Method for removing shells from sea sand and a separation device using same

A separation device and shell technology, applied in wet separation, solid separation, chemical instruments and methods, etc., can solve the problems of high cost, reduction of concrete strength and durability, waste of resources, etc., and achieve good separation effect and long service life , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

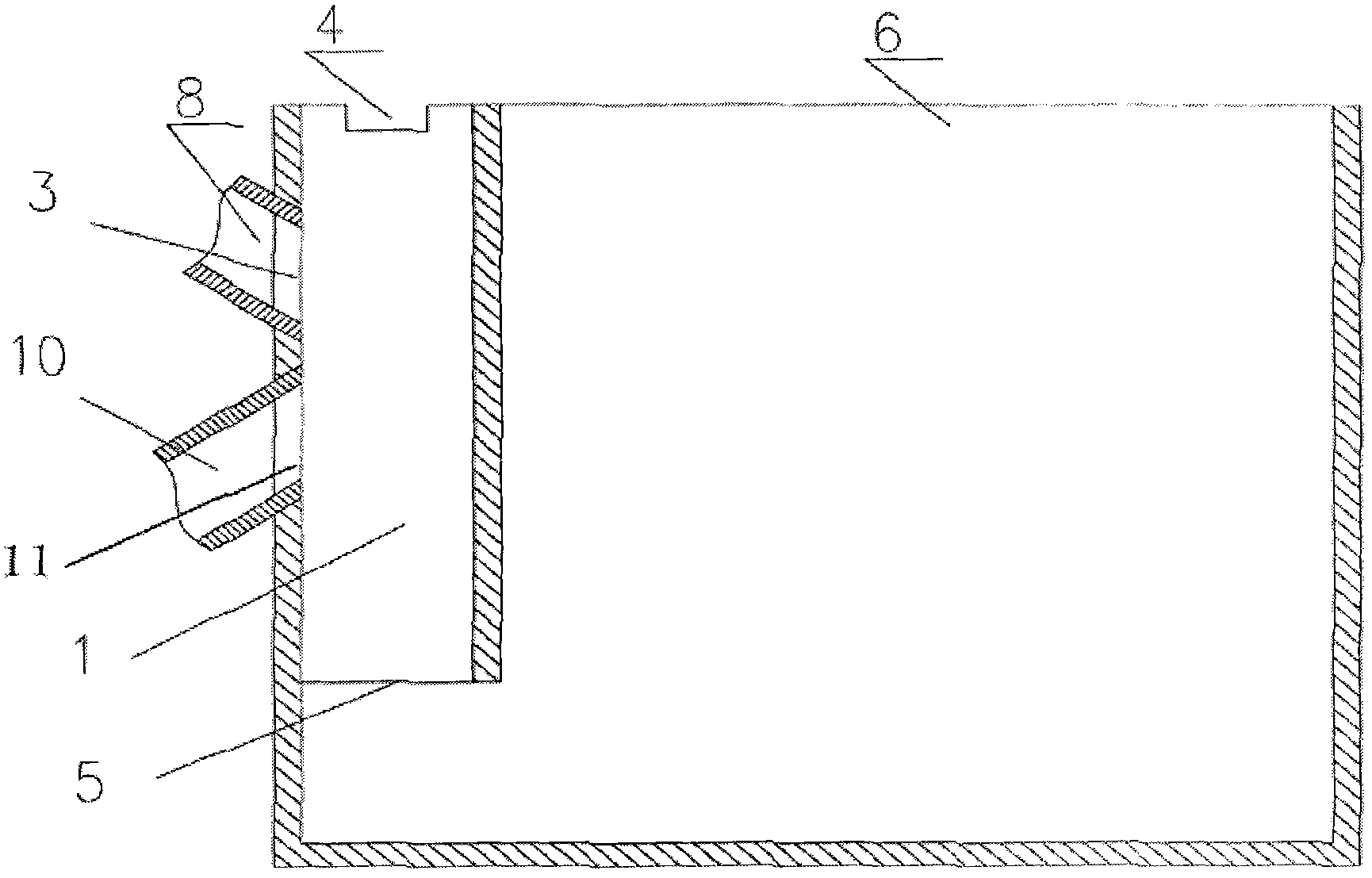

[0050] like figure 1 The separation device shown in this example includes a collection tank 6, a flow channel pipe 1 vertically arranged in the collection tank 6, and a tubular body 8 as a sand inlet channel. The water source pipe 10 extends through the wall of the flow pipe 1 obliquely upwards into the middle and lower part of the flow pipe 1, and forms a water inlet 11 on the flow pipe to provide upward water flow.

[0051] The tubular body 8 of the separation device of the present invention is located above the water source pipe 10, and the tubular body 8 passes through the wall of the flow pipe 1 obliquely downwards and extends into the middle and upper part of the flow pipe 1, forming an inlet on the flow pipe 1. The sand mouth 3, the sand inlet 3 is higher than the water inlet 11.

