Cathode material and preparation method and applications thereof

A technology of positive electrode materials and raw materials, applied in the field of positive electrode materials and their preparation, can solve problems such as poor lithium ion mobility and electronic conductivity, negative impact on material rate performance, and easy peeling, etc., to achieve high practical application prospects, Reduce the effect of surface side reactions and surface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the above-mentioned cathode material, which includes the following steps:

[0033] (1) The raw material spinel lithium nickel manganese oxide LiNi 0.5 Mn 1.5 O 4-δ (0≤δ<0.1), the doped metal precursor and the precipitant are dispersed in a solvent (the solvent can be water or ethanol); then a regulator is added to adjust the pH of the reaction system to 1.5-7.0, and the reaction is heated and stirred , So that the introduced precursor is converted into a solid phase compound containing the doped metal element, and deposited uniformly on the surface of the spinel-type lithium nickel manganate. After the reaction is completed, it is separated, washed, and dried to obtain an intermediate product .

[0034] (2) Grind the intermediate product of step (1) uniformly, calcinate, and cool to room temperature to obtain the positive electrode material of the present invention.

[0035] The use of the precursor form of the doped ...

Embodiment 1

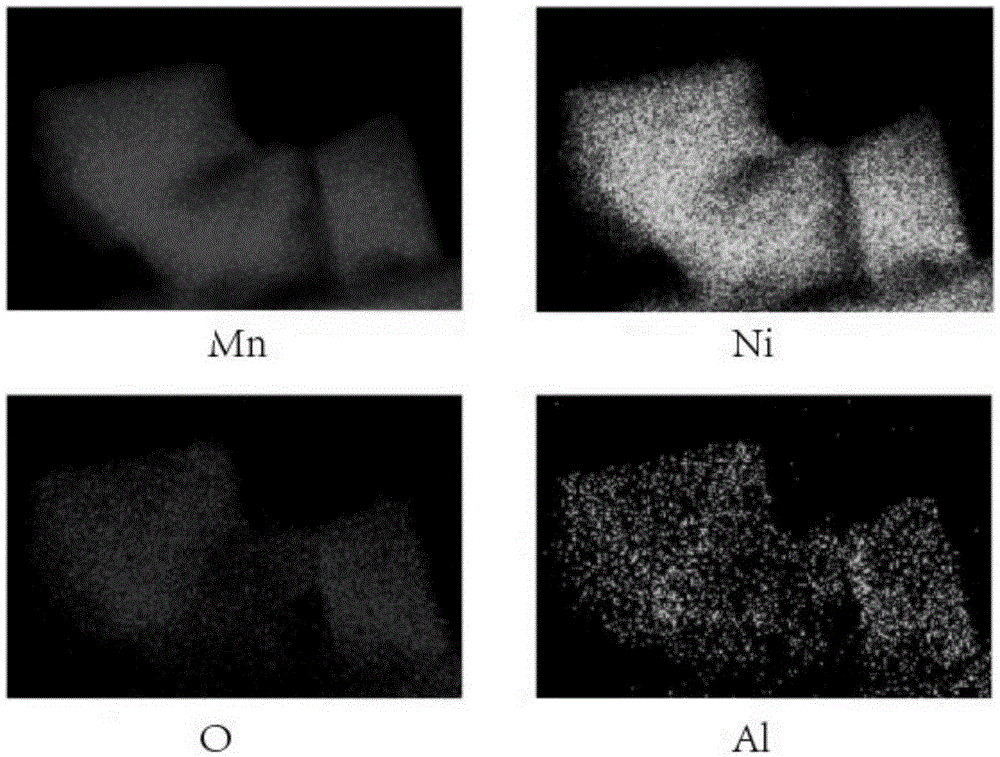

[0046] 1. Preparation of core-shell lithium nickel manganate doped with surface aluminum

[0047] Put spinel lithium nickel manganate LiNi in the flask 0.5 Mn 1.5 O 4-δ (0≤δ-3 mol / L; the concentration of the diammonium hydrogen phosphate is 2.5×10 -3 mol / L, the concentration of the ammonium formate is 1.06 mol / L.

[0048] The regulator hydrochloric acid was added to the reaction system to adjust the pH of the reaction system to 3, the reaction was stirred at 45° C. for 2 hours, and the intermediate product was obtained by centrifugation, washing and drying.

