Automatic assembling equipment for lithium battery

A technology for assembling equipment and lithium batteries, which is applied in lithium batteries, battery assembling machines, secondary battery manufacturing, etc., can solve problems such as damage and low efficiency, and achieve the effects of low labor costs, reduced manufacturing costs, and accurate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a non-restrictive description of the lithium battery automatic assembly equipment described in the present invention in conjunction with the accompanying drawings, in order to provide the public with a better understanding of the technical content.

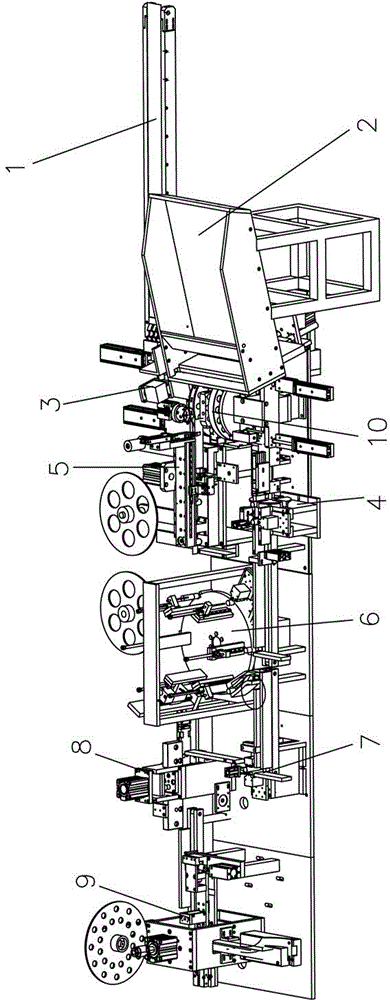

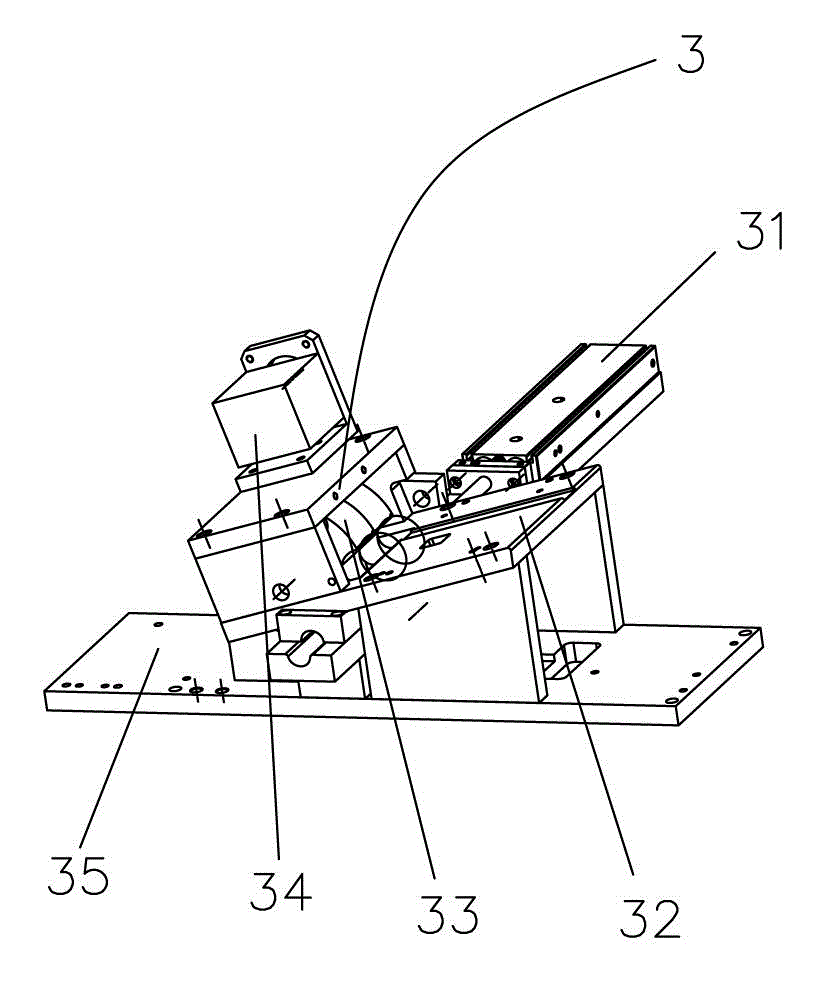

[0016] Such as figure 1 As shown, the lithium battery automatic assembly equipment 100 of the present invention includes a cell feeding bin 1, a steel shell feeding mechanism 2, a cell positioning mechanism 3, tab finishing mechanisms 4, 7, a handling mechanism 5, spot welding Mechanism 6, insulating sheet placing mechanism 8, rolling groove mechanism 9 and shell entering mechanism 10. Of course, some institutions or processes are not necessary, depending on the specific needs of production.

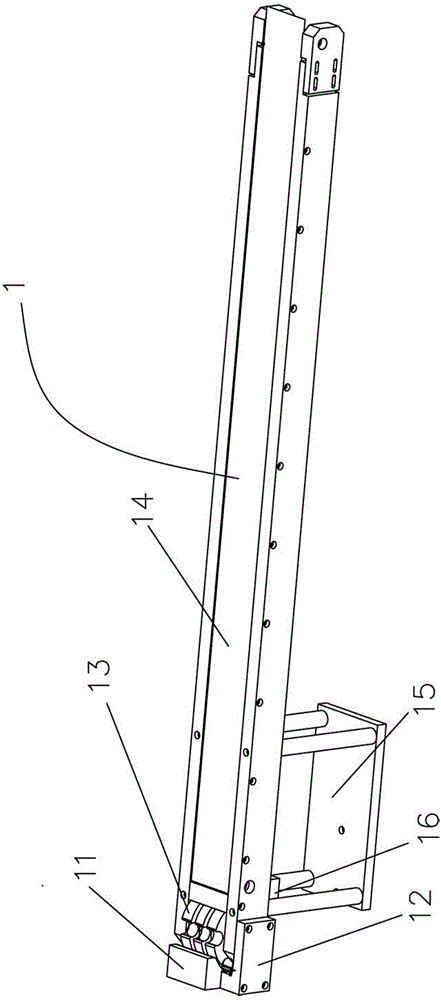

[0017] refer to figure 2 , The cell feeding bin 1 includes a guide plate 11, a fixing plate 12, a defective product separation mechanism, a transmission mechanism 14, a base 15 and an out-of-tolerance jaw 16 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com