[0052] The bottom opening of the flow pipe 1 of the separation device of the present invention is used as the sand outlet 5 , and the flow pipe 1 communicates with the collection tank 6 thro...

Embodiment 2

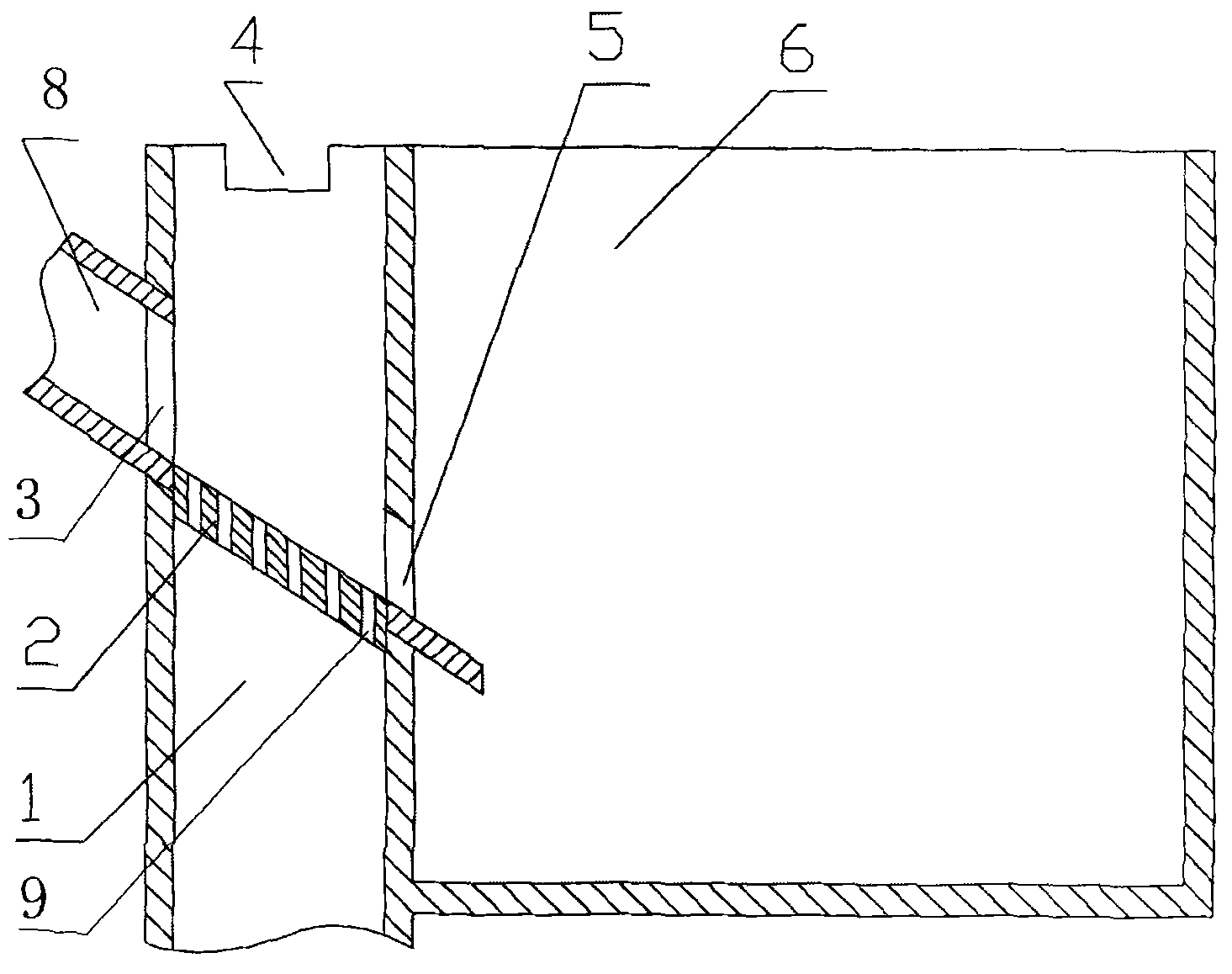

[0061] like figure 2 The separation device shown in this example includes a collection tank 6, a vertically arranged flow channel pipe 1 and a tubular body 8 as a sand inlet channel. The lower end of the flow channel pipe 1 communicates with the water source pipe (not shown in the figure), and the water source pipe is used to provide an upward water flow in the flow channel pipe; an inclined lining plate 2 is fixed around the inner wall of the middle part of the flow channel pipe 1, The vertical direction on the backing plate 2 is densely covered with through-holes 9 passing through from top to bottom.

