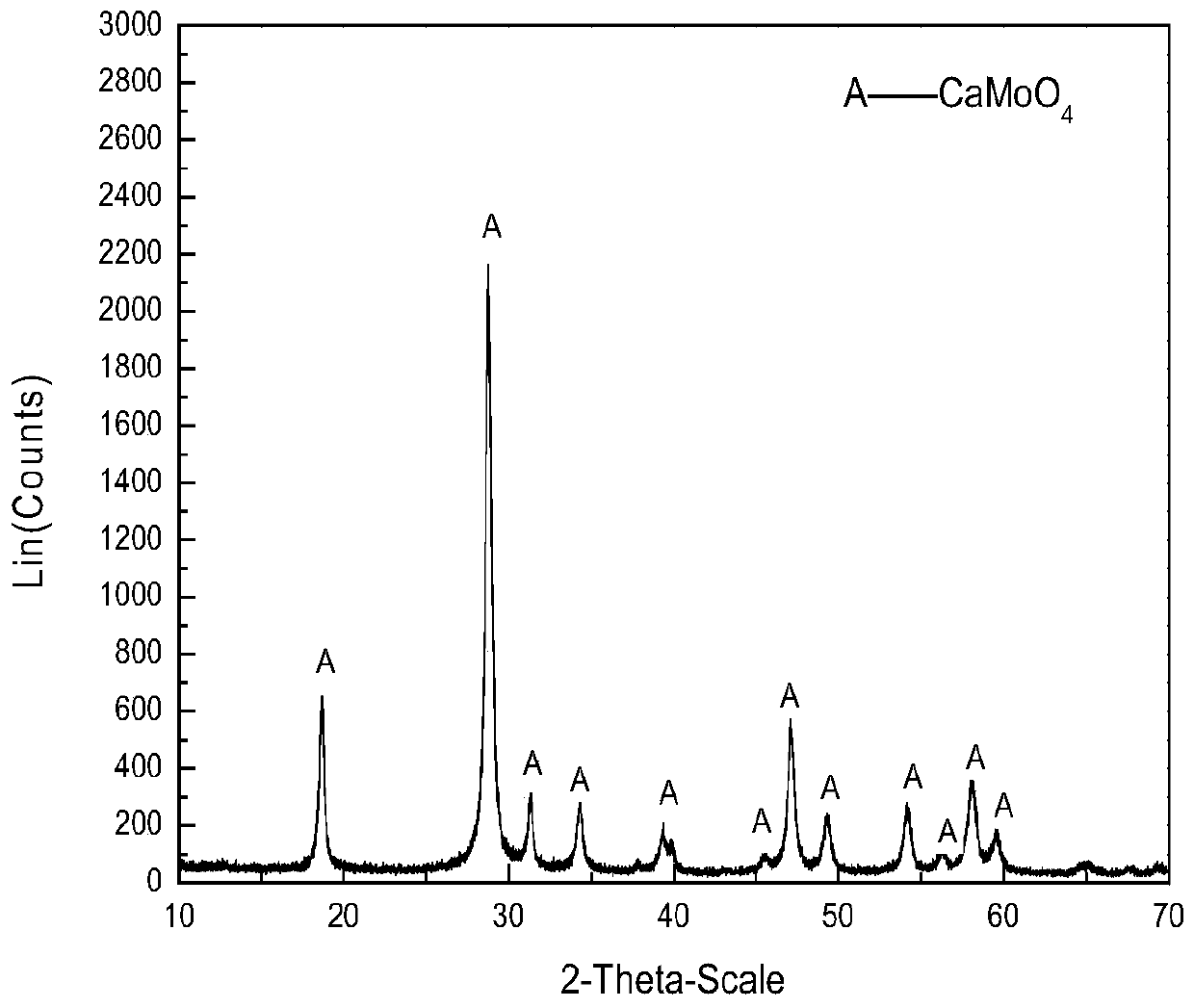

[0037] Take the rhenium extraction raffinate with acidity for molybdenum separation, add a certain amount of sodium sulfite according to the volume of the rhenium extraction raffinate, and then add industrial caustic soda to adjust the pH of the rhenium extraction raffinate to 1.2--1.5. This solution is the molybdenum extraction stock solution. Molybdenum extraction stock solution contains molybdenum 0.66g / L, pH=1.30, specific gravity D=1.173 (17°C); rhenium extraction is organic-poor (20% N235+40% sec-octanol+kerosene). Specific gravity D = 0.822 (19°C); remaining detergent, pH = 2.10, specific gravity D = 1.000; stripping agent 7N NaOH solution, specific gravity D = 1.236 The experiment of separating molybdenum in the extraction tank was carried out by using 6-stage extraction, 2-stage washing, 3 Stage stripping, washing water strings to the extraction section and combining with the original solution for extraction, the stripping solution is acidified with hydrochloric acid, ...

Embodiment 2

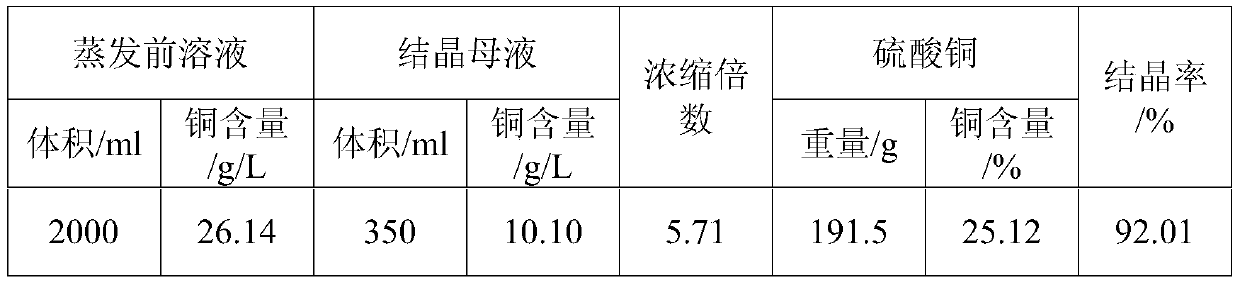

[0042] Take the molybdenum raffinate to directly carry out the copper extraction experiment, the copper extraction stock solution contains 5.41g / L of copper; the loaded organic is calculated according to the organic after extraction balance, the organic phase of the molybdenum extraction is 20% Lix984+kerosene, and the density ρ=0.839 (20°C); washing The agent is a weakly acidic aqueous solution with pH=2.0 (pure water pH=7.08, 2mL of 1:1 sulfuric acid is added to 20kg of pure water, and the pH value is measured as 2.10), density ρ=1.000); stripping agent is 180g / L sulfuric acid, Density ρ = 1.141.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com