Automatic assembly and automatic ultrasonic machine for data line plastic shell

An automatic assembly and data line technology, applied in the assembly/disassembly of contact parts, etc., can solve the problems of high labor intensity, many manpower, low efficiency, etc., and achieve the effect of reducing labor load and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

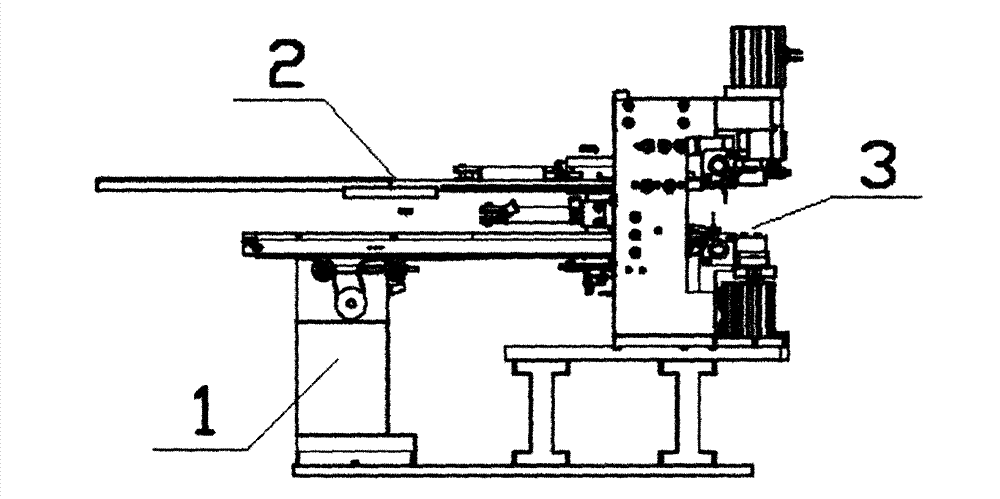

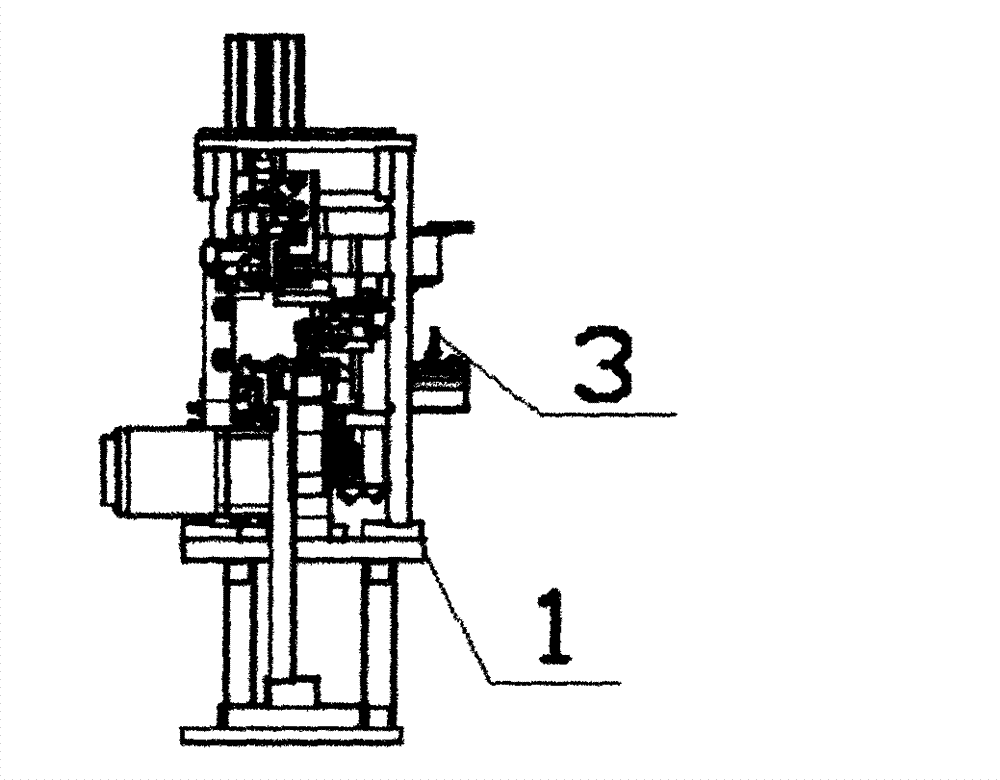

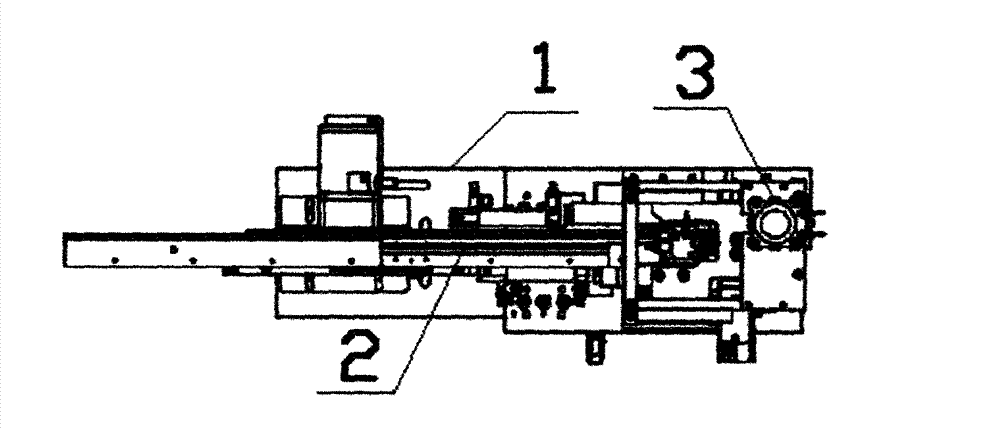

[0024] Such as figure 1 figure 2 and image 3 As shown, a data cable plastic case automatic assembly and automatic ultrasonic machine includes a base 1 and an automatic processing device provided on the base 1. The automatic processing device includes a plastic case separation mechanism 2, a plastic case assembly mechanism 3 And an automatic ultrasonic device. Before the plastic case is separated, a vibration plate is installed to divide the upper and lower plastic shells. The vibration plate, the plastic case separation mechanism 2, the plastic case assembly mechanism 3 and the automatic ultrasonic device constitute a group of automatic processing devices. , The automatic processing device is equipped with two groups on the installation base, the AM automatic processing device is set on the left of the base, and the BM automatic processing device is set on the right.

[0025] Such as Figure 4 and Figure 5 As shown, the AM automatic processing device includes an AM separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com