[0062] The tubular body 8 passes through the wall of the flow channel pipe 1 in an oblique downward direction and extends into the middle and upper part of the flow channel pipe 1, forming a sand inlet 3 on the side wall of the flow channel pipe 1. The sand inlet 3 in this example is located at On the side wall of the flow channel pipe at the upper part of the high-end side ...

Embodiment 3

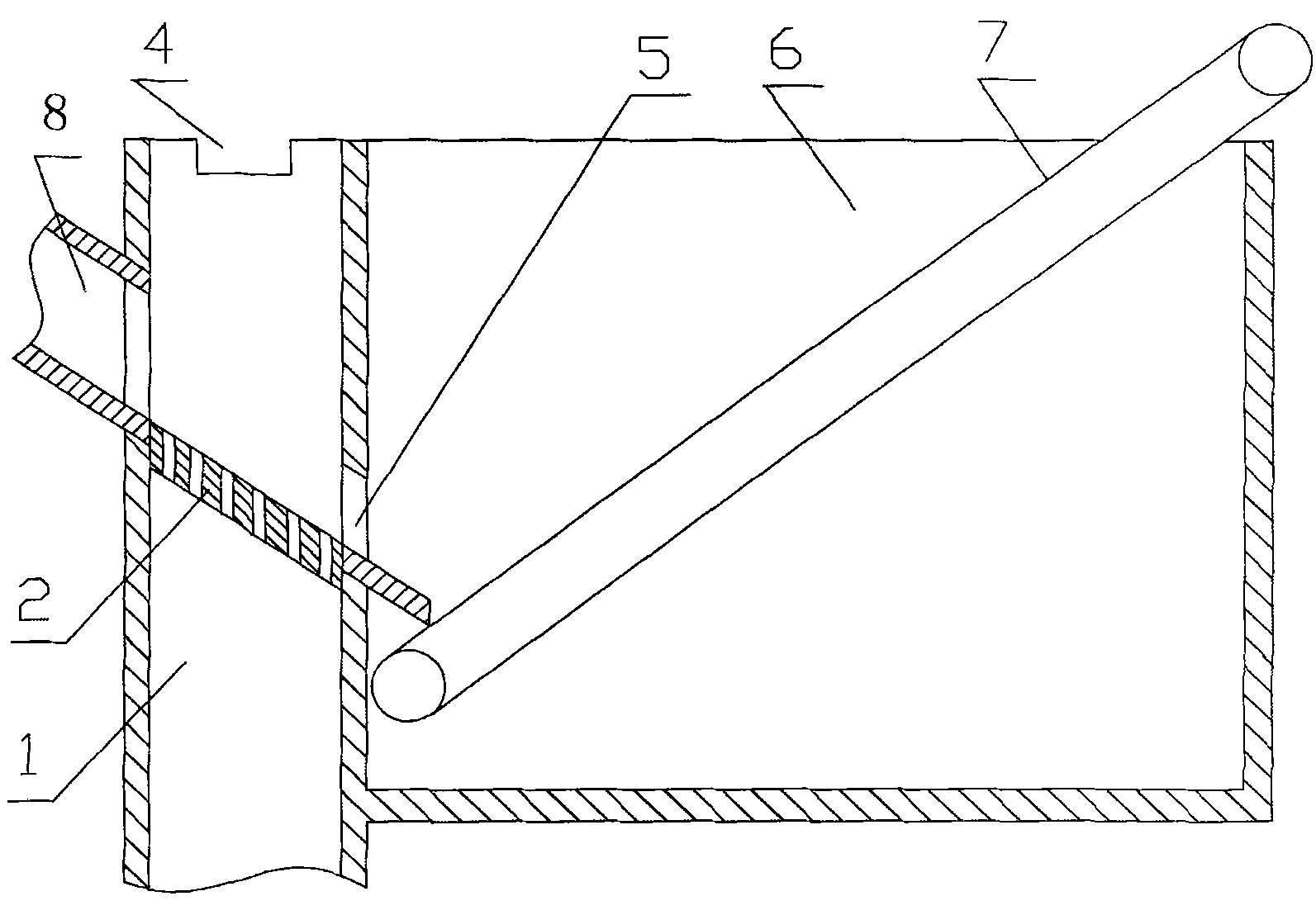

[0070] like image 3 The difference between the present example shown and Embodiment 2 is that the separation device also includes a belt conveyor (not shown in the figure), and the conveyor belt 7 of the belt conveyor is arranged in the collection tank obliquely upward, and the low end of the conveyor belt 7 is at the sand outlet 5 Below, the high end of the conveyor belt 7 stretches out of the pool mouth of the collection pool, and the belt conveyor will transmit the sea sand falling into the conveyor belt from the sand outlet to the outside of the collection pool in real time through the conveyor belt 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com