Muttony flavoring material manufactured by means of mutton fat control and oxidation and method for manufacturing muttony flavoring material

A flavoring material and mutton technology, which is applied in the field of food flavoring material processing, can solve the problems of waste, poor protein solubility, etc., and achieve the effect of satisfying the taste and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Determination of the formula for preparing mutton-flavored flavoring by controlling the oxidation of mutton fat

[0031] The formula of the mutton-flavored flavoring material is determined to use corn gluten powder enzymatic hydrolysis solution, D-xylose, L-cysteine hydrochloride, methionine, VB1, sodium chloride and oxidized suet through many tests and experiments. The optimal scheme of the mutton-flavored flavoring was determined by an orthogonal optimization experiment with 6 factors and 3 levels. See Table 1-3 for the factor level table and results of the orthogonal test.

[0032] Table 1 Factor levels of mutton flavoring ingredients

[0033]

[0034] Table 2 Orthogonal table and results of six factors and three levels of mutton-flavored flavoring ingredients

[0035]

[0036] Table 3 Analysis of variance table for formula optimization of mutton-flavored flavoring

[0037] factor sum of squared variance degrees of freedom F ra...

Embodiment 2

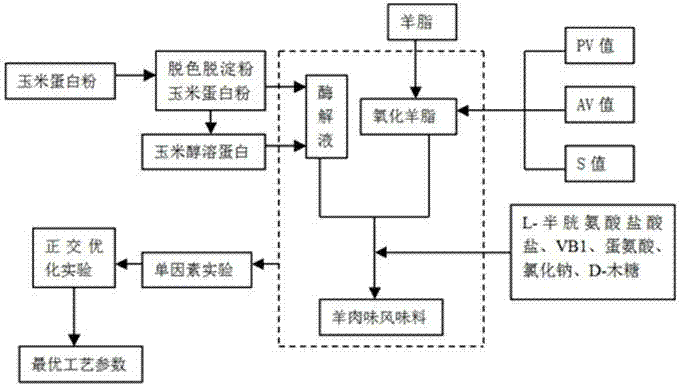

[0040] Embodiment 2: the preparation method of mutton-flavor flavor material

[0041] See attached figure 1 , using the fat controlled oxidation-thermal reaction system, the method for preparing the mutton-flavored flavoring material by using the controlled oxidation of suet, the specific preparation method steps are as follows:

[0042] (1) Preparation of zein: The corn is pretreated to decolorize and destarch to obtain corn gluten powder with high protein content, pass through an 80-mesh sieve, and use ethanol extraction to prepare zein, measured in g: mL , corn gluten powder and 80% ethanol according to the material-to-liquid ratio of 1:8, after leaching in a water bath at 60°C for 5 hours, centrifuged at 3500r / min for 15 minutes, the supernatant was taken, precipitated by isoelectric point, and then freeze-dried or Hot air drying to prepare zein;

[0043] (2) Preparation of zein enzymatic hydrolysis solution: Weigh the zein in step (1), use zein as the substrate, and ...

Embodiment 3

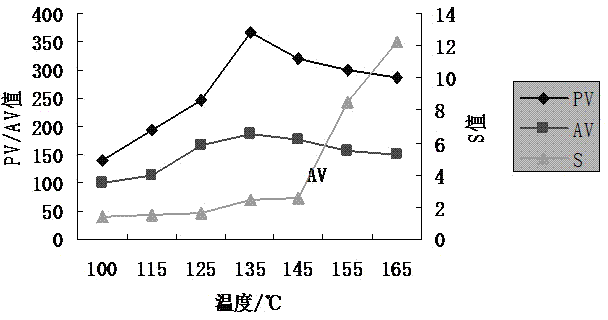

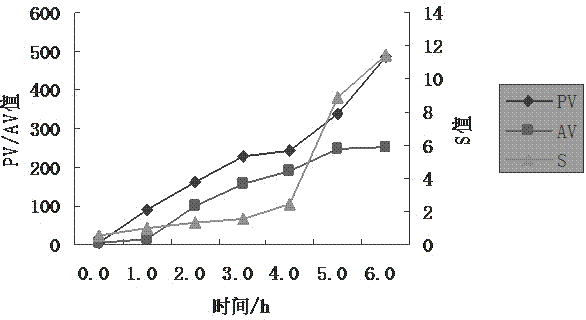

[0050] Example 3: Optimization of process conditions for preparing mutton-flavored flavoring by controlled oxidation of mutton fat

[0051] The maillard reaction was carried out with the enzymatic hydrolysis solution, and the optimal conditions were determined according to the sensory evaluation. Adopt the scheme that embodiment two provides, enzymatic solution is 90%, xylose is 3%, L-cysteine is 2%, oxidized suet is 5%, under this condition, utilizes orthogonal optimization test to The temperature, time and initial pH of the Maillard reaction were optimized, and the sensory score was used as the evaluation index. The factor level tables and results are shown in Tables 4-6.

[0052] Table 4 Factor levels of reaction conditions

[0053]

[0054] Table 5 Orthogonal table and results of three factors and three levels of mutton-flavored flavoring conditions

[0055] serial number A temperature / ℃ B time / h C pH D blank Score 1 110 1.0 6.0 -1 63 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com