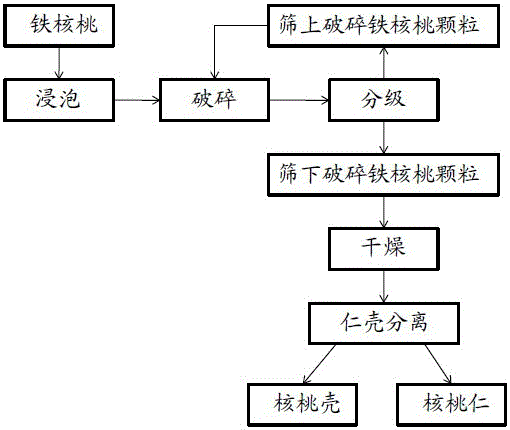

Method for crushing purely natural wild juglans sigillata and separating kernels from shells

A kernel-shell separation and iron walnut technology is applied in solid separation, chemical instruments and methods, shelling and other directions, which can solve the problems of labor-intensive and time-consuming efficiency, difficulty in using wild iron walnut kernels, waste of resources, etc., and achieves a simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Soak iron walnuts with a diameter of 20-25 mm in clear water. Before soaking, the water content of the walnut kernels in the iron walnuts is 7%, and the water content of the walnut shells is 12.5%. The soaking process is as follows: In the first stage, put the iron walnuts in Soak in clear water at a temperature of 20°C for 5 hours; in the second stage, heat the clear water to 50°C at a rate of 9°C / hour, and keep soaking for 7 hours; in the third stage, stop heating Temperature, with the speed of 5 ℃ / hour, clear water is cooled to 15 ℃, continue to soak for 5 hours, obtain the soaked iron walnut after soaking, the water content of walnut kernel in the described soaked iron walnut is 8%, the water content of walnut shell is 19.5%; soaked iron walnuts are placed in a crusher for crushing, and the crushing force during crushing is set to 200kg to obtain crushed iron walnut particles mixed with kernel shells; the crushed iron walnut particles mixed with shell kernels are pla...

Embodiment 2

[0031] Soak iron walnuts with a diameter of 25-30 mm in clear water. Before soaking, the water content of the walnut kernels in the iron walnuts is 7.5%, and the water content of the walnut shells is 12%. The soaking process is as follows: In the first stage, put the iron walnuts in Soak in clear water at a temperature of 25°C for 4 hours; in the second stage, heat the clear water to 45°C at a rate of 10°C / hour and keep soaking for 8 hours; in the third stage, stop heating temperature, clear water is cooled to 20 DEG C with the speed of 6 DEG C / hour, continue to soak for 6 hours, obtain the soaked iron walnut after soaking, the water content of walnut kernel in the described soaked iron walnut is 8.5%, the water content of walnut shell is 18.5%; the soaked iron walnuts are placed in a crusher for crushing, and the crushing force during crushing is set to 275kg to obtain the crushed iron walnut particles mixed with kernel shells; the crushed iron walnut particles mixed with she...

Embodiment 3

[0033]Soak iron walnuts with a diameter of 30-38 mm in clear water. Before soaking, the water content of the walnut kernels in the iron walnuts is 6.5%, and the water content of the walnut shells is 11.5%. The soaking process is as follows: the first stage, put the iron walnuts in Soak in clean water at a temperature of 20°C for 4.5 hours; in the second stage, heat the water to 55°C at a rate of 8°C / hour and keep soaking for 7.5 hours; in the third stage, stop adding temperature, clear water is cooled to 18 DEG C with the speed of 5 DEG C / hour, continue to soak for 5.5 hours, obtain the soaked iron walnut after soaking, the water content of walnut kernel in the described soaked iron walnut is 9%, the water content of walnut shell is 20.5%; soaked iron walnuts are placed in a crusher for crushing, and the crushing force during crushing is set to 350kg to obtain broken iron walnut particles mixed with kernels and shells; the broken iron walnut particles mixed with shells and ker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com