Process for manufacturing Wolter-I reflector by means of copying

A mirror and process technology, applied in the direction of mirrors, electrolysis process, electroforming, etc., can solve the problems of increasing the manufacturing cost of mirrors, inhaling nitrogen gas, health hazards, etc., to avoid health hazards, prevent damage, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

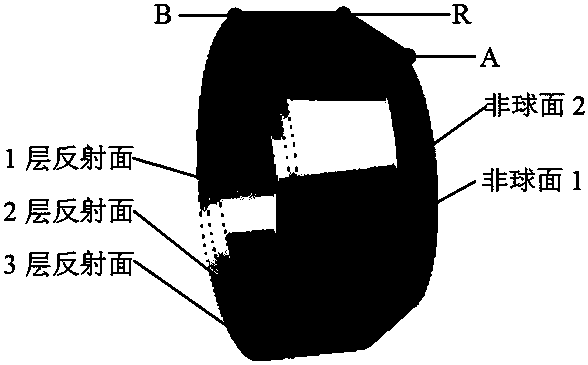

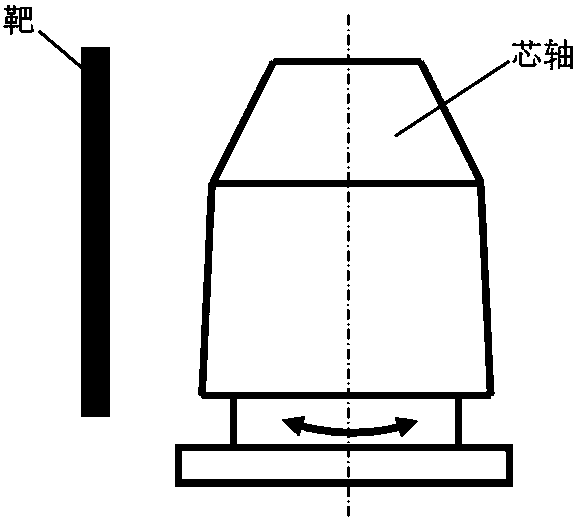

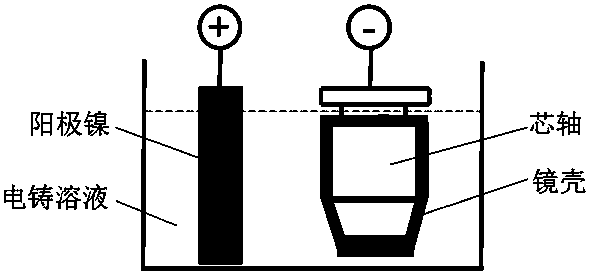

[0073] Taking the manufacture of the Woler-I mirror composed of ellipsoid and hyperboloid as an example, the replication experiment is carried out. The RMS value of the surface high-frequency roughness of the mandrel for replication is 1.56nm. After PVD mirror replication, electroforming mirror shell, mirror shell trimming, shelling and cleaning, etc., the Woler-I mirror with the same surface quality as the mandrel is replicated and manufactured, and the mirror wall thickness is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com