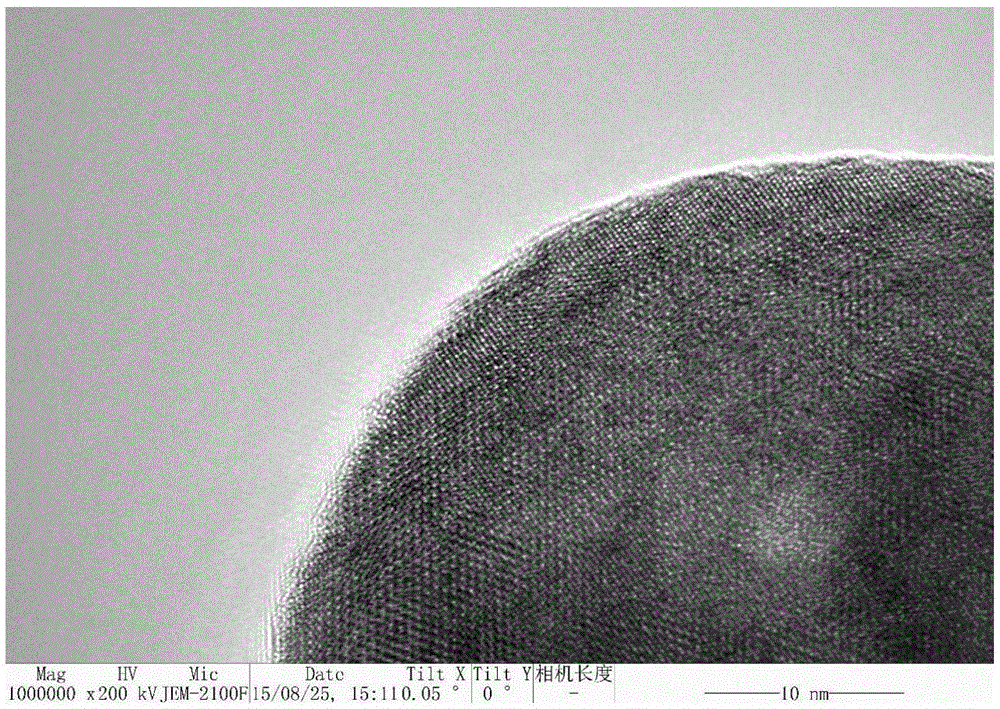

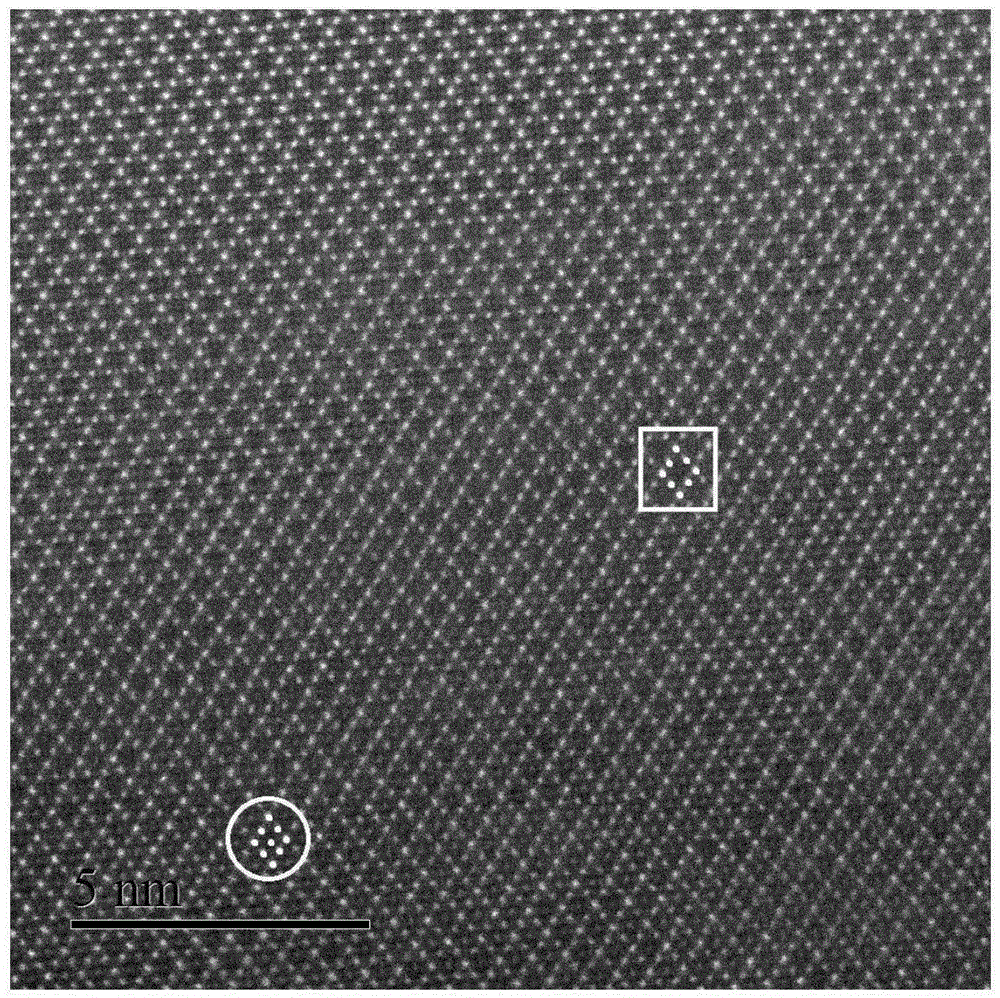

[0049] The intermediate product was heated to 800°C at a rate of 4°C / min, calcined at this temperature for 3 hours, and then cooled to room temperature to obtain spinel-type lithium nickel manganate powder with a core-shell structure doped with aluminum on the surface. Its core is spinel lithium nickel manganese oxide LiNi 0.5 Mn 1.5 O 4-δ (0≤δ<0.1), the doping amount of aluminum in the shell layer is 0.29wt.% of spinel lithium ...

Embodiment 2

[0061] 1. Preparation of iron-doped core-shell lithium nickel manganate

[0062] Put spinel lithium nickel manganate LiNi in the flask 0.5 Mn 1.5 O 4-δ (0≤δ-3 mol / L; the concentration of the ammonium formate is 1.06 mol / L.

[0063] Adding regulator nitric acid to the reaction system to adjust the pH of the reaction system to 2.0, stirring at 50° C. for 2 hours, centrifuging, washing, and drying to obtain an intermediate product.

[0064] The intermediate product was heated to 800°C at a rate of 3°C / min, and calcined at this temperature for 3 hours to obtain spinel-type lithium nickel manganate powder with a core-shell structure doped with iron on the surface. Its core is spinel lithium nickel manganese oxide LiNi 0.5 Mn 1.5 O 4-δ (0≤δ<0.1), the iron doping amount of the shell layer is 0.62wt% of spinel lithium nickel manganese oxide. The thickness of the shell layer is approximately 25 nm.

[0065] 2. Preparation of spinel-type lithium nickel manganate electrode with core-shell struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com