Domestic full-automatic poached egg frying machine

A poached egg machine, fully automatic technology, applied in household utensils, frying pans, applications, etc., can solve the problems of taking up a lot of time and energy and being unable to operate alone, and achieve the effect of simple structure and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

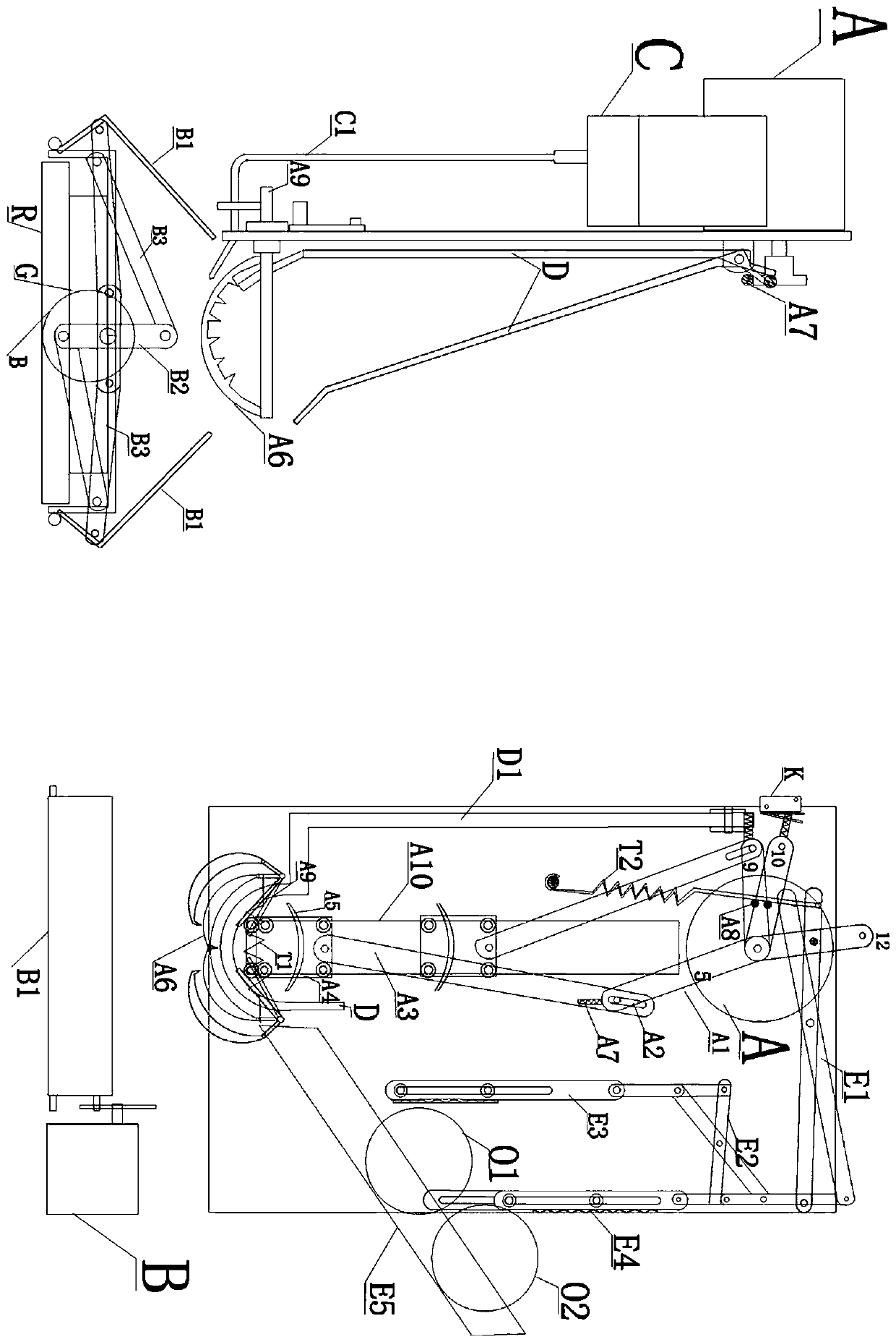

Embodiment Construction

[0022] When starting, the electric heating plate R heats up, with a delay of 30 seconds, the cover motor B drives the frying pan cover B1 through the cover motor connecting rod B2 and the cover connecting rod B3, opens to the open limit and stops, the oil pump C operates, a small amount Cooking oil is injected into the frying pan G through the filling pipe C1, and the time is 1.0 seconds. The extrusion motor A starts to move clockwise from the limit switch K. When it reaches the 12 o'clock position, the flange A8 at the middle end of the extrusion motor connecting rod pushes the baffle lever E1 Overcoming the baffle spring T2, the outer baffle E4 goes down, the inner baffle E3 goes up, the egg O2 is blocked, the egg O1 enters the cracker A6 along the slope egg trough E5, the baffles E3 and E4 are reset due to the spring force T2, and the egg O2 Enter the O1 position.

[0023] When the extrusion motor A passes through the connecting rod A1, and the extrusion connecting rod A3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com